Waste heat collecting cover of cooking range

A technology of waste heat collection and collection cover, which is applied in water heaters/stoves, household furnaces/stoves, household heating, etc. It can solve the problems of low heat utilization rate, waste of resources, small kitchen area, etc., and achieve high heat utilization rate , saving resources, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

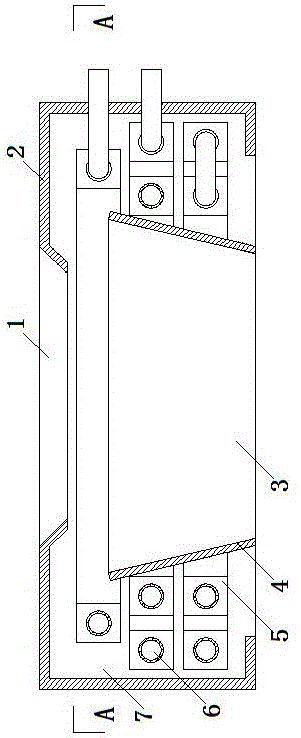

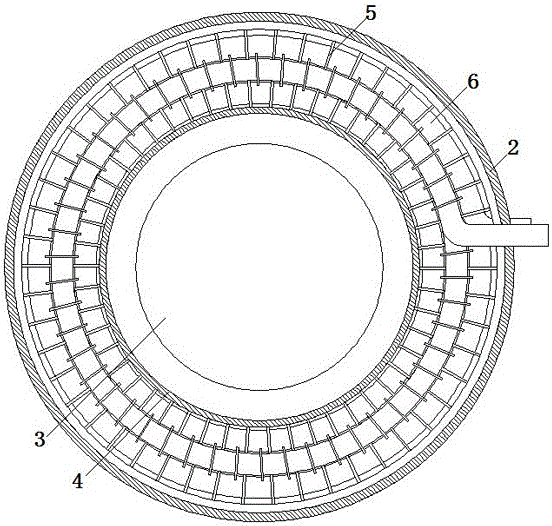

[0023] Embodiment one: if figure 1 , figure 2 As shown, the stove waste heat collection cover of the present invention includes a collection cover 2 , an isolation layer 4 and a heat exchange water pipe 6 . The top of the collection cover 2 is provided with a placement opening 1 for placing a heating body, and the bottom is provided with an opening for entering a stove burner. The placement opening 1 on the top of the collection cover 2 is closed by a heating body. Collect the opening at the bottom of the hood 2 and place it on the stove. The isolation layer 4 is placed in the collection hood 2 to divide the space in the collection hood 2 into a heating zone 3 and a waste heat collection zone 7 , so that the burner port of the stove is placed in the heating zone 3 . The tops of the heating zone 3 and the waste heat collection zone 7 communicate with each other, and the waste heat used for the heating zone 3 enters the waste heat collection zone 7 from the top of the heatin...

Embodiment 2

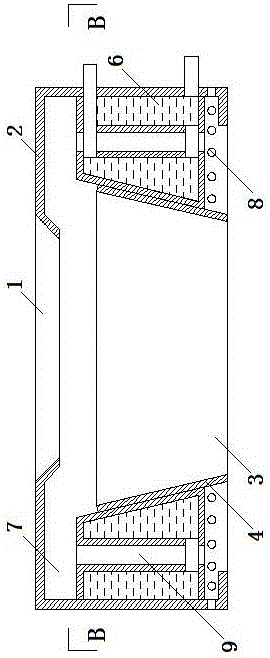

[0026] Embodiment two: if image 3 , Figure 4 As shown, the heat exchange water pipe 6 is a concave pipe. The heat exchange water pipe 6 is provided with a heat collecting tank 9 . The tank bottom of the heat collecting tank 9 communicates with the bottom of the waste heat collecting area 7, and the waste heat stays in the heat collecting tank for a long time, which increases the heat absorbing area of the heat exchange water pipe 6, and the waste heat is more fully utilized and the thermal efficiency is higher. A circulation hole 8 is provided at the bottom of the wall of the waste heat collection area 7 for exhaust gas discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com