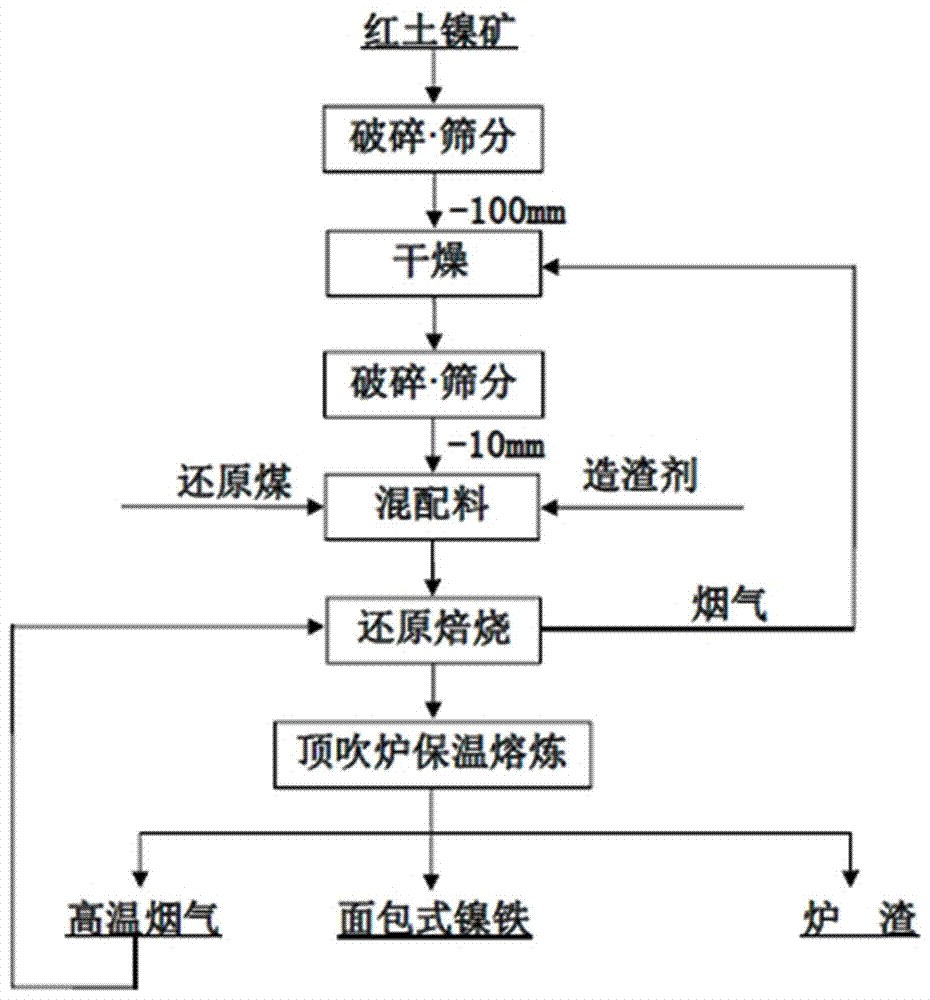

Method and device for producing ferronickel through nickel-laterite ore direct reduction and top-blown smelting method

A technology of laterite nickel ore and nickel iron, applied in the field of nickel metallurgy, can solve the problems of poor material adaptability, high energy consumption, environmental pollution, etc., and achieve the effects of large demand, high heat and wide sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

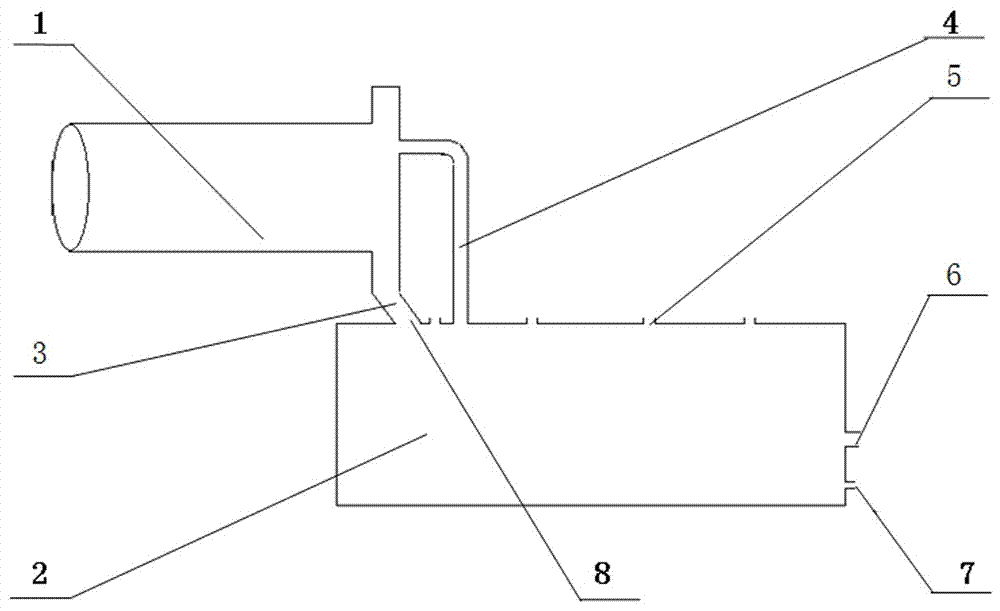

[0030] The laterite nickel ore that meets the process requirements and its mass proportion of 11% reduced coal and 6.5% quicklime are added to the mixing drum by a belt conveyor and mixed evenly; the mixed ingredients are added to the rotary kiln 1 through a belt conveyor and material pipe for reduction roasting. The reduction and roasting temperature is controlled at 1150°C, and the residence time of the material in the rotary kiln 1 is 120 minutes; the semi-molten slag ferronickel, which is the product of the reduction roasting, is directly flowed from the rotary kiln 1 through the chute 3 and automatically flows into the top-blown furnace from the feeding port 8 in the state of heat preservation. 2; in the top-blown furnace 2, the heat energy generated by the combustion of the gas injected by the burner 5 will further smelt the semi-molten slag ferronickel into liquid nickel-iron liquid and slag, and realize the slag and ferronickel in the heat preservation and settlement are...

Embodiment 2

[0032]The laterite nickel ore that meets the process requirements and its mass proportion of 12% reduced coal and 6.5% quicklime are added to the mixing drum by a belt conveyor and mixed evenly; the mixed ingredients are added to the rotary kiln 1 through the belt conveyor and material pipe for reduction roasting. The reduction roasting temperature is controlled at 1200°C, and the residence time of the material in the rotary kiln 1 is 120 minutes; the semi-molten slag ferronickel, which is the product of the reduction roasting, is directly flowed from the rotary kiln 1 through the chute 3 and automatically flows into the top-blown furnace from the feeding port 8 in the state of heat preservation. 2, in the top-blowing furnace 2, the heat energy generated by the combustion of the gas injected by the burner 5 further smelts the semi-molten slag ferronickel into liquid nickel-iron liquid and slag, and the slag is realized in the heat preservation and settlement area in the top-blow...

Embodiment 3

[0034] The laterite nickel ore that meets the process requirements and its mass proportion of 12.5% reduced coal and 7.5% quicklime are added to the mixing drum by a belt conveyor and mixed evenly; the mixed ingredients are added to the rotary kiln 1 through a belt conveyor and material pipe for reduction roasting. The reduction roasting temperature is controlled at 1250°C, and the residence time of the material in the rotary kiln 1 is 150 minutes; the semi-molten slag ferronickel, which is the product of the reduction roasting, is directly flowed from the rotary kiln 1 through the chute 3 and automatically flows into the top-blown furnace from the feeding port 8 under the state of heat preservation. 2; in the top-blown furnace 2, the heat energy generated by the combustion of the gas injected by the burner 5 will further smelt the semi-molten slag ferronickel into liquid nickel-iron liquid and slag, and realize the slag and ferronickel in the heat preservation and settlement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com