Copper smelting furnace

A copper smelting furnace and furnace body technology, applied in the field of copper smelting, can solve the problems of low throwing efficiency, large amount of smoke and dust, and low reaction efficiency, and achieve the effects of not being easy to coke and deform, suppressing smoke and dust, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

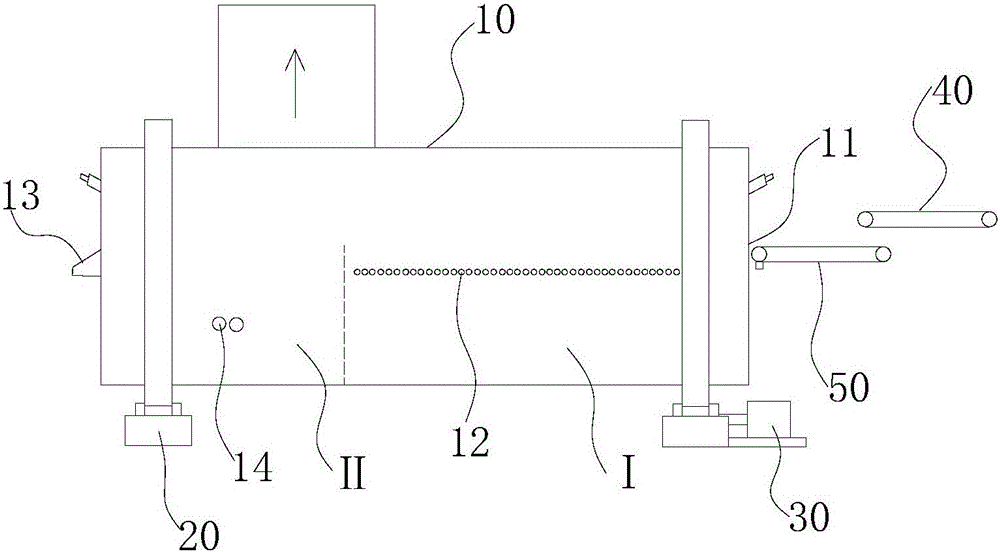

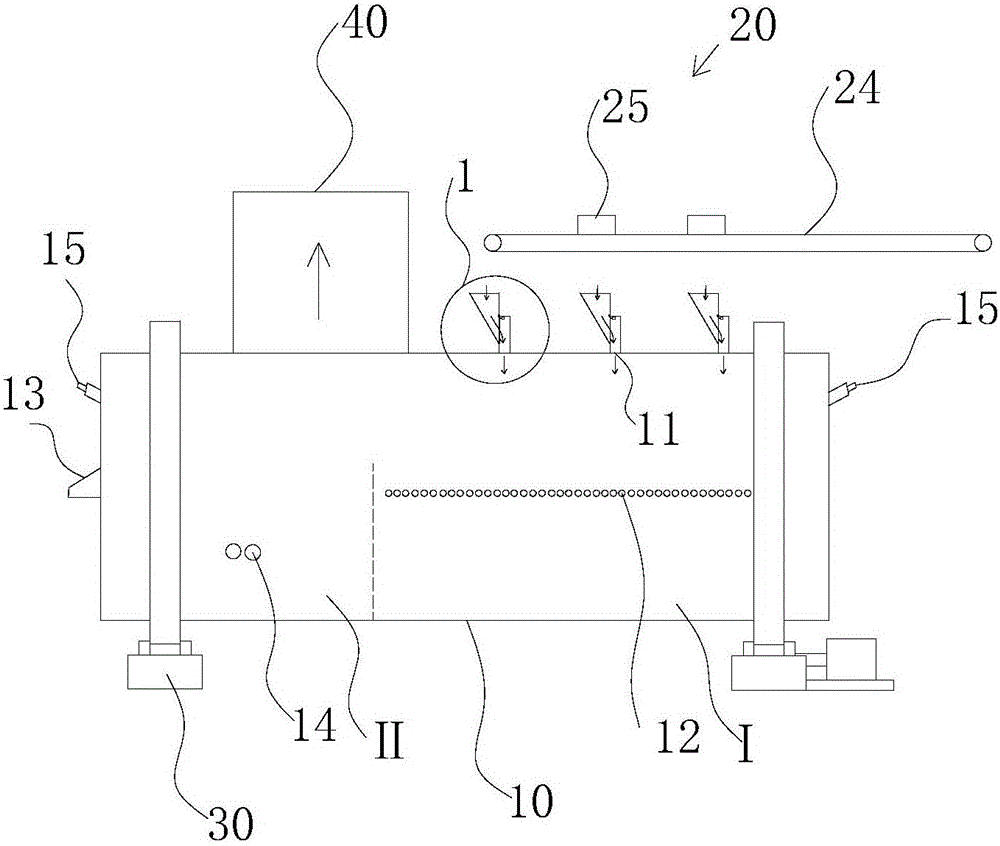

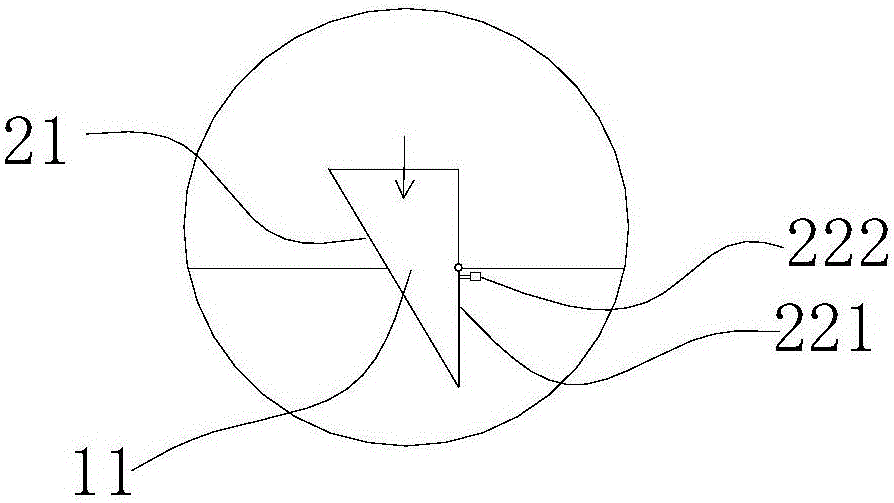

[0016] A copper smelting furnace includes a furnace body 10 , and a feeding port 11 on the furnace body 10 is located above the furnace body 10 . Put the feeding port 11 above the furnace body 10, the material can freely fall into the furnace through the feeding port 11, reducing the flying of the material, then the material forming the smoke will be reduced, and the corresponding smoke rate will be reduced; in addition, because the furnace body The flue gas temperature above 10 is high, and after the feeding port 11 is placed above the furnace body 10, the feeding port 11 is not easy to be coked and deformed; moreover, the feeding port 11 is located above the furnace body 10, and the materials can be evenly placed in the reaction zone I during feeding. The reaction efficiency is improved; in addition, the throwing mechanism is omitted, which saves a lot of equipment investment and maintenance costs.

[0017] In a further technical solution, the furnace body 10 is cylindrical,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com