Sintering combined oxygen-enriched side-blown smelting process of vertical drying kiln

A drying kiln and process technology, which is applied in the field of vertical drying kiln sintering combined with oxygen-enriched side-blowing smelting process, which can solve the problems of high energy consumption and production cost, long process flow, and low bed capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

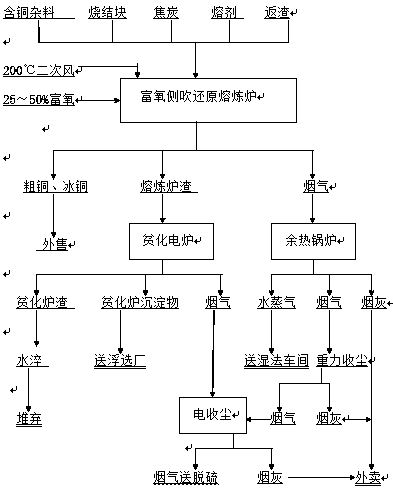

[0024] as attached figure 1 As shown, the present invention proposes a vertical drying kiln sintering combined with oxygen-enriched side blowing smelting process, including the following steps:

[0025] S1, add a small amount of lime and anthracite powder to the sludge containing copper and nickel, mix and stir evenly, after being granulated by the granulator, the feeding device is evenly fed into the vertical drying kiln from the top of the kiln, and moves down by its own weight; The air is blown in from the bottom and the side, and the anthracite in the material is burned to generate hot air, which flows upward through the gaps between the particles and exchanges h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com