6061G aluminum alloy for smart phone and processing method thereof

A technology of a smart phone and a processing method, applied in the field of non-ferrous metals and their processing technology, can solve the problems of difficult control of material grain defects, waste of aluminum materials, and large losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

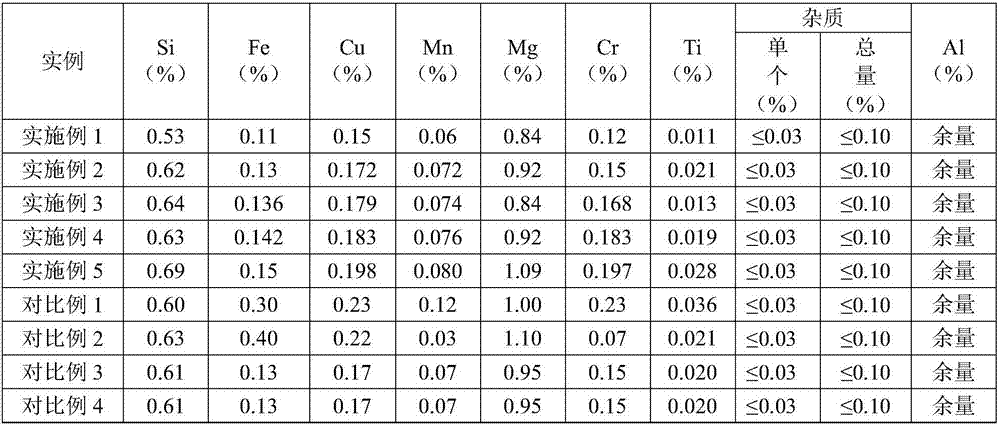

[0038] A method for processing 6061G aluminum alloys for smart phones is as follows: according to the alloy formula given in Example 1 in Table 1, aluminum water with corresponding alloy ratios is prepared and cast into ingots; the ingots are sent into a vertical pusher heating furnace for homogenization Annealing: heat up at a heating rate of 32°C / h, when the metal temperature rises to 530°C, keep it warm for 6 hours, then force the fan to cool the ingot to 452°C, keep it warm for 2 hours, then the ingot comes out of the furnace; hot rolled into coils; coil cooling After that, continue cold rolling to reduce to the thickness of intermediate annealing; then carry out intermediate annealing on the continuous annealing line (reserve 32% cold working rate after intermediate annealing), annealing temperature: 503 ° C, holding time: 10s; secondary cold rolling to Finished product thickness; return to continuous annealing line for finished product solution treatment, solution tempera...

Embodiment 2

[0041] A method for processing 6061G aluminum alloys for smart phones is as follows: according to the alloy formula given in Example 2 in Table 1, aluminum water with corresponding alloy ratios is prepared and cast into ingots; the ingots are sent into a vertical pusher heating furnace for homogenization Annealing: heat up at a heating rate of 40°C / h, when the metal temperature rises to 540°C, keep the temperature for 8 hours, then blow the fan to cool the ingot to 470°C, keep it for 2 hours, then the ingot is out of the furnace; hot rolled into coils; coil cooling After that, continue cold rolling to reduce to the thickness of intermediate annealing; then carry out intermediate annealing on the continuous annealing line (reserve 40% cold working rate after intermediate annealing), annealing temperature: 520 ° C, holding time: 15s; secondary cold rolling to Finished product thickness; return to the continuous annealing line for finished product solution treatment, solution temp...

Embodiment 3

[0044] A method for processing 6061G aluminum alloys for smart phones is as follows: according to the alloy formula given in Example 3 in Table 1, aluminum water with corresponding alloy ratios is prepared and cast into ingots; the ingots are sent into a vertical pusher heating furnace for homogenization Annealing: heat up at a heating rate of 45°C / h. When the metal temperature rises to 550°C, keep it warm for 9 hours, then blow the fan to cool the ingot to 490°C, keep it warm for 3 hours, and then release the ingot from the furnace; roll it into coils; cool the coils After that, continue cold rolling to reduce to the thickness of intermediate annealing; then carry out intermediate annealing on the continuous annealing line (reserve 45% cold working rate after intermediate annealing), annealing temperature: 540 ° C, holding time: 20s; secondary cold rolling to Finished product thickness; return to the continuous annealing line for finished product solution treatment, solution t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com