Method for retrofitting coal-fired boiler into biomass boiler

A technology for coal-fired boilers and boilers, which is applied in the direction of combustion methods, combustion product treatment, and solid fuel combustion. The effect of high efficiency and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

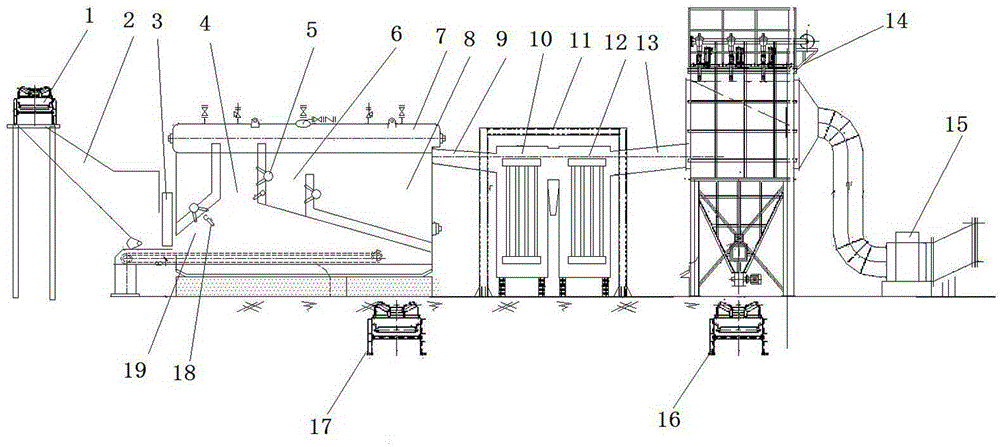

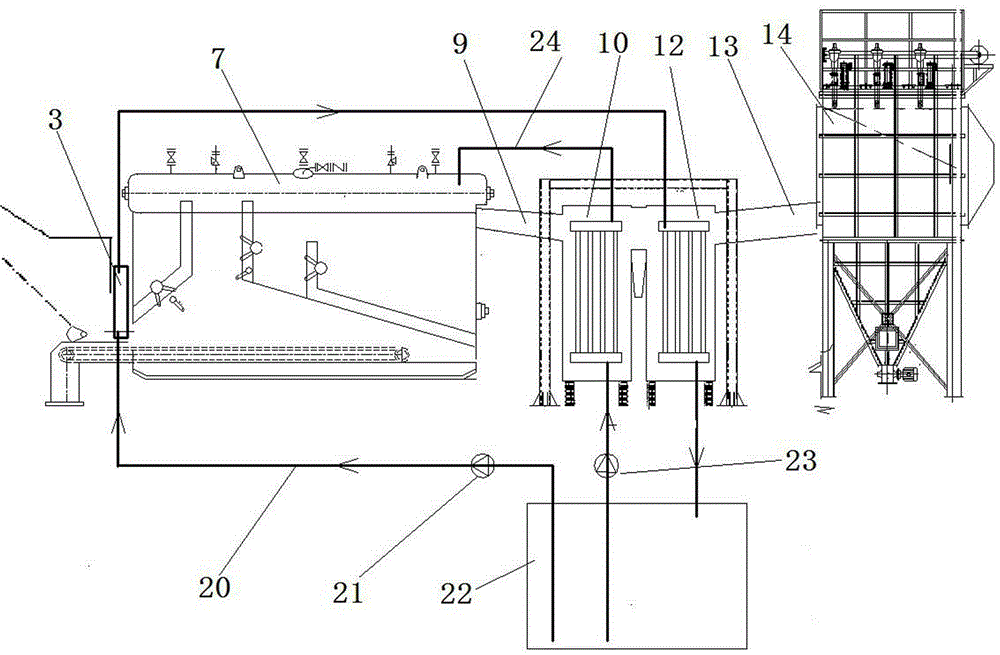

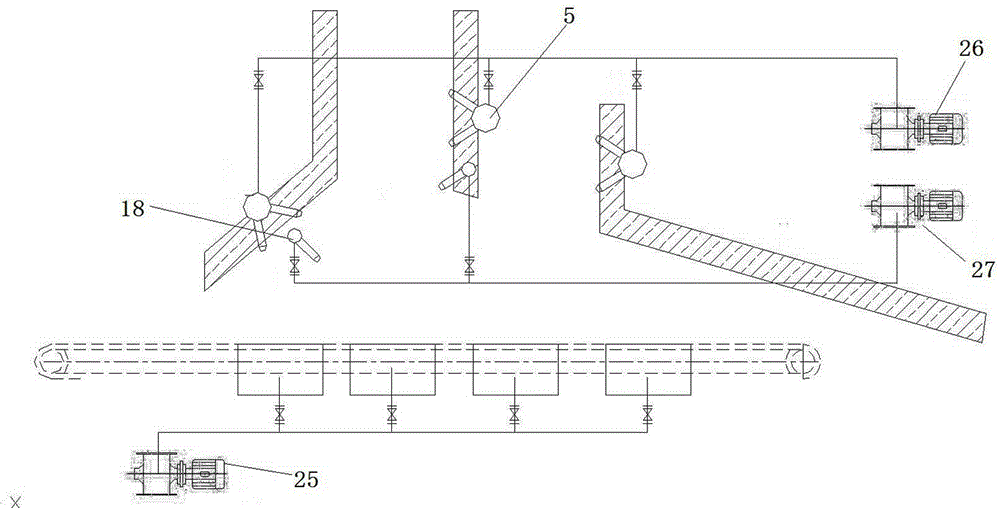

[0017] Embodiment of the method for transforming the coal-fired boiler of the present invention into a biomass boiler: as Figure 1-4 As shown, the pressure-bearing parts of the coal-fired boiler are kept basically unchanged, and the coal-fired chain boiler is transformed into a biomass briquette fuel boiler by transforming the boiler's feeding system, combustion system, air smoke system, water supply system, and slag removal system. For existing boiler equipment, on the premise of ensuring that the output of the boiler is not reduced, the exhaust gas temperature is reduced to below 100°C, the thermal efficiency of the boiler is improved, the boiler flue gas discharge reaches the standard, and the clean energy replacement of the coal-fired boiler is realized.

[0018] The method mainly includes the following steps. In the first step, the main combustion chamber 4 is formed by the front arch, the side arch and the rear arch, and the main combustion chamber 4 is a primary combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com