Cooling and afterheat recovering device of air-cooled oil-injected screw air compressor

A technology of a waste heat recovery device and an air compressor, which is applied to components, mechanical equipment, machines/engines, etc. of a pumping device for elastic fluids, and can solve the problem of numerous components of a waste heat recovery device, reduced service life of parts, and compressed air Problems such as high temperature, to achieve the effect of convenient material preparation and installation, shortening life, and avoiding noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

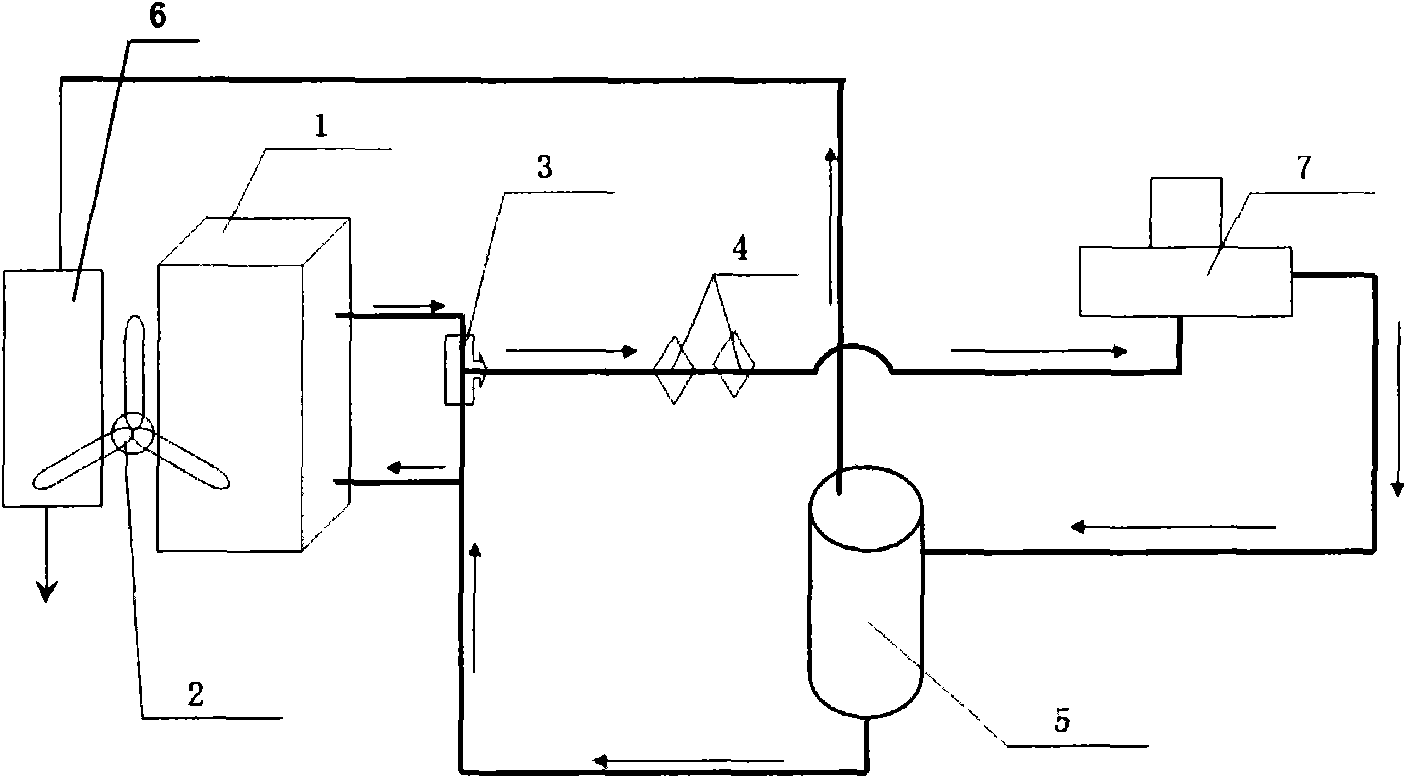

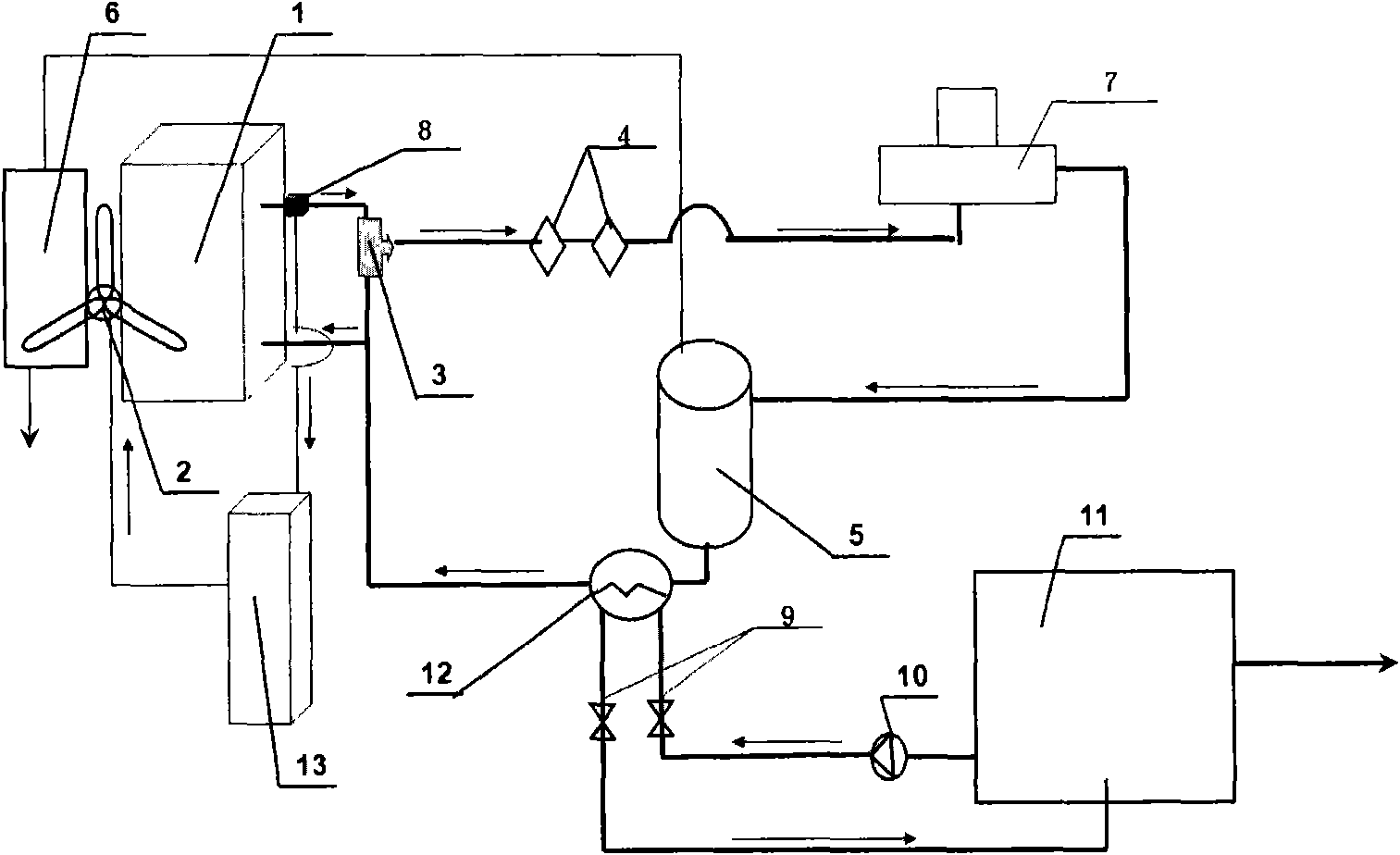

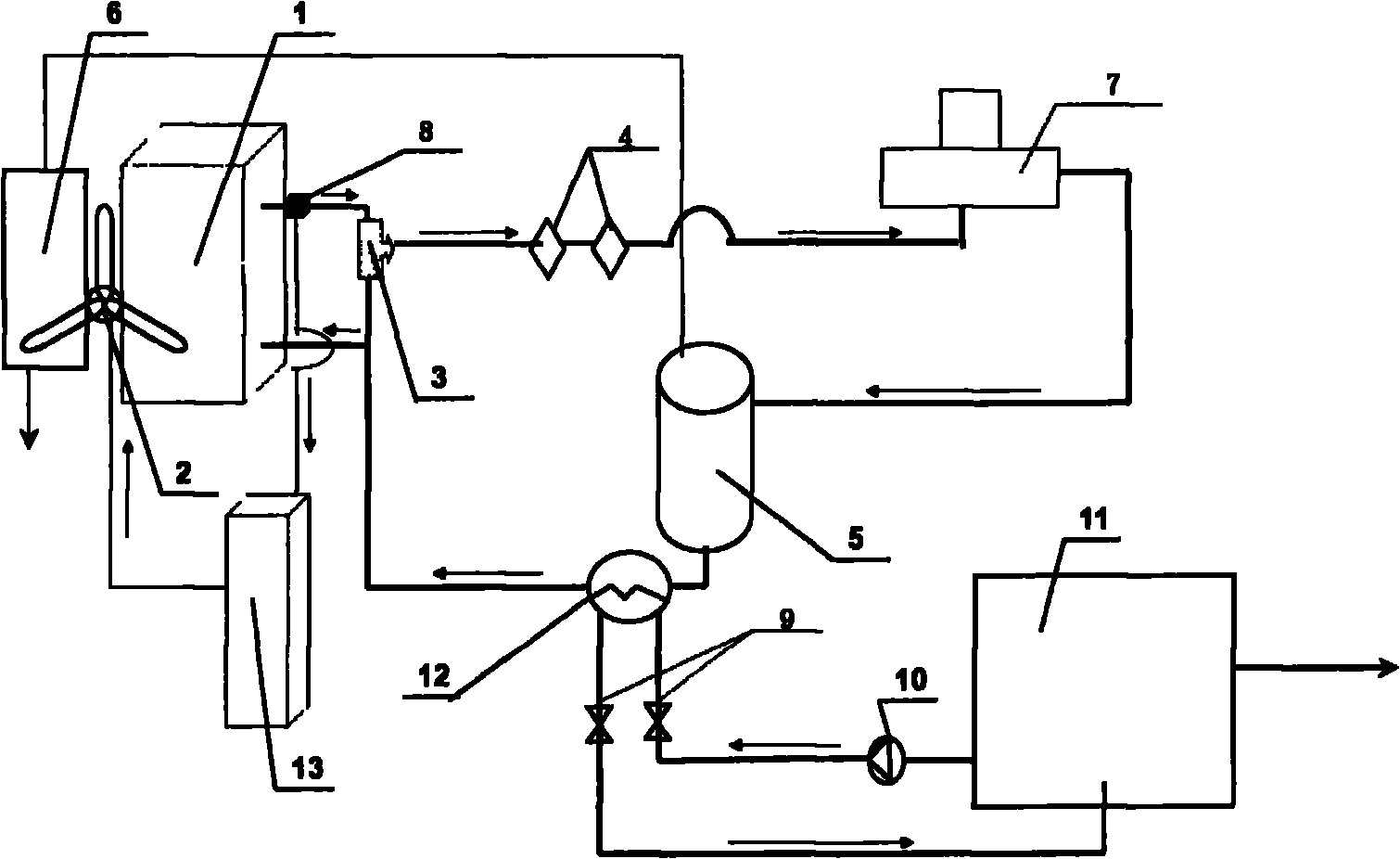

[0021] see figure 2 As shown, the air-cooled oil-injected screw air compressor heat dissipation and waste heat recovery device of the present invention maintains the original air compressor 7 and the oil-gas separator 5, temperature control valve 3, oil radiator 1, compressed air cooler 6, The structure and connection of cooling fan 2 and oil filter 4 remain unchanged; only the heat exchanger for waste heat recovery is connected in series between the oil outlet of oil-gas separator 5 and the oil inlet of oil radiator 1, the heat exchanger adopted in the present invention The exchanger is a brazed plate heat exchanger 12 with high heat exchange efficiency, high strength, and small volume. It is preferable that the oil inlet of the brazed plate heat exchanger 12 is directly connected with the oil outlet of the oil-gas separator 5, so that the original oil and gas The oil pipe connected to the oil outlet of separator 5 can be easily connected with the oil inlet of brazed plate h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com