Light-weight foamed concrete building component and production method thereof

A technology of concrete construction and lightweight foam, which is applied to other household appliances, ceramic products, household appliances, etc., can solve the problems affecting the load-bearing capacity of the building structure, the shift of the overall center of gravity of the building, and the safety of the main body of the building, and achieve good environmental protection benefits. and social benefits, reducing the difficulty of construction, and reducing the cost of human and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

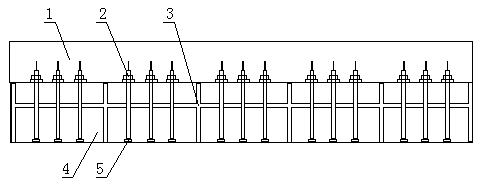

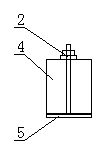

Image

Examples

Embodiment 1

[0037] The lightweight foamed concrete building components with a bulk density of 200 kg / m3 are prepared by chemical foaming, and its constituent materials are: Pc32.5 cement: 150 kg, water: 88 kg, small material: 1.5 kg, liquid foaming agent: 8.5 kg, admixture: 5 kg, and the pre-embedded steel bar is 40 meters of Φ12 steel bar.

[0038] Its process steps include:

[0039] 1. Formwork and pre-embedded steel bars;

[0040] 2. Use stirring equipment to stir the slurry;

[0041] 3. After the slurry is evenly stirred, add liquid foaming agent into the mixer;

[0042] 4. After adding the liquid foaming agent, stir for 3 seconds, then reverse the mixer for 5 seconds;

[0043] 5. Put the material into the mold;

[0044] 6. After the concrete is formed, cut the surface evenly, and then remove the formwork and put it into the stack for maintenance;

[0045] 7. Groove the lower part of the building components to make pre-embedded holes, and ship.

[0046] The mixing equipment is a...

Embodiment 2

[0050] The lightweight foamed concrete building components with a bulk density of 250 kg / m3 are prepared by chemical foaming. The components include: Pc32.5 cement: 200 kg, water: 115 kg, small material: 1.8 kg, liquid foaming agent: 10 kg, admixture: 6.5 kg, and the pre-embedded steel bar is 59 meters of Φ12 steel bar.

[0051] The difference between the process steps and the first embodiment is: after adding the liquid foaming agent, stir for 5 seconds, and then reverse the mixer for 9 seconds.

[0052]

Embodiment 3

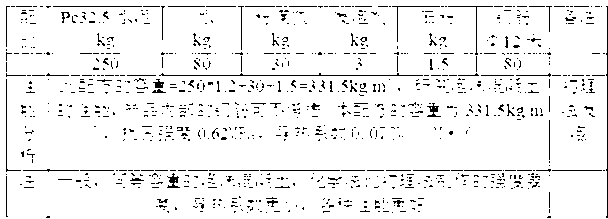

[0054] The lightweight foamed concrete building components with a volume density of 350kg / m3 are prepared by physical foaming. The components are: cement: 250kg, fly ash: 30kg, water: 80kg, stone powder: 1.5kg, foaming agent: 3kg, pre-embedded The reinforcement is 80 meters of Φ12 reinforcement.

[0055] Its process steps include:

[0056] 1. Support mold, pre-embedded steel bar;

[0057] 2. Prepare foam concrete with foam concrete equipment;

[0058] 3. Pouring and scraping the surface;

[0059] 4. Conservation for 3 days;

[0060] 5. Lifting mold transportation, stacking maintenance;

[0061] 6. Groove the lower part of the building components to make pre-embedded holes, and ship.

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com