System used for coal-fired power plant waste-heat utilization and desulfuration water saving

A technology for coal-fired power plants and waste heat, applied in preheating, steam application, feed water heaters, etc., can solve problems such as the limitation of heat exchange effect, achieve the effects of optimizing unit operation, increasing flue gas flow resistance, and fully utilizing waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

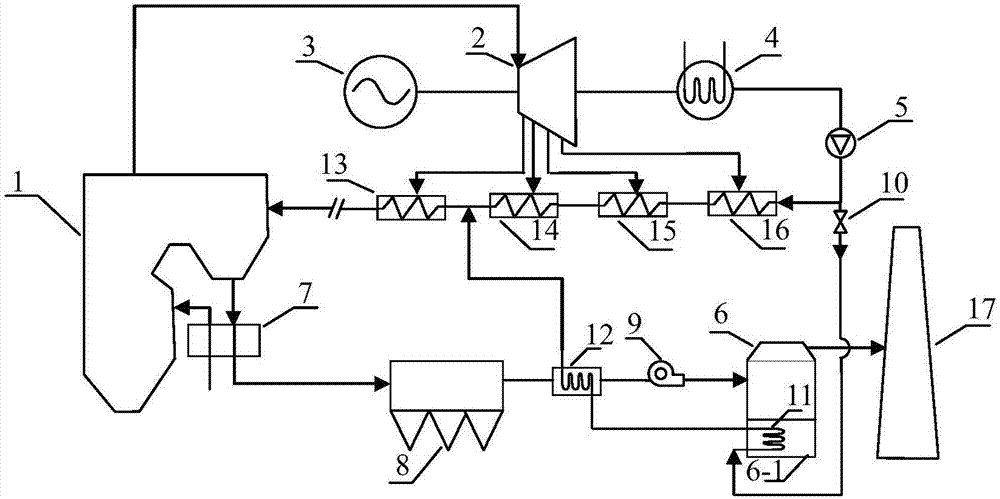

[0031] Example 1, such as figure 1 As shown, what is described in the first embodiment of the present invention is a system for waste heat utilization and desulfurization and water saving in coal-fired power plants. The system includes:

[0032] Steam turbine 2, its intake end is connected to boiler 1, the exhaust gas output end of steam turbine 2 is connected to the intake end of condenser 4, the high-temperature and high-pressure water vapor generated by boiler 1 enters steam turbine 2, and the high-temperature and high-pressure water vapor passes through steam turbine 2 After the energy conversion is completed, the final exhausted gas enters the condenser 4 for cooling and condensation to be converted into condensed water.

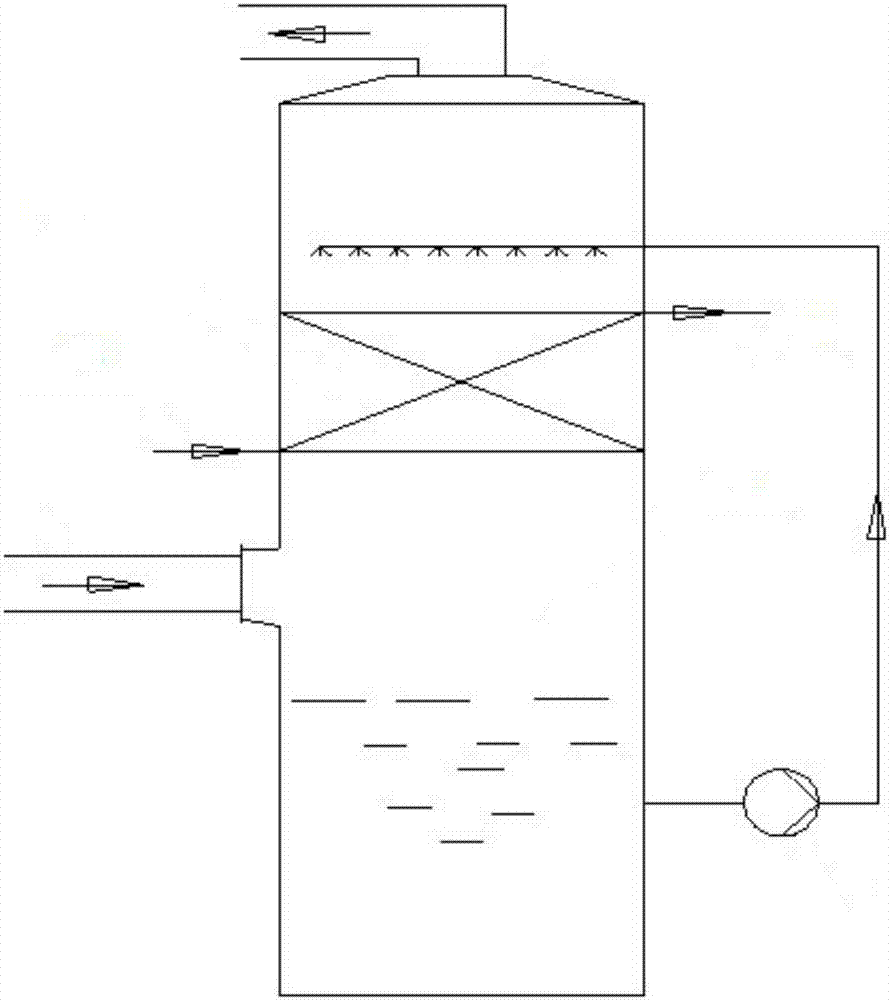

[0033] The primary heat exchanger 11 is arranged in the absorption tower slurry pool 6-1 at the bottom of the desulfurization absorption tower 6, and the condensed water in the primary heat exchanger 11 is heated once by using the temperature of the sl...

Embodiment 2

[0043] Embodiment 2, a waste heat utilization and desulfurization water-saving method for a coal-fired power plant waste heat utilization and desulfurization water-saving system described in the second embodiment of the present invention is:

[0044] The high-temperature and high-pressure water vapor generated by the boiler 1 enters the steam turbine 2, and the steam turbine 2 rotates to drive the generator 3 to generate electricity;

[0045] At the same time, the high-temperature flue gas generated by the boiler 1 enters the air preheater 7 to preheat the air, and then enters the dust collector 8 to remove dust and become medium-temperature flue gas;

[0046] The exhaust gas of the steam turbine enters the condenser 4 to condense to form condensed water, and the condensed water passes through the condensed water pump 5;

[0047] Part of the condensed water flows through the eighth-stage low-pressure heater 16, the seventh-stage low-pressure heater 15, the sixth-stage low-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com