Plastic lining composite pipe

A technology of composite pipe and plastic lining, applied in the field of composite pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

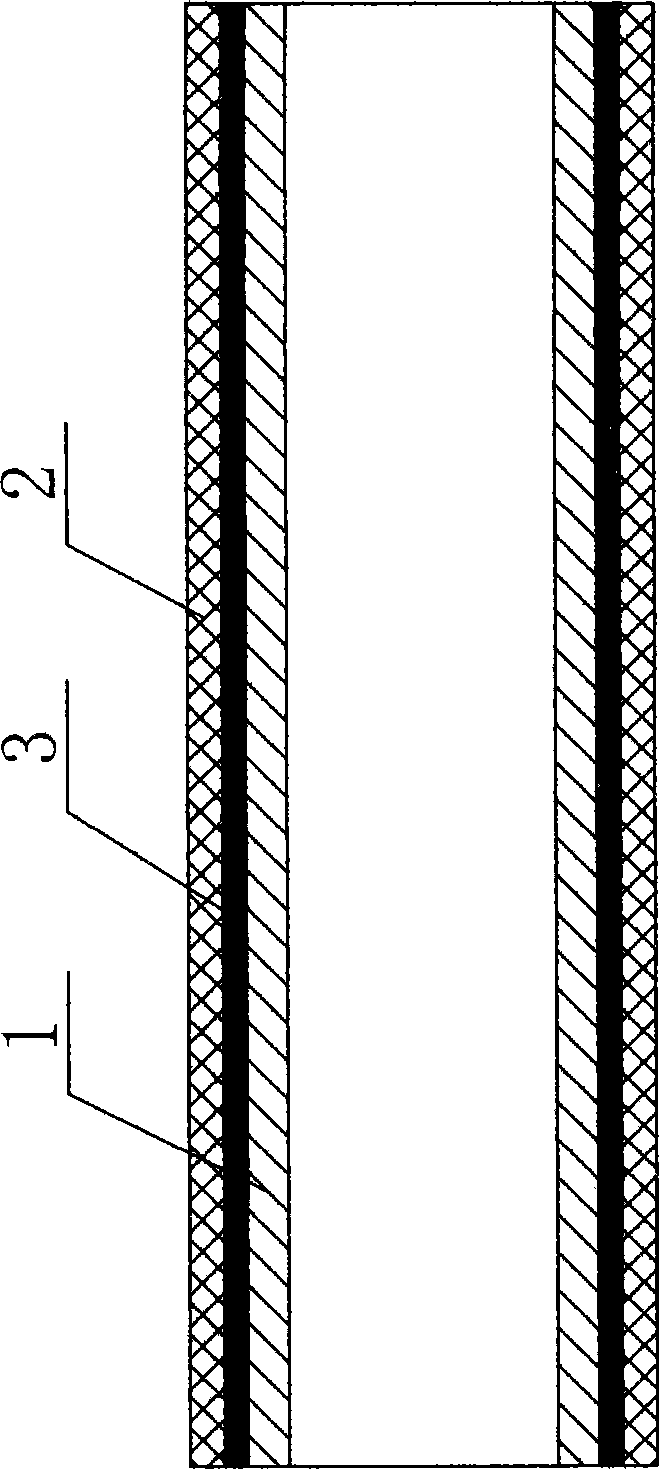

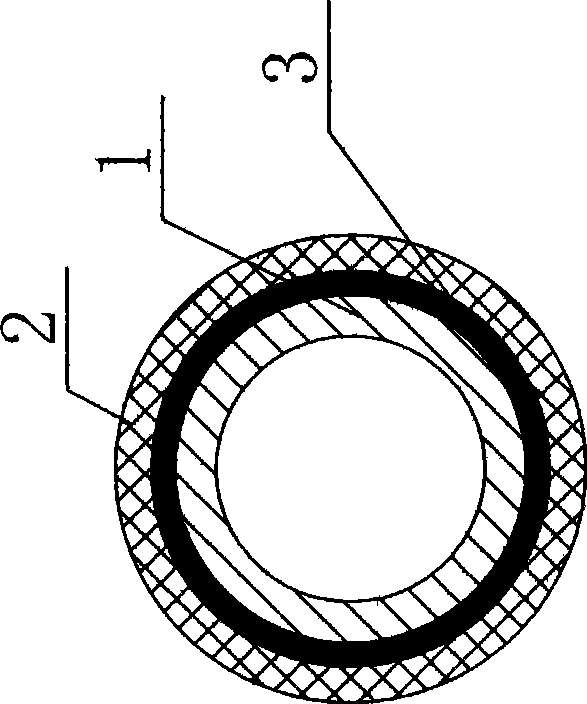

[0012] Such as figure 1 , figure 2 Shown is a preferred embodiment of the present invention. The plastic-lined composite pipe includes a plastic inner pipe 1, a metal outer pipe 2, and a polymer elastic thermal insulation layer 3 is compounded between the plastic inner pipe 1 and the metal outer pipe 2. The polymer elastic heat insulation layer 3 has a thickness of 0.00075 to 0.001 times the diameter of the plastic inner tube 1 and is made of a polymer elastic heat insulation material. The thickness of the polymer elastic thermal insulation layer 3 of the present invention is mainly determined according to the difference of the linear expansion coefficients of the plastic inner tube 1 and the metal outer tube 2, and its thickness is not limited by this embodiment.

[0013] During the production of the present invention, the plastic inner tube 1 and the polymer elastic material are compounded and co-extruded so that the polymer elastic heat insulation material is uniformly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com