Double-loop double-pyrogenation incinerator for garbage harmless treatment and its usage method

A technology of harmless treatment and incinerator, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of effect influence and restriction, inability to realize general promotion and use, difficulty in disposal of landfill leachate, etc. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

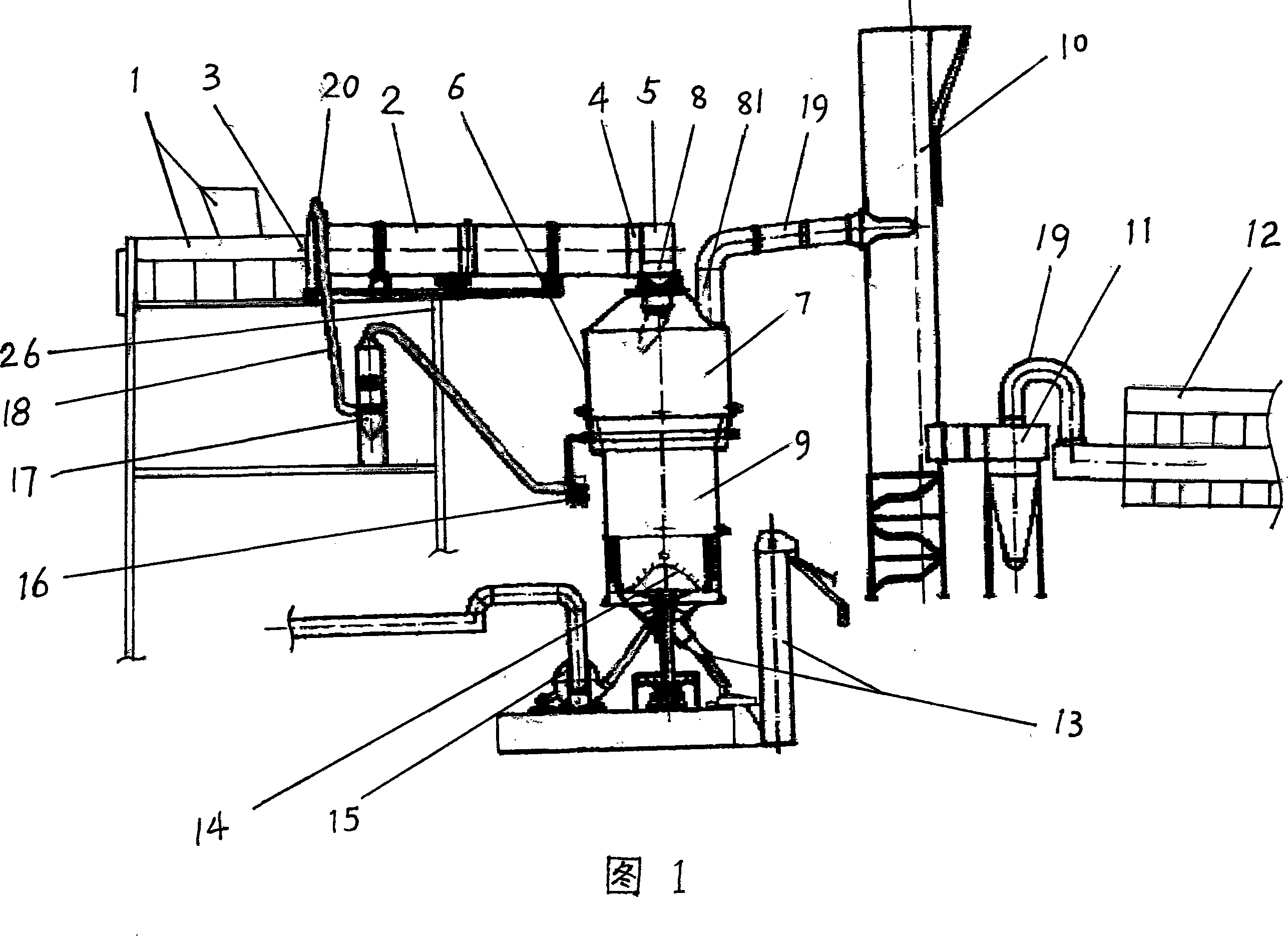

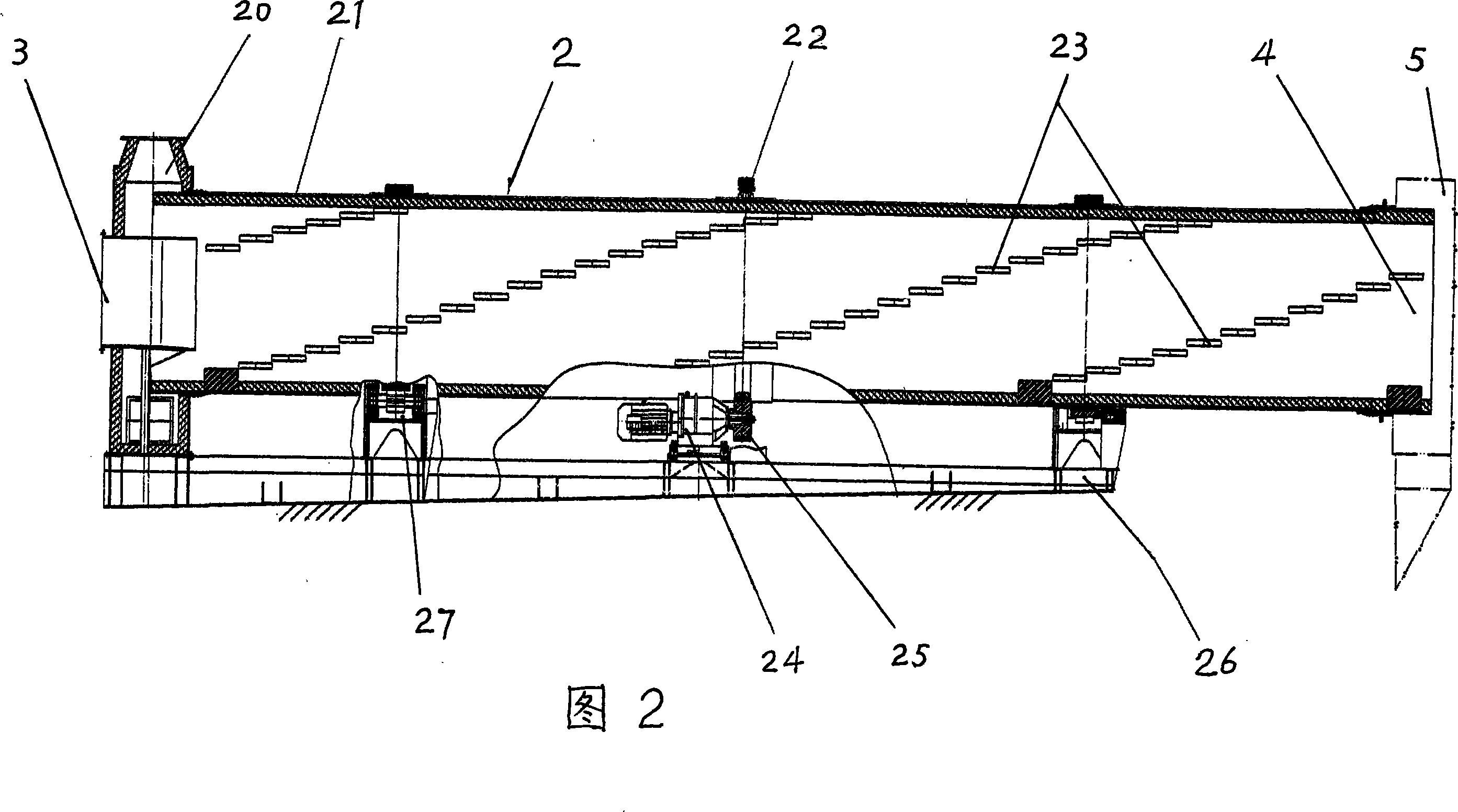

[0016]With reference to the embodiments of Figures 1 and 2, it can be seen that the specific parts and components of the present invention include: 1-feeding mechanism (material selection and pushing mechanism) for rotary kiln, 2-horizontal rotary kiln (or the main drying mechanism) Rotary kiln-type drying furnace), 3~rotary kiln feed inlet, 4~rotary kiln discharge mouth (also high temperature flue gas inlet), 5~pyrolysis furnace feeding mechanism (also known as unloading or distributing mechanism) ), 6~(fixed structure) vertical furnace body of pyrolysis incinerator, 7~secondary combustion chamber (second combustion chamber) as part of the incinerator, 8~second combustion chamber feed inlet, 81~2 Combustion chamber smoke outlet, 9~primary combustion chamber (a combustion chamber) as part of the pyrolysis furnace, 10~emergency discharge chimney, 11~cyclone dust collector, 12~waste heat boiler, 13~slag discharge mechanism, 14~rotary furnace Exhaust, 15~primary (blower) fans that ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com