Treatment device and treatment process applied to slag recycling

A technology of processing technology and processing device, which is applied in the direction of photography technology, photography auxiliary technology, process efficiency improvement, etc., can solve the problems that can not fully achieve resource utilization, and achieve the benefits of flue gas treatment, low copper content, and flue gas less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0024] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

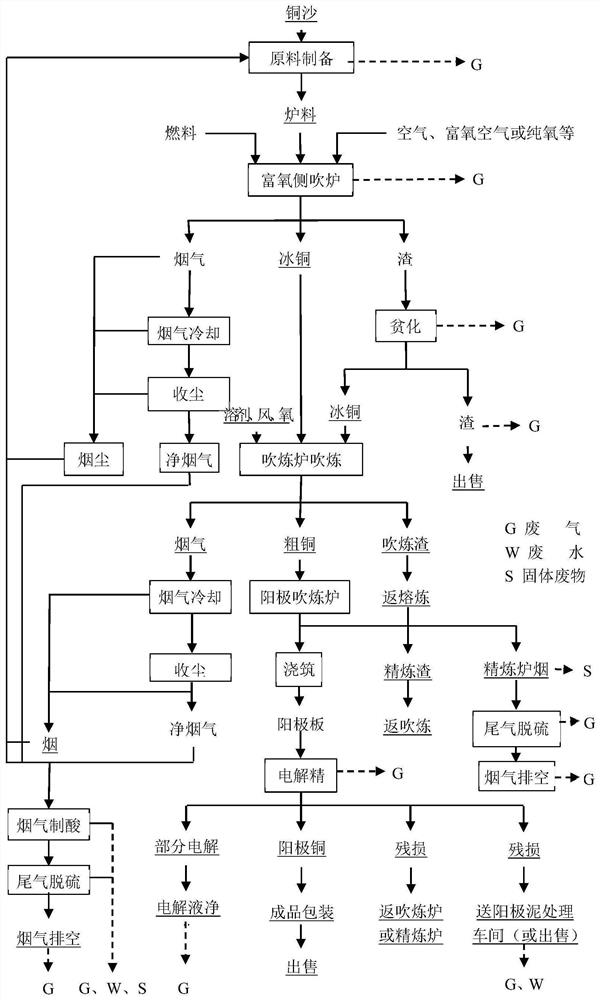

[0025] Such as figure 1 As shown, according to a preferred embodiment of the present invention, a processing device applied to slag recycling can be used to process copper sand separated from slag generated after municipal solid waste incineration. The processing device mainly includes oxygen-enriched side-blown Melting furnace, electrolysis system and acid system, etc. The oxygen-enriched side-blown smelting furnace inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com