Three-tower type atmospheric-vacuum tar distillation process

A technology of atmospheric pressure and tar, applied in the field of large and medium-sized coal tar processing engineering, can solve the problems of easy blockage of equipment and pipelines, hinder the continuous operation of the system, and increase the difficulty of operation, so as to reduce gas consumption and be beneficial to environmental protection. , reduce the effect of repeated heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

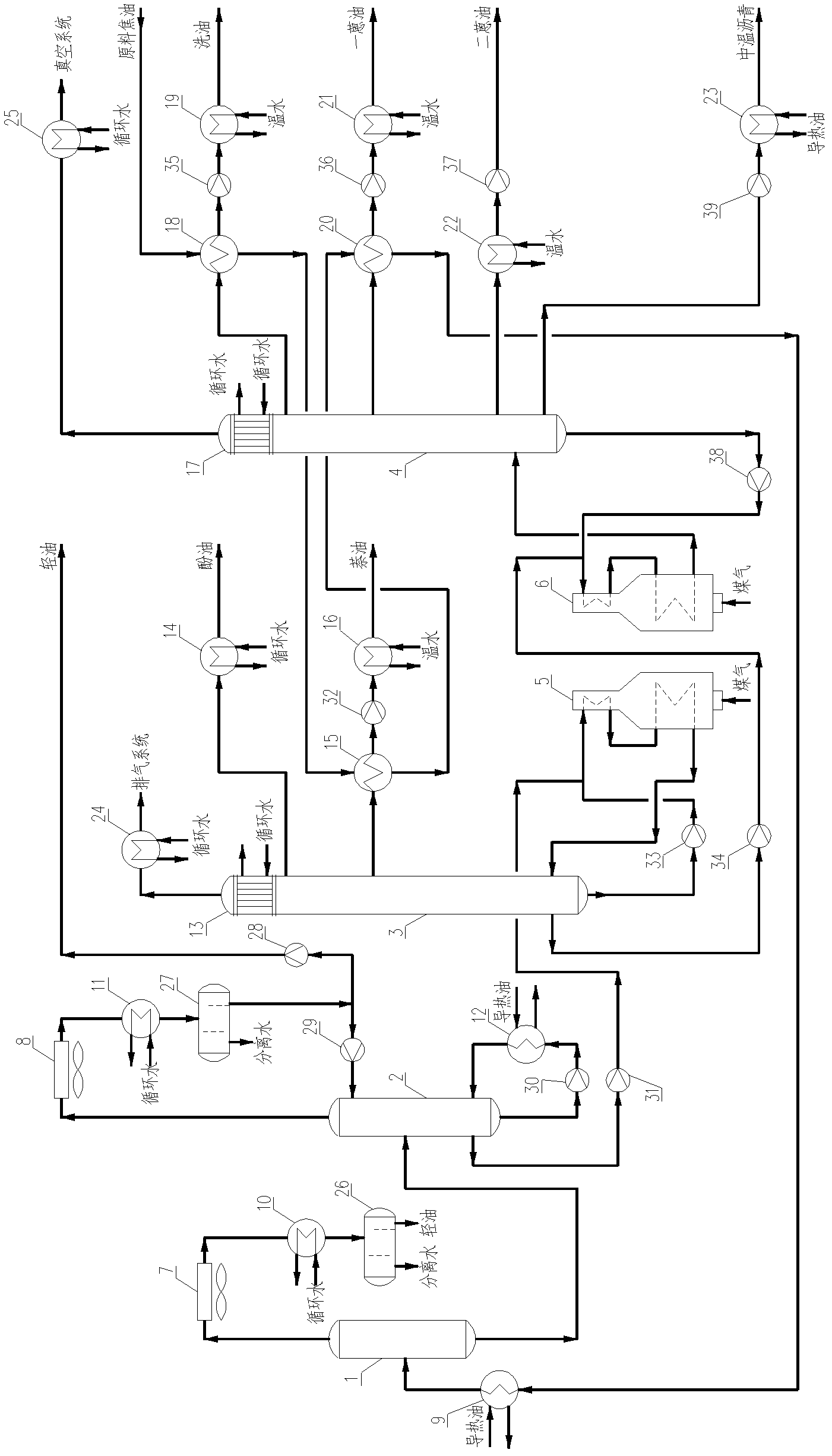

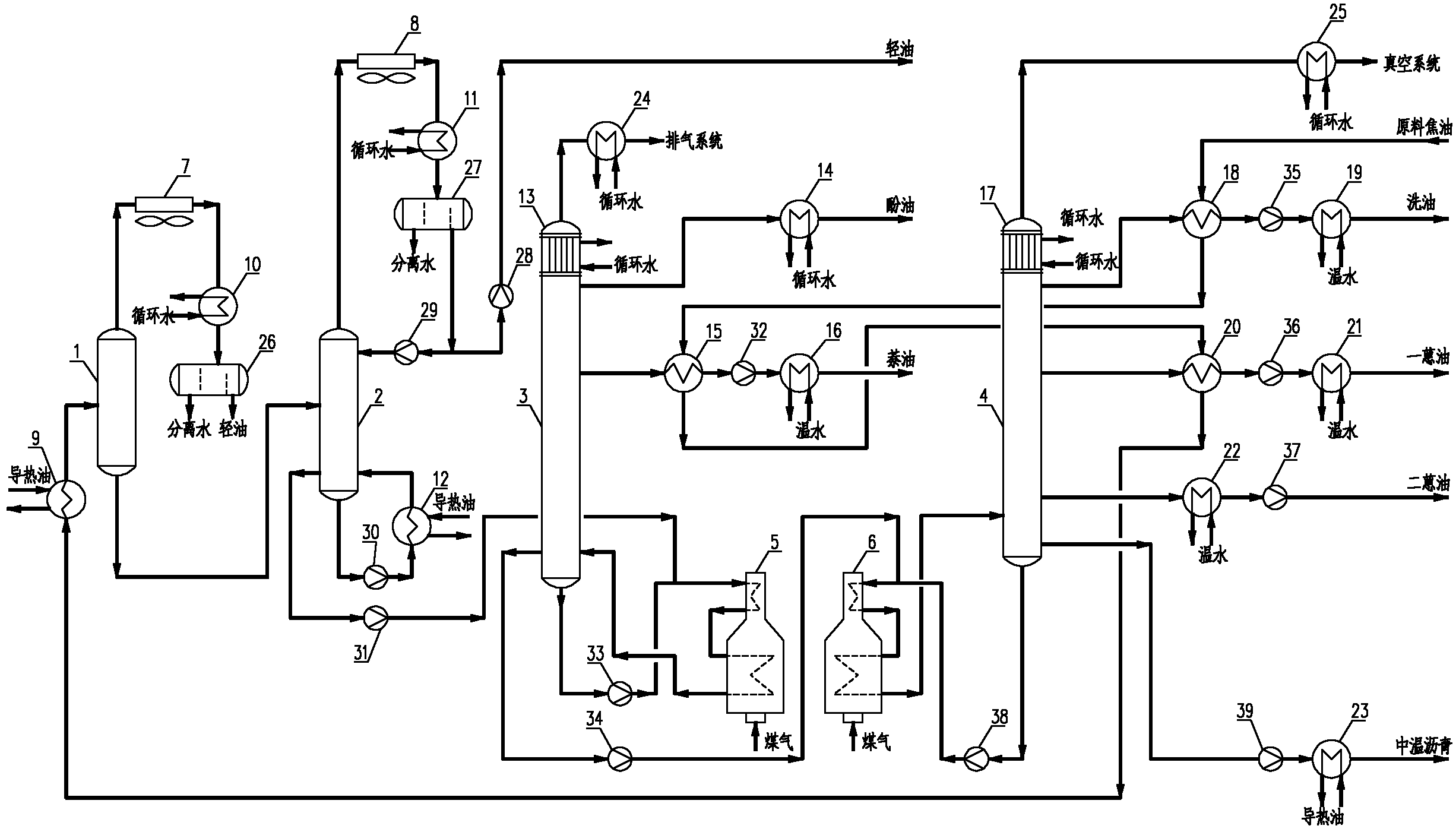

[0050] Attached below figure 1 The present invention will be described in further detail in the specific embodiments.

[0051] Such as figure 1 As shown, raw material tar first enters tar / washing oil heat exchanger 18, tar / naphthalene oil heat exchanger 15, tar / anthracene oil heat exchanger 20 and after washing oil, naphthalene oil, and anthracene oil fraction heat exchange, It enters the tar preheater 9, where it is heated to 125-135°C by heat conduction oil, and then enters the pre-dehydration tower 1.

[0052] The pre-dehydration tower is a flash tower, and the temperature at the top of the tower is about 110-125°C. The light oil fraction and water escaping from the top of the tower are first cooled to 50-60°C by 1# light oil air cooler 7, and then cooled by 1# light oil The device 10 is cooled to 40-45°C, and flows into the 1# light oil oil-water separator 26, and the separated light oil is used as reflux in the dehydration tower or blended back into the raw tar, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com