Method and system for utilizing engine waste heat

An engine and engine cylinder technology, applied in engine components, combustion engines, engine cooling, etc., can solve the problems of crowding power grid power consumption, long charging time, unfavorable promotion and use of gasoline-electric hybrid vehicles, etc., to reduce the overall volume. , the effect of saving resource investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

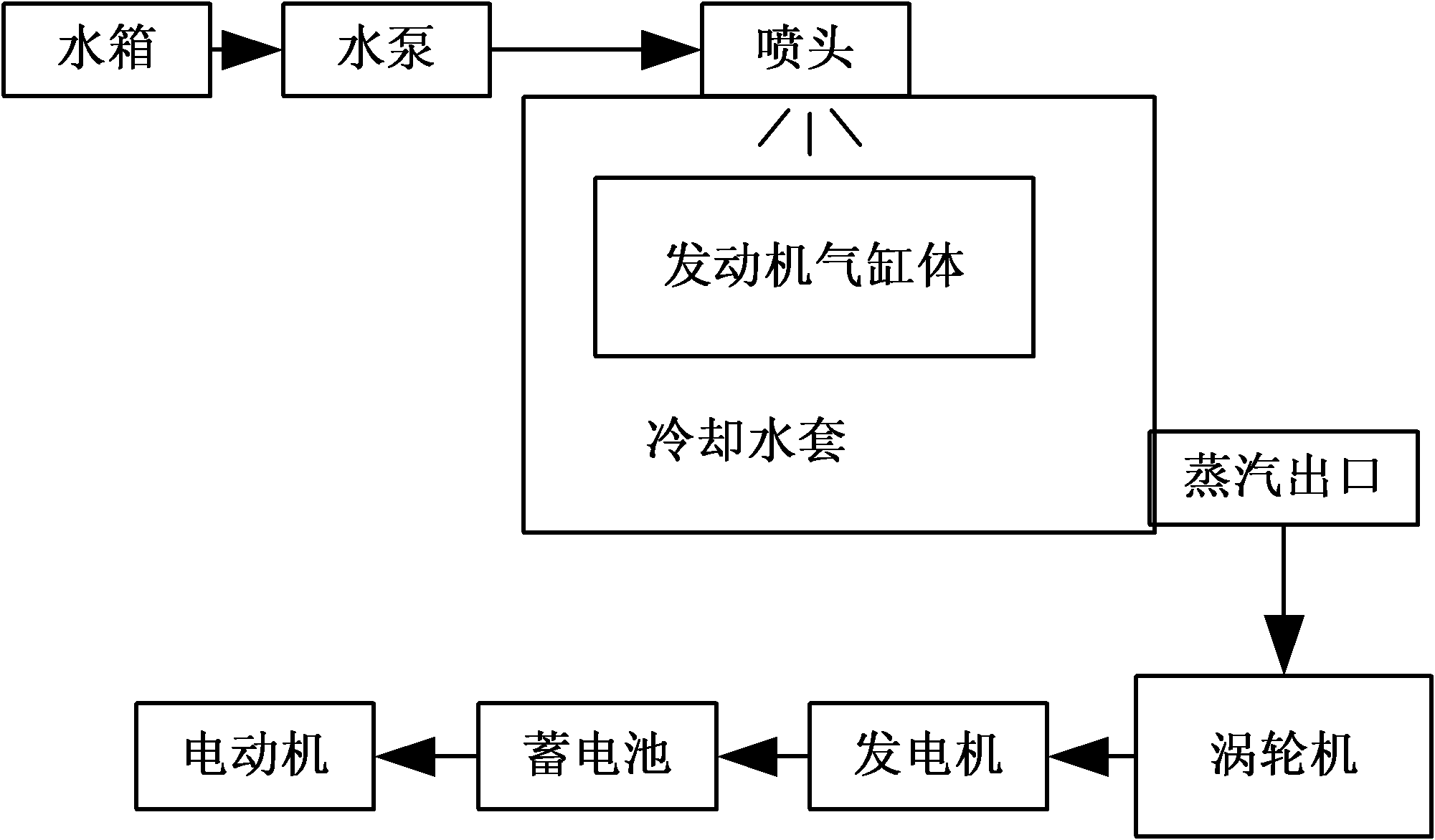

[0026] Such as image 3 , Figure 4 , the engine waste heat utilization system of the present invention comprises an engine cylinder block and a cooling water jacket arranged outside the engine cylinder body, a plurality of nozzles are arranged on the cooling water jacket, and each nozzle is connected to a water tank through a water pump, and the water tank may be the original water tank of the engine, or It may be an additional water tank, the cooling water jacket is provided with a steam outlet, the steam outlet is connected to a steam driving device, the steam driving device is connected to a generator, and the generator is connected to a storage battery.

[0027] The steam drive device may be a turbine, the impeller of which is connected to the shaft of the generator. The steam is blown axially towards the impeller of the turbine.

[0028] The steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com