Liquid waste treatment device

A waste liquid treatment and waste liquid technology, applied in the field of waste liquid treatment devices, can solve the problems of catalyst wear and loss, and achieve the effects of efficient treatment, increased flow resistance of waste liquid, and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

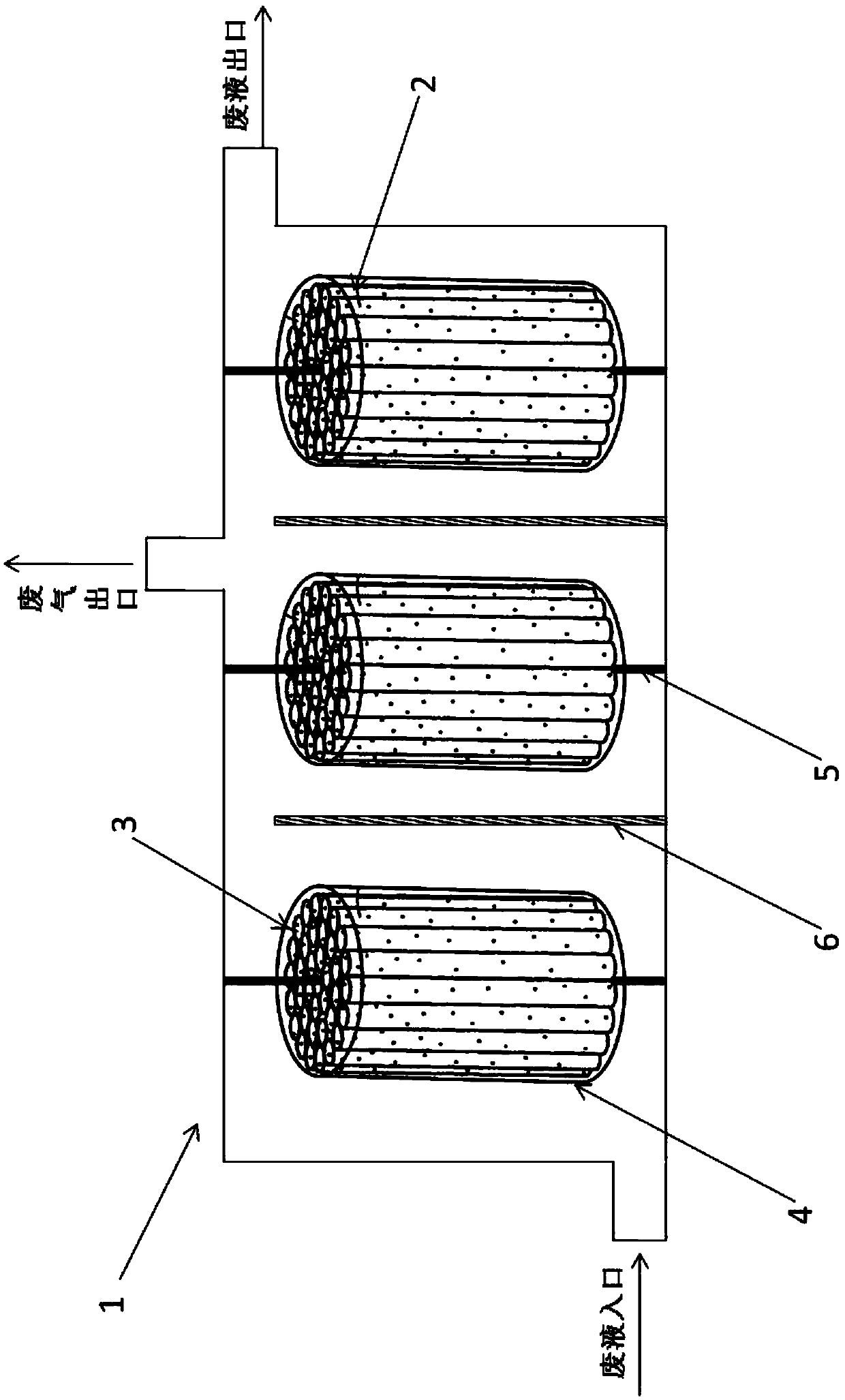

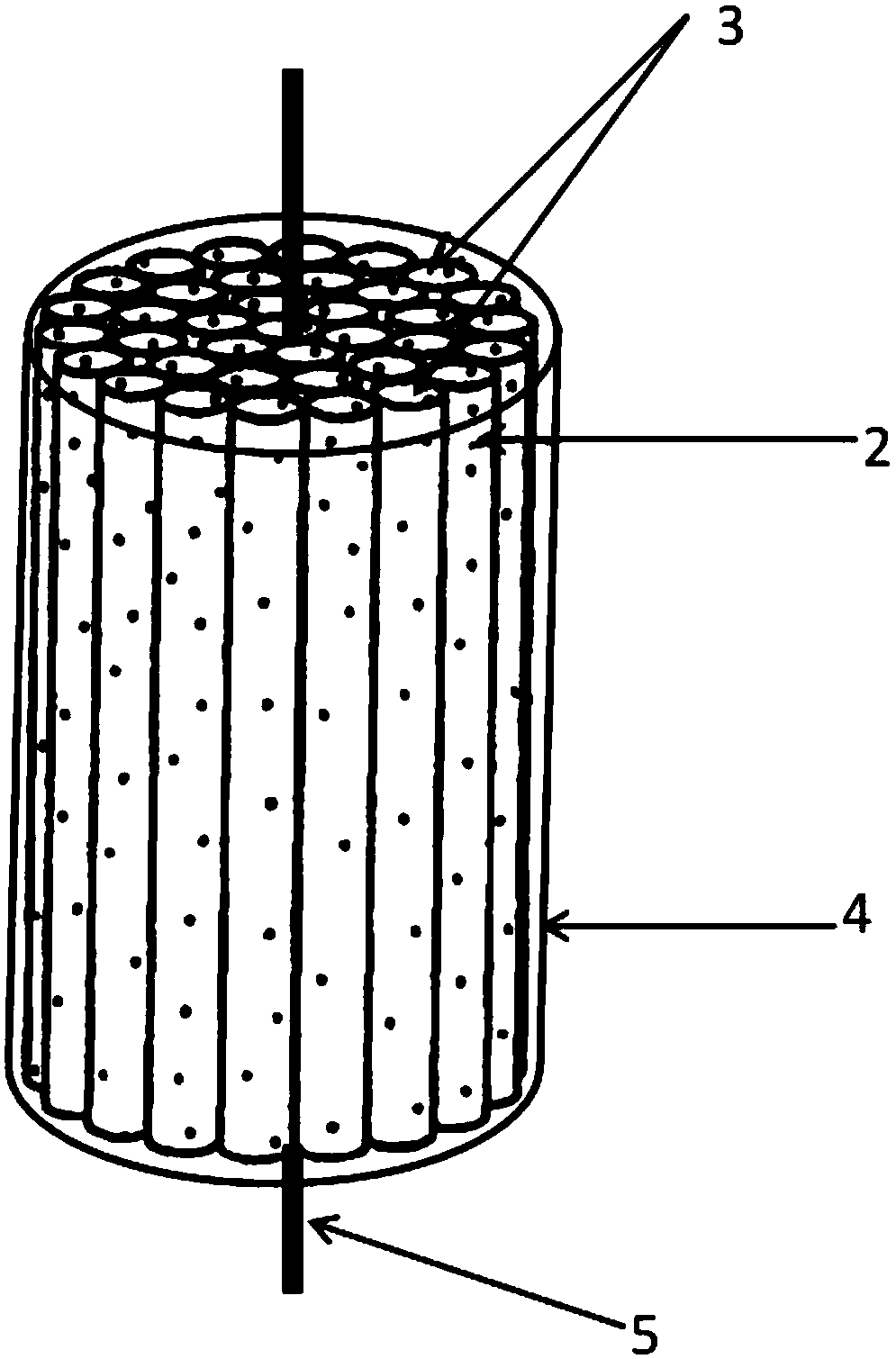

[0022] like figure 1 As shown, a waste liquid treatment device includes a reaction chamber 1, a waste gas outlet is arranged on the top wall of the reaction chamber 1, and a waste liquid inlet and a waste liquid outlet are respectively arranged at both ends of the reaction chamber 1, wherein the waste liquid inlet is arranged near the reaction chamber. At the bottom of the chamber 1, the waste liquid outlet is set on the top of the other end of the reaction chamber 1, and the waste liquid inlet, waste liquid outlet and waste gas outlet are all provided with switch control valves; the reaction chamber 1 is fixed with 3 catalytic treatment units, parallel and spaced Fixedly distributed in the reaction chamber 1, each catalytic treatment unit is provided with a catalyst loading assembly 2, and the catalyst loading assembly includes a plurality of catalyst loading tube bundles 3 bound together with fiber activated carbon as tube walls. A baffle 6 is arranged between the catalyst p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com