MVR coupled heat pump evaporative concentration system and evaporative concentration method

An evaporation concentration system, coupled heat pump technology, applied in the field of energy saving and environmental protection, can solve the problems of difficulty in increasing equipment operation, small application range, complicated distillation operation, etc., achieve full utilization of waste heat, reduce the size of heat exchange equipment, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

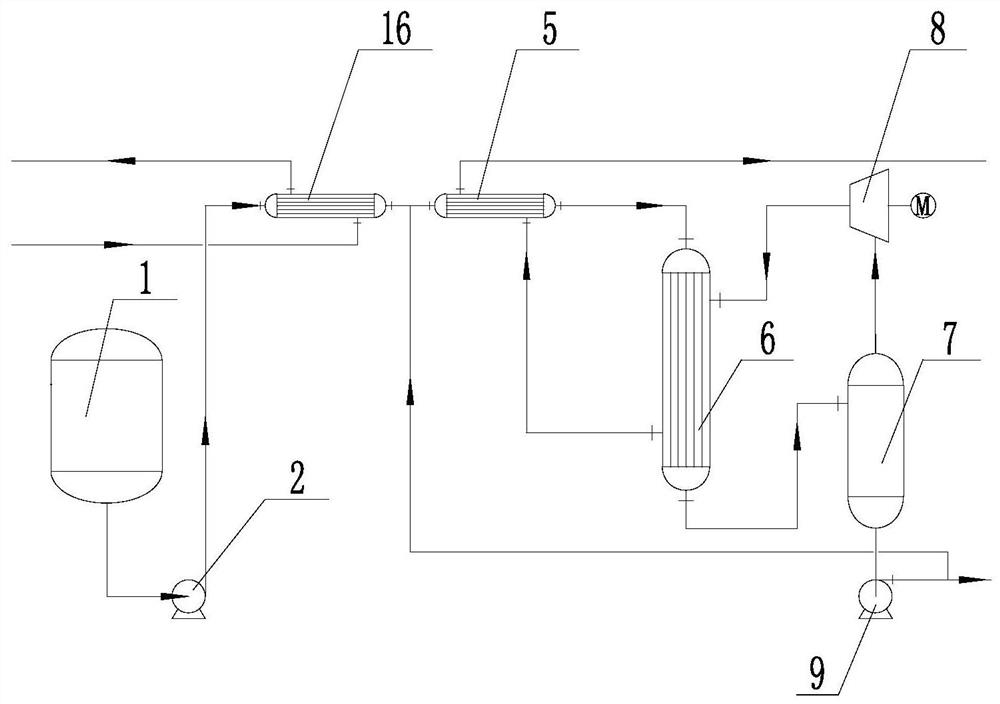

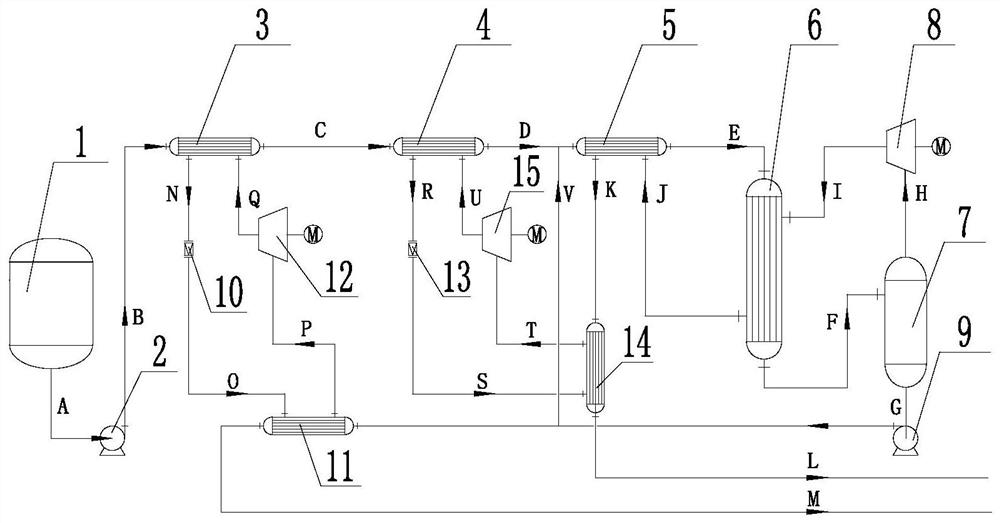

[0042] Such as figure 2 As shown, the MVR coupling heat pump evaporation and concentration system includes the MVR system and the heat pump system. The MVR system specifically includes the raw material tank, the feed pump, the MVR waste heat recovery device, the MVR evaporator, the MVR two-phase separator, the MVR compressor and the reflux extraction pump. The heat pump system specifically includes a primary preheater, a primary throttling and pressure reducing valve, a primary compressor, a primary low temperature heat exchanger, a secondary preheater, a secondary throttling and pressure reducing valve, a secondary compressor and Two-stage low-temperature heat exchanger; raw material tank, feed pump, primary preheater, secondary preheater, MVR waste heat recovery device, MVR evaporator, MVR two-phase separator and MVR compressor are connected in sequence, MVR evaporator It is connected to the MVR compressor, the MVR two-phase separator is connected to the reflux extraction p...

Embodiment 2

[0052] The MVR coupling heat pump evaporative concentration system and the evaporative concentration method are the same as in Example 1.

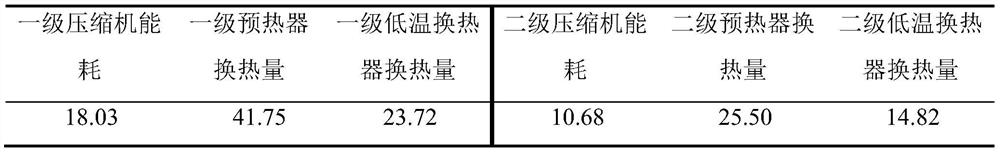

[0053] Wastewater containing 5w% NaCl at 10000kg / h enters the MVR system at 25°C. After being preheated by the primary preheater, the temperature is 62°C. After being preheated by the secondary preheater, the temperature is 81°C. In the MVR evaporator 77 Evaporation is carried out at ℃, the evaporation rate is 50%, the MVR compressor is a Roots compressor, and the working compression ratio is 1.4. The Roots compressor uses frequency conversion to adjust the speed, and the working medium is chlorofluorocarbon (R152A). After the condensed water leaves the MVR waste heat recovery device, the temperature of the condensed water is 84°C, and after passing through the secondary low-temperature heat exchanger, the temperature of the low-temperature condensed water reaches 57.7°C. After the concentrated liquid leaves the MVR two-phase separator, t...

Embodiment 3

[0058] The MVR coupling heat pump evaporative concentration system and the evaporative concentration method are the same as in Example 1.

[0059] Wastewater containing 5w% NaCl at 1000kg / h enters the MVR system at 25°C. After being preheated by the primary preheater, the temperature is 60°C. After being preheated by the secondary preheater, the temperature is 78.64°C. Evaporation is carried out at ℃, the evaporation rate is 40%, the MVR compressor is a Roots compressor, and the working compression ratio is 1.4. Roots compressor frequency conversion to adjust the speed. The working medium of the first heat pump group is liquid ammonia, and the working medium of the second heat pump group is chlorofluorocarbon (R152A). After the condensed water leaves the MVR waste heat recovery device, the temperature of the condensed water is 91°C, and after passing through the secondary low-temperature heat exchanger, the temperature of the low-temperature condensed water reaches 68°C. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com