Process and apparatus for dry suspension sintering flash smelting of ferronickel

A dry and flash technology, applied in the direction of improving process efficiency, can solve problems such as high energy consumption and high pollution, and achieve the effects of reducing pollutant emissions, low investment cost, and short investment payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: the present invention is a kind of dry-process suspension sintering flash smelting ferronickel technology, and its specific implementation is as follows:

[0057] The laterite nickel ore used in this example comes from Indonesia, containing more than 1.8% nickel, 14% total iron, and about 30-35% moisture (inner water and outer water).

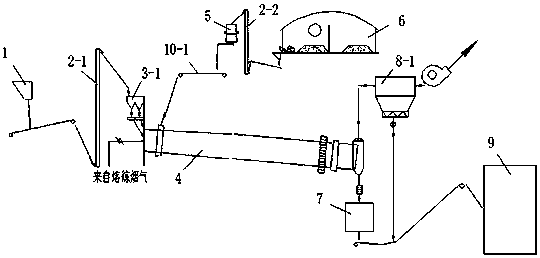

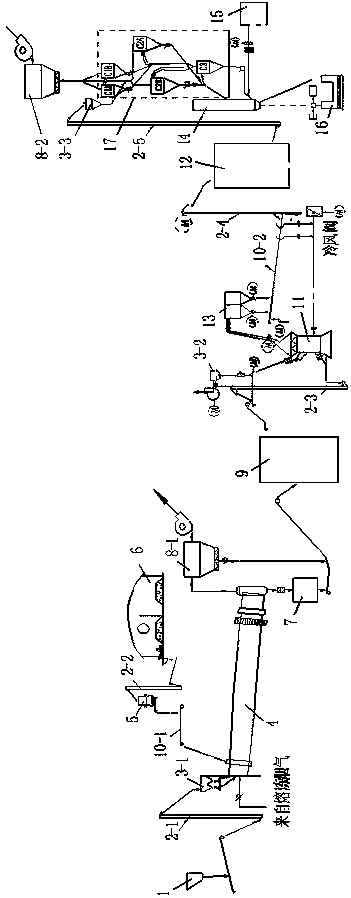

[0058] A dry-process suspension sintering flash smelting process for ferronickel, its process flow chart is as follows figure 1 shown, including the following steps:

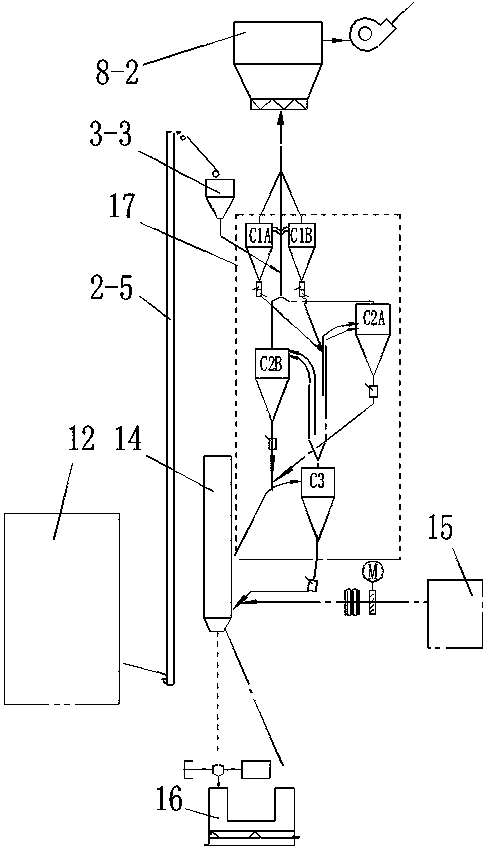

[0059] Step 1, drying: Take the laterite nickel ore, send the crushed laterite nickel ore to a hot air dryer for dehydration, and then enter the laterite nickel ore storage after drying. Among them: the moisture (external water) content of the material after drying is about 6%, (see figure 2 ).

[0060] Step 2, Grinding: The material is taken out from the laterite nickel ore storage and enters the pulverizer, and after being ground into powder, it is tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com