By-product steam hydrogen chloride graphite synthesis furnace with economizer

A technology of graphite synthesis furnace and by-product steam, which is applied in the direction of chlorine/hydrogen chloride, preparation of hydrogen chloride, steam generation method using heat carrier, etc., which can solve the limitation of material temperature resistance and strength, small heat extraction temperature range, and heat exchange efficiency Low-level problems, to achieve the effect of reducing thermal damage, small space height, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

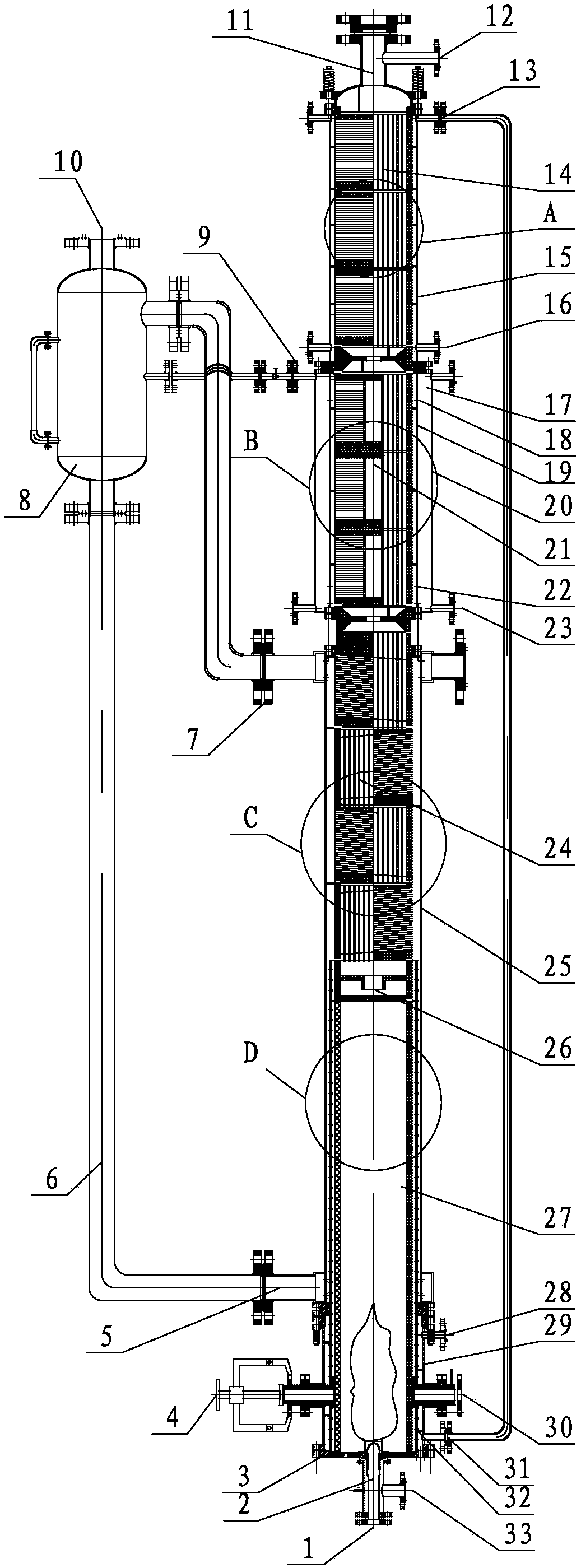

[0026] The present invention will be further described below in conjunction with accompanying drawing:

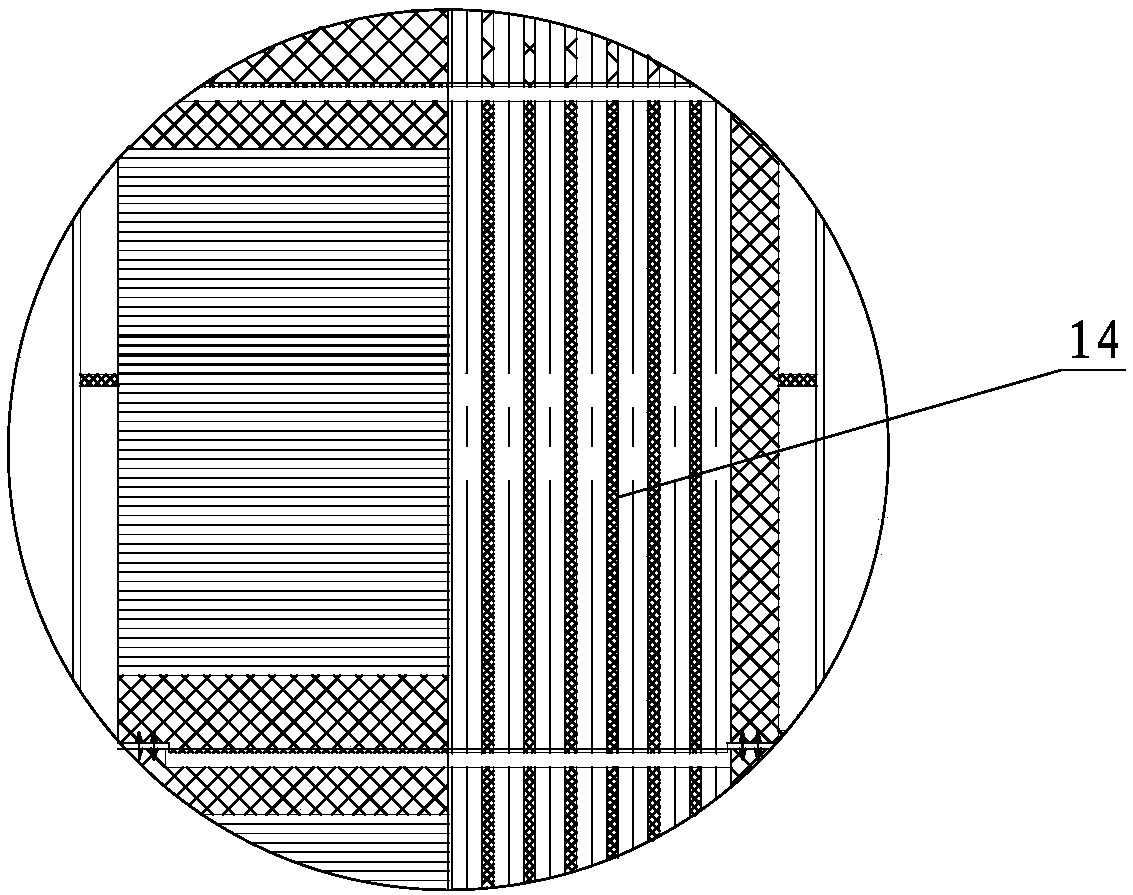

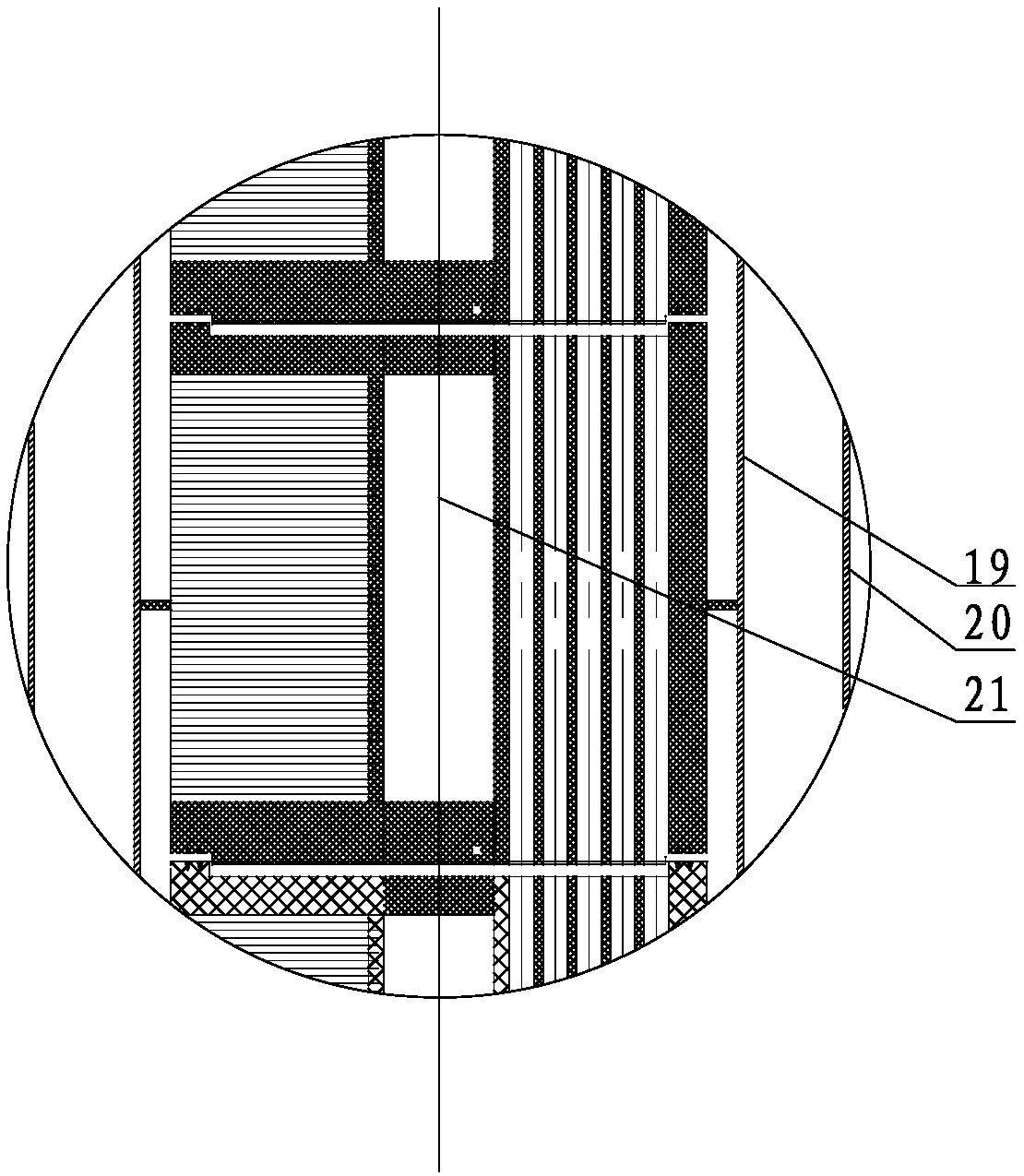

[0027] Such as Figure 1 to Figure 7As shown, the by-product steam hydrogen chloride graphite synthesis furnace with economizer of the present invention comprises a graphite furnace cylinder 27 and a steam drum 8, and the top of the graphite furnace cylinder 27 is provided with a gas remixer 26, and the gas remixer The top of 26 is provided with sealed and connected evaporation structure section, economizer section and cooling structure section in sequence from bottom to top. The evaporation structure section includes the heat exchange block assembly 24 of the evaporation section. There is a metal structure cylinder 25 in the evaporation section. The upper and lower parts of the metal structure cylinder 25 in the evaporation section are connected in series with the steam drum 8 through a circulation pipeline. Install the pre-mixed synthetic furnace lamp head 2, install the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com