An Improved Blast Furnace

An improved technology for blast furnaces, applied in furnaces, vertical furnaces, furnace components, etc., can solve the problems of long continuous working hours of blast furnaces, small daily processing raw materials, high smoke and dust rate of exhaust gas, etc., and achieve long continuous working hours and maintenance times The effect of less, high amount of processing raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

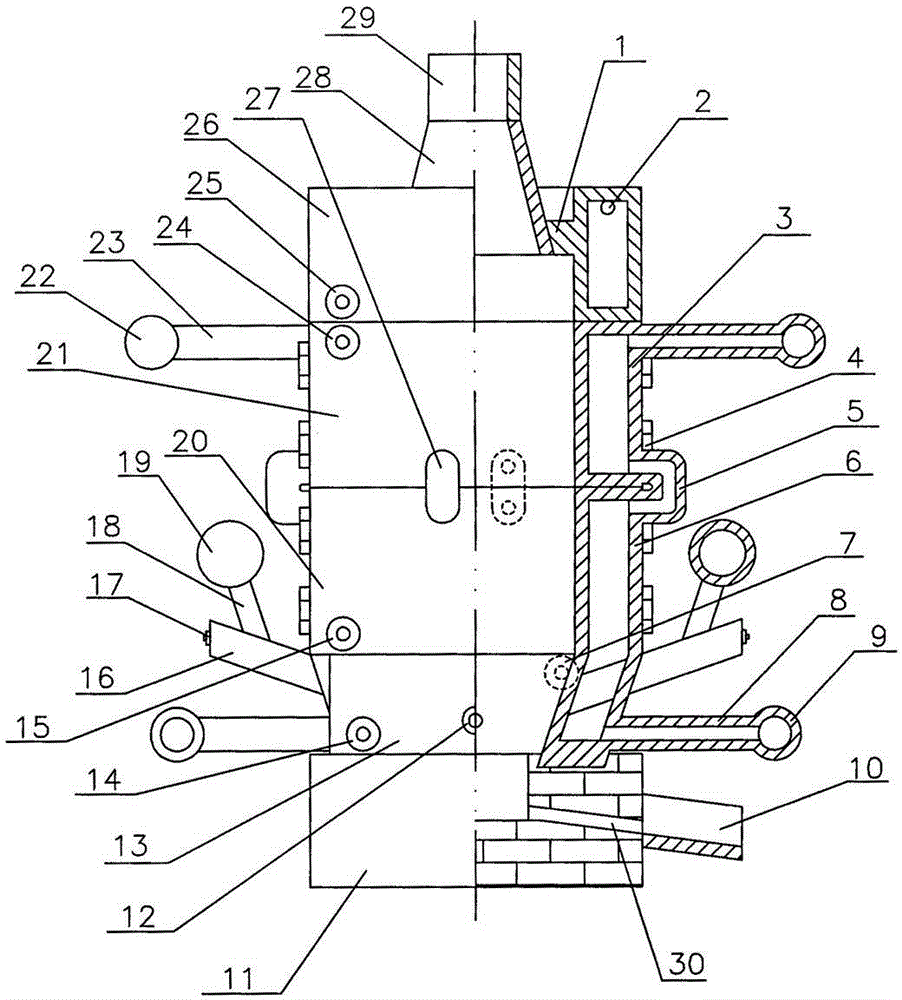

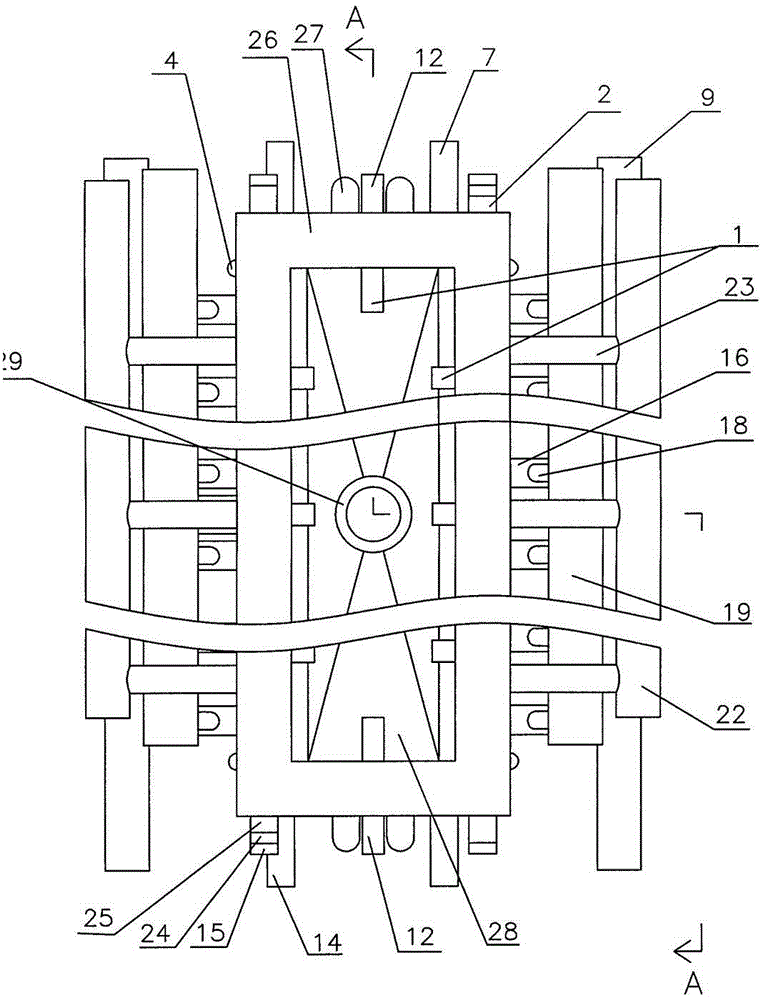

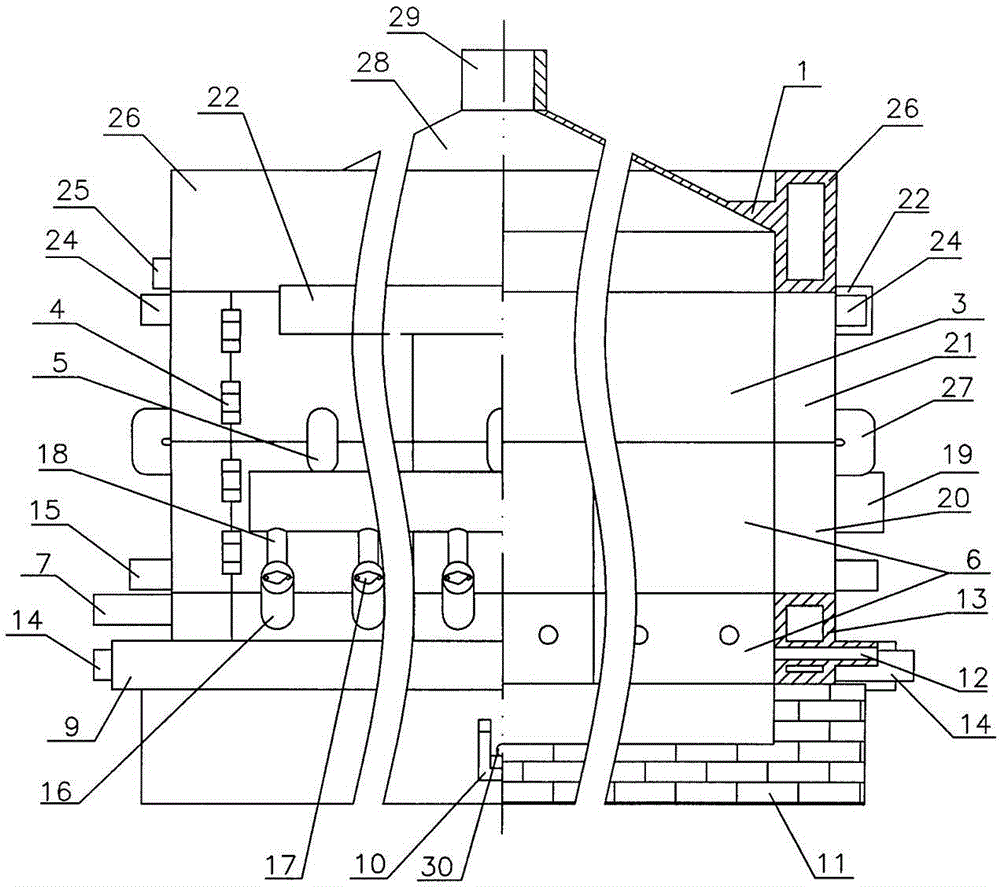

[0032] exist figure 1 , Figure 2, image 3 In the shown embodiment, the base 11 of the blast furnace is built by heat-resistant bricks, and there is a row of coarse lead holes 30 in the base 11, and a row of coarse lead grooves 10 is installed at the outlet of the row of coarse lead holes 30.

[0033] The left and right side walls of the blast furnace are respectively composed of a set of upper water jackets 3 and a set of lower water jackets 6. The adjacent upper water jackets 3 and lower water jackets 6 are connected by water jacket connecting pipes 5. Each upper water jacket 3 A water outlet branch pipe 23 communicates with the water outlet main pipe 22 of the water jacket, and each lower water jacket 6 communicates with the water jacket water inlet main pipe 9 through a water jacket water inlet branch pipe 8; each lower water jacket 6 has two inlet inclined pipes 16 Pass through, the upper end of each air intake inclined pipe 16 has observation hole, the observation hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com