Novel heat exchange tube of heat exchanger

A heat exchanger, a new type of technology, applied in the direction of heat exchanger types, indirect heat exchangers, tubular elements, etc., can solve the problems of small heat exchange area, low heat exchange efficiency, heavy heat exchanger weight, etc., to achieve heat exchange The effect of large area, low production cost and overall weight reduction

Inactive Publication Date: 2011-04-27

张家港市华菱化工机械有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The cross-section of the heat exchange tube in a conventional shell-and-tube heat exchanger is generally a circular tube with the same inner and outer diameters. The heat exchange area of such pipelines and cooling medium flow is small, the heat exchange efficiency is relatively low, and the overall weight of the heat exchanger is relatively large.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

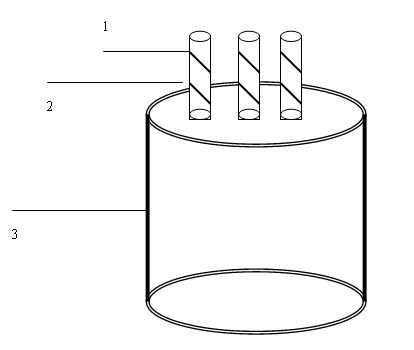

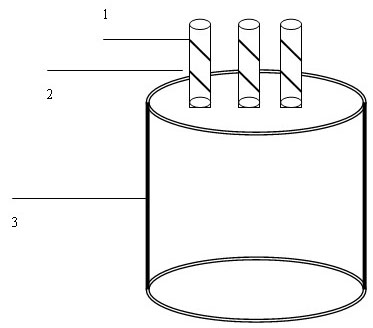

[0010] exist figure 1 Among them, several heat pipes (1) pass through the heat exchanger shell (3), and the outer wall of the heat pipe is bored with a spiral ring with a width of 1 / 4 pipe diameter and a depth of 1 / 2 wall thickness. The projection angle of the annular groove and the axial direction is 45°. The heat pipe is connected to the shell of the heat exchanger with a support plate.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a novel heat exchange tube of a heat exchanger, which can be used for improving heat exchange efficiency by boring a spiral rectangular groove on the outer wall of the heat exchange tube.

Description

Technical field [0001] The purpose of the present invention is a novel heat exchange tube in a shell-and-tube heat exchanger with higher heat exchange efficiency. Background technique [0002] Shell and tube heat exchangers are widely used in the process industry. Conventional tube heat exchangers are usually composed of circular tubes, where one medium flows inside the tube and the other medium flows outside the tube. Due to this structure, tube heat exchangers are suitable for applications requiring high temperature and pressure. The most common types of tube heat exchangers include double tube heat exchangers and shell and tube heat exchangers. [0003] The cross-section of the heat exchange tube in a conventional shell and tube heat exchanger is generally a circular tube with the same inner and outer diameters. The heat exchange area of such pipelines and cooling medium flow is small, the heat exchange efficiency is relatively low, and the overall weight of the heat e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F28D7/10F28F1/34

Inventor 顾晓忠

Owner 张家港市华菱化工机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com