Method for efficiently removing fluorine-chlorine impurities in zinc oxide smoke

A zinc oxide and removal technology, applied in the field of metallurgy, can solve the problems of large fuel consumption, difficult wastewater treatment, and large water resource consumption, and achieve the effects of improving bed capacity, improving recovery, and improving heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

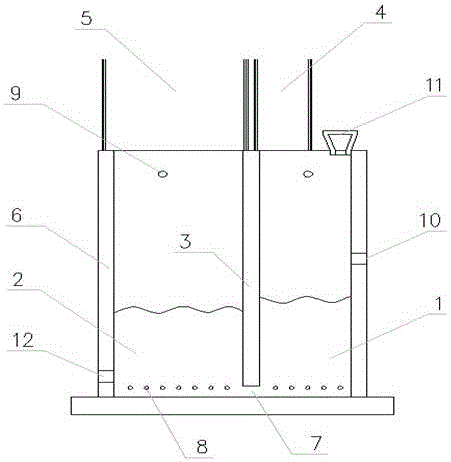

Method used

Image

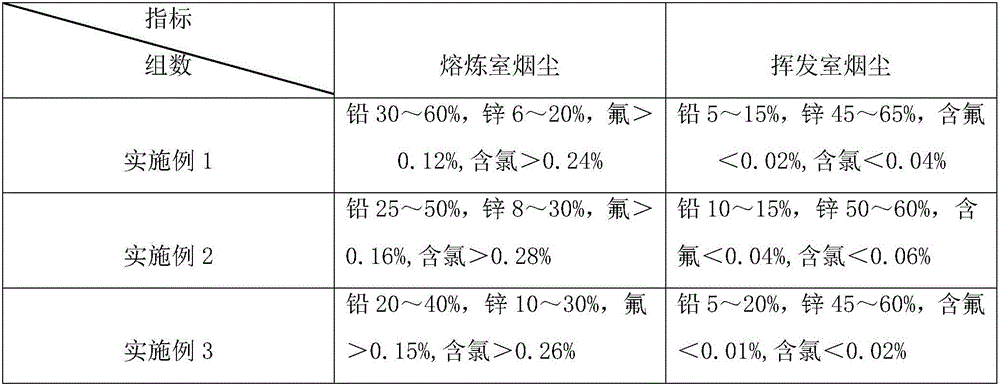

Examples

Embodiment 1

[0026] A method for efficiently removing fluorine and chlorine impurities in zinc oxide smoke dust comprises the following steps:

[0027] (1) Open the slag inlet 10, add 40t of reduced slag (Pb1-6%, Zn5-12%) into the smelting chamber 1, and close the slag inlet 10;

[0028] (2) Open the tuyere 8 and tertiary tuyere 9 of the smelting-volatilization compound furnace, pulverized coal and oxygen-enriched air are blown into the tuyere 8, air is blown into the tertiary tuyere 9, and the air volume blown in by the tuyere 8 of the smelting chamber 1 is adjusted to 8000m 3 / h, wind pressure 180KPa, oxygen-enriched concentration 23%, pulverized coal volume 1.3t / h; adjust the air volume blown into the volatilization chamber 2 blast outlet 8 to 10000m 3 / h, wind pressure 180KPa, oxygen enrichment concentration 23%, pulverized coal amount 2.0t / h;

[0029] (3) Add acid leaching residue (containing 3-8% of lead, 8-18% of zinc, and 6-12% of sulfur) from the cold feed inlet 11 at a rate of 1...

Embodiment 2

[0034] A method for efficiently removing fluorine and chlorine impurities in zinc oxide smoke dust comprises the following steps:

[0035] (1) Open the slag inlet 10, add 30t of reduced slag (Pb2-5%, Zn6-14%) into the smelting chamber 1, and close the slag inlet 10;

[0036] (2) Open the tuyere 8 and tertiary tuyere 9 of the smelting-volatilization compound furnace, pulverized coal and oxygen-enriched air are blown into the tuyere 8, air is blown into the tertiary tuyere 9, and the air volume blown into the 1st tuyere 8 of the smelting chamber is adjusted to 10000m 3 / h, wind pressure 160KPa, oxygen enrichment concentration 21%. The amount of pulverized coal is 1.5t / h; adjust the air volume blown into the volatilization chamber 2 blast outlet 8 to 12000m 3 / h, wind pressure 160KPa, oxygen enrichment concentration 21%, pulverized coal amount 2.2t / h;

[0037] (3) Add acid leaching residue (containing 3-10% of lead, 4-12% of zinc, and 8-10% of sulfur) from the cold feed inlet 1...

Embodiment 3

[0042] A method for efficiently removing fluorine and chlorine impurities in zinc oxide smoke dust comprises the following steps:

[0043] (1) Open the slag inlet 10, add 60t of reduced slag (Pb3-7%, Zn8-14%) into the smelting chamber 1, and close the slag inlet 10;

[0044] (2) Open the tuyere 8 and the tertiary tuyere 9 of the smelting-volatilization compound furnace, the tuyere 9 blows in pulverized coal and oxygen-enriched air, and the tertiary tuyere 9 blows in air. Adjust the air volume blown into the smelting chamber 1 blast outlet 8 to 12000m 3 / h, wind pressure 200KPa, oxygen-enriched concentration 25%, pulverized coal volume 1.6t / h; adjust the air volume blown into the volatilization chamber 2 blast outlet 8 to 14000m 3 / h, wind pressure 200KPa, oxygen enrichment concentration 25%, pulverized coal amount 2.2t / h;

[0045] (3) Add acid leaching slag lead (4-8%, zinc 6-18%, sulfur-containing 4-8%) from the cold feed inlet 11 at a rate of 18t / h;

[0046] (4) Adjust the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com