Fine-fraction high-silicon low-iron zinc concentrate fluidized bed roaster roasting treatment method

A treatment method and technology of a boiling furnace, applied in the field of zinc smelting, can solve unsolved problems, and achieve the effects of reducing labor intensity and reducing the rate of smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

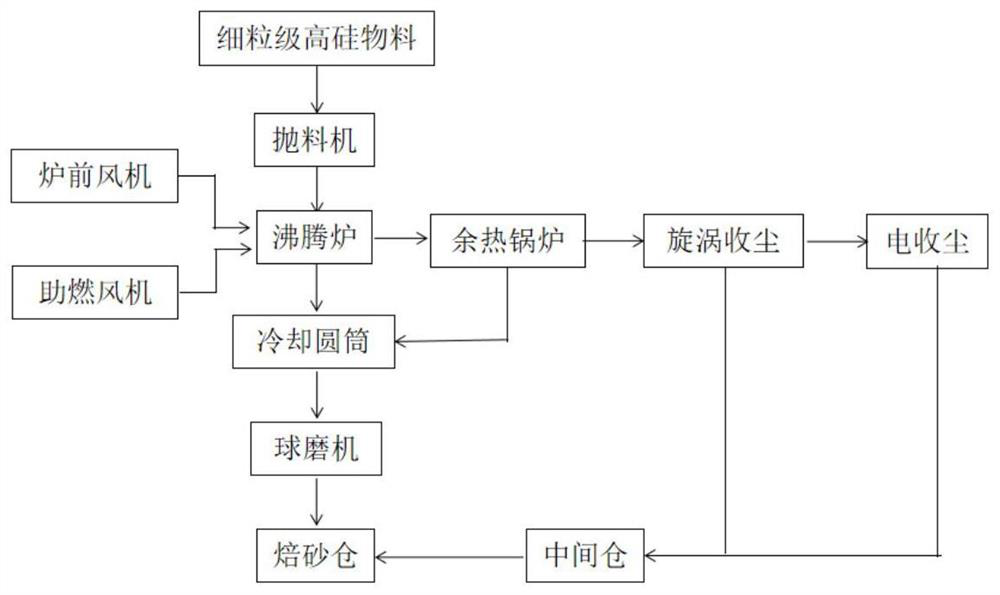

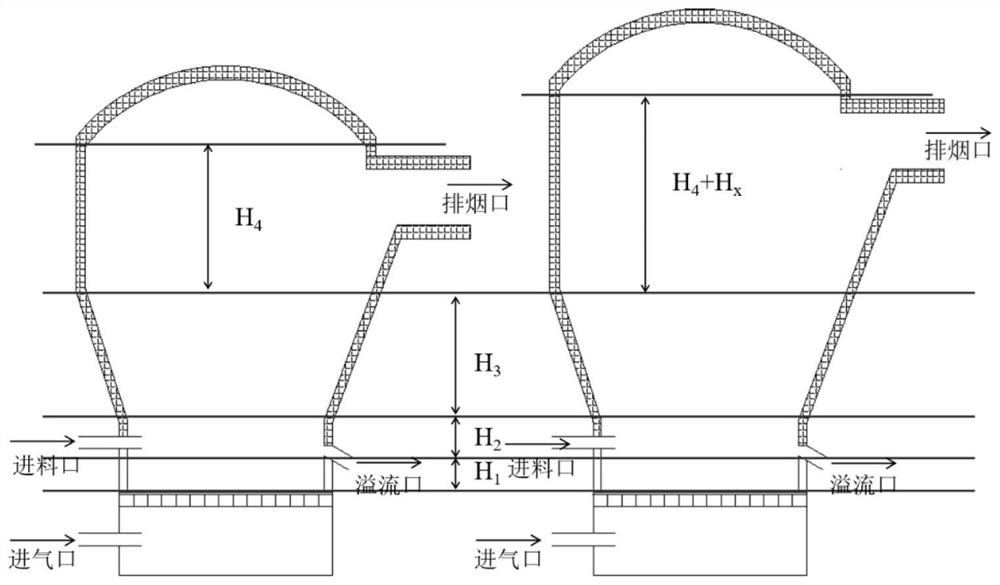

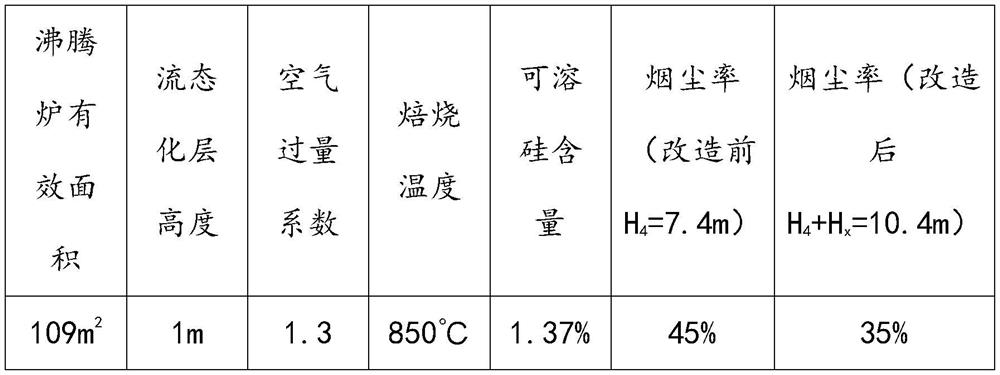

[0023] A kind of fine-grained high-silicon low-iron zinc concentrate fluidized furnace roasting treatment method, such as figure 1 As shown, the specific process is:

[0024] Feed the fine-grained high-silicon and low-iron zinc concentrate into the effective area of 109m through the throwing machine 2 In the fluidized bed furnace, the height of the fluidized bed layer in the fluidized bed furnace is 1m. By controlling the fan in front of the furnace and the combustion-supporting fan, the air excess coefficient is controlled to be 1.3, and the air-to-material ratio is 1800m 3 / t, the roasting temperature is controlled at 850°C, so that the zinc concentrate is oxidized and roasted at a low temperature in the fluidized bed; the product calcine is discharged from the overflow port of the fluidized bed furnace, and enters the calcination bin after being cooled by the cooling cylinder and ball milled by the ball mill. After the product dust and flue gas pass through the waste he...

Embodiment 2

[0031] This embodiment provides a fine-grained high-silicon and low-iron zinc concentrate fluidized furnace roasting treatment method, the specific process is:

[0032] Feed the fine-grained high-silicon and low-iron zinc concentrate into the effective area of 109m through the throwing machine 2 In the fluidized bed furnace, the fluidized bed layer height of the fluidized furnace is 1m. By controlling the fan in front of the furnace and the combustion-supporting fan, the air excess coefficient is controlled to be 1.2, and the air-to-material ratio is 1700m 3 / t, the roasting temperature is controlled at 900°C, so that the zinc concentrate is oxidized and roasted at a low temperature in the fluidized bed; the product calcine is discharged from the overflow port, and enters the calcine bin after being cooled by the cooling cylinder and ball milled by the ball mill. and flue gas pass through the waste heat boiler, vortex dust collector, and electric dust collection for waste h...

Embodiment 3

[0038] This embodiment provides a fine-grained high-silicon and low-iron zinc concentrate fluidized furnace roasting treatment method, the specific process is:

[0039] Feed the fine-grained high-silicon and low-iron zinc concentrate into the effective area of 109m through the throwing machine 2 In the fluidized bed furnace, the height of the fluidized layer is 1m. By controlling the fan in front of the furnace and the combustion-supporting fan, the air excess coefficient is controlled to be 1.1, and the air-to-material ratio is 1600m 3 / t, the roasting temperature is controlled at 920°C, so that the zinc concentrate is oxidized and roasted at a low temperature in the fluidized bed; the product calcine is discharged from the overflow port of the fluidized bed furnace, and enters the calcination bin after being cooled by the cooling cylinder and ball milled by the ball mill. The product smoke dust and flue gas pass through the waste heat boiler, vortex dust collector, and el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com