Solar cell panel temperature adjusting and controlling device

A solar panel and control device technology, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve problems such as solar cell cracking, shortening the service life of solar panels, reducing the service life of solar panels and power generation efficiency, and achieving Prevent freezing and cracking, prevent overheating and overheating, and reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

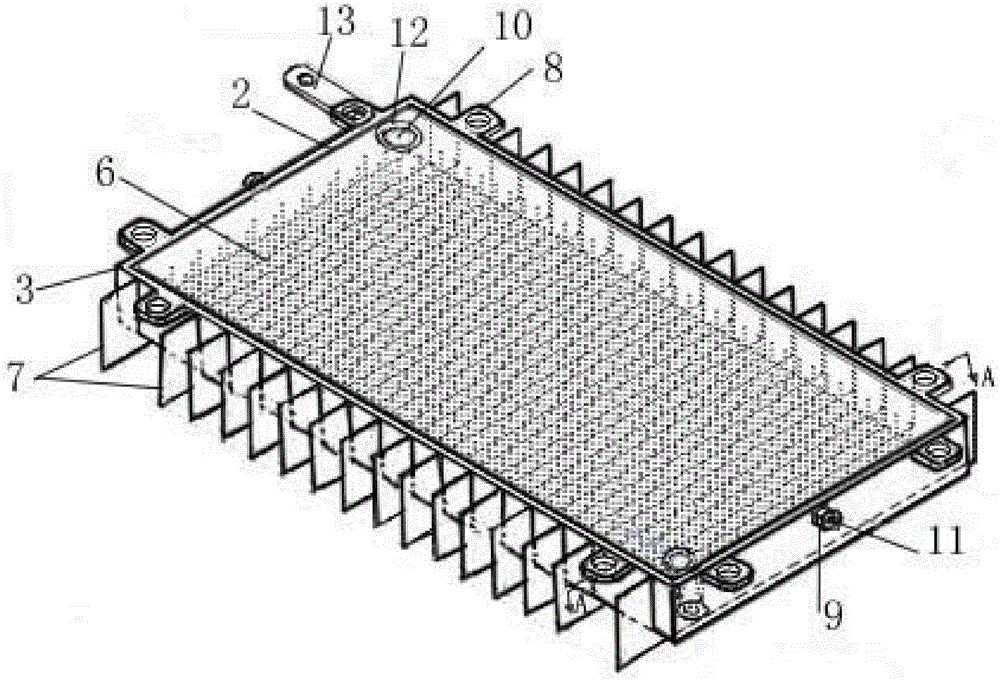

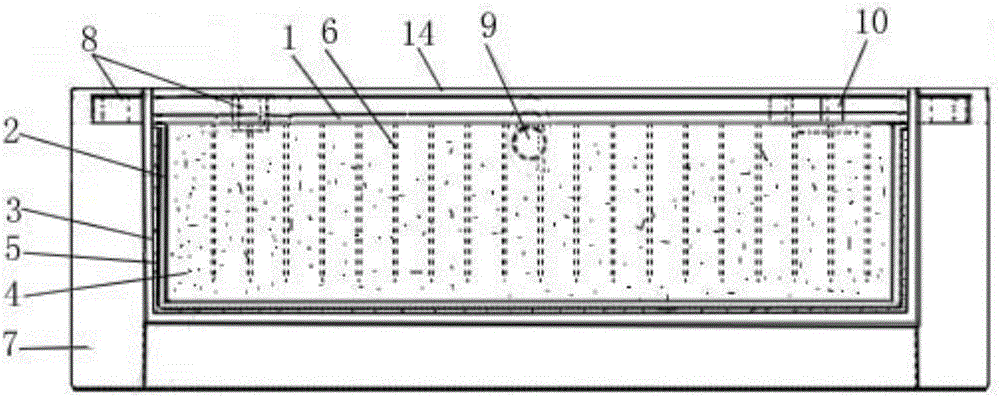

[0016] The invention provides a solar panel temperature control device. The present invention will be described in detail below with reference to the accompanying drawings. figure 1 , figure 2 Shown is a schematic diagram of the overall structure. The solar panel temperature control device shown in the figure is connected by phase change material box 2 and device shell 3 by welding, and a toughened glass plate 14 is placed on the upper port of the device shell 3; the outer heat dissipation ribs are welded equidistantly on the two long sides of the device shell 3 7. The solar cell panel bottom plate 1 is welded to the phase change material box body 2, and the inner pin ribs 6 are welded to the solar cell panel 1 bottom plate in a staggered distribution manner, and the phase change heat storage material 4 is filled through the heat storage material injection hole 10 In the heat storage cavity formed by the phase change material box 2 and the solar panel bottom plate 1, the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com