Patents

Literature

33results about How to "Wide market" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving ability of paddy field parasitic bee control plant hopper and rice leaf roller

InactiveCN101233817AIncrease diversityEnhance natural controlFertilising methodsRice cultivationPhosphatePotassium

The invention discloses a method for improving the ability of paddy parasitoids to control rice hoppers and rice leaf tiers, which pertains to a technical filed of agricultural biological control of insect pests. The method comprises the following steps: (1) a bund is consolidated 30 days before seedling transplanting of single cropping rice or double-cropping late rice; (2) sesame seed is sowed in the bund 30 days before seedling transplanting, and urea is applied after sesame is in bloom and potassium dihydrogen phosphate is applied on leaf area; (3) pesticide is not allowed to use within 40 days after seedling transplanting and steps such as spraying pesticide under the condition of no wind 40 days after seedling transplanting are carried out. The method of the invention is characterized by labor saving, time saving, simple operation, etc. and can not only improve the ability of paddy parasitoids to control rice hoppers and rice leaf roller but also reduce the application of pesticide with obvious economic, ecological and social benefits. The method can be widely applied in rice cultivation areas.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

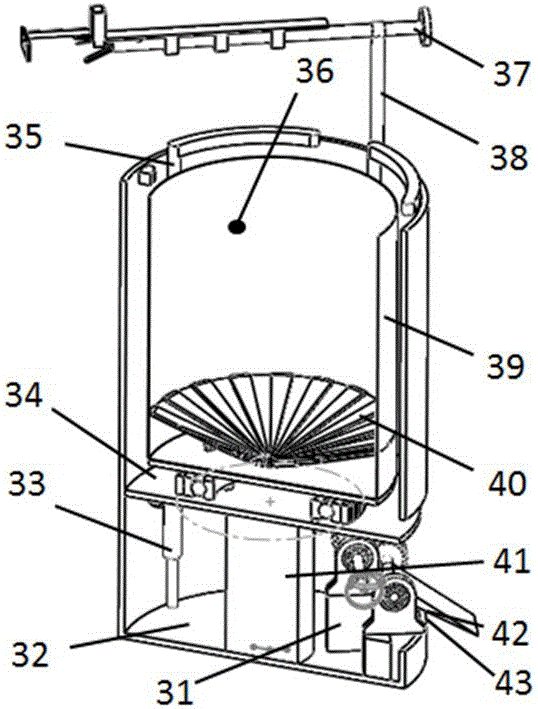

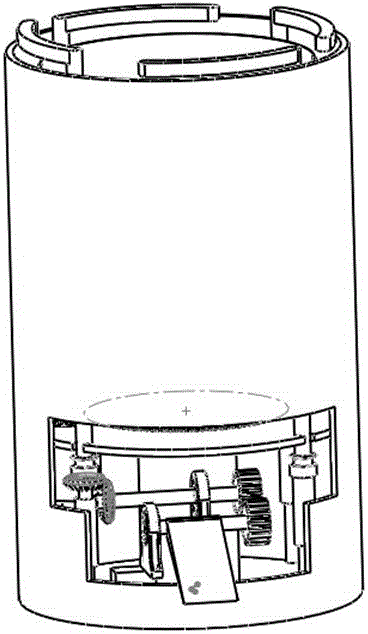

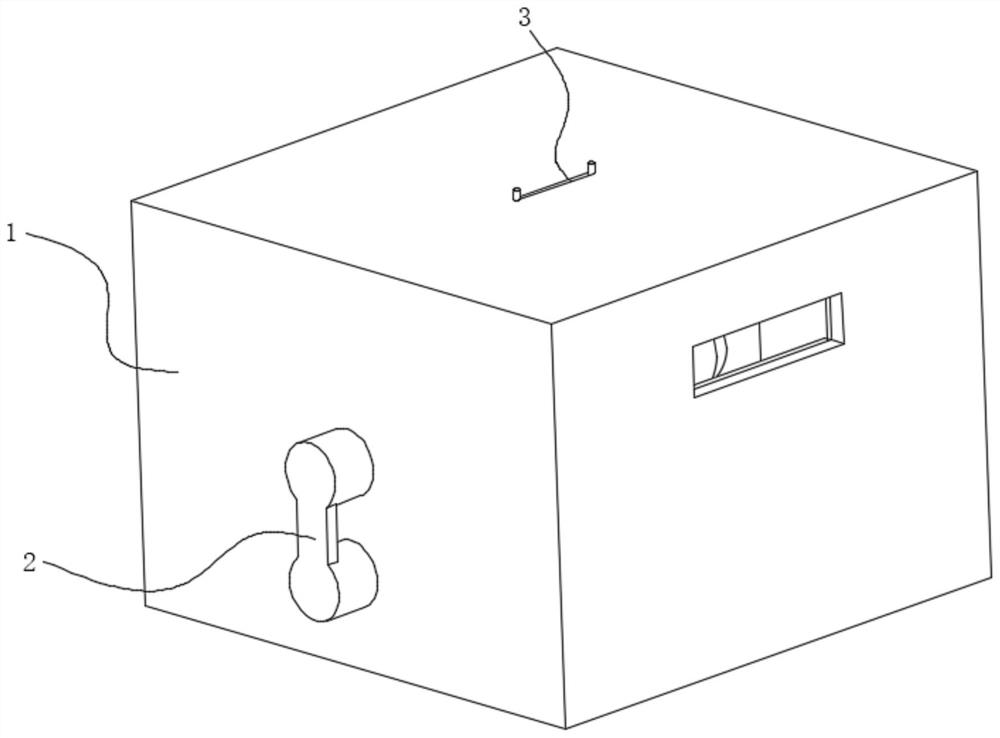

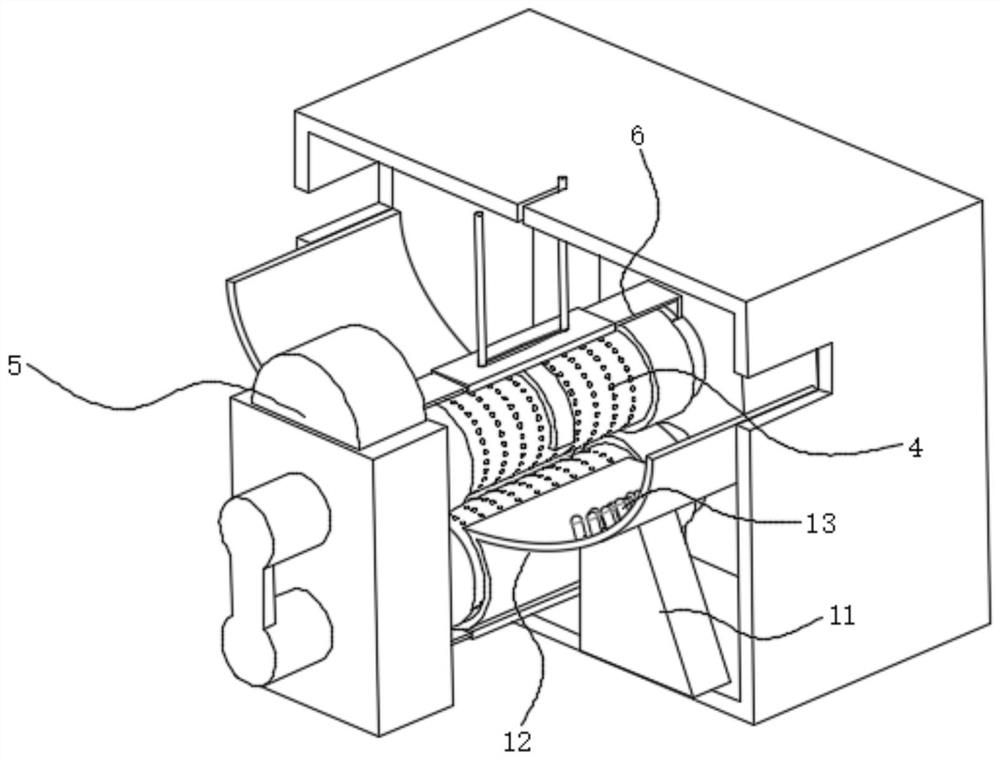

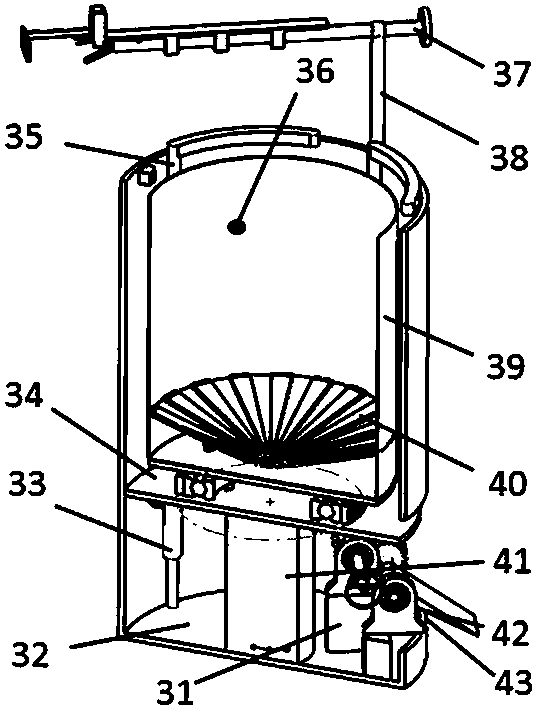

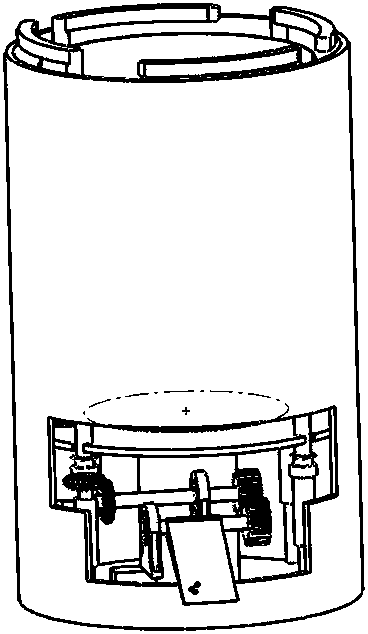

Automatic garage packaging method and automatic garage packaging machine

The invention discloses an automatic garage packaging method and an automatic garage packaging machine. Infrared detection of garbage fullness is performed; a synchronous belt controls rotating rods at barrel opening to rotate synchronously, and a closing action of a garbage bag is completed; a bottom disk rotates, and preliminary packaging of the garbage bag is completed; finally, the garbage bag is automatically sealed by the aid of push rods and a sealing device. The automatic garage packaging machine comprises a packaging unit, a sealing unit, a speed adjustment control unit, an alarm control unit and a cell unit. Practical problems in real life are solved by the aid of simple mechanical structures through the convenient control manner, and the automatic garage packaging machine is particularly applicable to solving of the problem of recovery of medical garbage, industrial garbage, biological garbage and the like which cannot be touched by people and has the characteristics of convenience in maintenance, light as a whole, simplicity in use and wide in market range.

Owner:ZHEJIANG UNIV

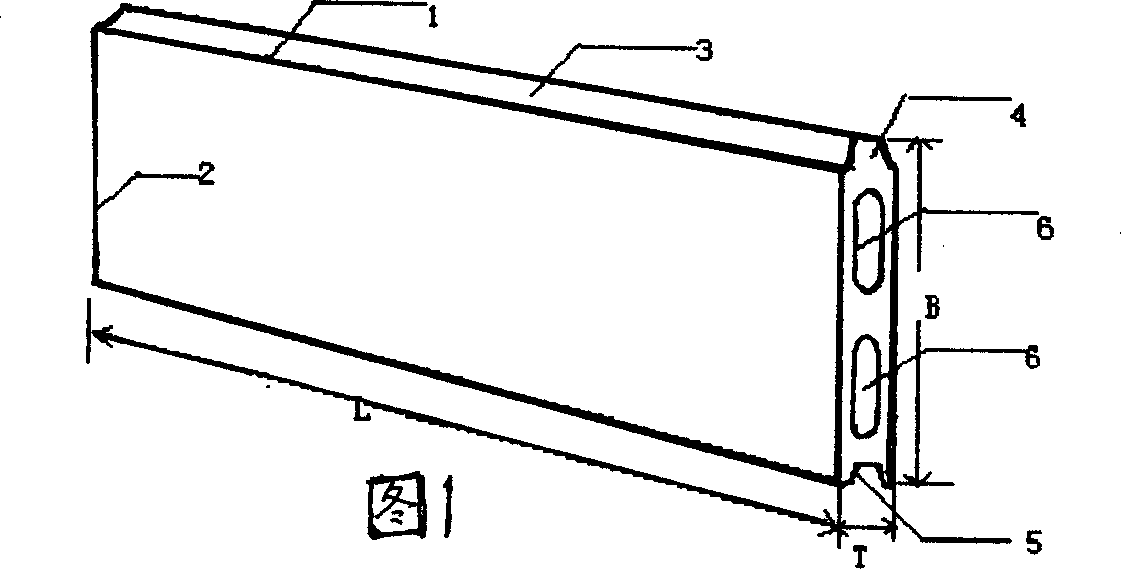

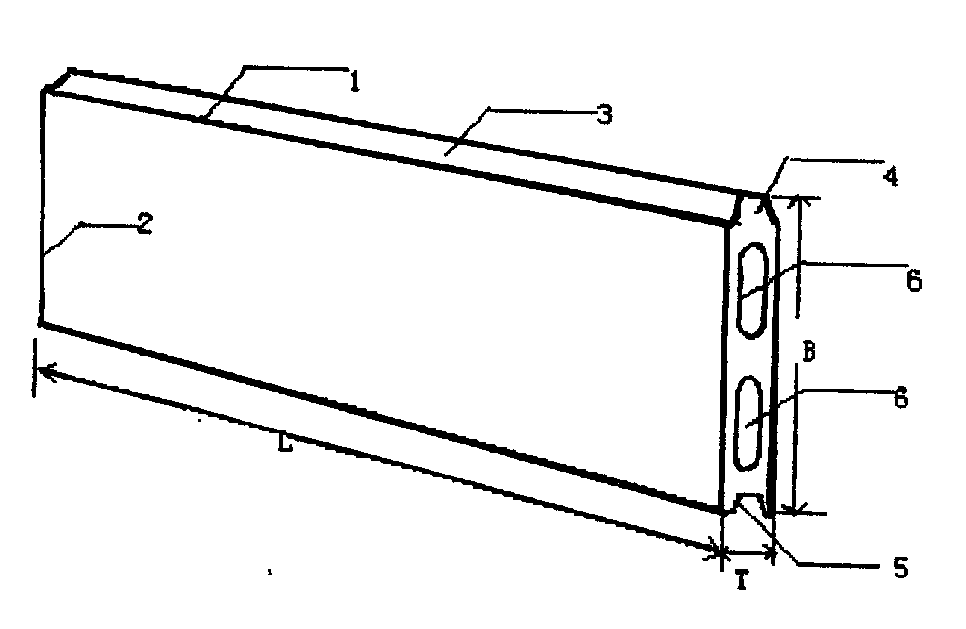

Heat-insulating light sandwich wall board

InactiveCN1362563ADoes not affect strengthLight weightSolid waste managementLayered productsWhitening AgentsPolystyrene

The sandwich heat-insulating light wall panel is made up by using crop straw and stalk as main raw material, matching with light ore powder, gelling agent and other components and sandwiching polystyrene foam plate and utilizing special-purpose equipment through one-step process. Its composition comprises straw and stalk powder 48-50%, light ore powder 35-42%, flyash 4-8%, halide powder 10-12%, glass fibre 1-2%, gelling agent 0.2-1%, fiore-resisting agent 0.5-0.8%, whitening agent 0.05-0.1% and solidifying agent 0.01-0.09%, and its internal core is polystyrene foam plate, its thickness is 30-100 mm.

Owner:范广俭

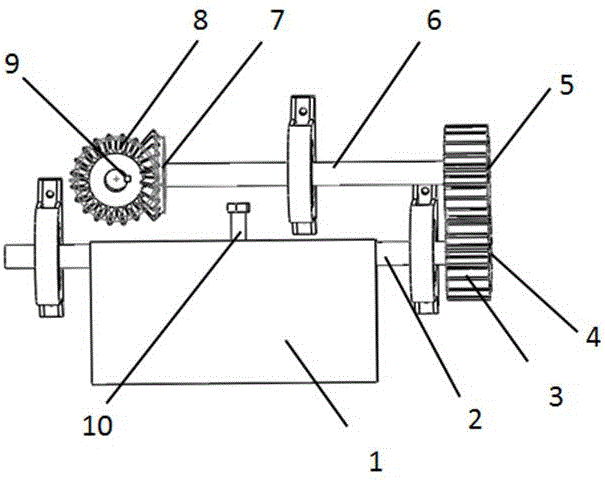

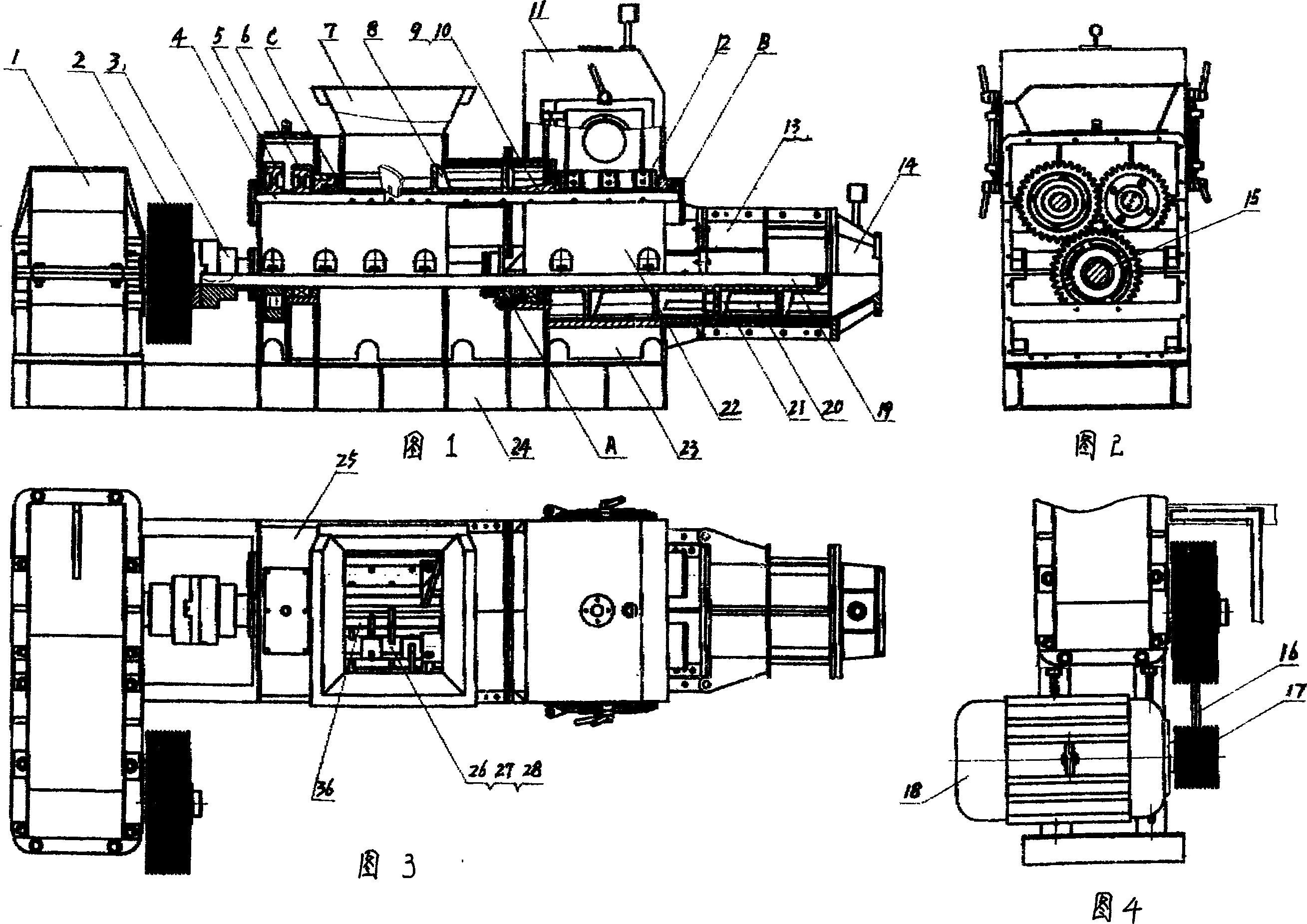

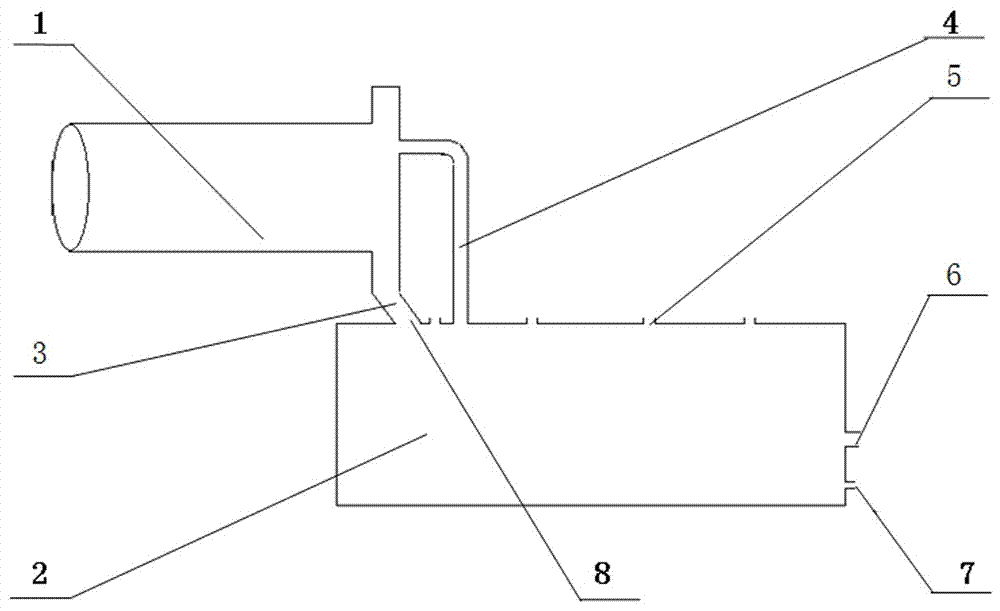

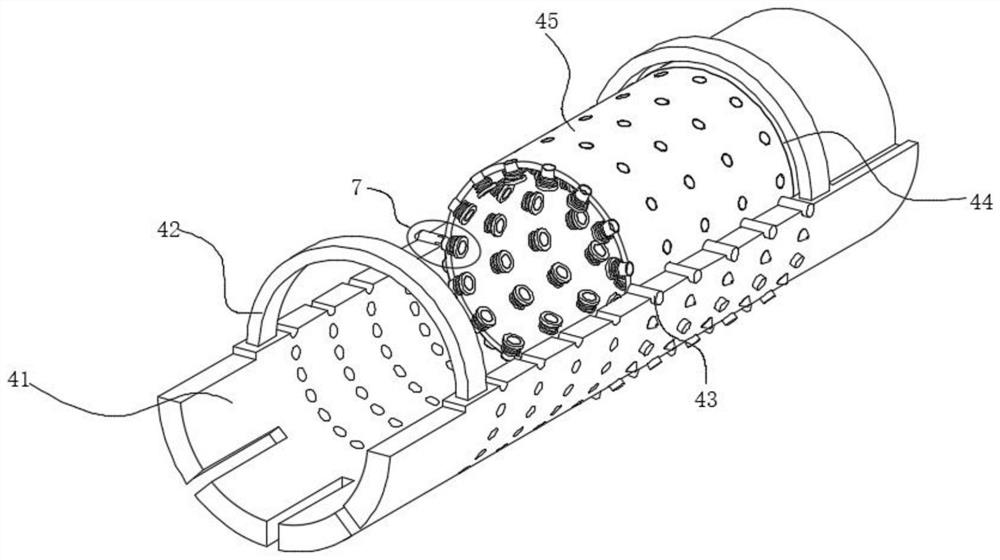

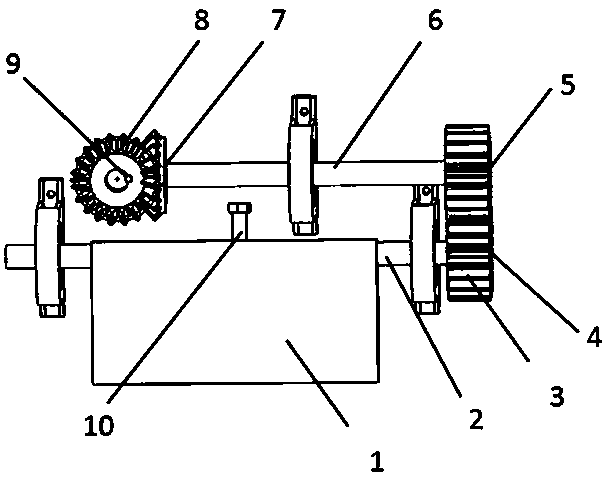

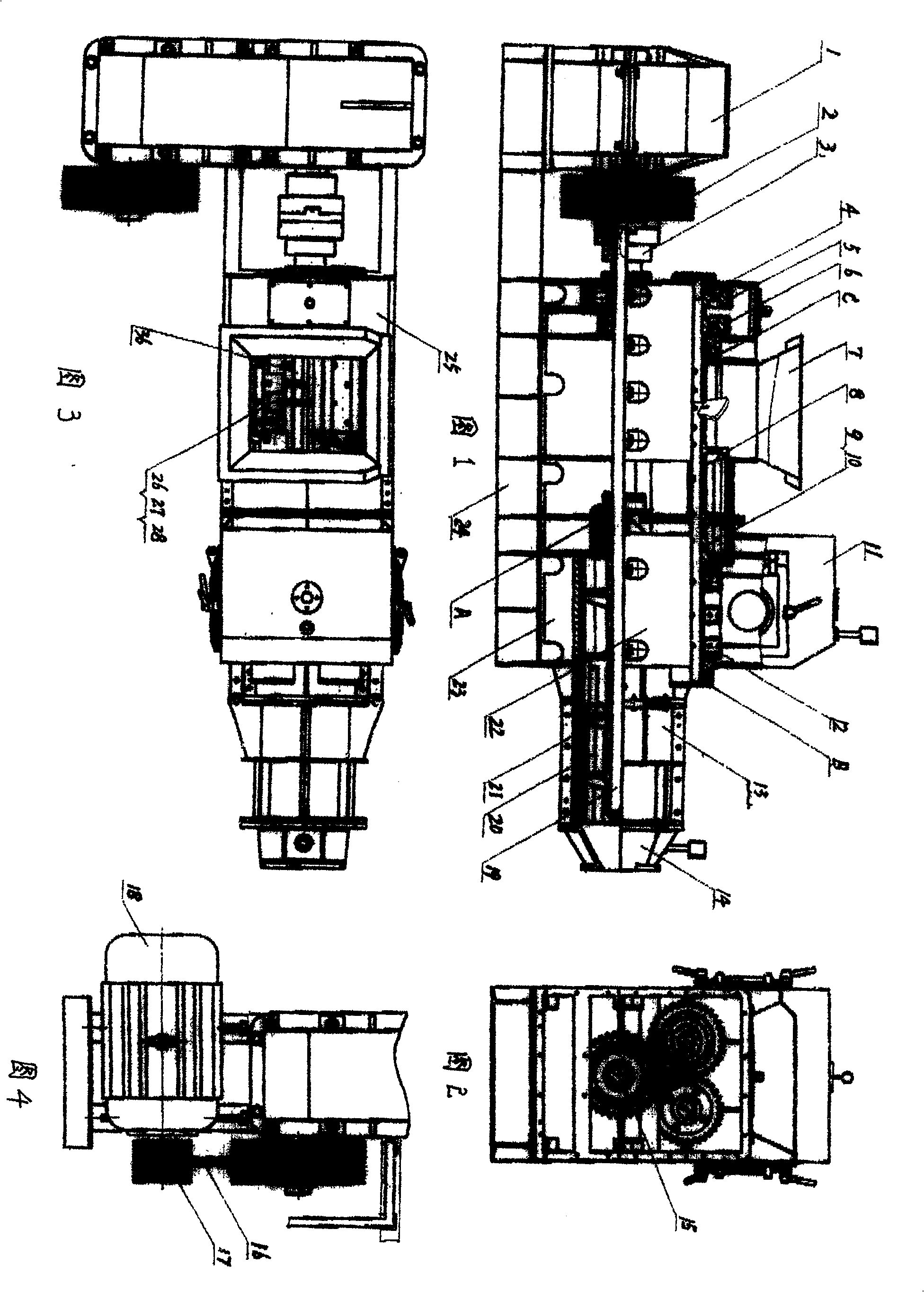

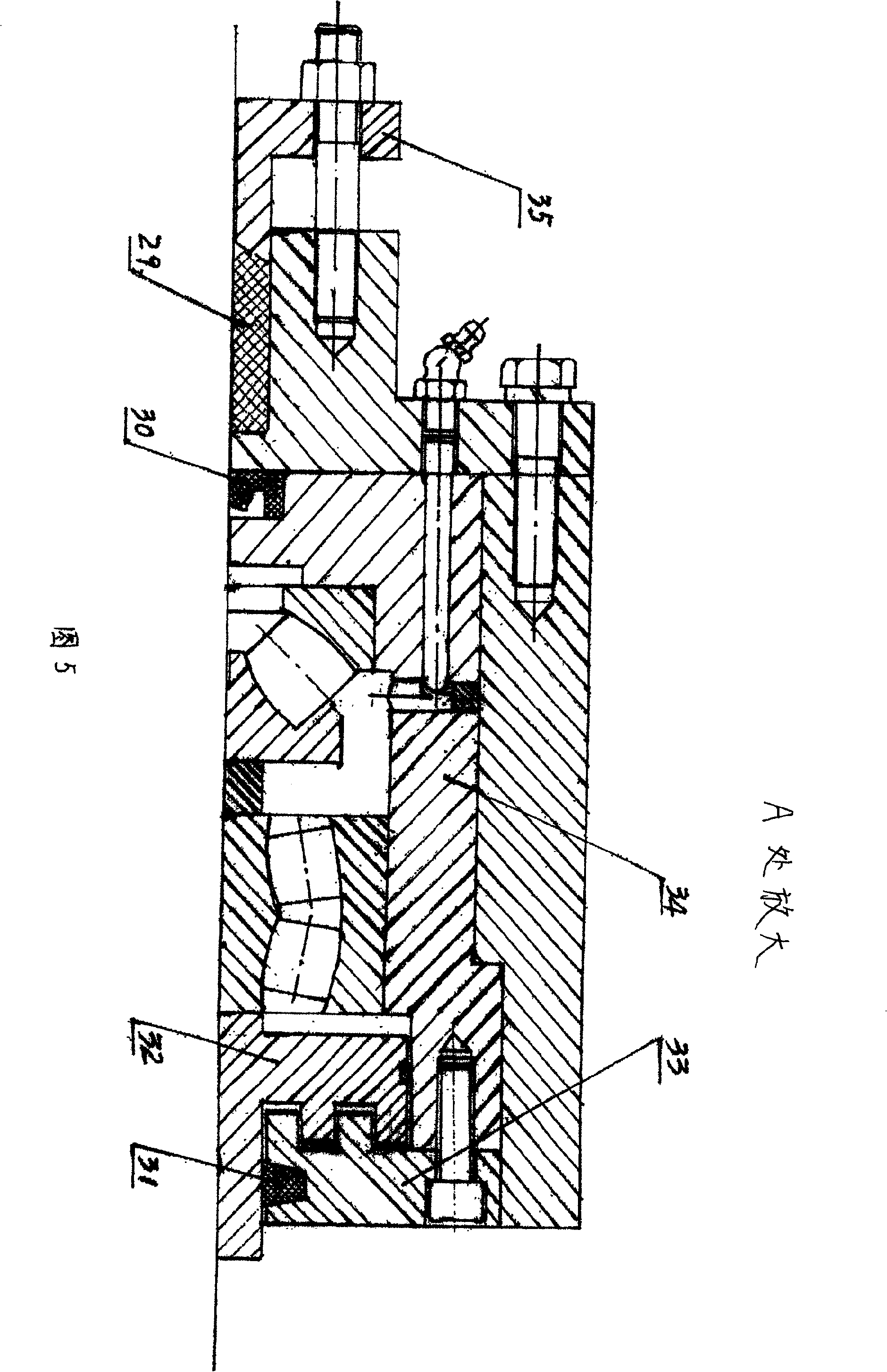

Energy-saving compact type vacuum extrusion machine

InactiveCN1951655AReduce non-functional spaceReduce manufacturing costCeramic shaping apparatusCouplingTransmission belt

The invention relates to an energy-saving compact vacuum extruder, which comprises speed reducer (1), aerated clutch (2), block coupler (3), extruding axle (19), transmission gears (5, 6, 15), mixing axles (4, 26), Haf mixing blade (8), vacuum room (11), compressing plate (12), extruding cylinder (13), head (14), extruding mold (21), upper, middle, and lower boxes (22, 23, 25), machine base (24), and material hopper (7). The invention is characterized in that: the output axle wheel (17) of power machine (18) via transmission belt (16) drives the aerated clutch belt wheel (2) at the input of speed reducer (1); the output of speed reducer via block coupler (3) rotates the extruding axle (19); the active gear (15) at the back extruding axle makes the inactive gear (5) to rotate the active mixing axle (4), and makes the gear (6) axial with active gear (15) to rotate the inactive mixing axle (26). The invention can reduce mechanical friction and save enegy.

Owner:程玉全

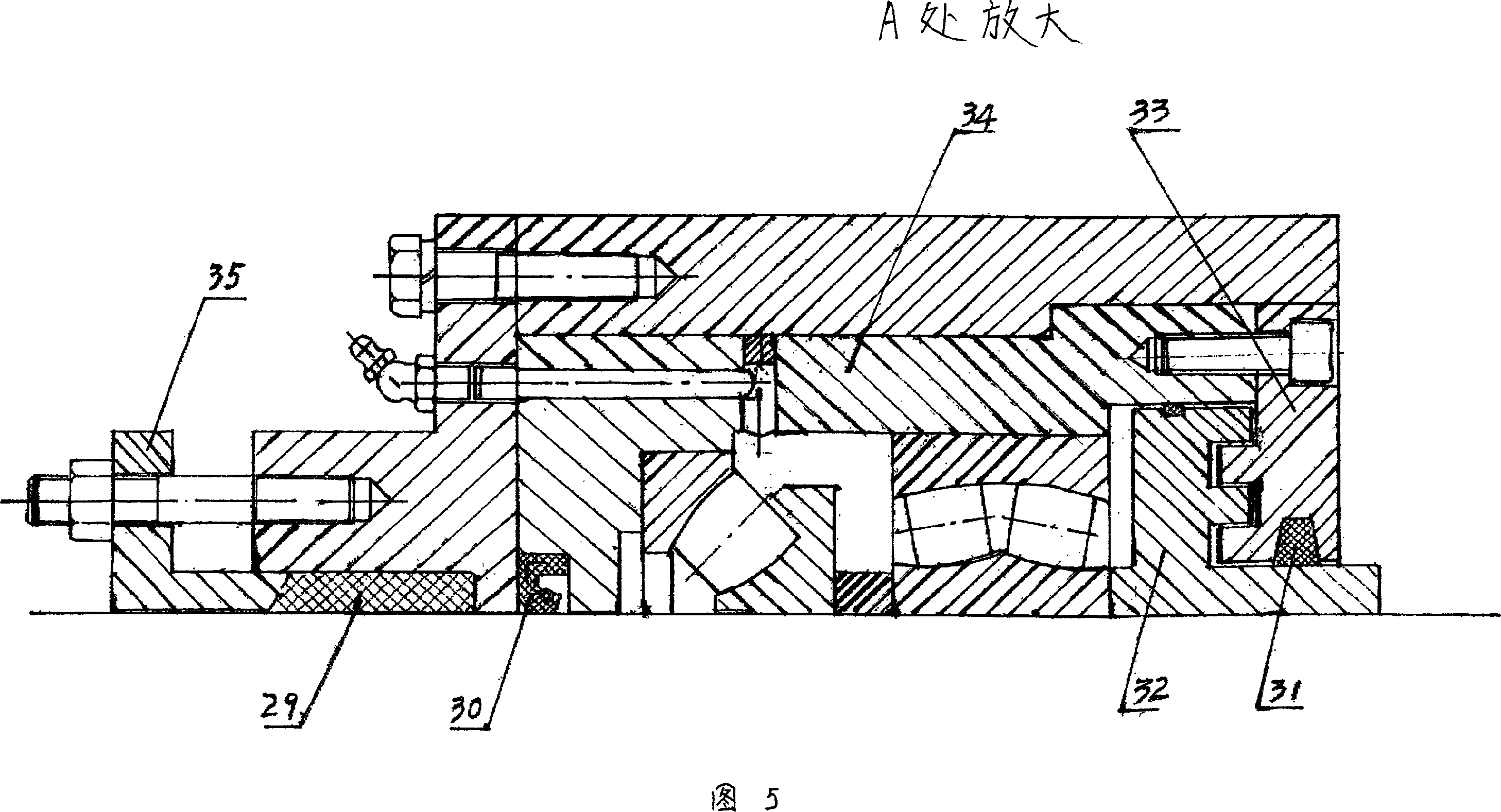

Method and device for producing ferronickel through nickel-laterite ore direct reduction and top-blown smelting method

The invention belongs to the field of nickel metallurgy and particularly relates to a method for producing ferronickel through a nickel-laterite ore rotary kiln direct reduction and flue gas top-blown smelting method and a smelting device adopting the same. The method comprises the following steps of (1) drying treatment of nickel-laterite ores; (2) crushing and screening; (3) ingredient mixing; (4) reduction roasting; and (5) flue gas top-blown smelting. By means of the method, the problems of high energy consumption, serious environmental pollution, poor material adaptability and the like in the process of treating nickel-laterite ores through an existing pyrogenic process are solved.

Owner:SHENYANG RES INST OF NONFERROUS METALS

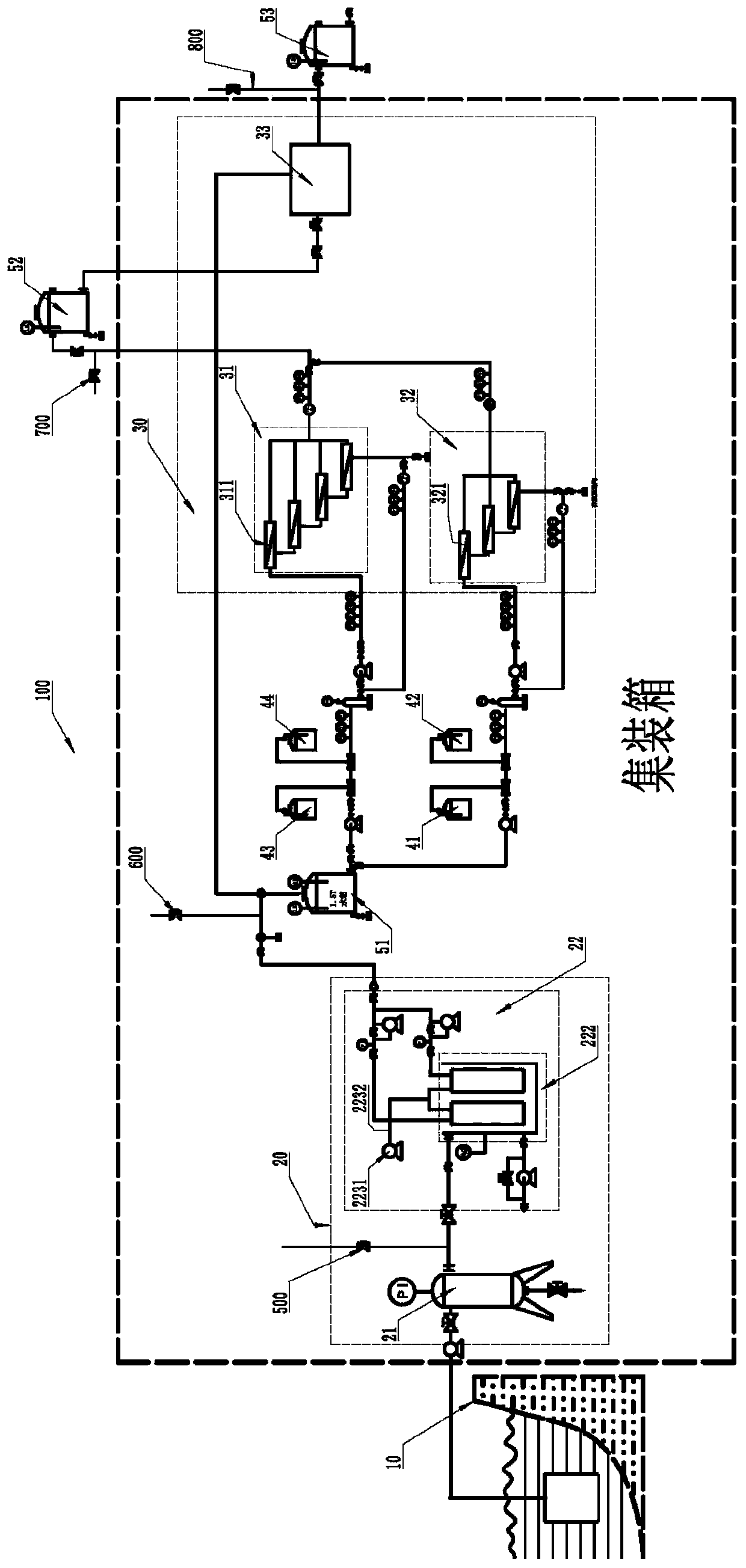

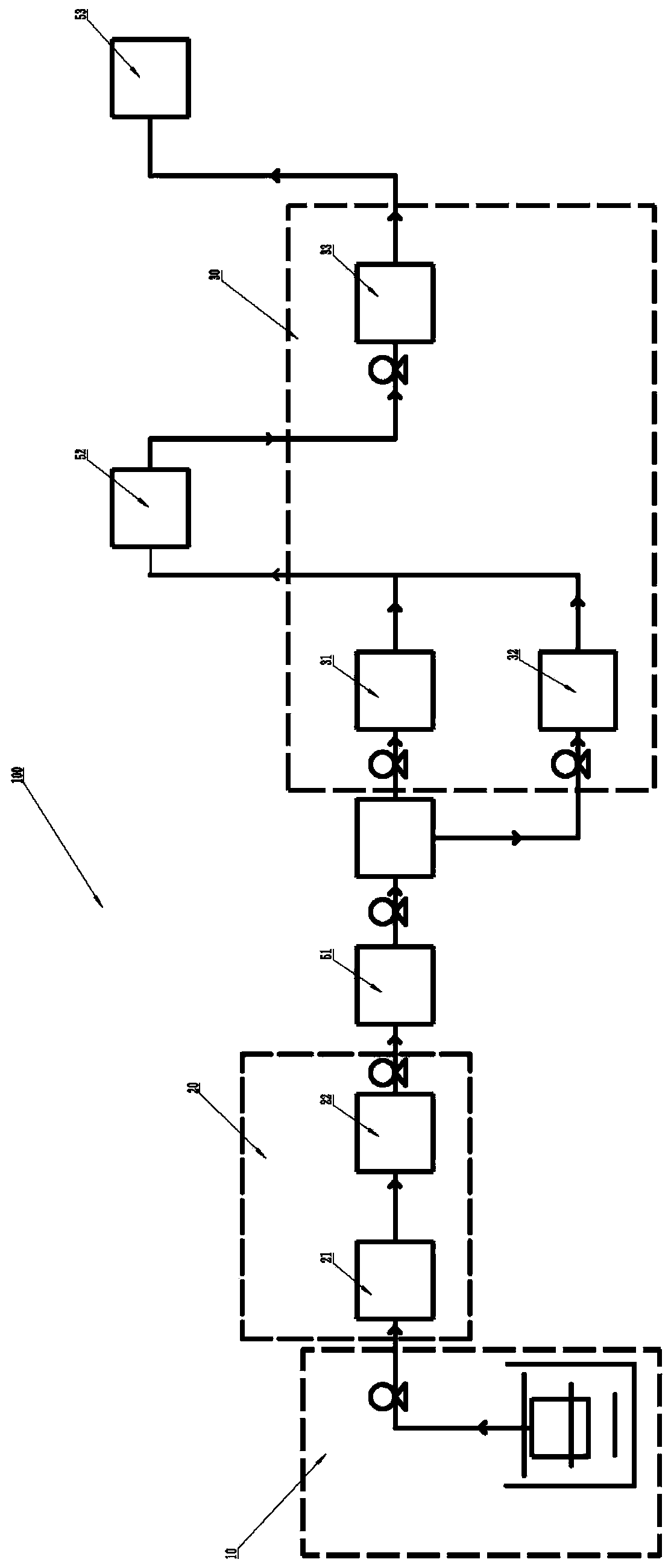

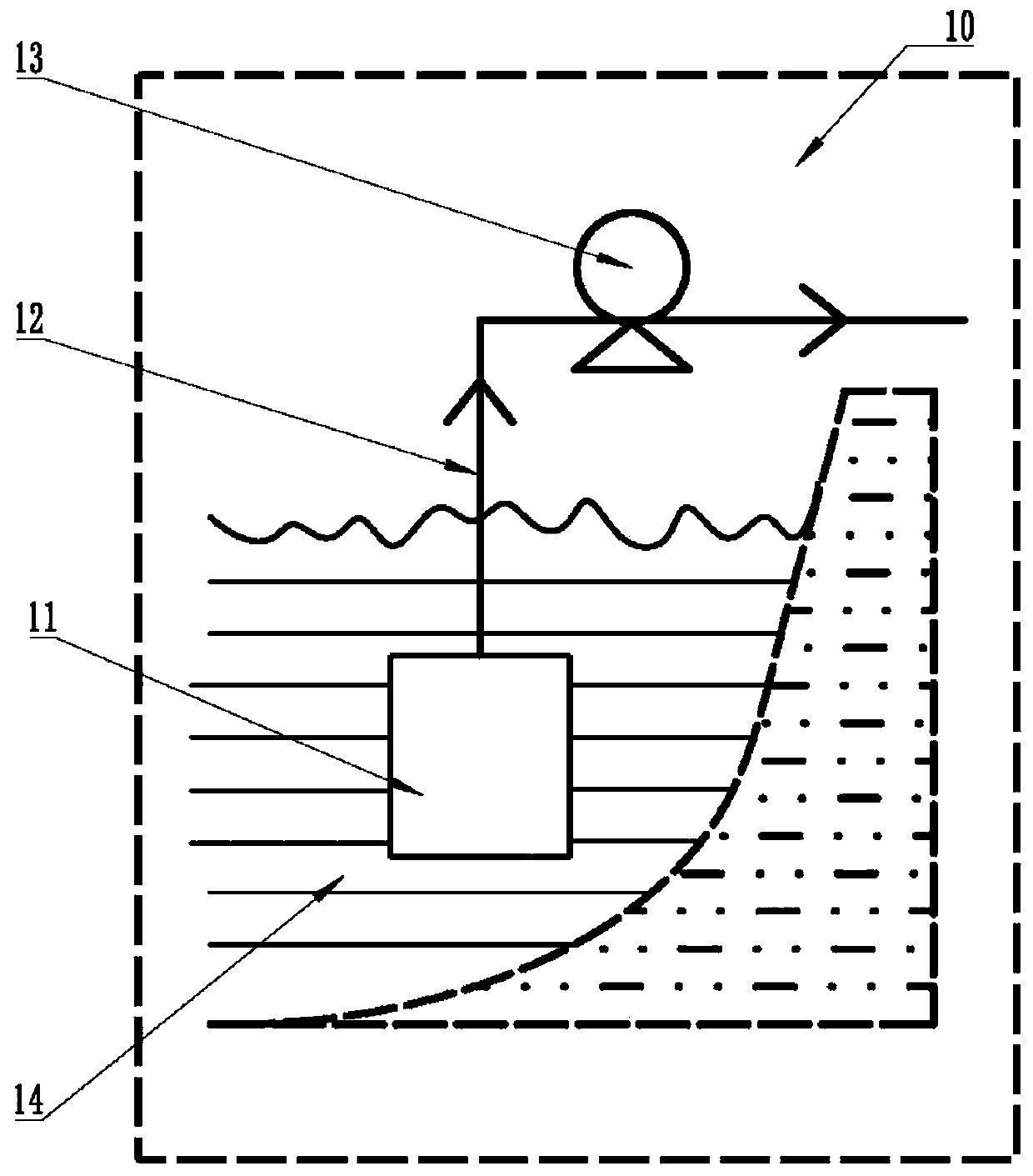

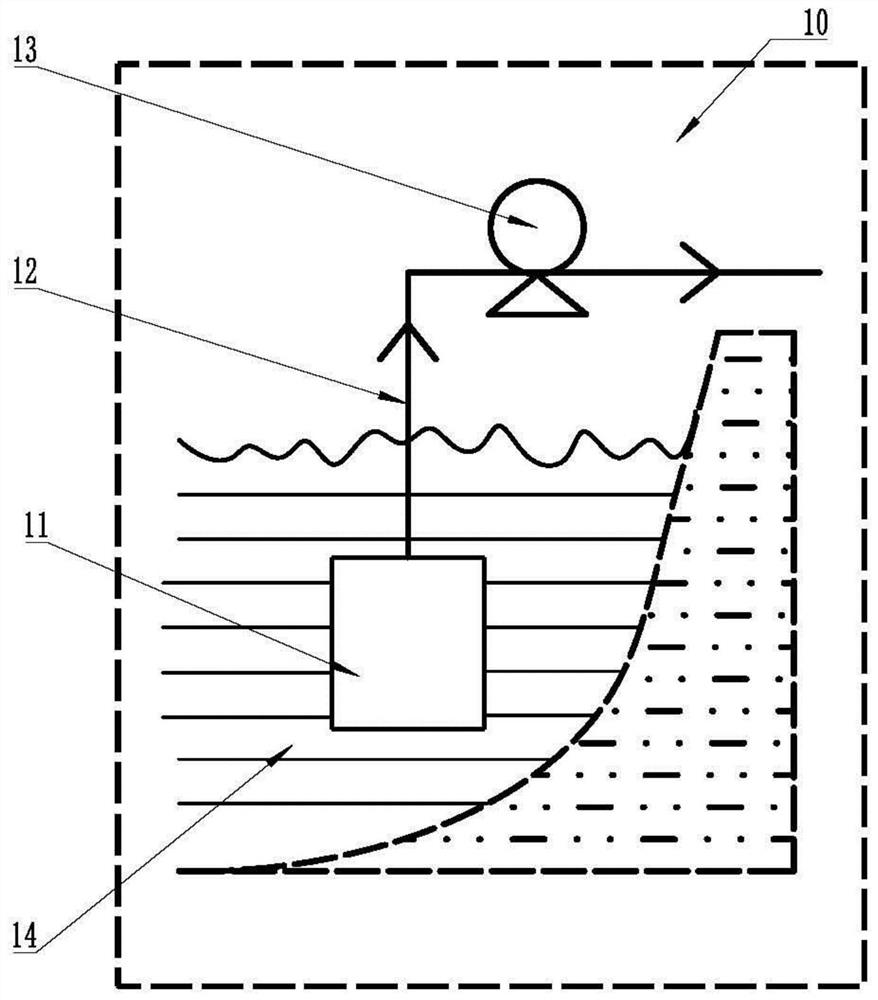

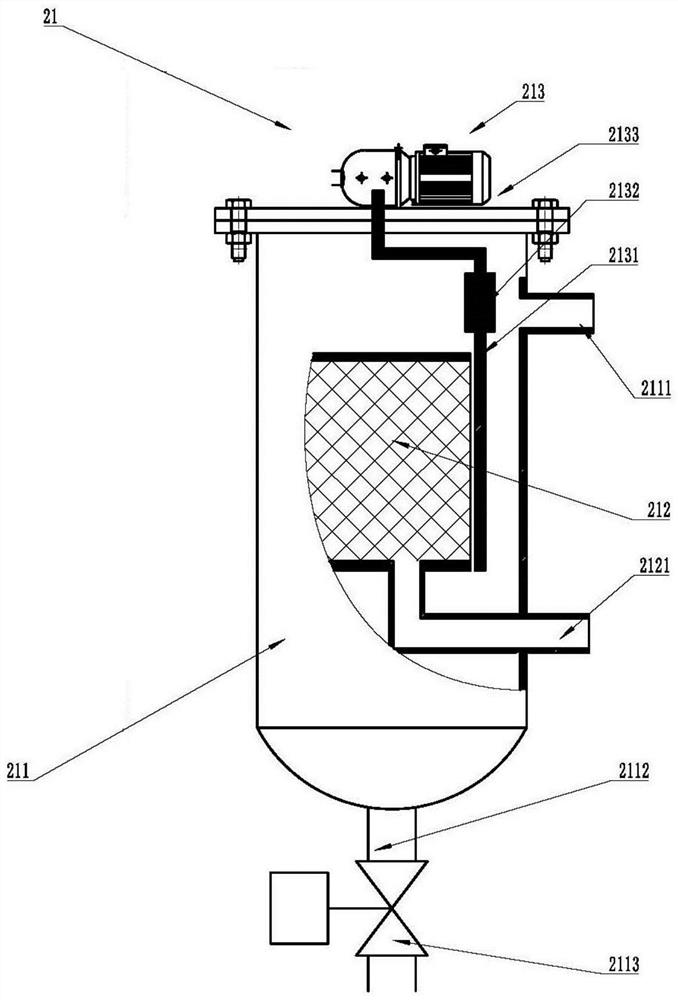

Equipment for preparing fresh water with various water qualities

PendingCN111453871AWide marketReduce the burden of purchasingWater treatment parameter controlGeneral water supply conservationWater sourceBrackish water

The invention provides equipment for preparing fresh water with various water qualities, which is characterized by comprising a raw water collection device for collecting raw water from a water source, wherein the raw water is selected from seawater or brackish water or fresh water, a raw water pre-treatment device which comprises a filter screen filtering part used for filtering raw water to intercept suspended solids with the particle size larger than or equal to 30-80 microns, a membrane filtering part used for further filtering water to intercept suspended solids with the particle size larger than or equal to 0.1 micron to obtain C-grade water, a reverse osmosis treatment device which comprises a first reverse osmosis unit used for carrying out reverse osmosis treatment on C-grade water with seawater as raw water so as to obtain water with the ion concentration of 200-500ppm, a second reverse osmosis unit used for carrying out reverse osmosis treatment on C-level water with brackish water or fresh water as raw water to obtain water with the ion concentration smaller than or equal to 200 ppm, and a third reverse osmosis unit used for carrying out secondary reverse osmosis treatment on the water to obtain water with the ion concentration smaller than or equal to 10 ppm.

Owner:舟山梅朋水处理有限公司 +1

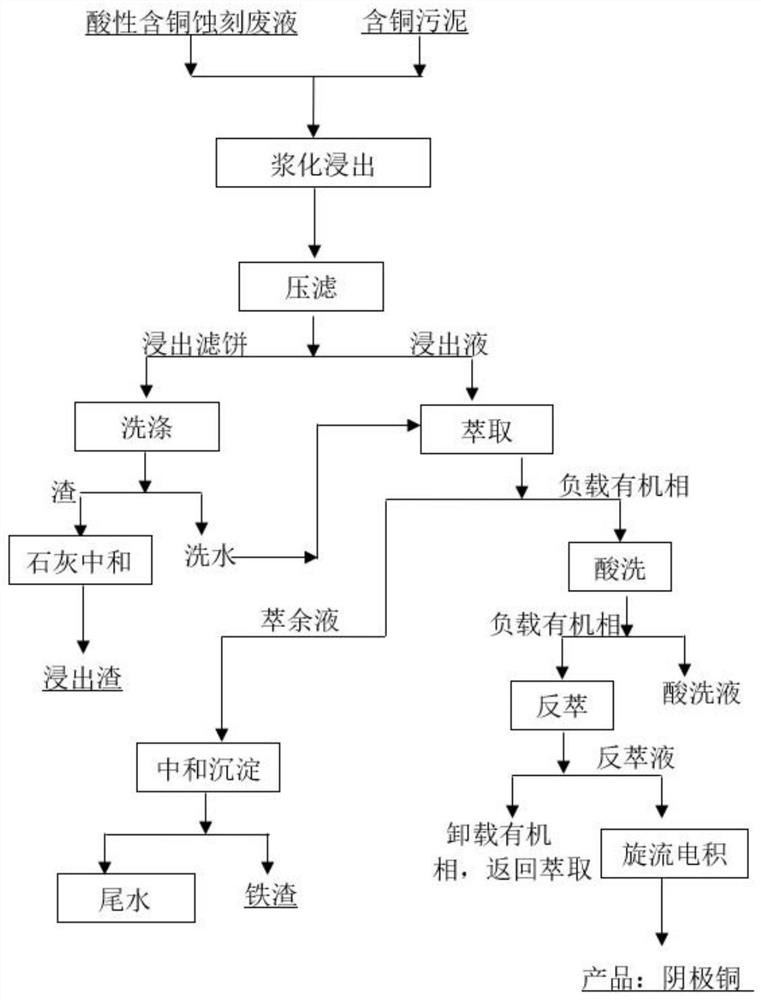

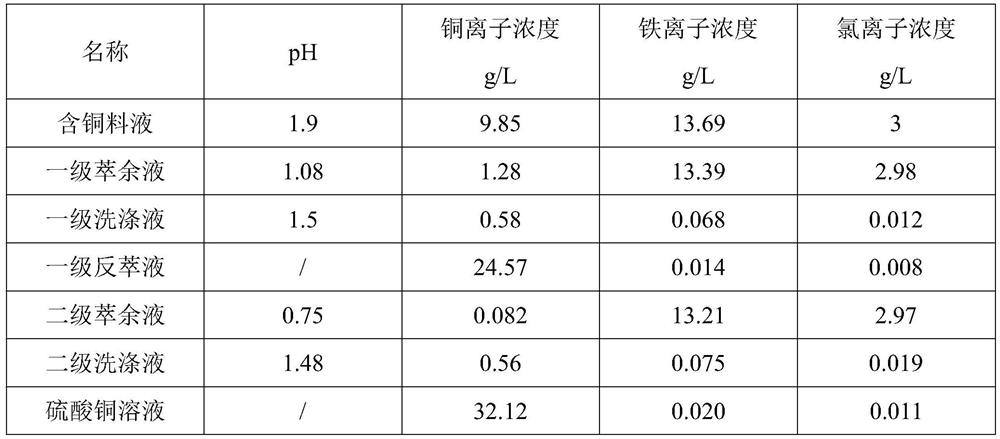

Combined treatment method of copper-containing sludge and copper-containing etching waste liquid

PendingCN112941562AReduce acid and alkali consumptionReduce manufacturing costPhotography auxillary processesProcess efficiency improvementSludgeIon transfer

The invention discloses a combined treatment method of copper-containing sludge and copper-containing etching waste liquid. The combined treatment method comprises the following steps that the acidic copper-containing etching waste liquid and the copper-containing sludge are pulped together, the solid-to-liquid ratio is adjusted by using water, the pH value of the slurry is adjusted to be acidic by using concentrated sulfuric acid, reacting is carried out, and filtering is carried out to obtain copper-containing feed liquid and leaching residues; washing and neutralizing are carried out on the leaching residues, and tailings are obtained; and copper extraction, organic phase washing and copper reverse extraction are sequentially carried out on the copper-containing feed liquid, copper electrodeposition is carried out on a solution obtained through copper reverse extraction, and cathode copper is obtained. According to the method, acid-base neutralization reaction is utilized, so that the acid-base consumption is greatly reduced, and the production cost is reduced; the copper content of the final leaching residues is lower than 0.05%, and the final leaching residues can be used as common solid waste; after the copper extraction process, loaded organic phase washing is carried out, in the process of washing with water, a large number of chloride ions and iron ions are carried out in washing liquid, and therefore the chloride ions and the iron ions transferred into strip liquor are remarkably reduced, the copper electrodeposition efficiency is improved, and the purity of a cathode copper product is increased.

Owner:HUNAN AIGE ENVIRONMENTAL PROTECTION TECH CO LTD

Oily and crisp passion fruit powder and preparation method thereof

The pastry passion fruit powder and the preparation method of the present invention relate to the preparation method of passion fruit and passion fruit condiment. A preparation method of pastry passion fruit powder is characterized in that the preparation process is as follows: fresh passion fruit washing→draining→crushing into granules→quick freezing→vacuum frying to dry→cooling→powdering→powder sieving→packing. In the frying and drying process, edible salad oil is used, the oil temperature is controlled at 60°C-150°C, and the frying time is based on frying and drying the crushed passion fruit grains; in the quick freezing process , the temperature of the quick-freezing box is -23°C to -27°C, and the quick-freezing time is 15-48 hours; the mesh number of the sieve in the powder sieving process is 10-20 mesh. The pastry passion fruit powder of the present invention has crisp and crisp mouthfeel, unique seasoning, long shelf-life, convenient use, and wide product market; the preparation method of the pastry passion fruit powder is advanced and practical, is favorable for industrialized mass production, and has high economic and social benefits and Promote value.

Owner:CHONGQING PINYOU AGRI DEV

Fried crisp pumpkin chips and preparation method

InactiveCN105851949AThe preparation method is simple and easyThe preparation method is feasibleFood scienceSocial benefitsPumpkin seed

The invention discloses fried crisp pumpkin chips and a preparation method, and relates to pumpkin leisure food and a preparation method thereof. The preparation method of the fried crisp pumpkin chips is characterized by comprising the preparation processes of pumpkin peel and core removing, pumpkin chipping, quick-boiling in sweet water, leaching, glucose adding, cooling, quick freezing, vacuum frying, cooling and packaging. The fried crisp pumpkin chips are novel leisure food and have the advantages of being crisp, tasty, unique in taste, natural, capable of achieving healthcare, long in quality guarantee period, convenient to transport and wide in product marketing; the preparation method of the fried crisp pumpkin chips is advanced, feasible and beneficial for processing massive pumpkins into the fried crisp pumpkin chips and has the high economic benefit and social benefit and the promotional value.

Owner:CHONGQING PINYOU AGRI DEV

Crispy okra and making method thereof

InactiveCN105851950AFavorable marketingThe preparation method is simple and easyFood scienceSnack foodPassion fruit

The invention relates to okra snack food and a making method thereof, in particular to crispy okra and a making method thereof. The making method of the crispy okra is characterized by comprising the steps of fresh okra pedicel and tip removing, washing, dewatering, blanching, dewatering, glucose adding, spice powder adding, cooling, quick freezing, vacuum frying, cooling and packaging. The spice powder is one or mixed powder of more of orange powder, tea powder, passion fruit powder, cedrela sinensis powder and food-grade dried fruit powder. According to the crispy okra and the making method thereof, the crispy okra is new snack food with okra as a main carrier, product seriation and flavor diversification are achieved, the taste is fragrant and crispy, and the crispy okra is natural food, and is nutritious and healthy, long in expiration date, convenient to transport and wide in product marketing. The making method of the crispy okra is advanced, feasible and beneficial to industrial mass production, and high economic benefits, social benefits and popularization value are achieved.

Owner:CHONGQING PINYOU AGRI DEV

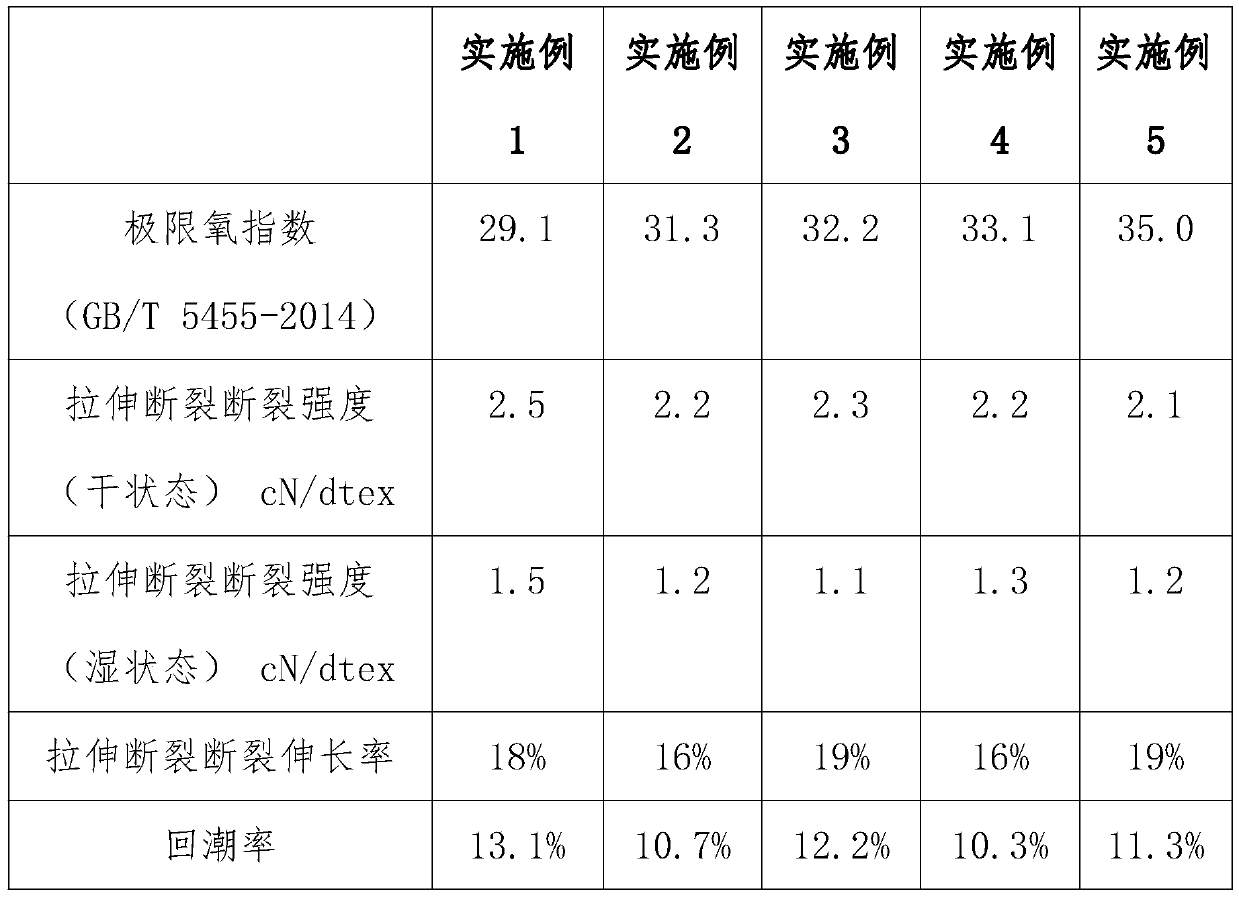

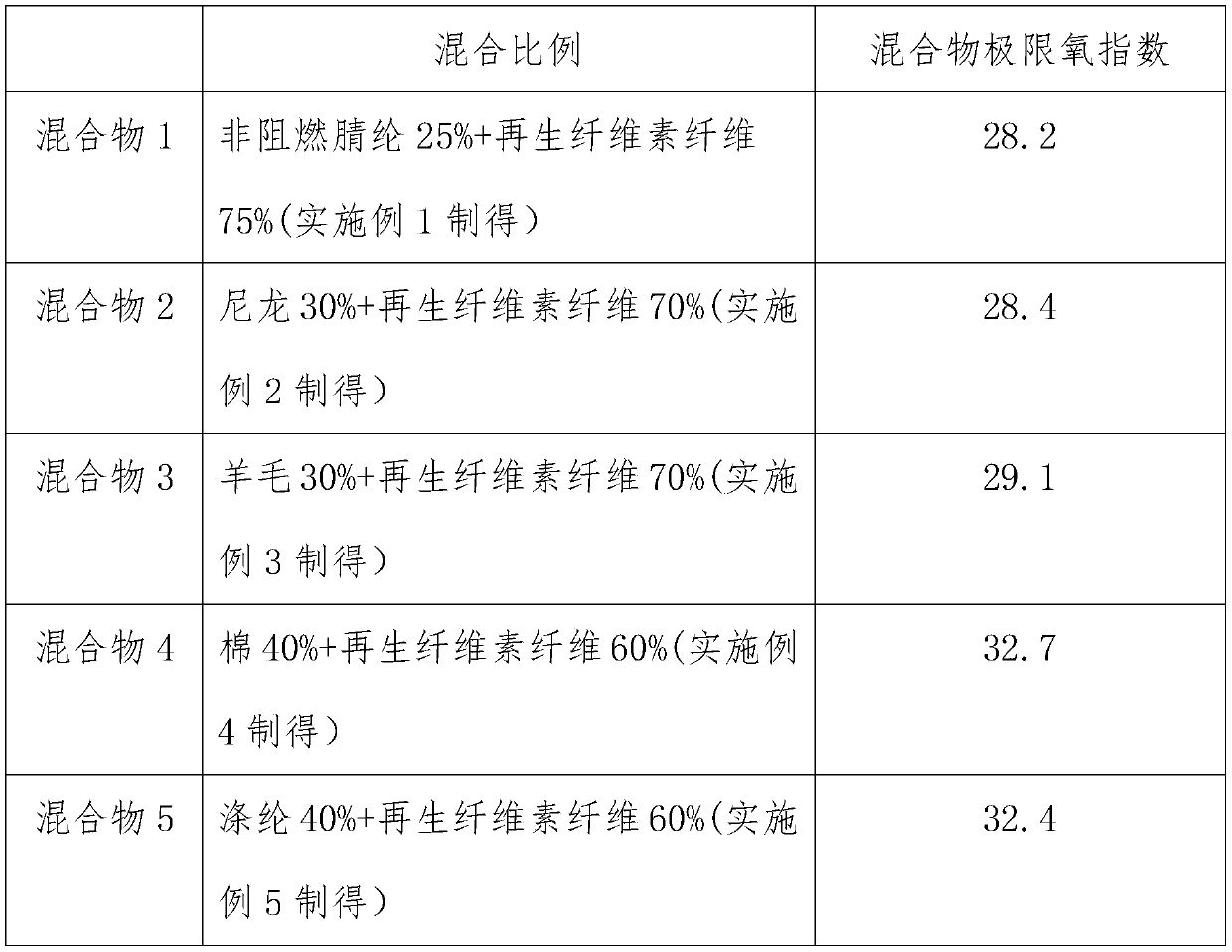

Regenerated cellulose fiber

InactiveCN110067037AFlame retardantImprove flame retardant performanceFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsPolyesterPolyvinyl bromide

The invention discloses a regenerated cellulose fiber which comprises the following components: regenerated cellulose, a component A and a component B, wherein the component A is one or more of polyvinyl chloride, polyvinylidene chloride and polyvinyl bromide; the component B is an oxide of antimony or a mixture of the oxide of antimony and an organic phosphorus burning agent; the mass ratio of dry weight of the regenerated cellulose to the component A is 100:(10-80); and the mass ratio of the component A to the component B is 100:(2-70). The invention also describes a method for producing theregenerated cellulose fiber. The regenerated cellulose with the flame retardancy prepared in the invention can be mixed with non-flame retardant cotton, viscose and other cellulose fibers, animal fibers or non-flame retardant polyester fibers, acrylic fibers, nylon and other synthetic fibers at a certain ratio, and a mixture, prepared from other fibers which are not subjected to any flame retardant treatment, has certain flame retardant properties; raw materials of the regenerated cellulose fiber are wide in sources and low in price, and the production cost can be greatly reduced.

Owner:中科国联劳动防护技术研究院(北京)有限公司

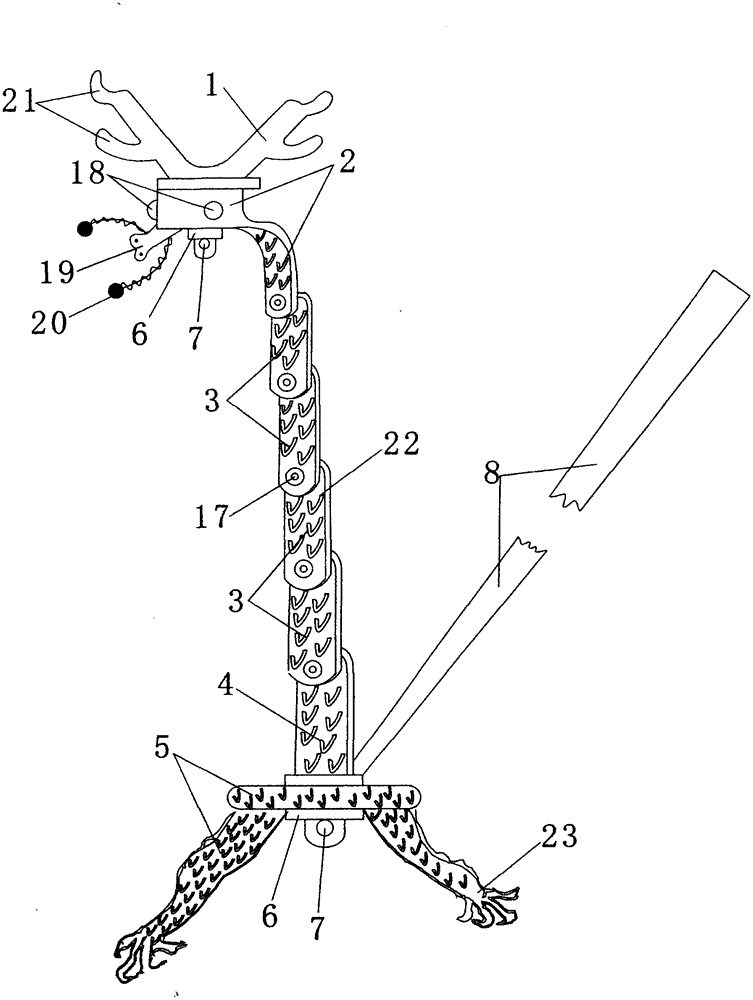

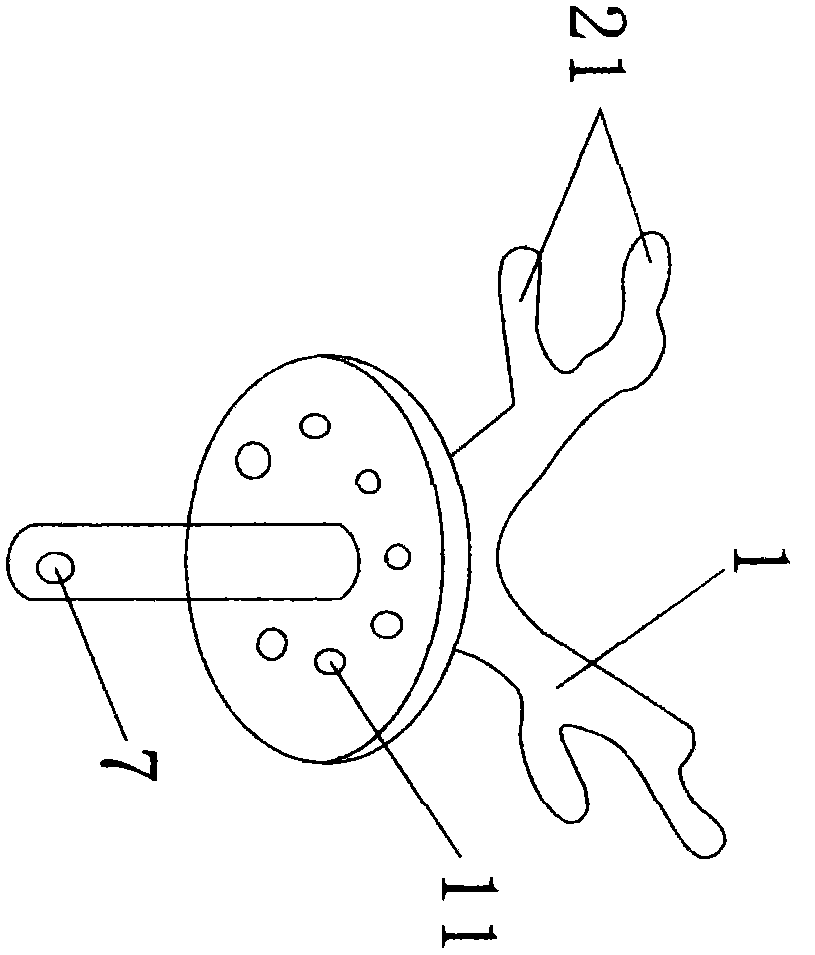

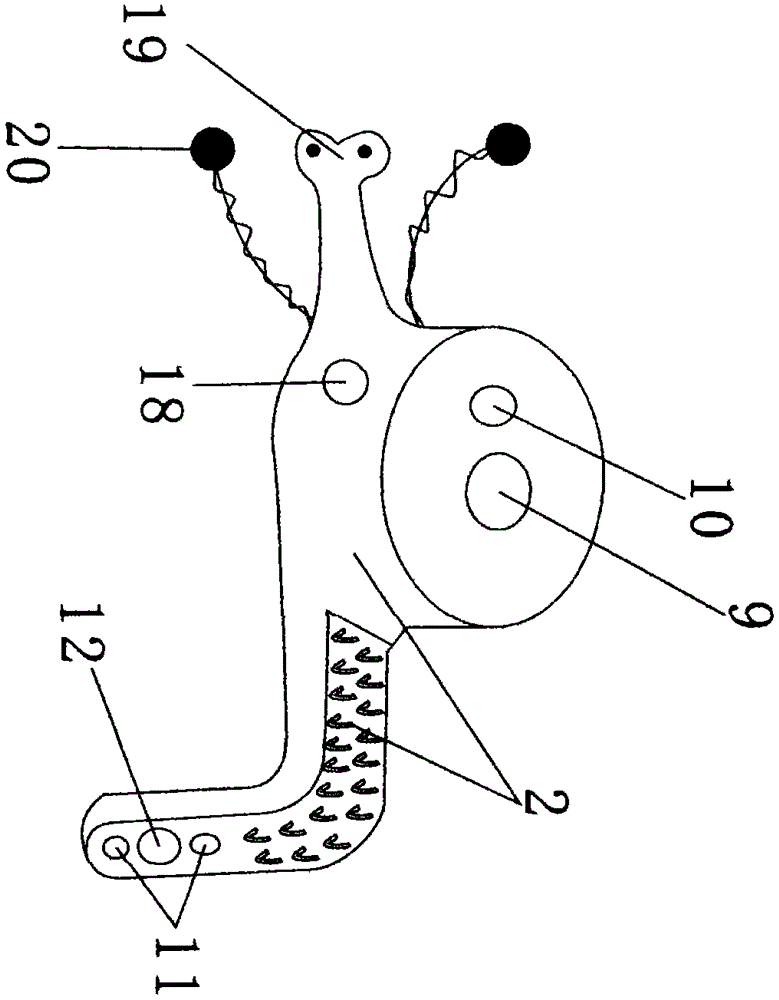

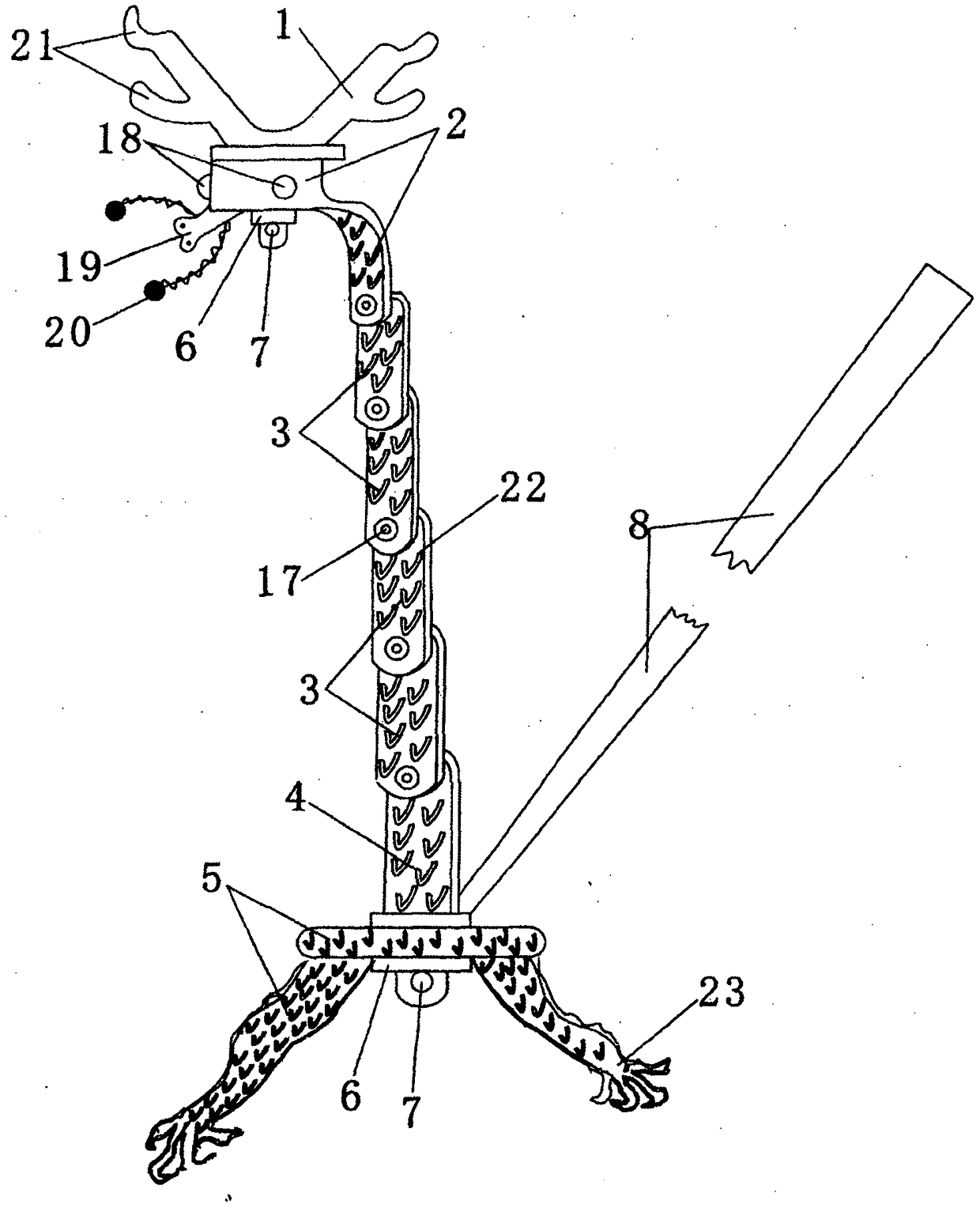

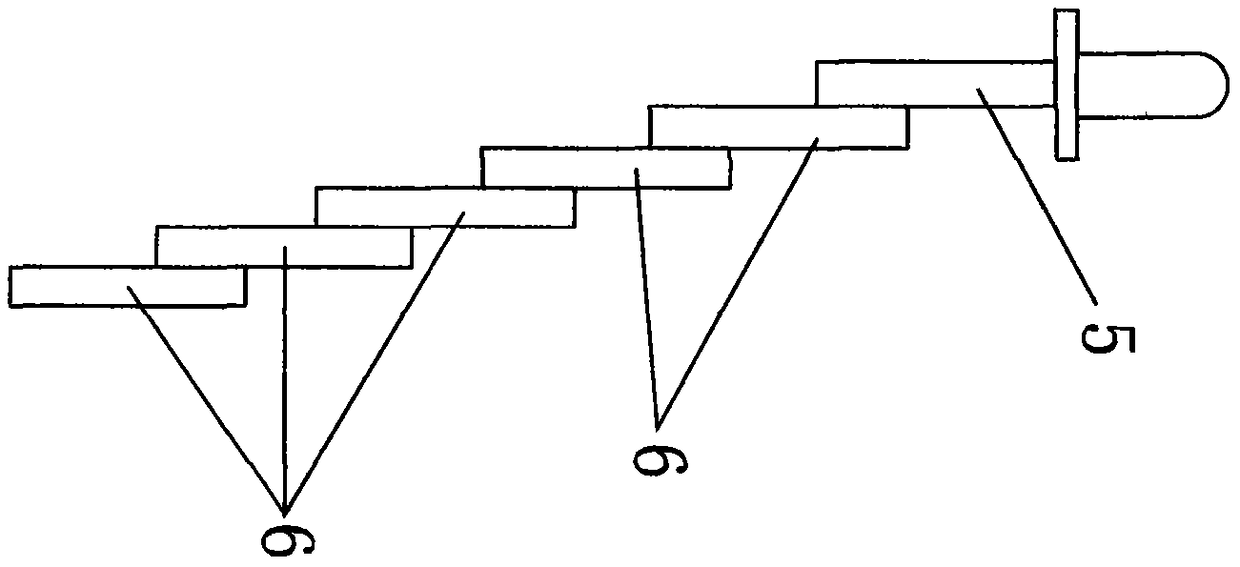

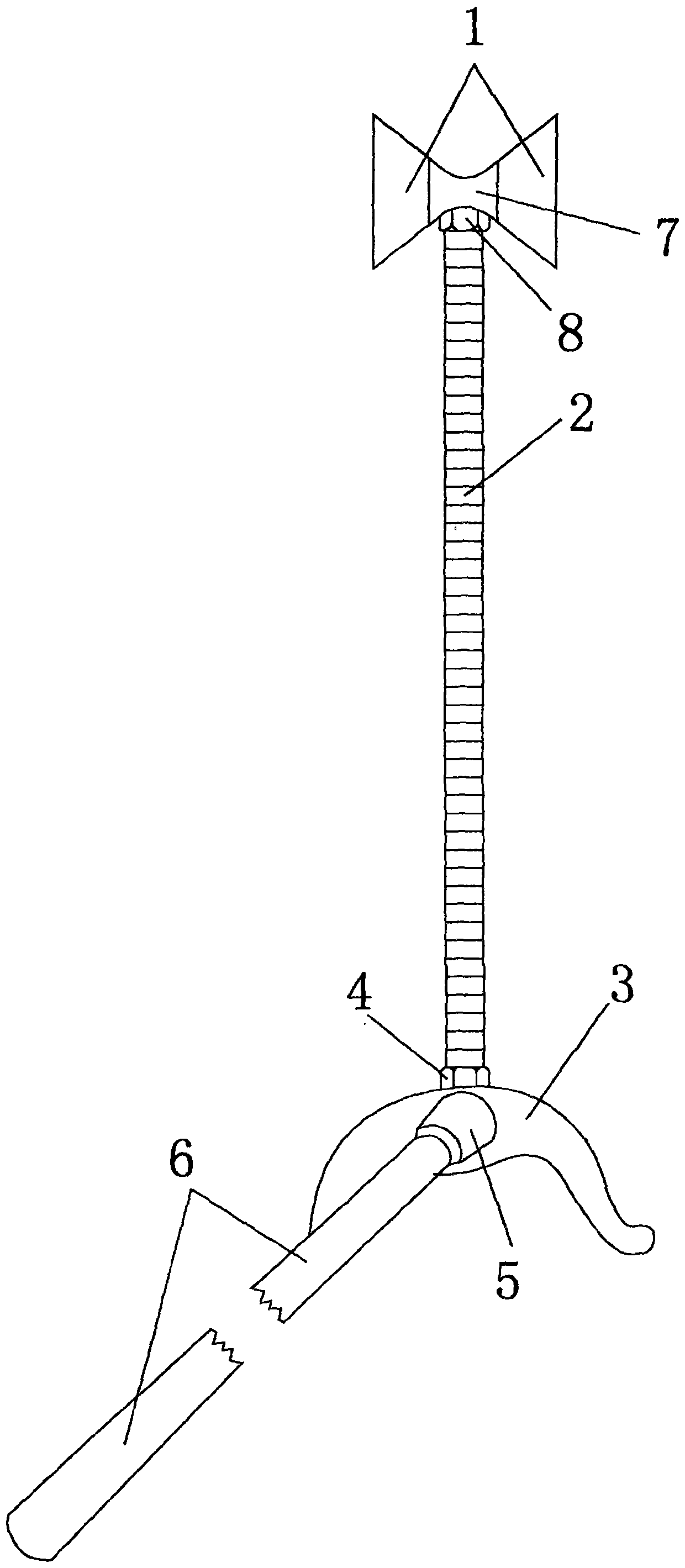

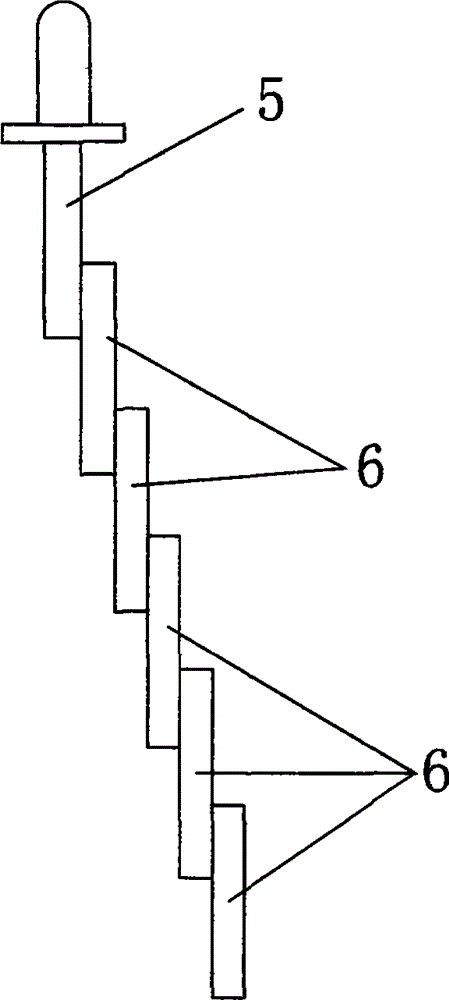

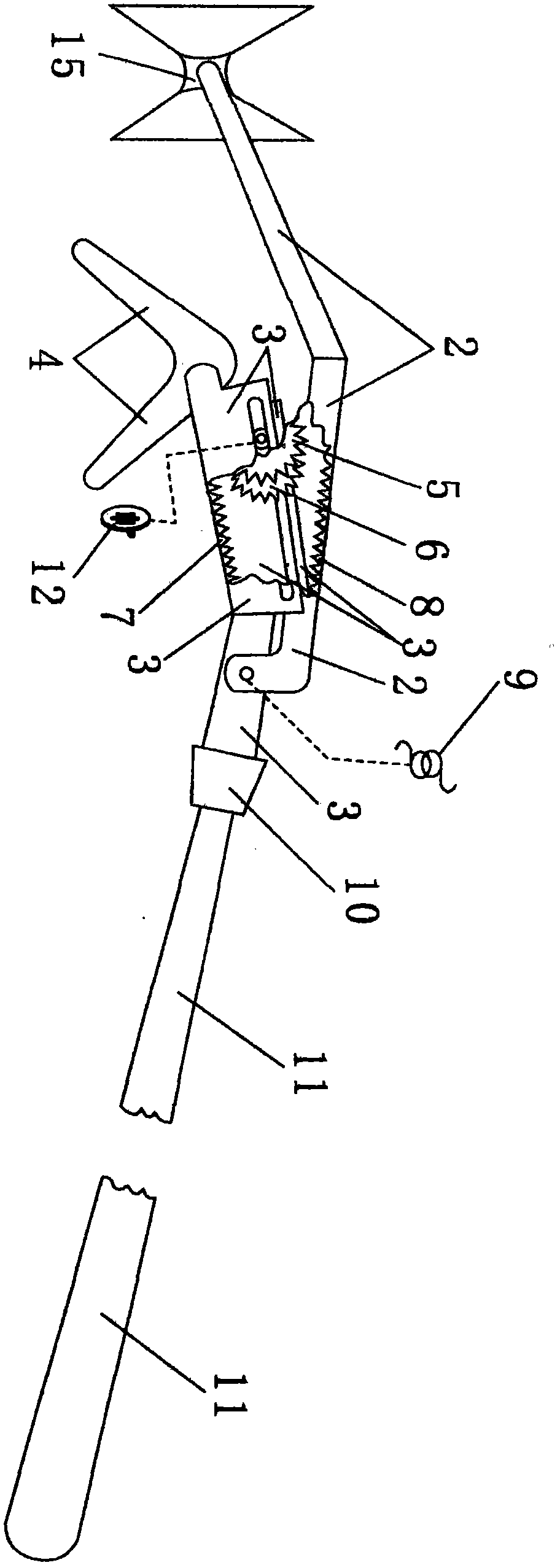

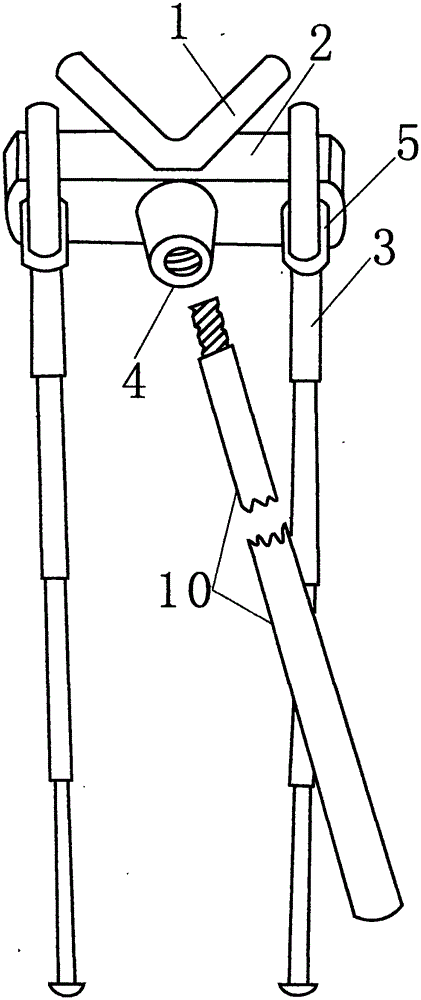

Multistage upper fork height-adjustable billiard rest

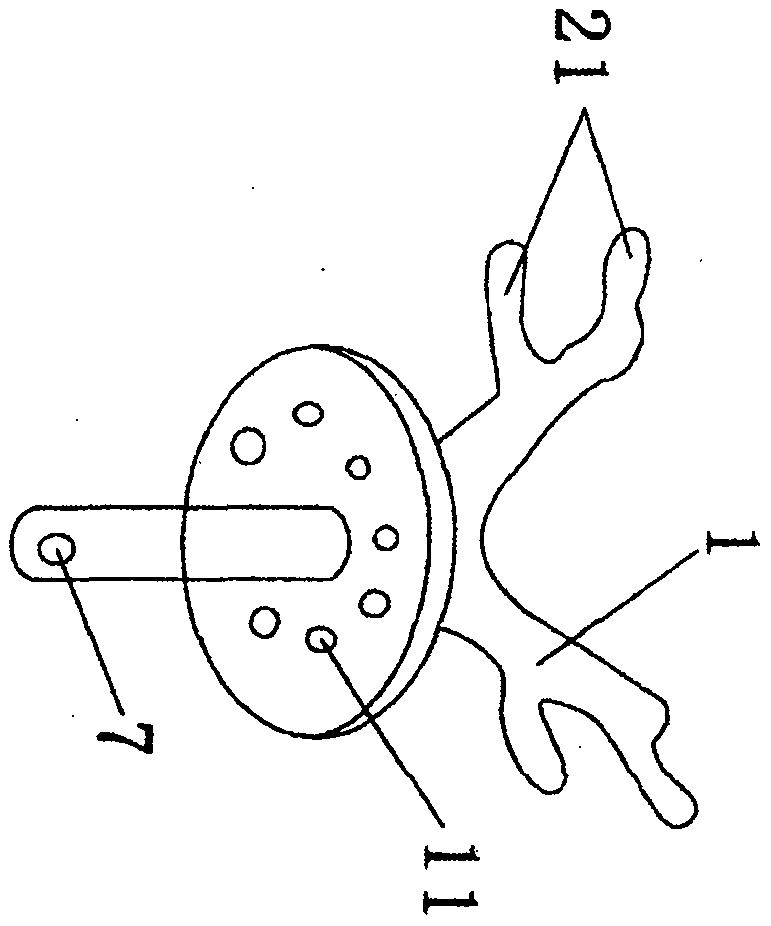

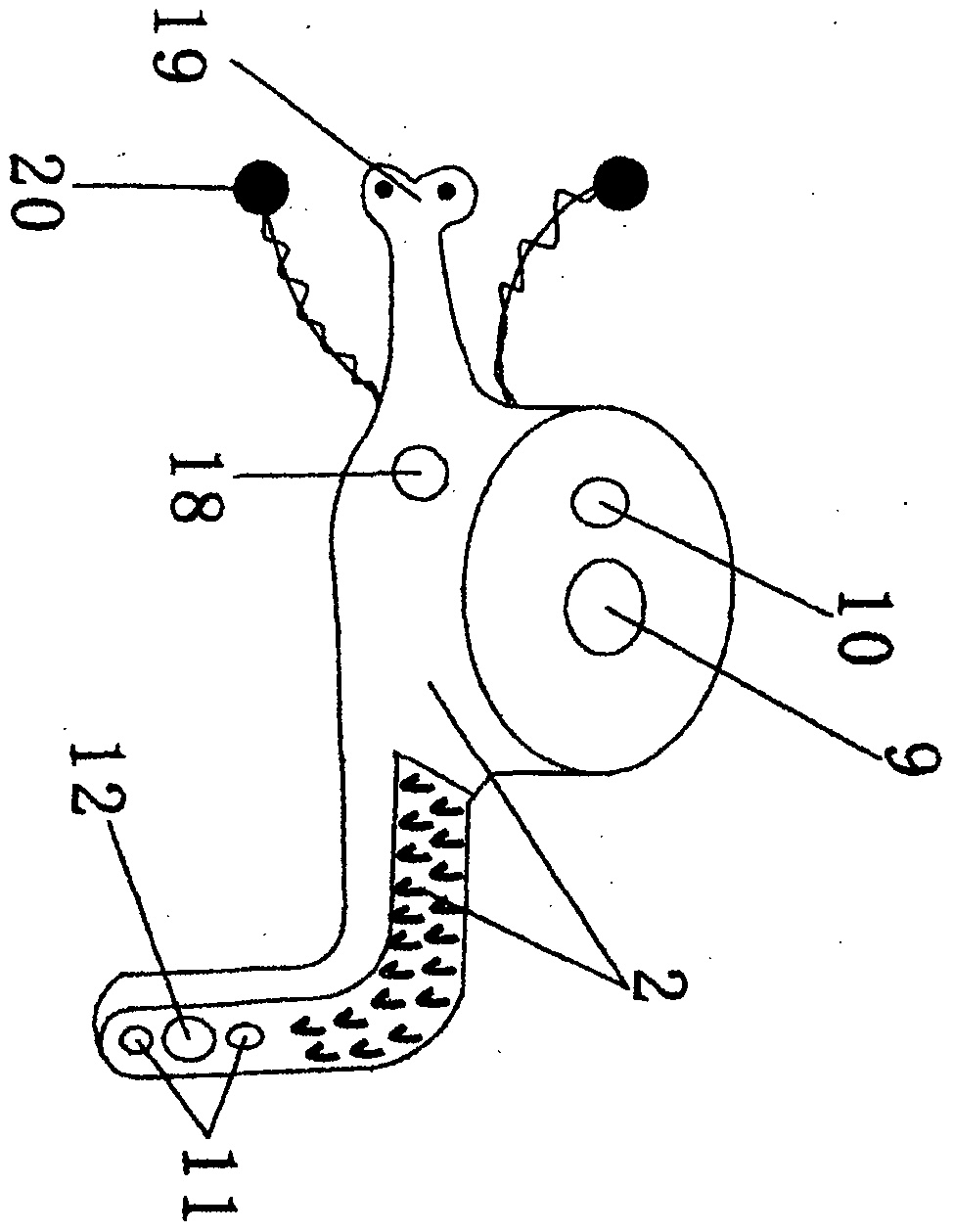

The invention discloses a multistage upper fork height-adjustable billiard rest, which comprises an upper fork, a connecting fork, movable forks, a fixed fork, a lower fork and a handle. The billiard rest is characterized in that the upper fork is shaped into a dragon horn, and can rotate by 360 degrees on the connecting fork; the connecting fork is shaped into a dragon head, and the rear extending part of the connecting fork is connected with the movable forks; the movable forks are connected in series with the fixed fork; the fixed fork is connected with the lower fork shaped into splay dragon legs. All the movable parts are provided with springs and collision balls, so that high overall stability can be ensured. When an athlete is required to support the rest on a billiard table, the billiard rest is equal to a low fork when all the movable forks are folded, is higher than a high fork when all the movable forks are unfolded, and may have fork positions at multiple heights between the low fork and the high fork, so that the billiard rest can be used instead of three rests, and has functions more than those of the three rests; the upper fork can also rotate by 360 degrees, so that a user can favorably operate a rod to win; all the forks are ornamented with dragon scale pictures, and the lower fork is further shaped into the dragon legs and dragon claws, so that the billiard rest is completely a cartoon golden dragon, is practical, great in artistic appeal, easy to manufacture, low in cost and economical, and has high market value.

Owner:西安丝路知星科技服务有限公司

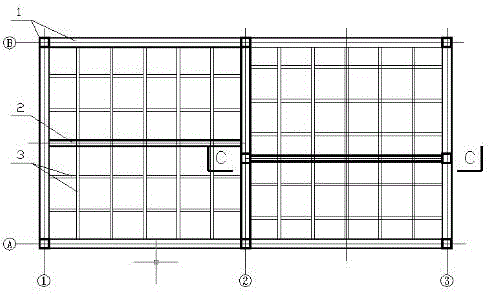

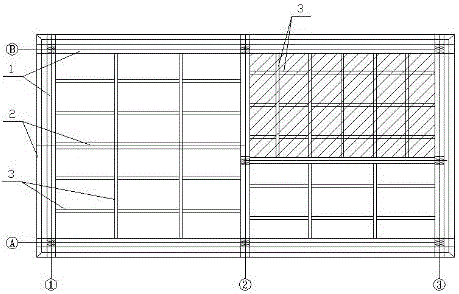

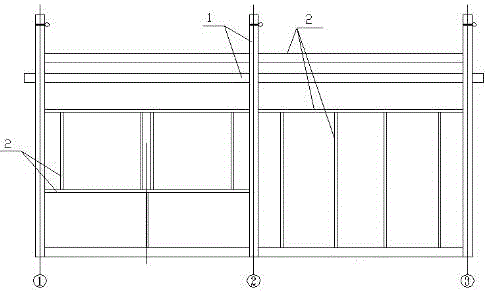

New-structure police-bank booth

ActiveCN105926991AImprove anti-theftHigh recycling valueSpecial buildingBuilding constructionsLarge sizeMaterials science

The invention discloses a new-structure police-bank booth and relates to the field of fixed buildings. The inside of the new-structure police-bank booth is divided into a police booth and a bank booth, a door and a window are designed for each of the police booth and the bank booth, a main bearing frame is made of large-size aluminum alloy pipes, a secondary bearing frame is made of medium-size aluminum alloy pipes, a supporting frame is made of small-size aluminum alloy pipes, and the main bearing frame, the secondary bearing frame and the supporting frame are fixedly connected mutually and form a beam framework structure of the police-bank booth; a bottom beam framework forms a checkered structure, the top is of a beam framework plane eaved checkered structure, a facade framework is formed between the top and the bottom, and aluminum alloy plates are fixed on the upper face of the bottom beam framework, upper and lower undersurfaces of a top beam framework and inner and outer side faces of the facade framework respectively. The new-structure police-bank booth is lightweight, durable, attractive, fashionable, safe and reliable, and does not need repair and maintenance after being mounted and fixed, so that producing and mounting cost and using and maintaining cost are lowered; when the police-bank booth is not need any more, the police-bank tooth which is out of service is high in recycling value, and the new-structure police-bank booth has high market application value and social value.

Owner:GUIYANG AL-MG DESIGN & RES INST +1

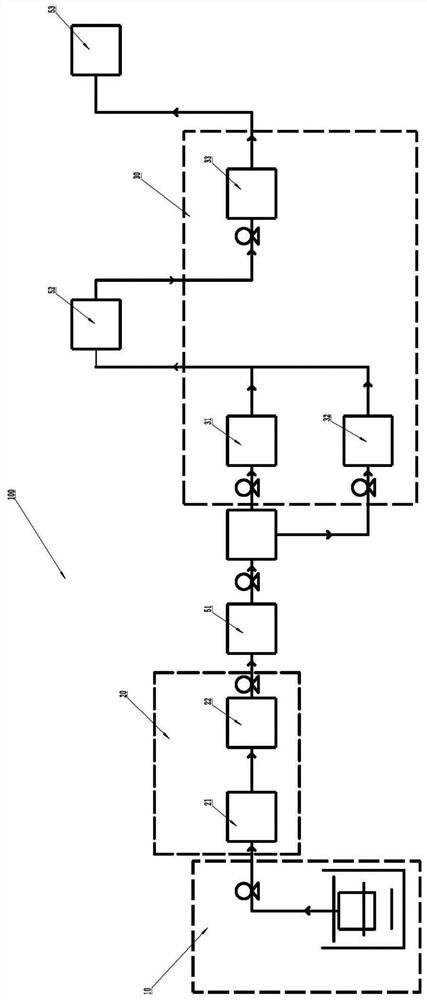

Method for preparing fresh water with various water quality grades

PendingCN111689601AWide marketReduce the burden of purchasingWater treatment parameter controlSpecific water treatment objectivesWater sourceBrackish water

The invention provides a method for preparing fresh water with various water quality grades, which utilizes equipment used for preparing fresh water with various water quality grades to prepare freshwater. The method is characterized by comprising the following steps of: 1, collecting raw water from a water source by using a raw water collecting device, the raw water being any one of seawater, brackish water and fresh water; 2, filtering the raw water by using a scraper type filter screen filtering part so as to intercept suspended solids with the granularity of more than or equal to 30-80 [mu]m to obtain D-grade water; 3, filtering the D-grade water by using a membrane filtering part to obtain C-grade water with turbidity of less than or equal to 5NTU; 4, if the raw water is seawater, carrying out reverse osmosis treatment on the C-grade water by utilizing a first reverse osmosis unit so as to obtain first B-grade fresh water; and if the raw water is brackish water or fresh water, performing reverse osmosis treatment on the C-grade water by a second reverse osmosis unit to obtain second B-grade fresh water; and 5, carrying out second-grade reverse osmosis treatment on the first B-grade fresh water or the second B-grade fresh water by a third reverse osmosis unit to obtain A-grade water.

Owner:舟山梅朋水处理有限公司 +1

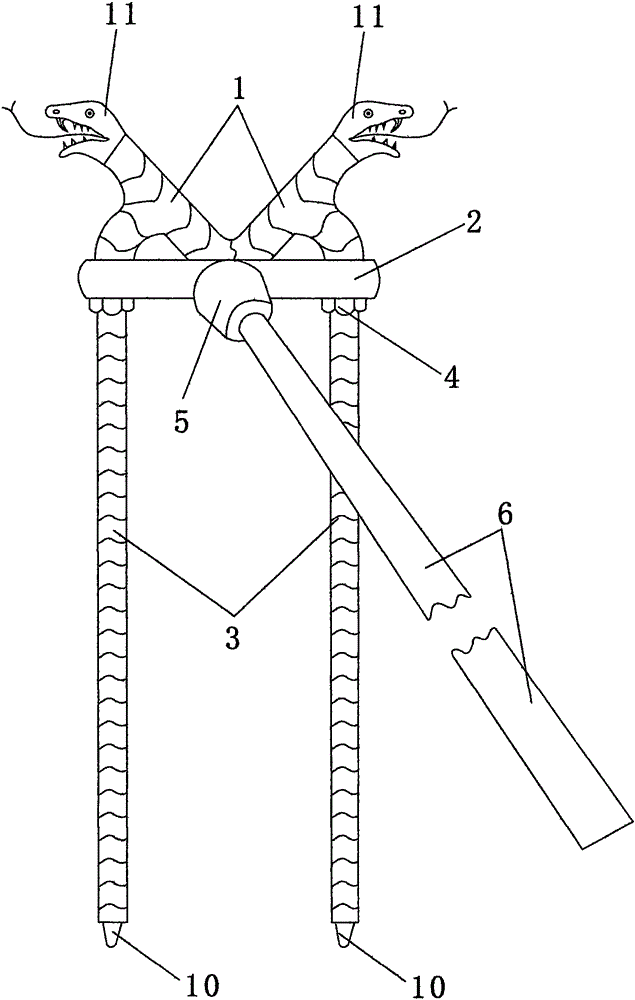

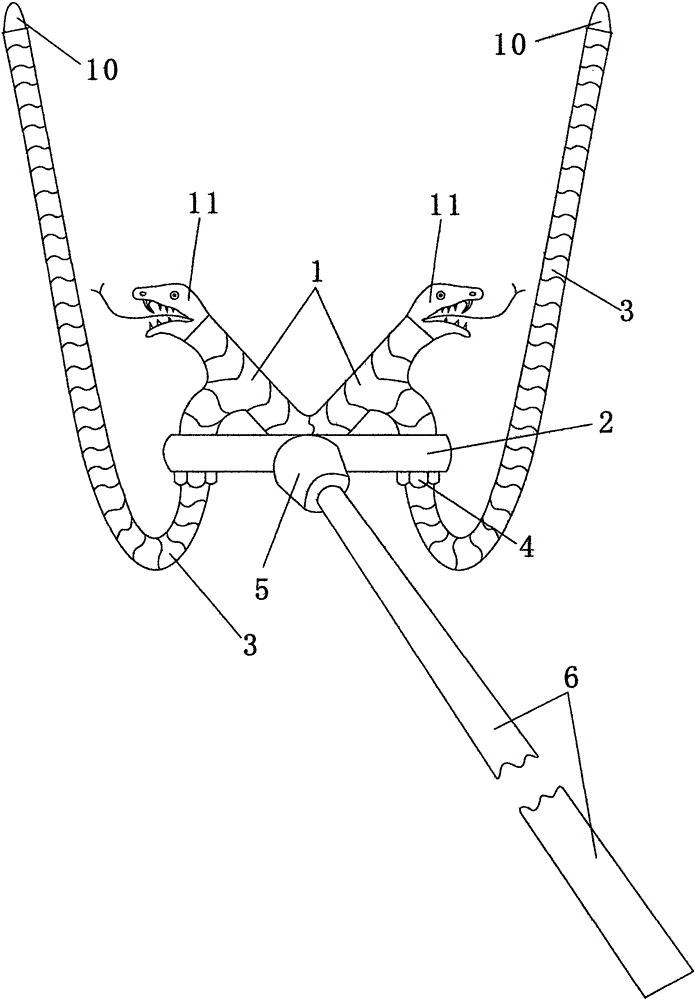

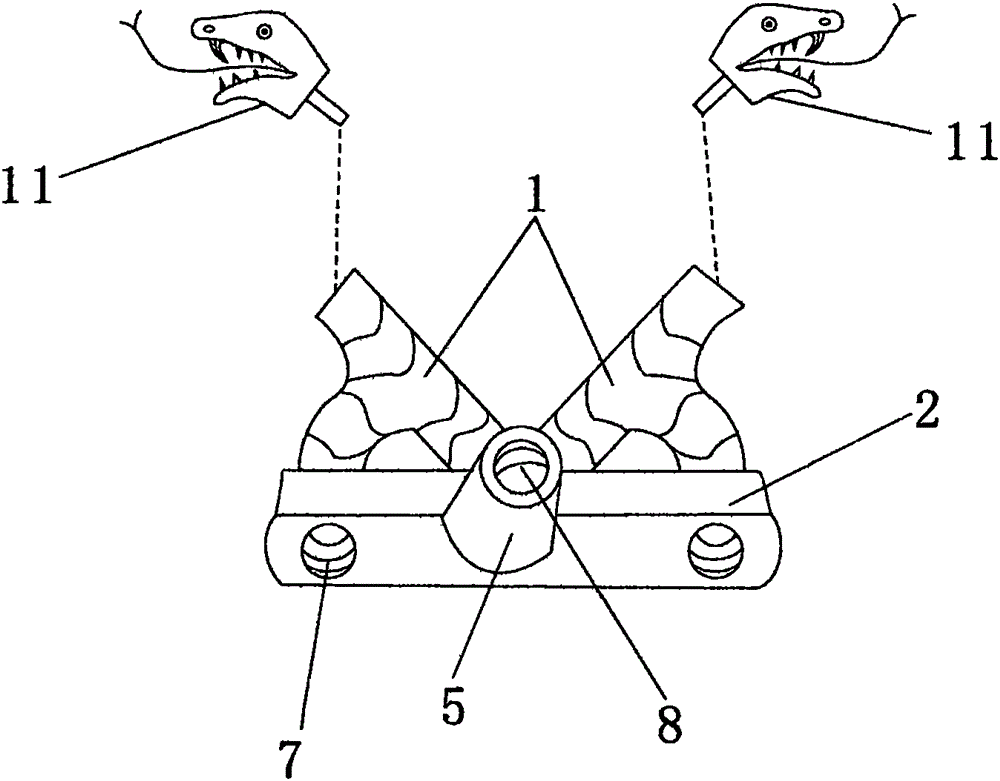

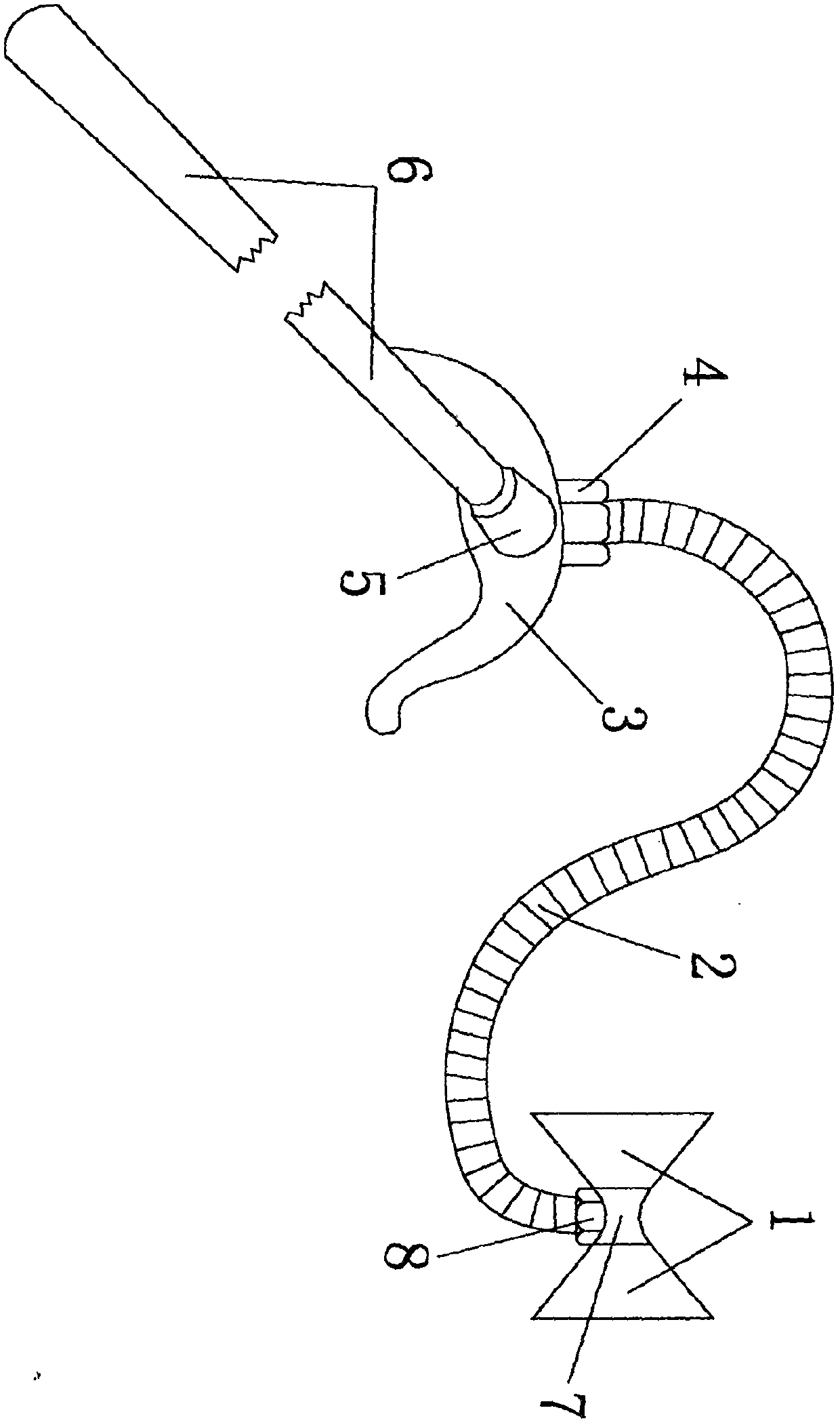

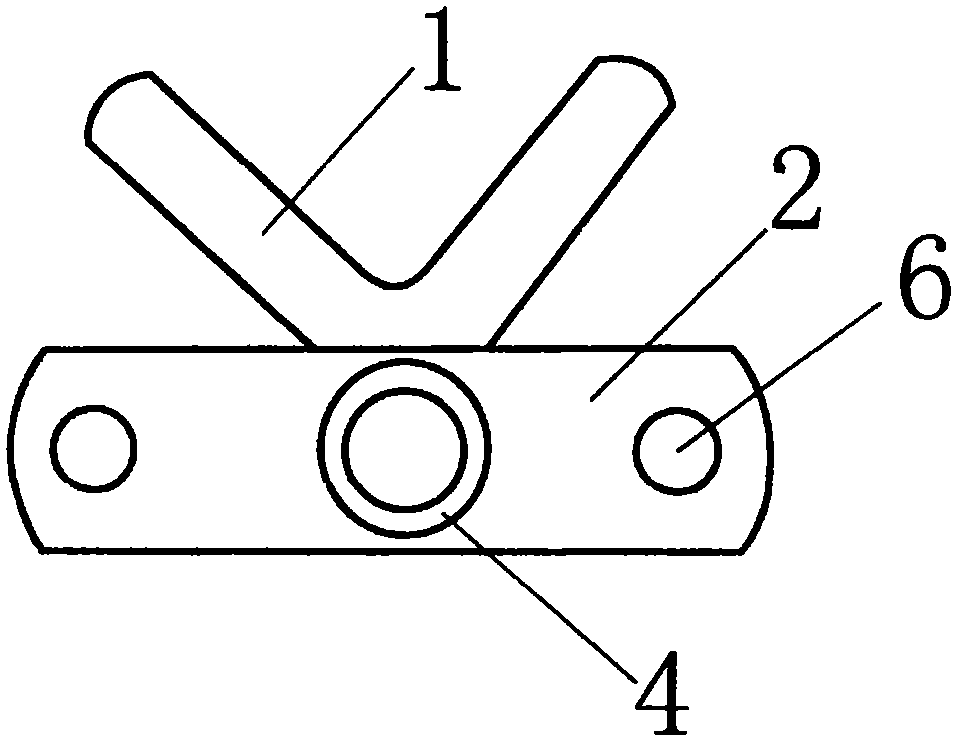

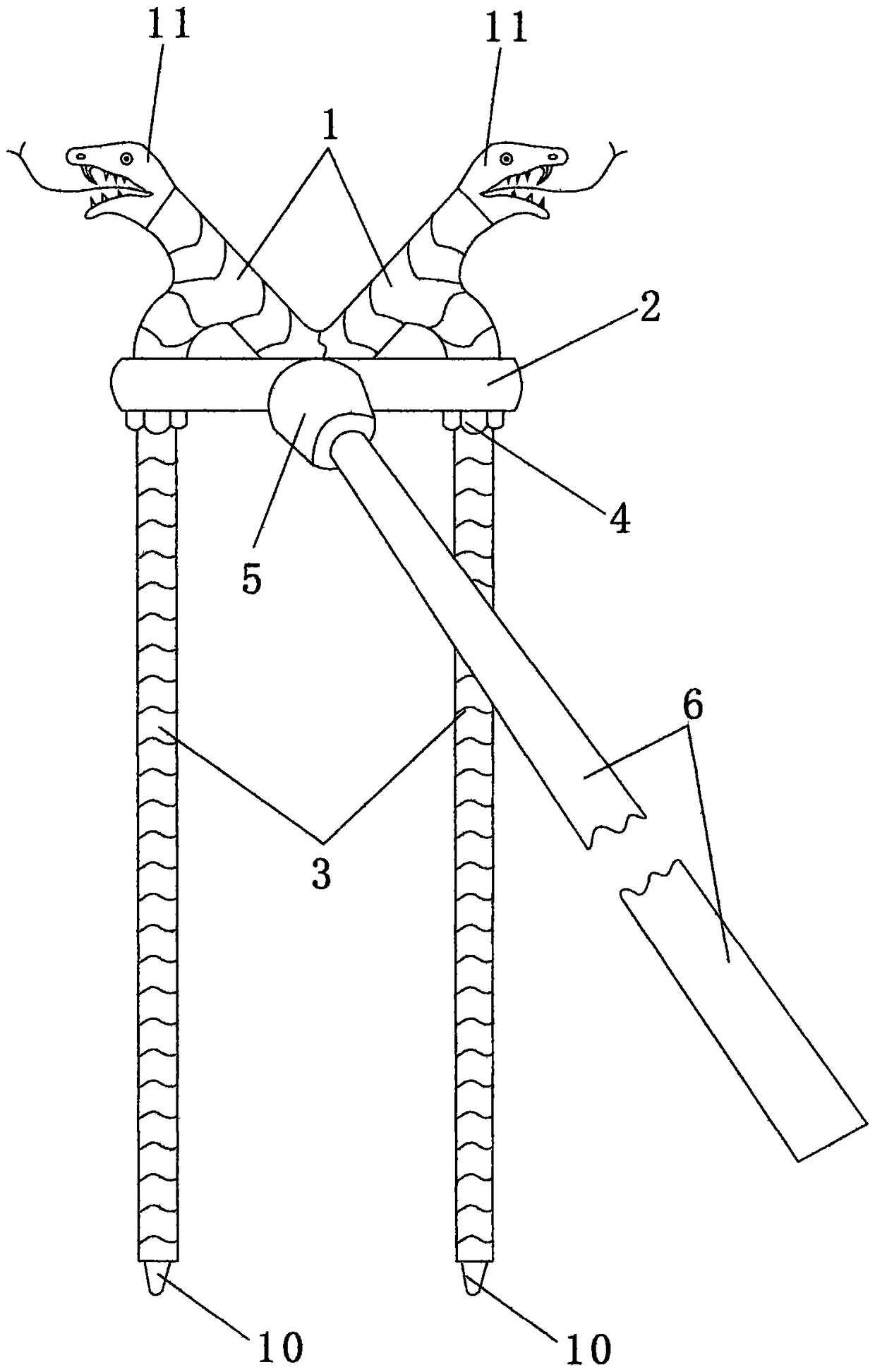

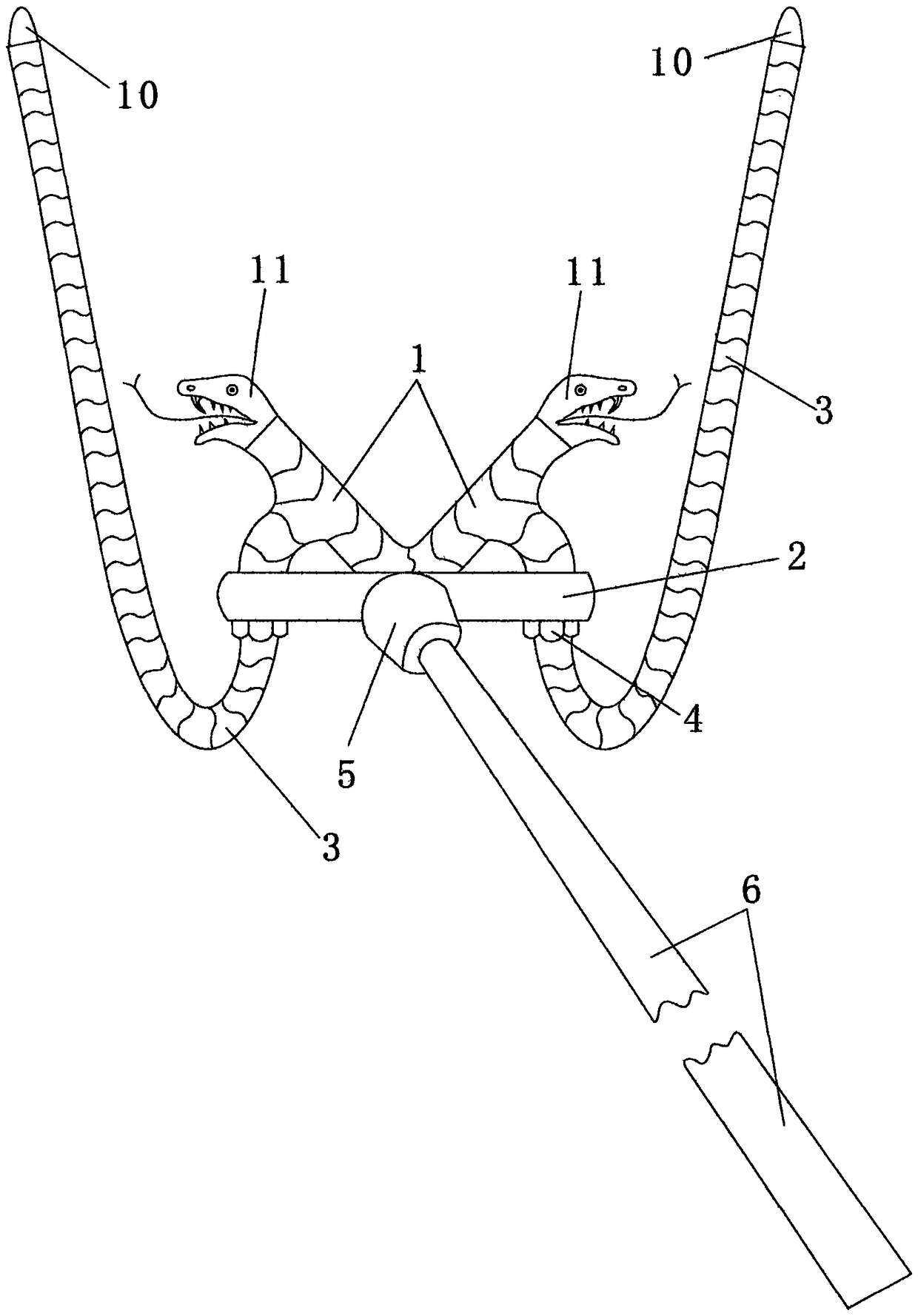

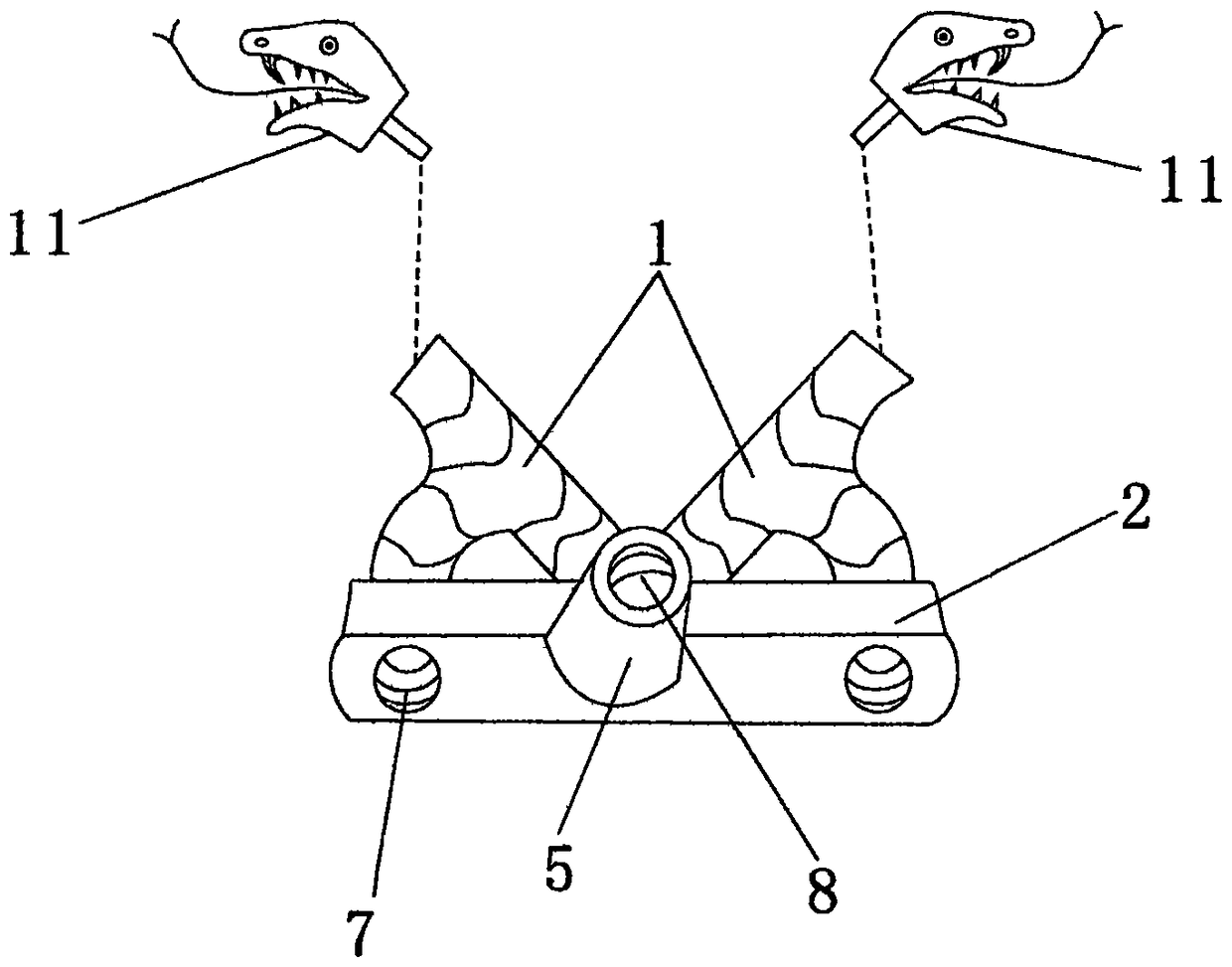

Dual-snake fork

The invention discloses a dual-snake fork. The fork consists of an upper fork, a cross beam, a lower fork, fastening bolts, a handle seat and a handle. The fork is characterized in that the upper fork is two cylindrical bodies perpendicular to each other and like snake heads in shape; the lower ends of the cylindrical bodies are connected integrally and connected with the cross beam integrally; a part extends out of the middle of the upper fork and is connected with the cross beam integrally; the cross beam is a cuboid; the cylindrical handle seat is arranged on one side of the middle of the cross beam; a screw hole is reserved in the middle of the handle seat; and the lower fork adopts an existing flexible conduit and is screwed in screw holes in two ends of the cross beam through the fastening bolts. When an athlete needs to adjust the height of a rest, the bending degree of the lower fork is moved by a hand at will, so that different height demands of the upper fork as the rest in stepless adjustment from low to high can be met; win is achieved by force; the fork is one of pioneered billiard rests with stepless adjustment of lower fork heights; the popularity of a product can be improved in the world; and the honor can be won for China. The fork is skillful in design, simple in structure, easy to manufacture, low in cost, wide in market and high in economic benefit.

Owner:西安丝路知星科技服务有限公司

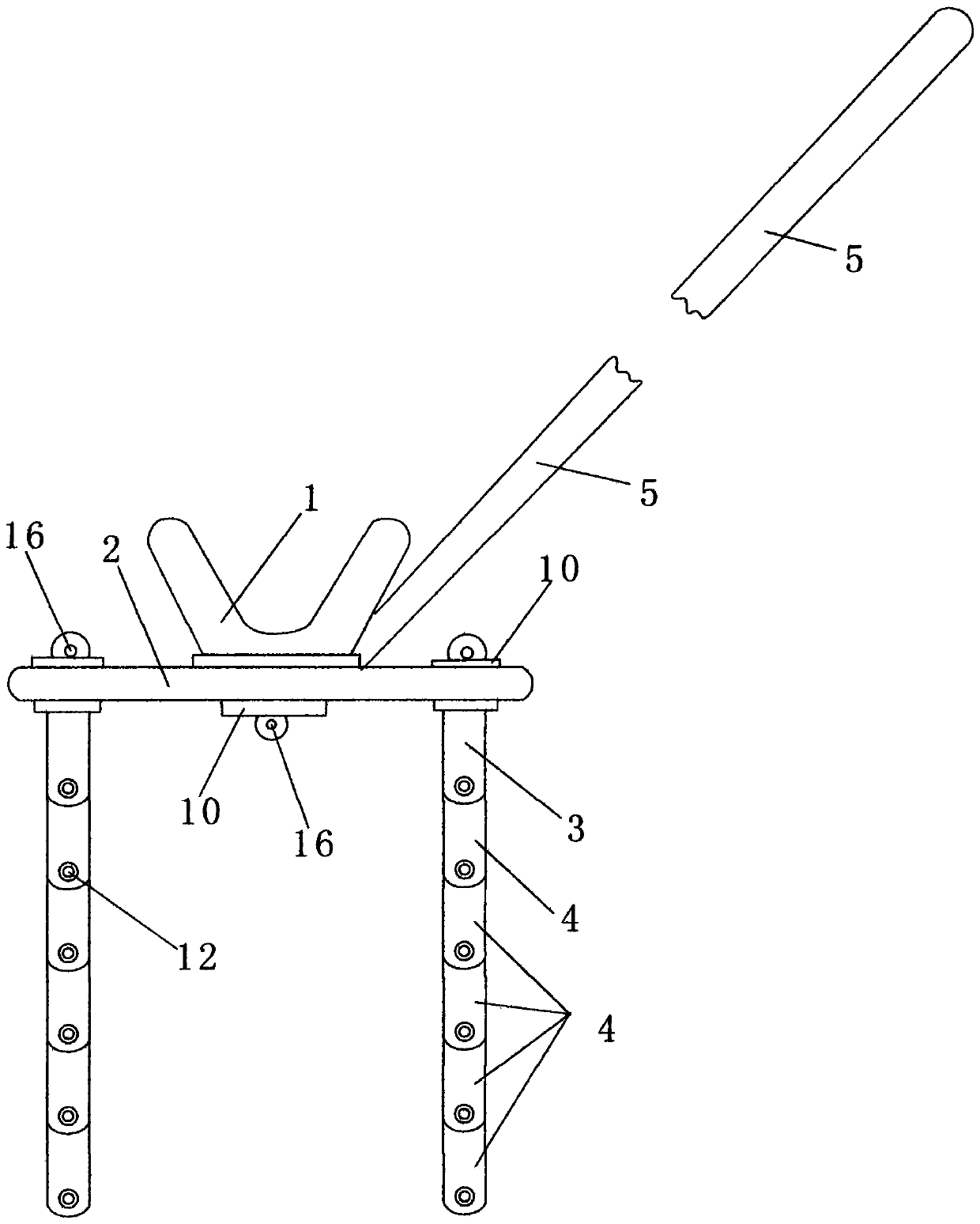

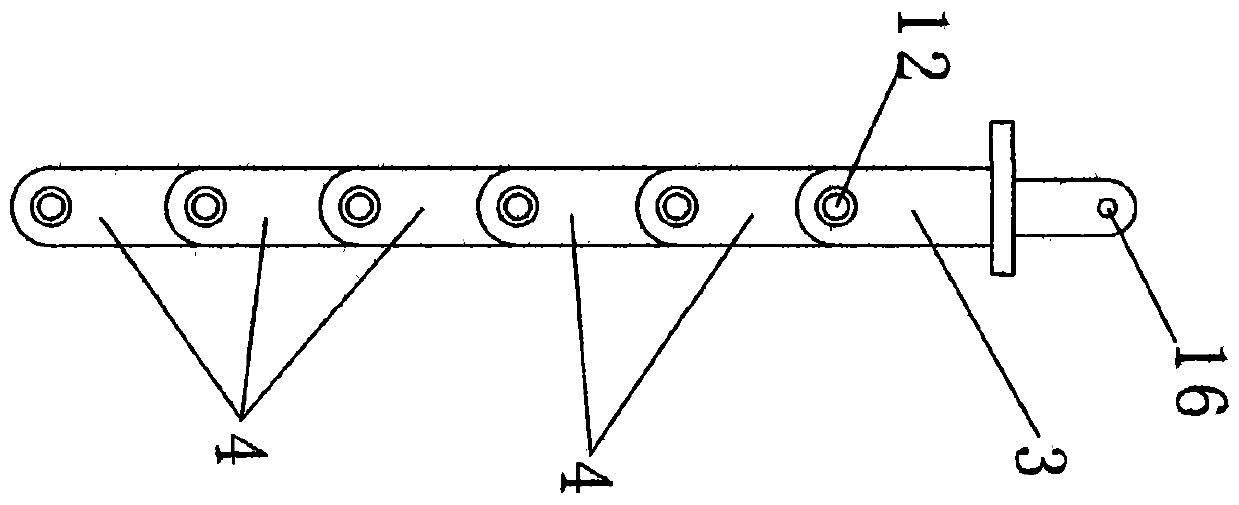

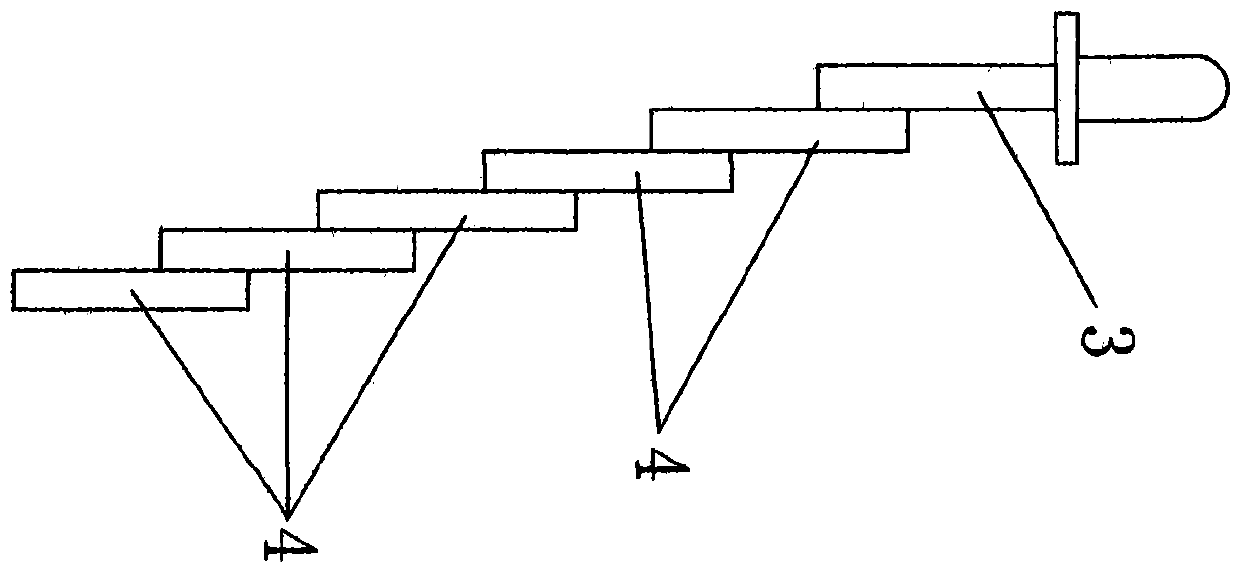

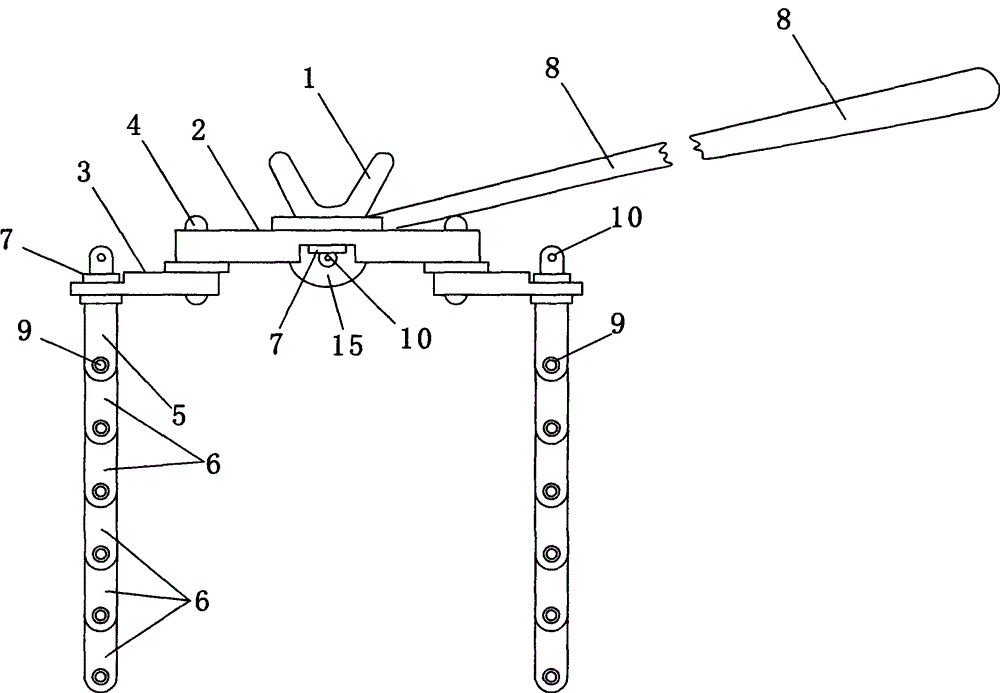

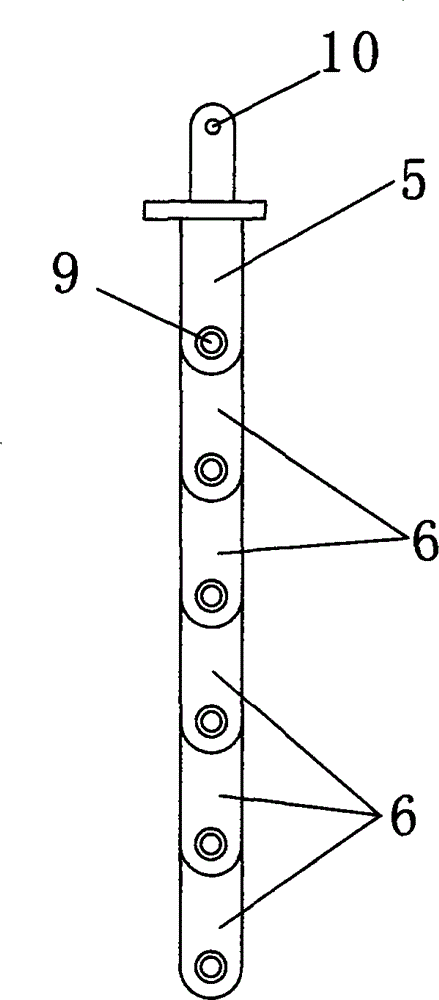

Chinese Fork—Folding Multi-level Adjustable Double Lower Feet Height Billiard Stand Rod

A kind of Chinese-style fork——foldable multi-stage adjustable billiard stand rod with double lower leg height, including: upper fork, beam, fixed fork, movable fork and handle, characterized in that: the upper fork is made of current cross One-half of the upper fork is set in the middle of the beam, and the lower end of the middle of the upper fork is provided with a cylinder so that the upper fork can rotate 360 degrees to facilitate the transportation of the pole. There are fixed forks at both ends of the beam, and several movable forks are connected to the lower end of the fixed fork. The movable fork can be folded arbitrarily, the pole is the highest when it is fully unfolded, and the lowest is when it is fully folded back. The intermediate state is multi-level and can adapt to the needs of different heights. Each movable part is equipped with a spring, and the bumper ball is used to cooperate with the shallow pit to achieve a stable overall position. Purpose In terms of function, a Chinese-style fork can support the current low, medium and high poles or even more, and is convenient for users to transport poles. It is cleverly designed, simple in structure, easy to manufacture, low in cost, and has a large market for use throughout the country and even worldwide.

Owner:李沛

A billiard stand rod with multi-stage adjustable upper fork height

The invention discloses a multistage upper fork height-adjustable billiard rest, which comprises an upper fork, a connecting fork, movable forks, a fixed fork, a lower fork and a handle. The billiard rest is characterized in that the upper fork is shaped into a dragon horn, and can rotate by 360 degrees on the connecting fork; the connecting fork is shaped into a dragon head, and the rear extending part of the connecting fork is connected with the movable forks; the movable forks are connected in series with the fixed fork; the fixed fork is connected with the lower fork shaped into splay dragon legs. All the movable parts are provided with springs and collision balls, so that high overall stability can be ensured. When an athlete is required to support the rest on a billiard table, the billiard rest is equal to a low fork when all the movable forks are folded, is higher than a high fork when all the movable forks are unfolded, and may have fork positions at multiple heights between the low fork and the high fork, so that the billiard rest can be used instead of three rests, and has functions more than those of the three rests; the upper fork can also rotate by 360 degrees, so that a user can favorably operate a rod to win; all the forks are ornamented with dragon scale pictures, and the lower fork is further shaped into the dragon legs and dragon claws, so that the billiard rest is completely a cartoon golden dragon, is practical, great in artistic appeal, easy to manufacture, low in cost and economical, and has high market value.

Owner:西安丝路知星科技服务有限公司

Pungent and spicy barbecue powder and making method

The invention relates to barbecue powder and a making method, in particular to pungent and spicy barbecue powder and a making method.The pungent and spicy barbecue powder is characterized by being made from, by weight, 60-80 parts of deep-fried dried chilli powder, 5-8 parts of deep-fried dried Chinese prickly ash seed powder, 15-22 parts of deep-fried cumin powder, 4-8 parts of deep-fried sesame powder, 5-8 parts of deep-fried potato powder, 1-1.5 parts of deep-fried spring bud powder, 2-5 parts of dried ginger, 2-5 parts of dried garlic powder, 4-7 parts of dried green onion powder, 2-4 parts of monosodium glutamate, 5-7 parts of chicken essence, 2-4 parts of white sugar and 2-4 parts of salt.The making method of the pungent and spicy barbecue powder comprises the steps of (a) making the deep-fried powder, firstly performing deep frying and then using a crusher to crush raw materials into the powder, (b) drying ginger powder, garlic powder, green onion powder, (c) mixing raw materials by using a stirrer, and (d) performing package.The pungent and spicy barbecue powder is scientific and reasonable in composition and has an obvious and comfortable pungent and spicy taste and an inviting flavor, and the making method of the pungent and spicy barbecue powder is unique and good in effect.

Owner:CHONGQING YOUJUN FOOD

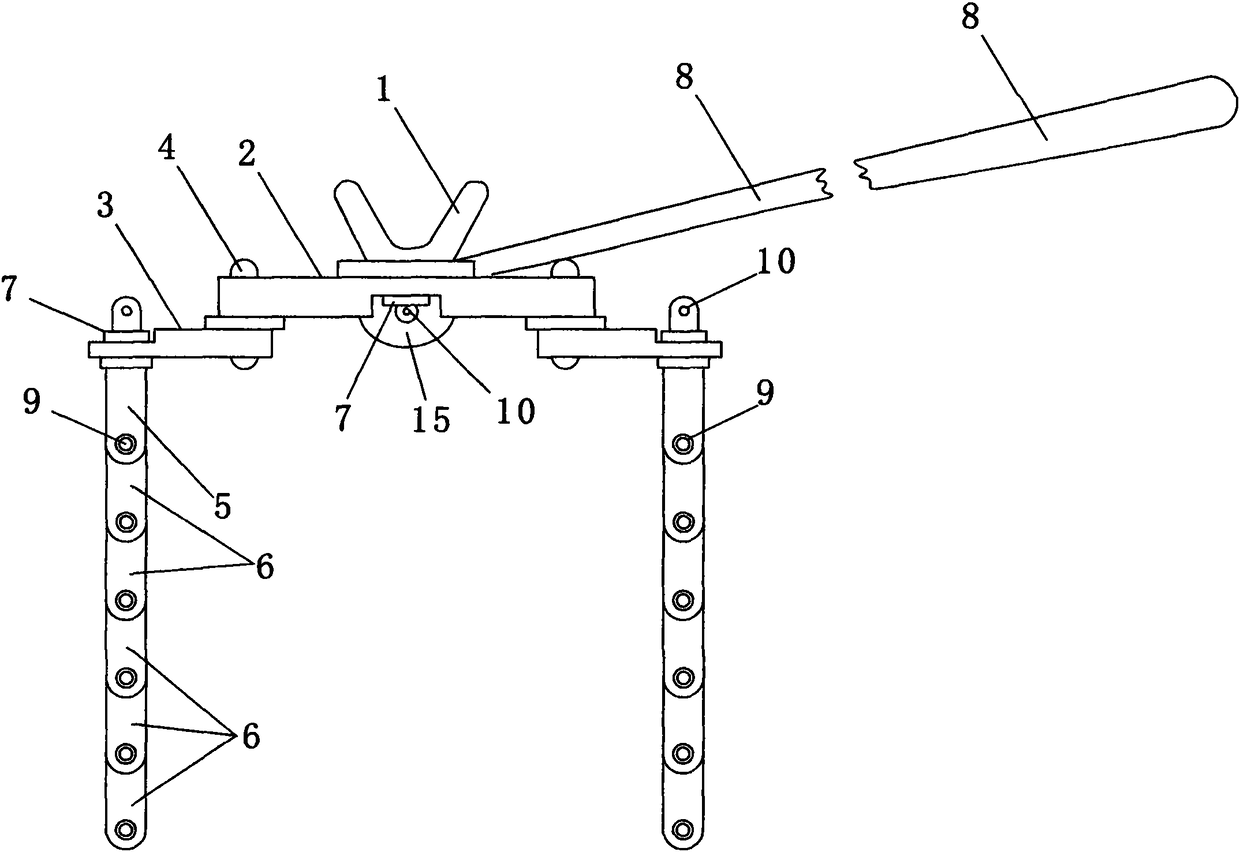

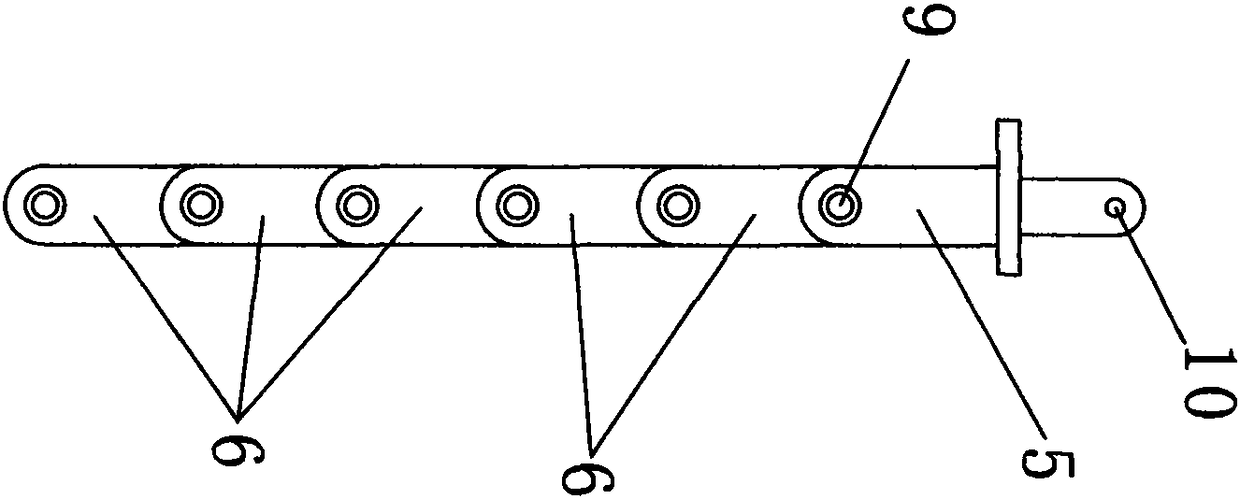

Folding multi-level adjustable double lower leg height and width Chinese-style fork billiard stand pole

A billiards frame rod capable of multi-stage regulation of height and width of a lower support leg comprises an upper fork, a horizontal beam, movable arms, fixed forks, multiple movable forks and a handle and is characterized in that the upper fork is disposed on the middle part of the horizontal beam by half of a joint spider; a cylindrical body is disposed on the middle lower end of the upper fork and can make the upper fork rotate within 360 DEG so as to make rod application convenient; the movable arms are connected to two ends of the horizontal beam; the fixed forks are disposed on the movable arms; the multiple movable forks are connected to the lower ends of the fixed forks; the movable forks can be folded at will; the frame rod can reach the highest point after the movable forks are completely unfolded, and on the contrary, the frame rod can descend to the lowest point; the two movable arms can be rotated within 360 DEG; the lower support leg is narrowest when the movable arms are rotated to the middle part, and on the contrary, the lower support leg is widest; a spring is disposed at each movable part; and a collision bead is matched with a shallow pit, so that the overall structure becomes stable. An intermediate-type fork has functions of an existing low frame rod, an existing middle frame rod and an existing high frame rod or the like, so that a user can use the rod conveniently; and the frame rod has skillful design, a simple structure, simple manufacture technologies, low cost and broad application markets in the whole country or around the world.

Owner:李沛

Method for processing instant crispy fish

InactiveCN102132901BIncrease profitReduce manufacturing costFood preparationFreshwater fishRaw material

The invention provides a method for processing an instant crispy fish, in particular to a processing method for preparing an instant crispy fish by utilizing processing leftovers of a freshwater fish. The leftovers obtained after a raw finish is thawed, cleaned, salted, cleaned, dried, fermented and cut are used as raw materials in the fish block process for processing. The method comprises the following concrete steps of: desalting raw materials; and drying, cutting, frying, soaking, frying, bagging, packaging in vacuum, sterilizing for cooling, inspecting, packaging a finished product and storing. The method disclosed by the invention can be used for carrying out curing and flavouring treatment on the fish raw materials by efficiently utilizing the processing leftovers of a fish body according to a prescription and a specific procedure to obtain the crispy fish and is a freshwater fish leftover utilization and processing method with the advantages of high utilization ratio of fish body, low production cost, long storage period and obvious increment.

Owner:ZHEJIANG SHANSHUILANG FOOD

Preparation method of antibacterial and flame-retardant garment fabric

InactiveCN114158806AHave diversityMeet needsBiochemical fibre treatmentHeat resistant fibresFiberSpinning

The invention belongs to the technical field of special cloth spinning production, and particularly relates to a cloth processing machine which comprises a processing box, insertion openings are symmetrically formed in the left side and the right side of the outer surface of the processing box, side opening plates are movably connected to the two sides of an inner cavity of the processing box through the insertion openings, and a cloth inlet is formed in the back of the outer surface of the processing box; a cloth outlet is formed in the front face of the processing box, and a top sliding opening is formed in the upper portion of the inner wall of the processing box. According to the device, in the process of processing the antibacterial flame-retardant garment fabric, only existing fabric needs to be used for processing, new fabric fibers do not need to be manufactured again for fabric weaving, the production efficiency and the yield are higher and higher, in addition, most fabric can be theoretically used for processing and synthesizing, and the production cost is reduced. Therefore, the processed antibacterial flame-retardant garment fabric has diversity, and the made garments can meet the requirements of more people and have a wider market range.

Owner:张亚

Garbage automatic packing method and garbage automatic packing machine

Owner:ZHEJIANG UNIV

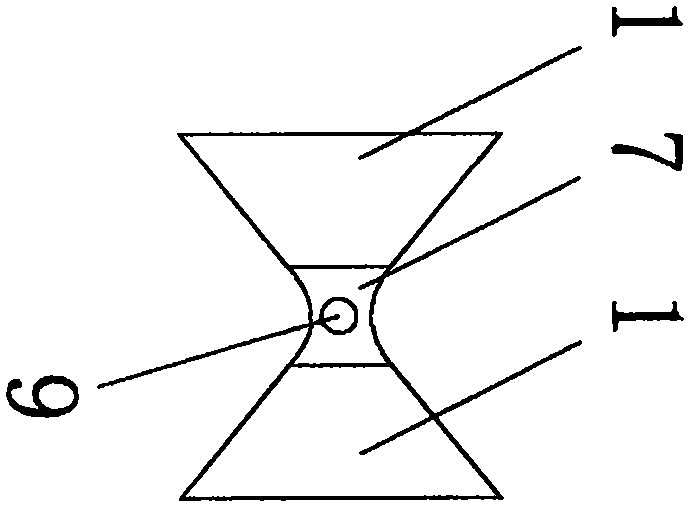

silver snake fork

The invention discloses a sliver snake fork. The silver snake fork is composed of an upper fork, a snakeskin movable fork, a lower fork and a hand shank. The sliver snake fork is characterized in that the upper fork is connected to an organic whole by two symmetrical trapezoid shape cones on the upper parts with a concave shape cylinder in the middle, and the purpose is to make the upper fork have a good ball arm supporting function from the highest to the lowest; the function of the snakeskin movable fork is to make the upper fork change from the highest position to the lowest position in a stepless mode so as to make the silver snake fork capable of replacing the existing three kinds of forks, namely, a low fork, a middle fork and a high fork, and make the silver snake fork have more functions than the three kinds of forks; in addition, the snakeskin movable fork can adjust the height of the upper fork in a stepless mode; the functions of the lower fork and the hand shank are the same as those of an existing joint spider. The silver snake fork has the advantages that the upper fork capable of supporting the ball arm and changing from the lowest position to the highest position in a stepless mode can be provided for athletes, victory is won by advantages, the silver snake fork is pioneered and capable of adjusting the height of the upper fork in a stepless mode and is one of hack levers, and can promote product popularity worldwide and win honor for our country; in addition, the silver snake fork is ingenious in design, simple in structure, east to make, low in cost, broad in use market, and high in economic benefit.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

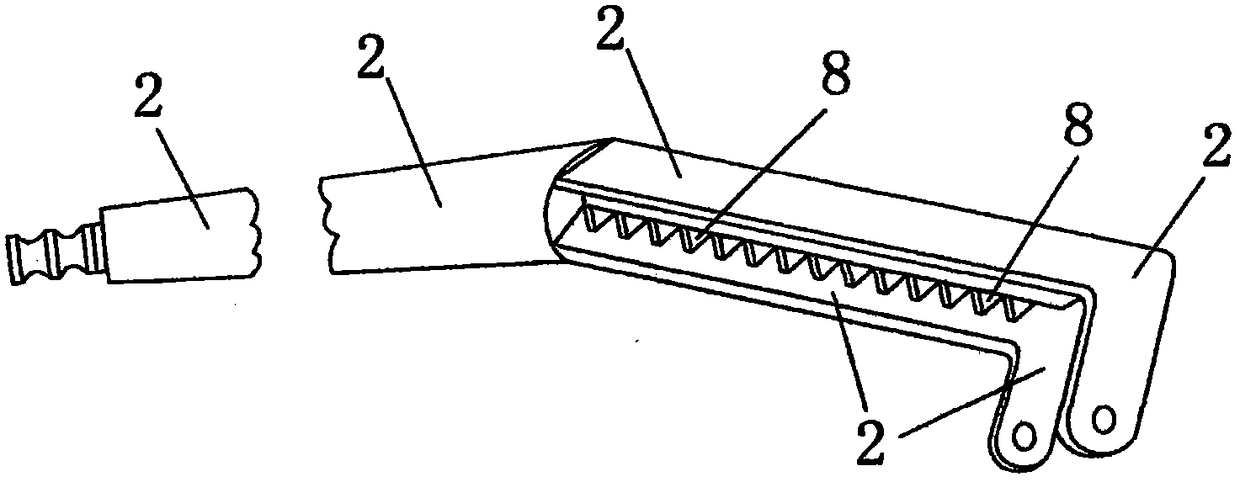

Billiards frame rod capable of multi-stage regulation of height and width of lower support leg

A billiards frame rod capable of multi-stage regulation of height and width of a lower support leg comprises an upper fork, a horizontal beam, movable arms, fixed forks, multiple movable forks and a handle and is characterized in that the upper fork is disposed on the middle part of the horizontal beam by half of a joint spider; a cylindrical body is disposed on the middle lower end of the upper fork and can make the upper fork rotate within 360 DEG so as to make rod application convenient; the movable arms are connected to two ends of the horizontal beam; the fixed forks are disposed on the movable arms; the multiple movable forks are connected to the lower ends of the fixed forks; the movable forks can be folded at will; the frame rod can reach the highest point after the movable forks are completely unfolded, and on the contrary, the frame rod can descend to the lowest point; the two movable arms can be rotated within 360 DEG; the lower support leg is narrowest when the movable arms are rotated to the middle part, and on the contrary, the lower support leg is widest; a spring is disposed at each movable part; and a collision bead is matched with a shallow pit, so that the overall structure becomes stable. An intermediate-type fork has functions of an existing low frame rod, an existing middle frame rod and an existing high frame rod or the like, so that a user can use the rod conveniently; and the frame rod has skillful design, a simple structure, simple manufacture technologies, low cost and broad application markets in the whole country or around the world.

Owner:李沛

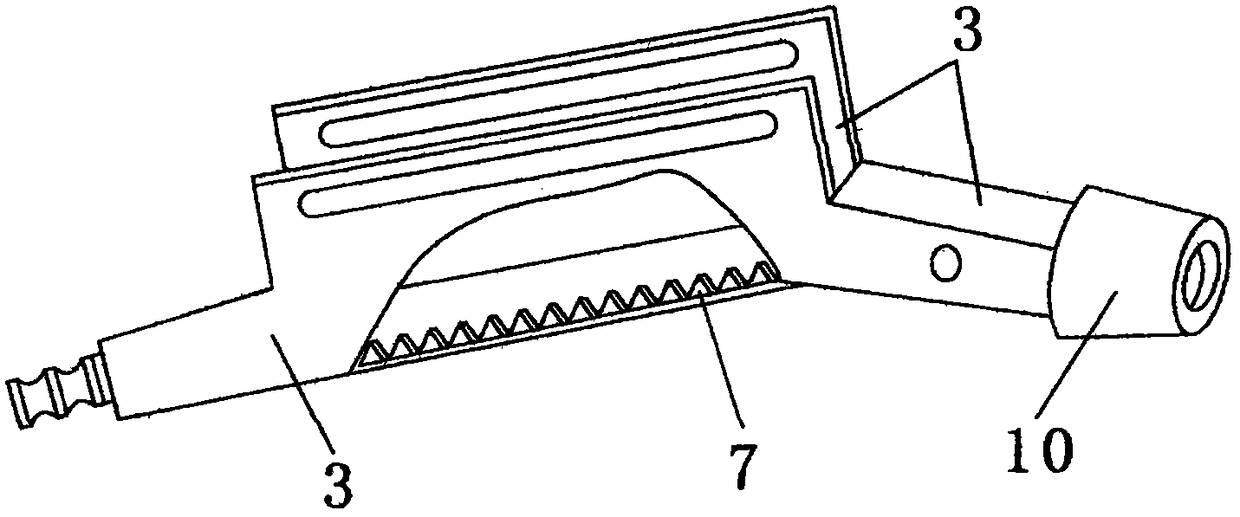

crocodile fork

The invention discloses a crocodile fork, which is composed of an upper fork, a movable fork, a fixed fork, a lower fork, two independent cones, two independent gear racks, a torsional spring and a stopper; the crocodile fork is characterized in that the tail end of the movable fork is connected to a square solid body of the fixed fork by virtue of a pin, and the movable fork can move in a fan-shaped form; an included angle is formed between the movable fork and the fixed fork; the gear racks are each arranged at the bottom of a groove of each fork; two cones are arranged on a same shaft and are meshed with the corresponding gear racks; and the stopper is screwed at two ends of a shaft head. The stopper is pushed forwards by an athlete's finger, so that the cone on the movable fork can rotate in a clockwise direction and the cone on the fixed fork, which can take a damping effect, can rotate in an anticlockwise direction, the included angle between the two forks is minimized and the upper fork which is arranged on the movable fork is descended to the lowest position; the included angle between the fixed fork and the movable fork is maximized and the upper fork is ascended to the highest position when the stopper is pulled backwards by a hand; the upper fork, which moves from the lowest position to the highest position in a mode of stepless regulation, can have a plurality of rest points, so that functions are enriched in comparison with current low, middle and high rest points, more choices are offered to an athlete and the possibility of winning is improved; and the crocodile fork is simple to make, low in cost, economical and practical.

Owner:李沛

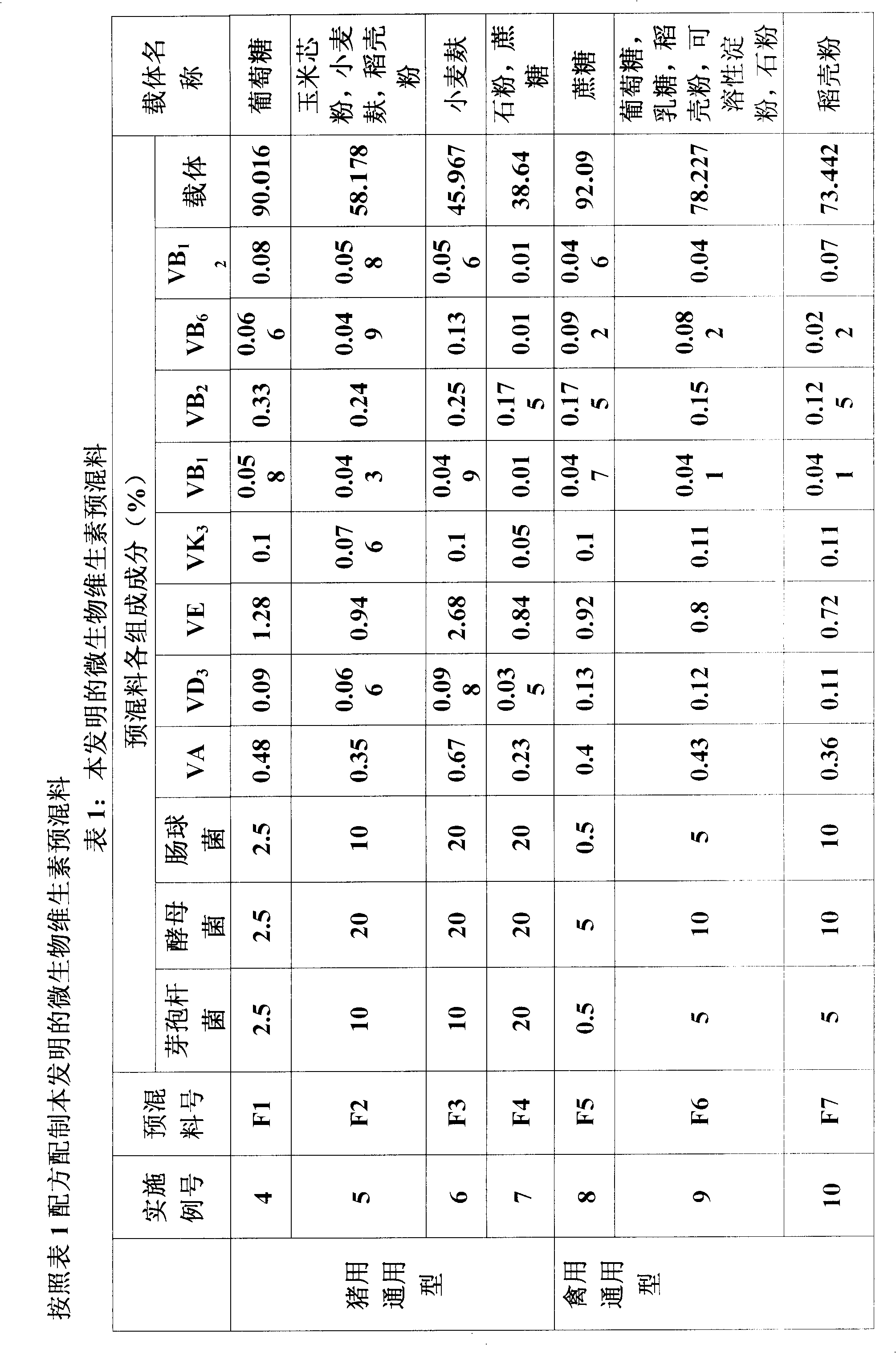

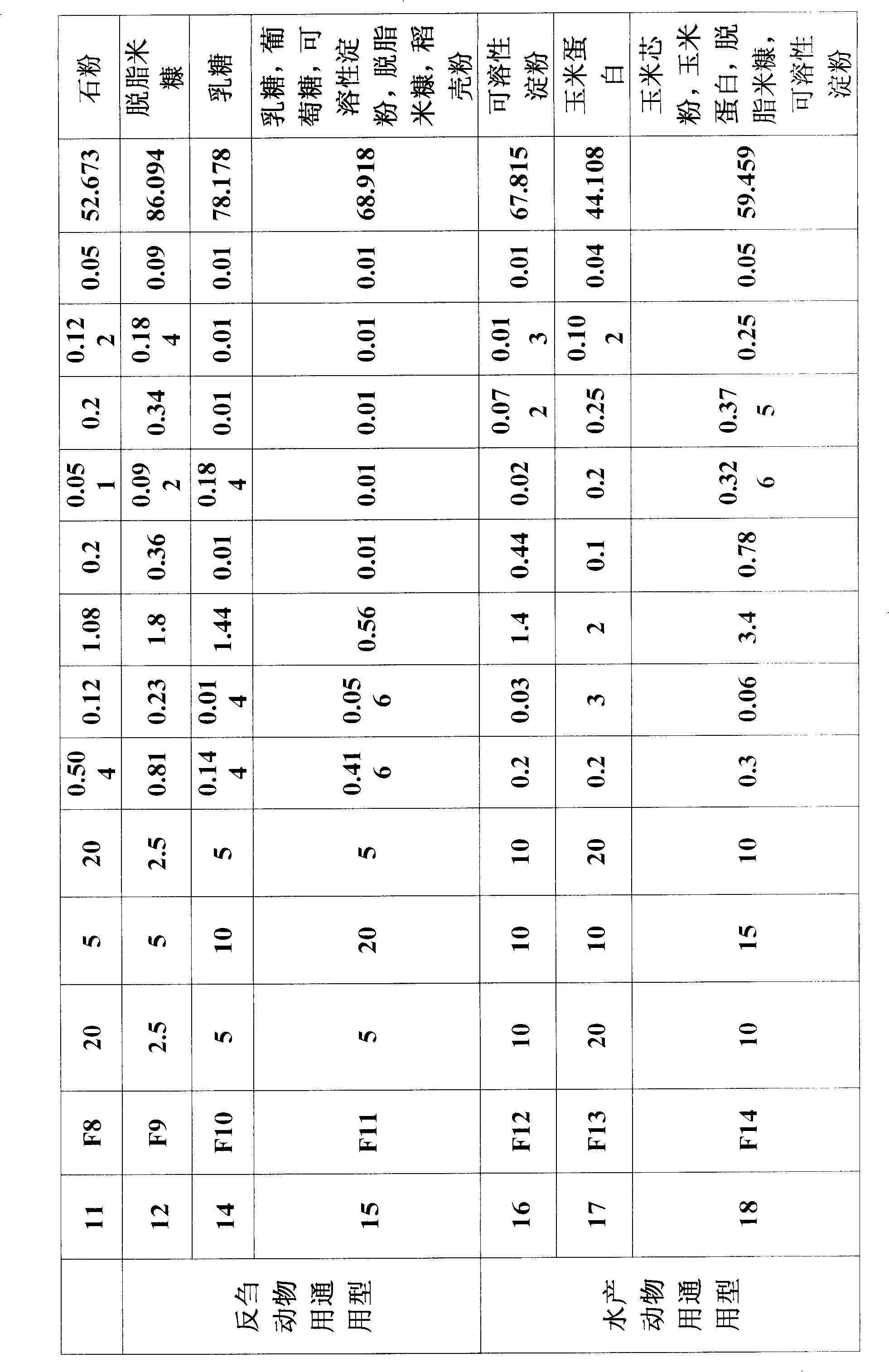

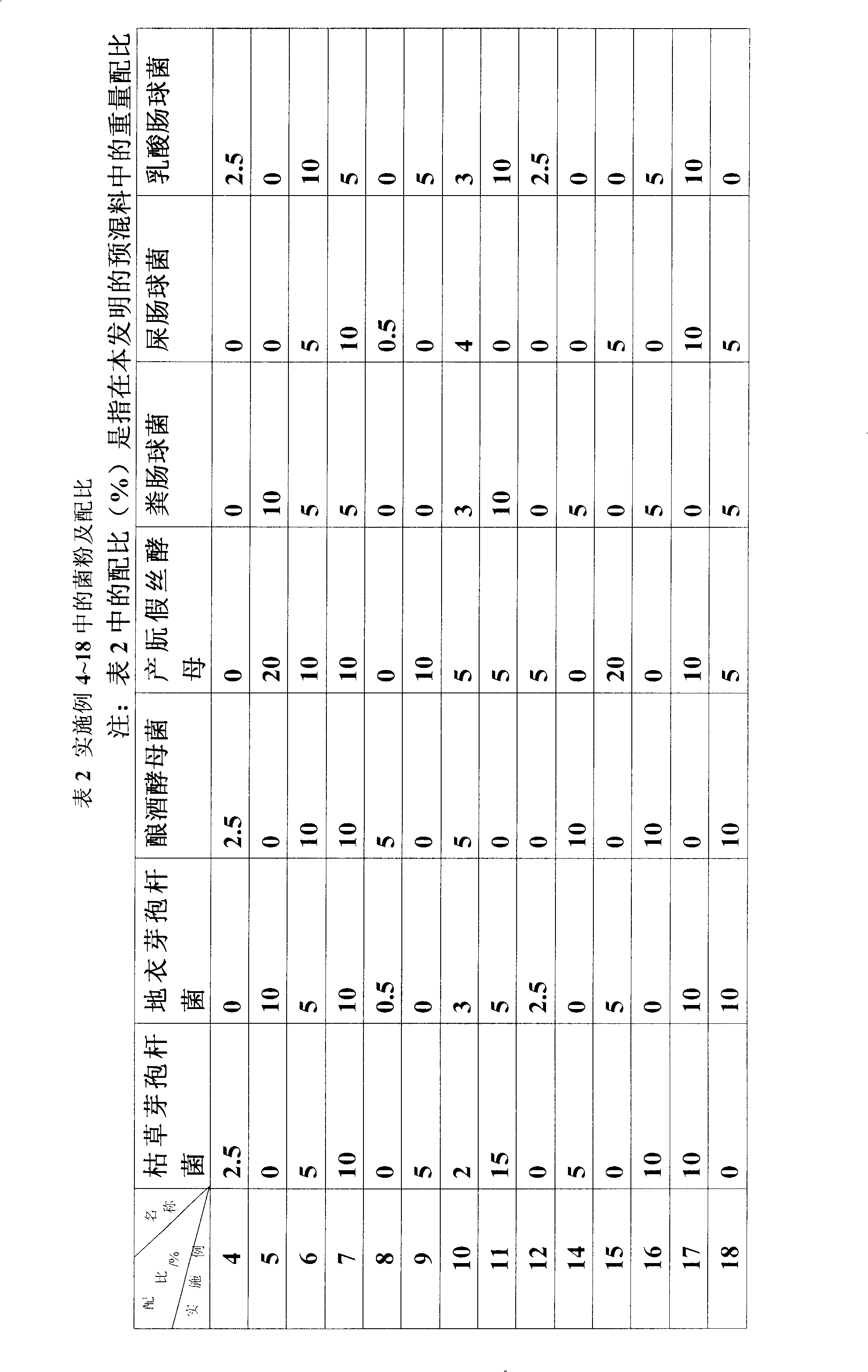

Microorganism vitamin premixed material and preparation method

ActiveCN101366449BSolve the core technology of popularization and applicationPromote digestionAnimal feeding stuffAccessory food factorsEcological environmentAquatic animal

The present invention relates to a microbe vitamin premix material and a method for preparing the same, in particular to a microbe vitamin premix material consisting of a plurality of useful microbes and vitamins and a method for preparing the same. The microbe vitamin premix material comprises bacillus, microzyme, enterococcus, vitamin A, vitamin D3, vitamin E, vitamin K3, vitamin B1, vitamin B2, vitamin B6 and vitamin B12, and is the microbe vitamin premix material generally for pigs, poultries, ruminant or aquatic animals. The microbe vitamin premix material has the animal immunization health care function as well as nutrient efficacy, and can improve illness resistant capability of animals, reduce the consumption of antibacterial drugs in feed, lower the drug resistant degree of bacteria, improve the feed utilization ratio, promote health of mankind and improve the ecological environment.

Owner:BEIJING DABEINONG TECH GRP CO LTD +1

Energy-saving compact type vacuum extrusion machine

InactiveCN100528505COptimize the transmission modeReduce mechanical frictionCeramic shaping apparatusMotor driveHigh energy

Owner:程玉全

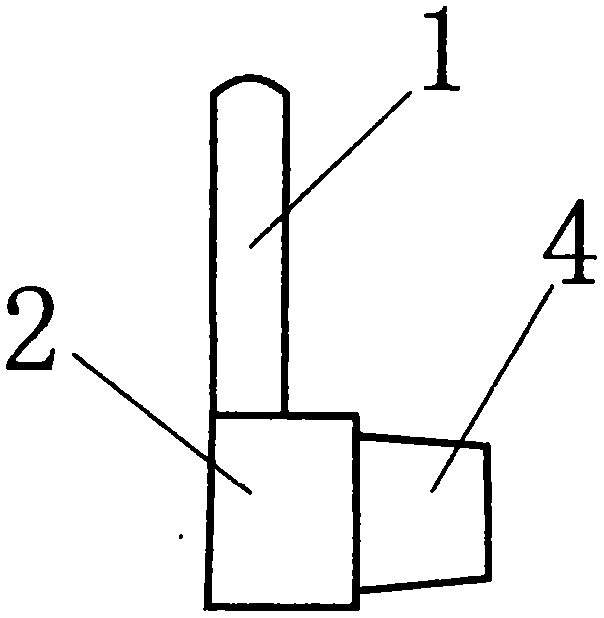

Pull rod fork with stepless adjustable height of double lower support legs

The invention discloses a pull rod fork with stepless adjustable height of double lower support legs. The pull rod fork consists of an upper fork, a cross beam, pull rods, a handle seat, a rotary column and a handle. The pull rod fork is characterized in that the upper fork is manufactured into two cylinders which are perpendicular to each other, and the lower ends of the two cylinders are connected integrally, and the connecting place is also integrally connected with the cross beam; the cross beam is a cuboid; the handle seat is arranged in the middle of the side surface of the cross beam; through holes are formed in two ends of the side surface of the cross beam respectively and the through holes can penetrate through the rotary column; a hole is formed in a relatively thick section of the rotary column, and the hole can penetrate through the thickest section of multiple sections of the pull rods; after half of the section of the pull rod is penetrated, the pull rod and the circular hole in the rotary column are firmly glued through a strong binder; in installation, after a thin section of the rotary column penetrates through the circular hole in the cross beam, a spring spacer is placed and then a pin is adopted in a penetration manner, so that the length of a frame bar can be changed by an athlete by freely pulling the movable parts of the pull rods manually when the height of the frame bar needs to be adjusted; the corresponding pull rods also can rotate left and right so as to take advantage in motion; and the universal frame bar is creative in design, simple in manufacturing, low in cost and high in market prospect.

Owner:李沛

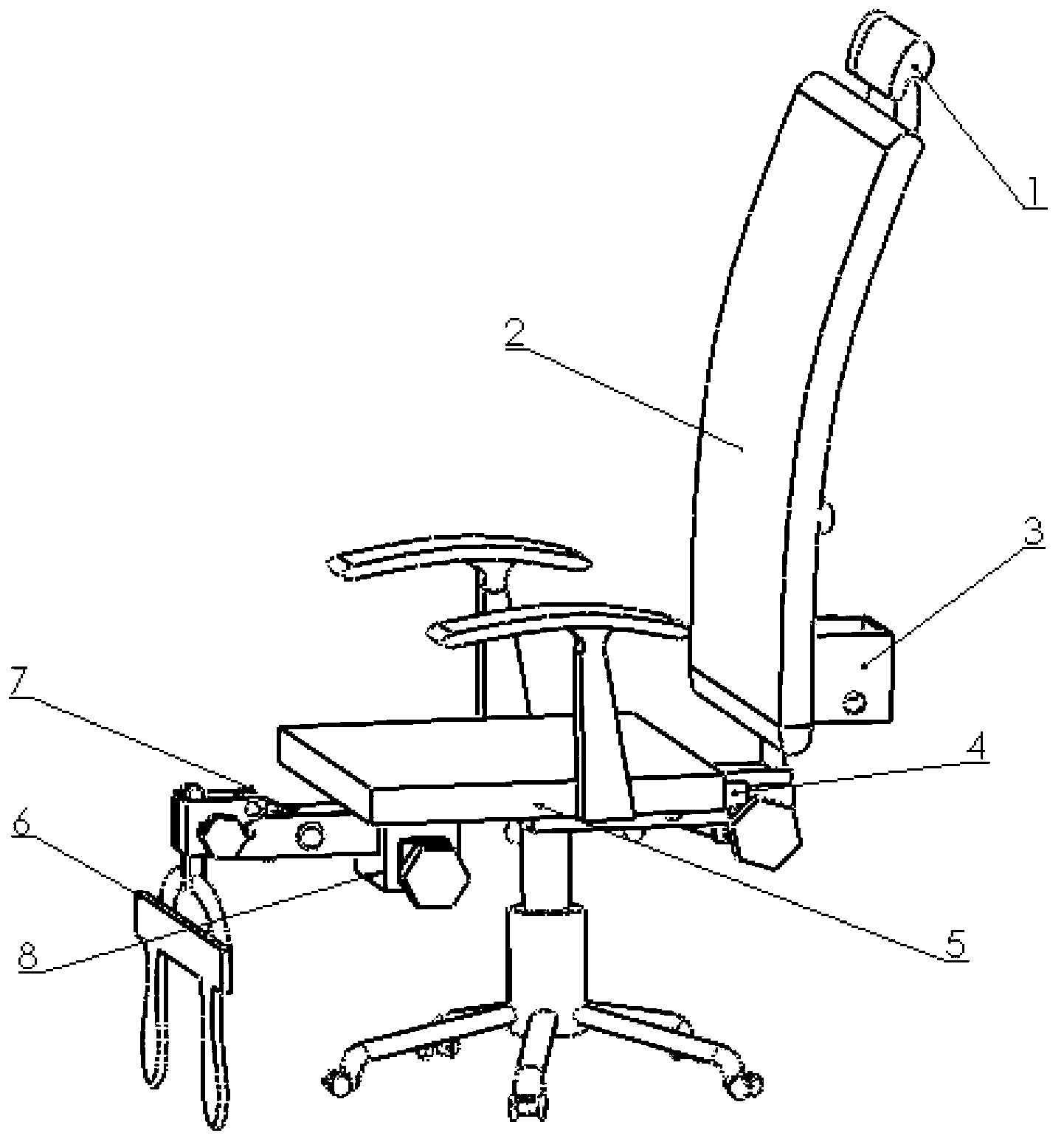

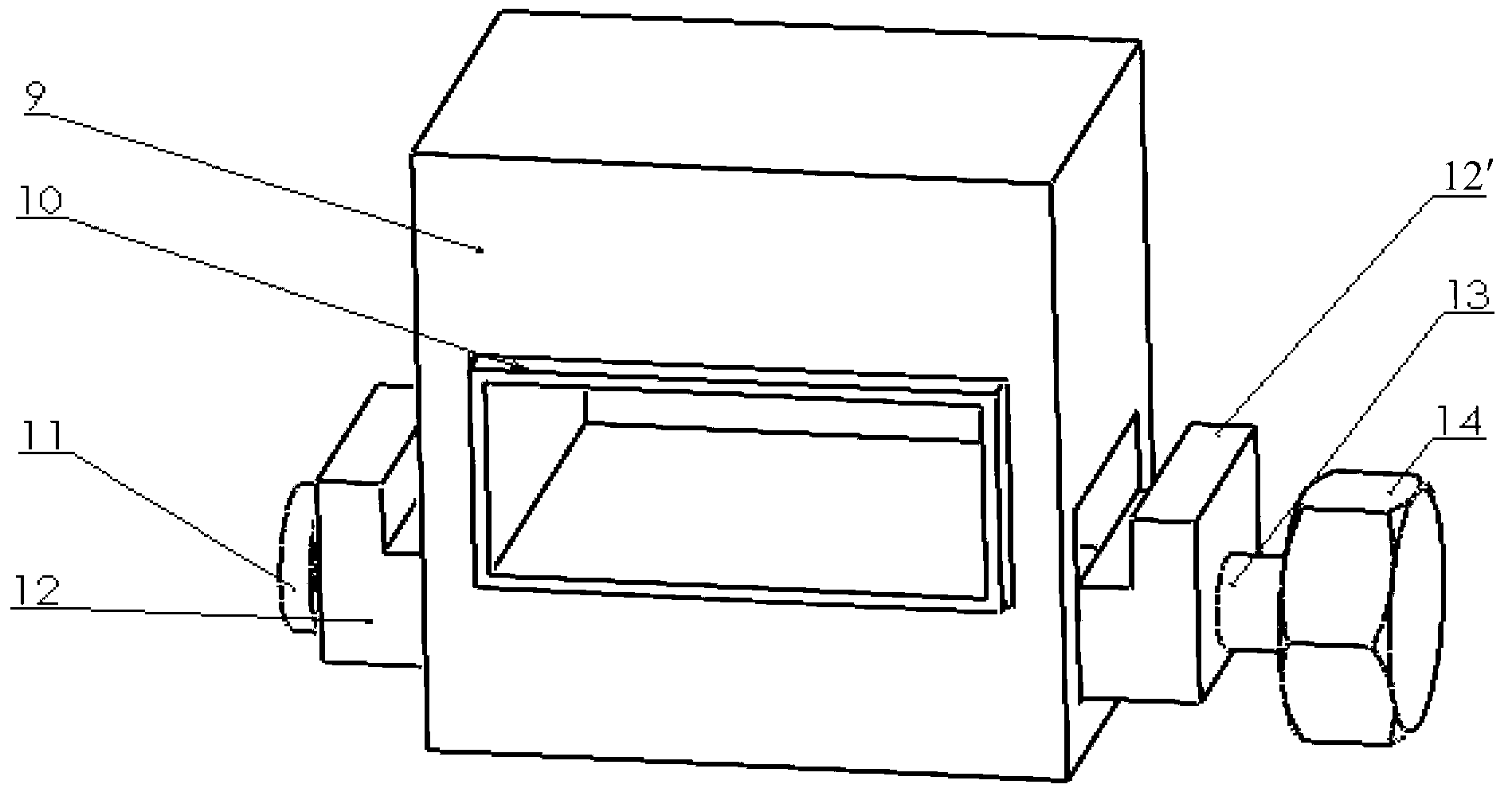

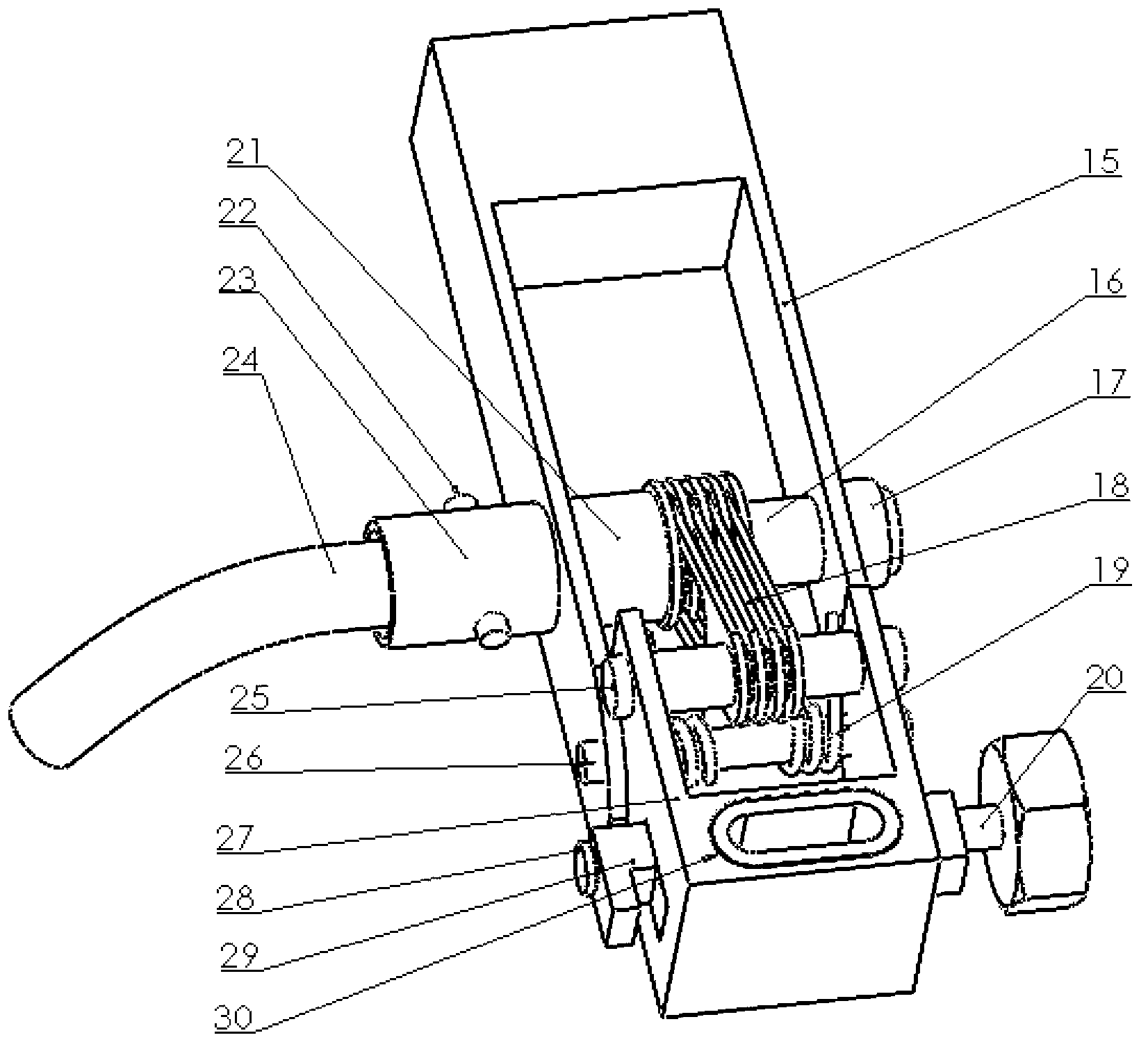

Audio control massage chair

The invention relates to an audio control massage chair, belonging to the field of mechanical and electrical integration. The audio control massage chair is provided with a leg support mechanism, the leg support mechanism can be detached conveniently, the legs can be relieved and freed to certain extent; the chair has a massaging function, so that people can enjoy massaging while resting; the intensity of massage can be controlled by music or according to the set procedures, people can be prevented from feeling bored as a result of the same massaging frequency in a long time, and massaging can be carried out in a special massaging method; the chair has a light structure and good cooling performance and can be moved and adjusted conveniently; and the chair is affordable for workers and hasa wide marketing range.

Owner:NORTHEASTERN UNIV LIAONING

double snake fork

The invention discloses a dual-snake fork. The fork consists of an upper fork, a cross beam, a lower fork, fastening bolts, a handle seat and a handle. The fork is characterized in that the upper fork is two cylindrical bodies perpendicular to each other and like snake heads in shape; the lower ends of the cylindrical bodies are connected integrally and connected with the cross beam integrally; a part extends out of the middle of the upper fork and is connected with the cross beam integrally; the cross beam is a cuboid; the cylindrical handle seat is arranged on one side of the middle of the cross beam; a screw hole is reserved in the middle of the handle seat; and the lower fork adopts an existing flexible conduit and is screwed in screw holes in two ends of the cross beam through the fastening bolts. When an athlete needs to adjust the height of a rest, the bending degree of the lower fork is moved by a hand at will, so that different height demands of the upper fork as the rest in stepless adjustment from low to high can be met; win is achieved by force; the fork is one of pioneered billiard rests with stepless adjustment of lower fork heights; the popularity of a product can be improved in the world; and the honor can be won for China. The fork is skillful in design, simple in structure, easy to manufacture, low in cost, wide in market and high in economic benefit.

Owner:西安丝路知星科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com