Lead skim reducing furnace

A reduction furnace, lead slag technology, applied in the improvement of process efficiency, lighting and heating equipment, etc., can solve the problems of low vertical recovery rate, high smoke dust rate, increased energy consumption, etc., to improve the total recovery rate, pulverized coal The effect of reducing the dosage and reducing the soot rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

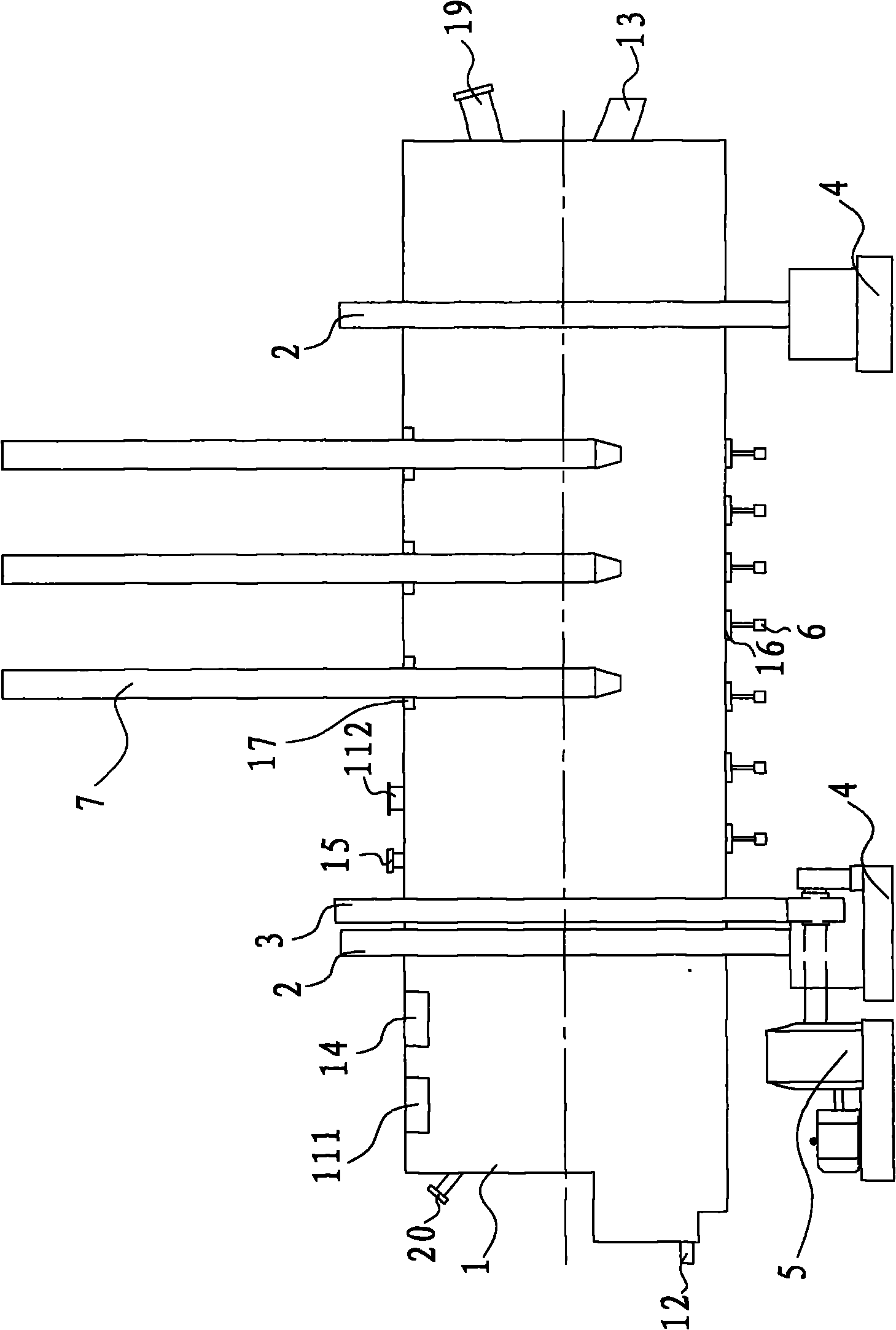

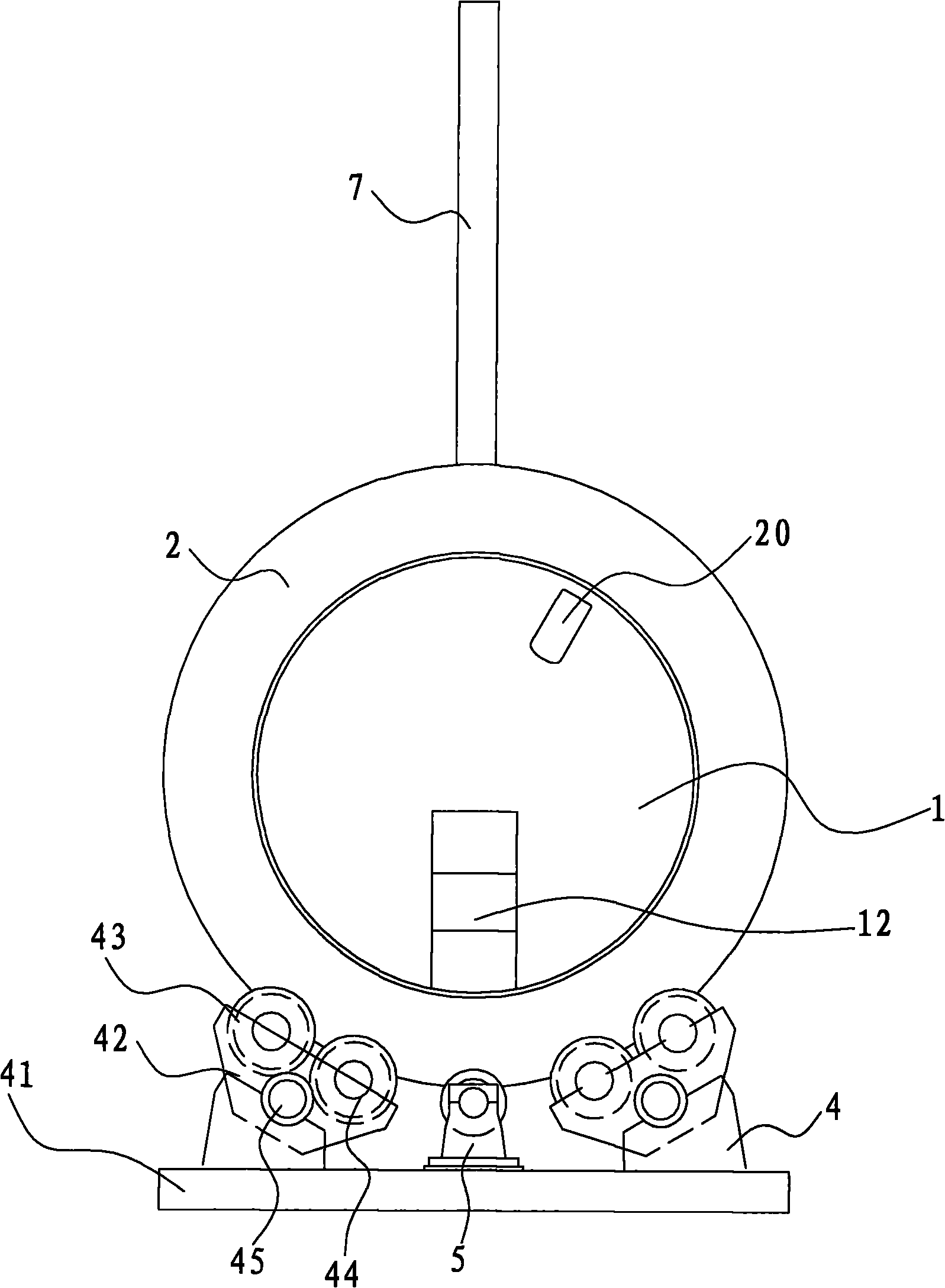

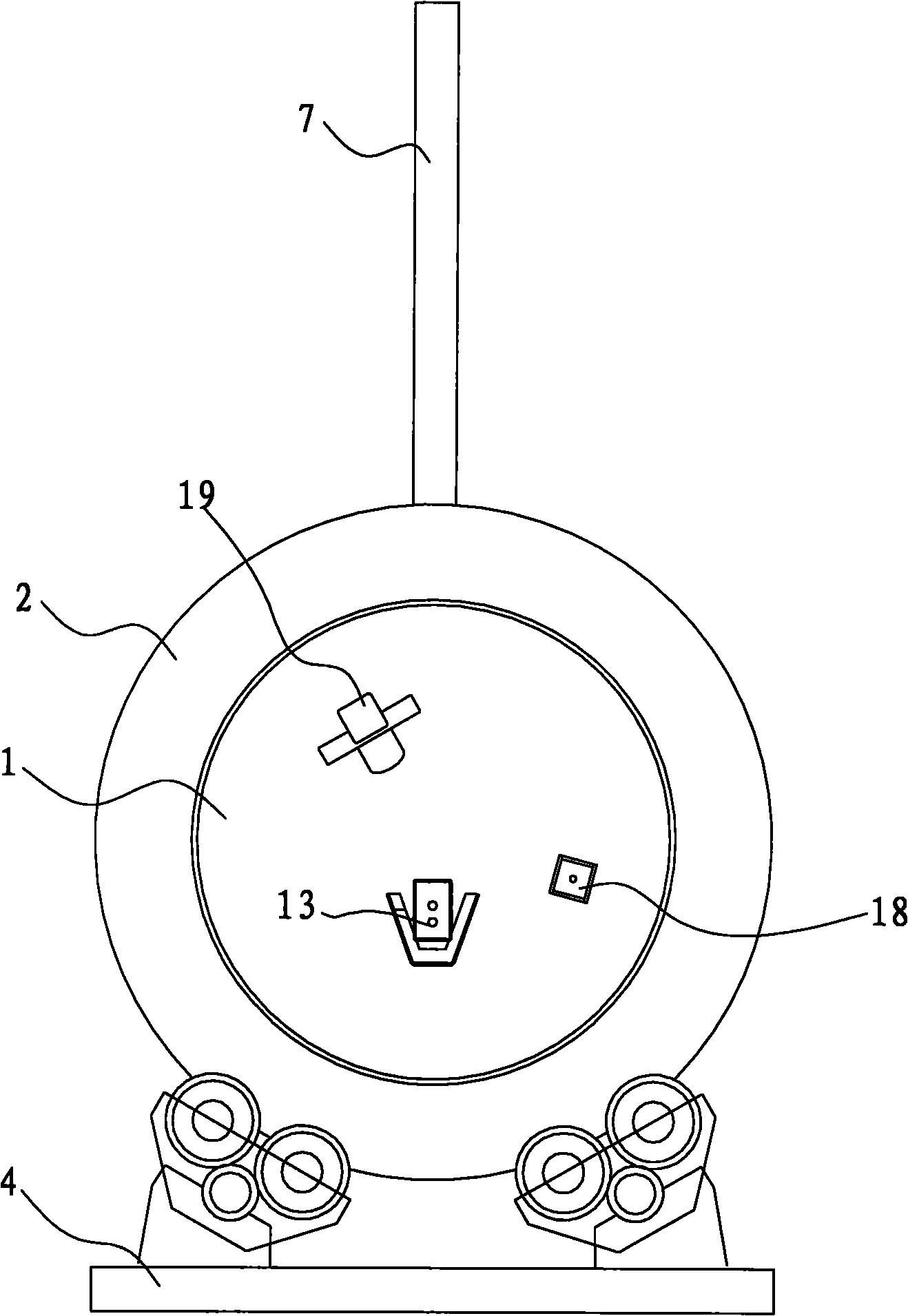

[0035] Refer below Figure 1-4 A lead slag reduction furnace according to one embodiment of the present invention will be described.

[0036] Such as figure 1 As shown, the lead slag reduction furnace according to an embodiment of the present invention includes a furnace body 1 , a support 4 , a pulverized coal spray gun 6 and an electrode 7 . The lead slag reducing furnace of the present invention can be used for processing lead slag, such as high lead oxide slag with a lead content of 25%-45%. It should be noted that since the electrode 7 is provided in the lead slag reduction furnace according to the embodiment of the present invention, secondary materials containing lead and oxidized lead ore can also be processed. In other words, the lead slag reduction furnace according to the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com