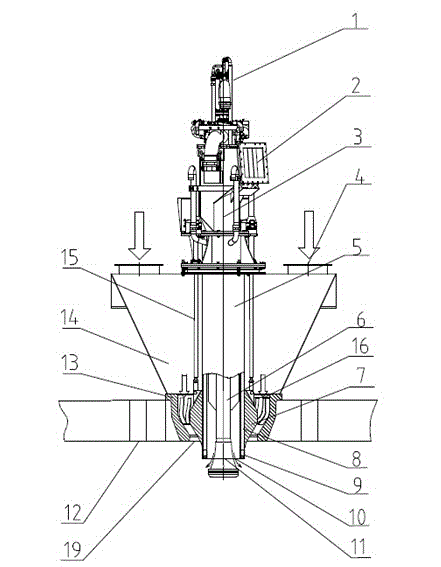

Cyclone concentrate spray nozzle

A cyclone, concentrate technology, applied in furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of uneven mixing of concentrate nozzle materials, complicated manufacturing process of concentrate nozzles, weakening of the strength of the rotating wind flow field, etc. Improve the production capacity of concentrate feeding, ensure the strength, and the effect of strong downward trend of airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

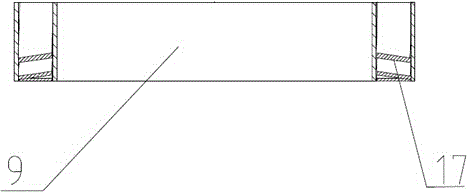

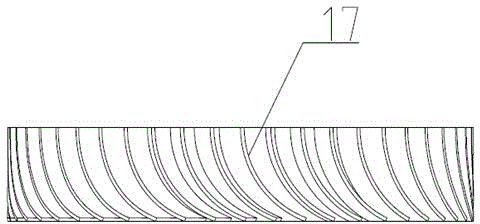

[0031] The invention discloses a cyclone concentrate nozzle, as attached figure 1 As shown, it is arranged above the reaction tower 12, and it includes a feed and discharge mechanism that provides the concentrate to the reaction tower 12. A feed pipe 5, the feed housing 3 is provided with a feed inlet 2, the outside of the feed pipe 5 is provided with an outer layer 8 of the feed pipe for providing cooling gas, and the outer layer 8 of the feed pipe It is a hollow tube coaxial with the feeding pipe 5, and the interlayer between the feeding pipe 5 and the outer layer 8 of the feeding pipe forms a channel for cooling gas, and the cooling gas is used to cool the feeding pipe. Air in the feed pipe 5 and the outer layer 8 of the feed pipe; the lower end of the feed pipe 5 is provided with a discharge port 10 .

[0032] The feed pipe 5 is coaxially equipped with a distributor 6 that evenly disperses the concentrate, and the end of the distributor 6 is fixed with a device capable of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com