Power lithium battery flexible packaging film

A flexible packaging film, lithium battery technology, applied in the direction of lithium battery, battery pack parts, non-aqueous electrolyte battery, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

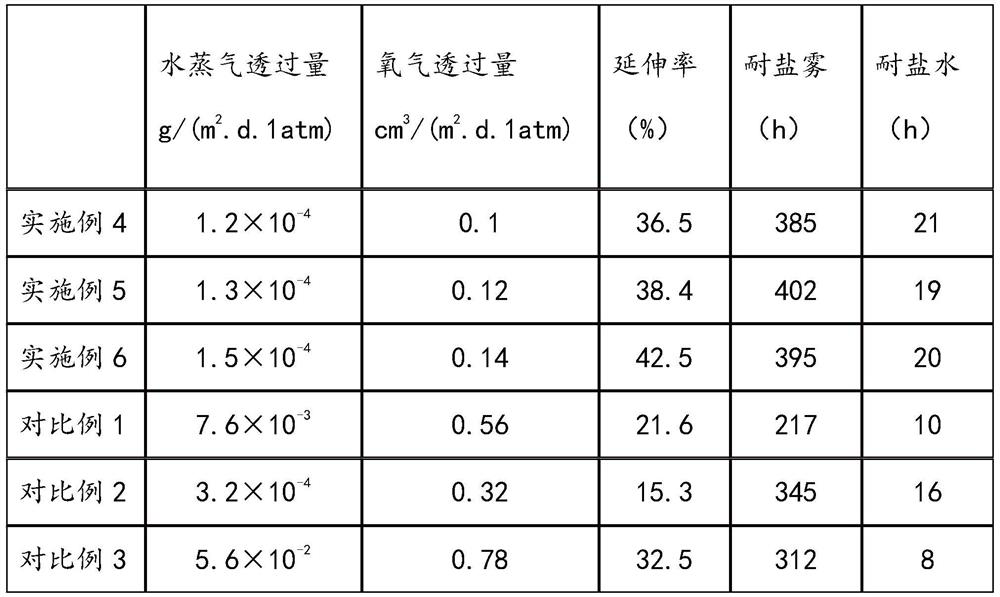

Examples

Embodiment 1

[0037] The specific preparation process of the middle layer of modified aluminum foil is as follows:

[0038] Step S1, placing 2.5 mmol of high-purity aluminum, 1.1 mmol of rare earth lanthanum, and 3 mmol of iron powder in a furnace to melt the alloy, pouring the liquid alloy into a mold for alloy casting, and obtaining an ingot;

[0039] Step S2, placing the ingot prepared in step S1 in a resistance furnace for homogenization treatment at 600°C for 12 hours, then cooling to room temperature, and performing hot rolling, cold rolling and foil rolling on the ingot after face milling, and then annealing After 2 hours, it was pressed into a 0.06mm sheet-shaped modified aluminum foil middle layer, wherein the hot rolling temperature was 510°C, the cold rolling temperature was 480°C, and the annealing temperature was 350°C.

Embodiment 2

[0041] The specific preparation process of the modified PET outer layer is as follows:

[0042] Step C1, add 10g caprolactam, 100mL concentrated hydrochloric acid, 5mg organotin catalyst, 150mL deionized water into the flask, heat to reflux for 2 hours, and prepare 6-aminocaproic acid hydrochloride after cooling, wherein the mass fraction of concentrated hydrochloric acid is 37.5 %, the heating temperature is 120°C;

[0043] Step C2, add 20g of sodium montmorillonite and 60mL of deionized water into the reaction kettle, heat and stir for 2 hours, then add the 6-aminocaproic acid hydrochloride prepared in step C1, stir at constant temperature for 12-16 hours, and cool to room temperature , fully washed with 40 mL of absolute ethanol, filtered and discarded the filtrate, and the filter residue was dried in a vacuum oven to constant weight, and ground to obtain 6-aminocaproic acid hydrochloride modified montmorillonite;

[0044] Step C3, add 200g of terephthalic acid, 100g of et...

Embodiment 3

[0050] The specific preparation process of the micro-crosslinked polypropylene inner layer is as follows:

[0051] Step F1, adding ternary copolymerized polypropylene, homopolymerized polypropylene, mixed polypropylene, crosslinking agent, initiator, and graphene into the reaction kettle, and fully mechanically stirring and mixing after heating to obtain a mixture, wherein the ternary The parts by weight of copolymerized polypropylene, homopolypropylene, mixed polypropylene, crosslinking agent, initiator, and graphene are 12 parts of ternary copolymerized polypropylene, 8 parts of homopolypropylene, 10 parts of mixed polypropylene, crosslinking agent 3 parts, 3 parts of initiator, 4 parts of graphene, the crosslinking agent is pentaerythritol tetraacrylate, the initiator is dicumyl peroxide, the heating temperature is 200 ° C, and the stirring rate is 200 rpm;

[0052] In step F2, the mixture prepared in step F1 is subjected to double-screw extrusion, the rotating speed of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com