Method for direct low-temperature smelting of waste lead accumulator

A waste lead storage battery, low-temperature technology, applied in the production of regenerated lead, direct low-temperature smelting of waste lead storage batteries, can solve the problems of low concentration of sodium sulfate, high energy consumption of sodium sulfate recovery, bulky volume, etc., to achieve low smelting temperature, lead The effect of high direct yield and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

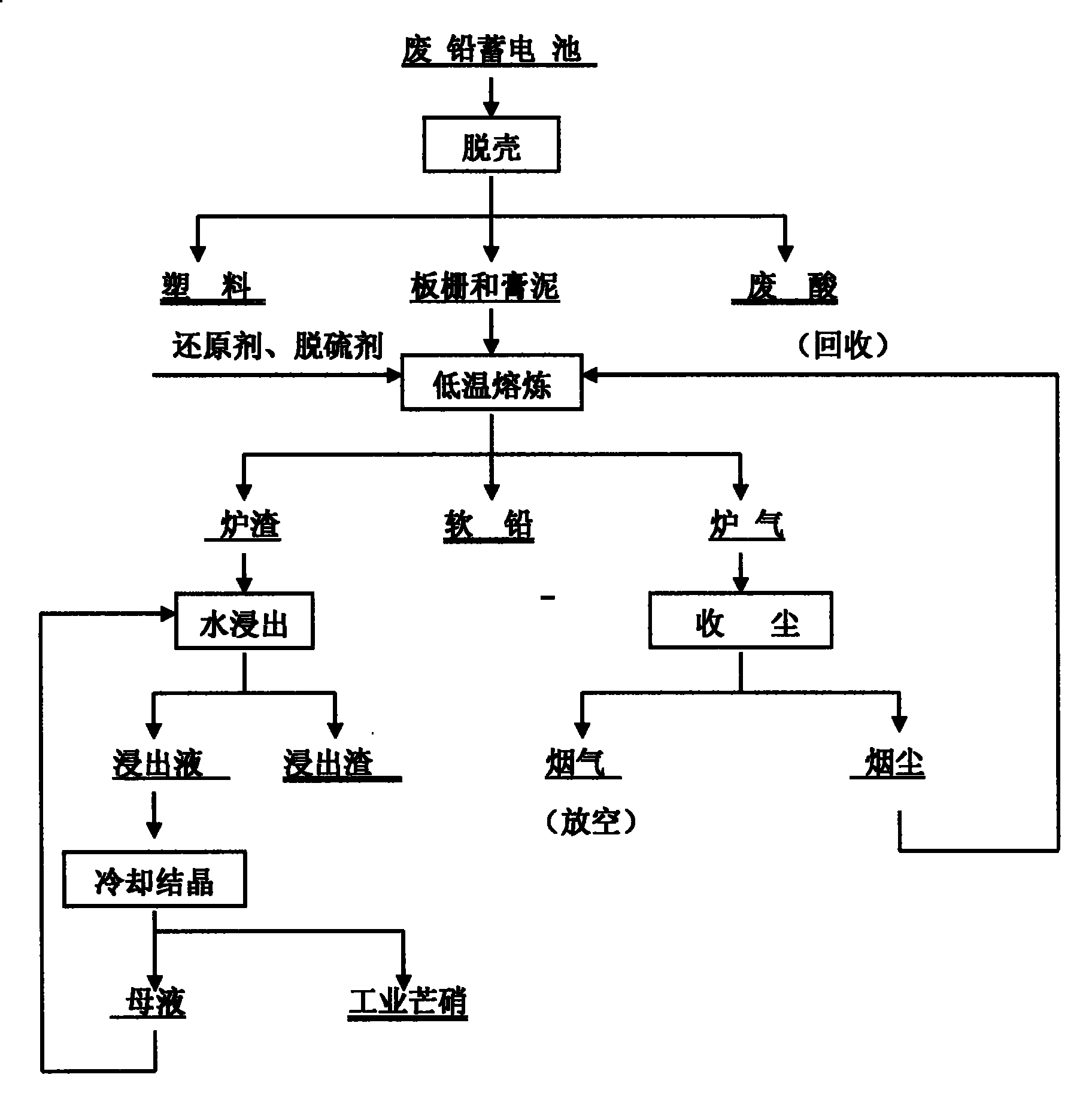

[0029] Now in conjunction with the accompanying drawings and examples of the description, the method for direct low-temperature smelting of waste lead-acid batteries provided by the present invention will be further described.

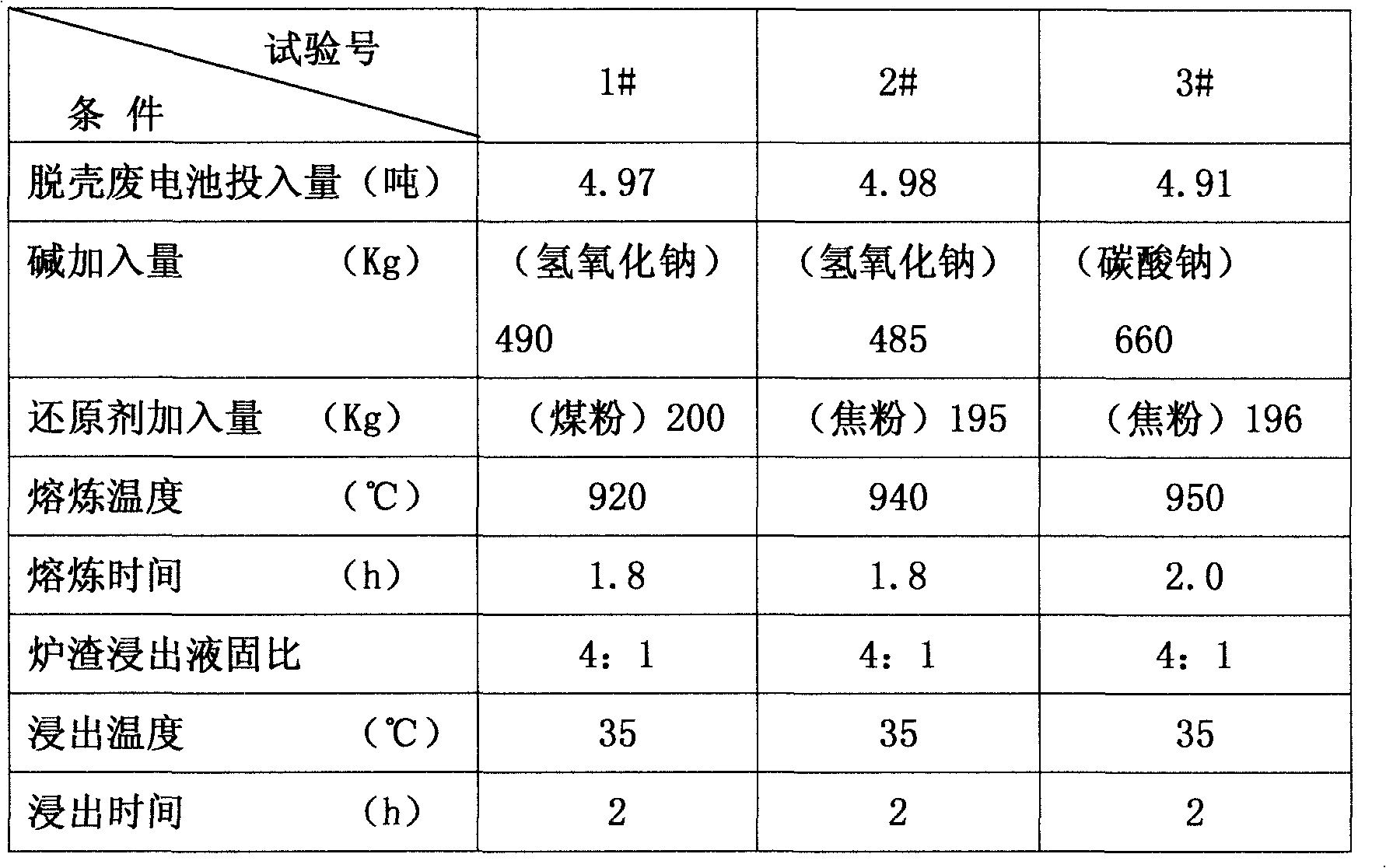

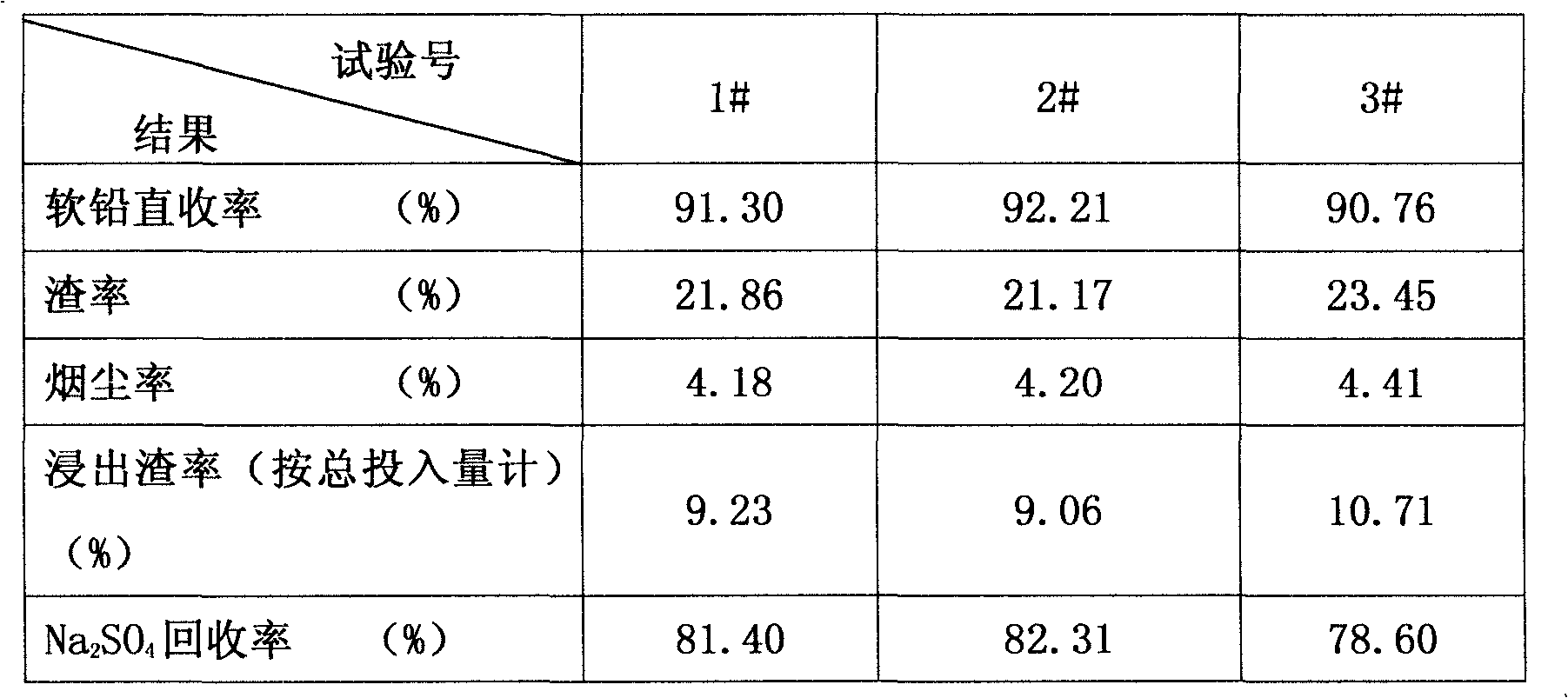

[0030] The test is carried out according to the direct low-temperature smelting process of waste lead-acid batteries given in the accompanying drawings. The technical conditions, test results and main chemical components of the end products are given in Table 1-3.

[0031] Table 1. Test conditions for direct low-temperature smelting of waste lead-acid batteries

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com