Microorganism vitamin premixed material and preparation method

A vitamin premix and vitamin technology, applied in animal feed, animal feed, additional food elements, etc., can solve problems that threaten human health, reduce market competitiveness, consumer trust, and drug residues, and achieve competitiveness and industrialization prospects, improve animal non-specific immunity, and regulate the effect of animal micro-ecological balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

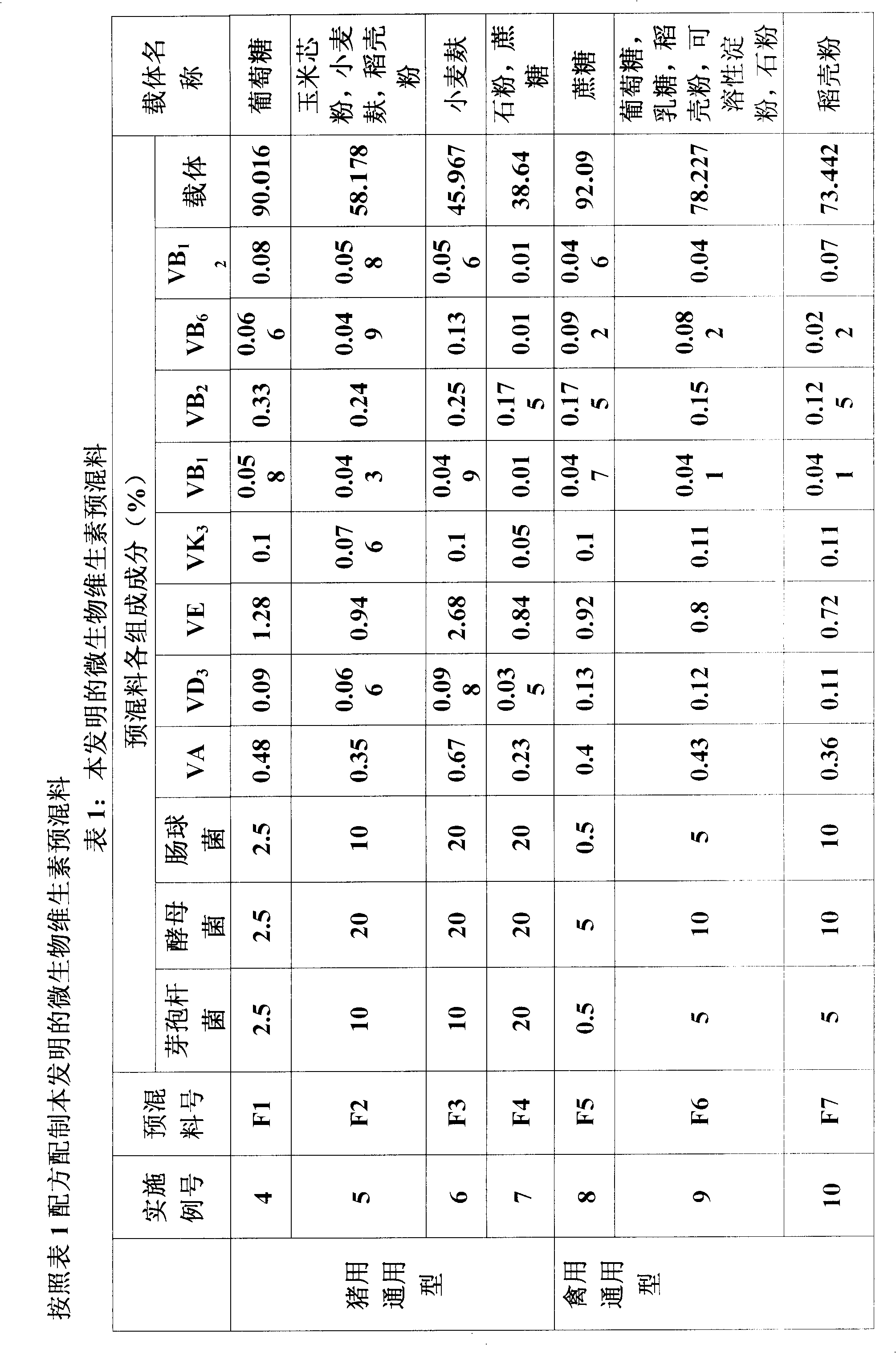

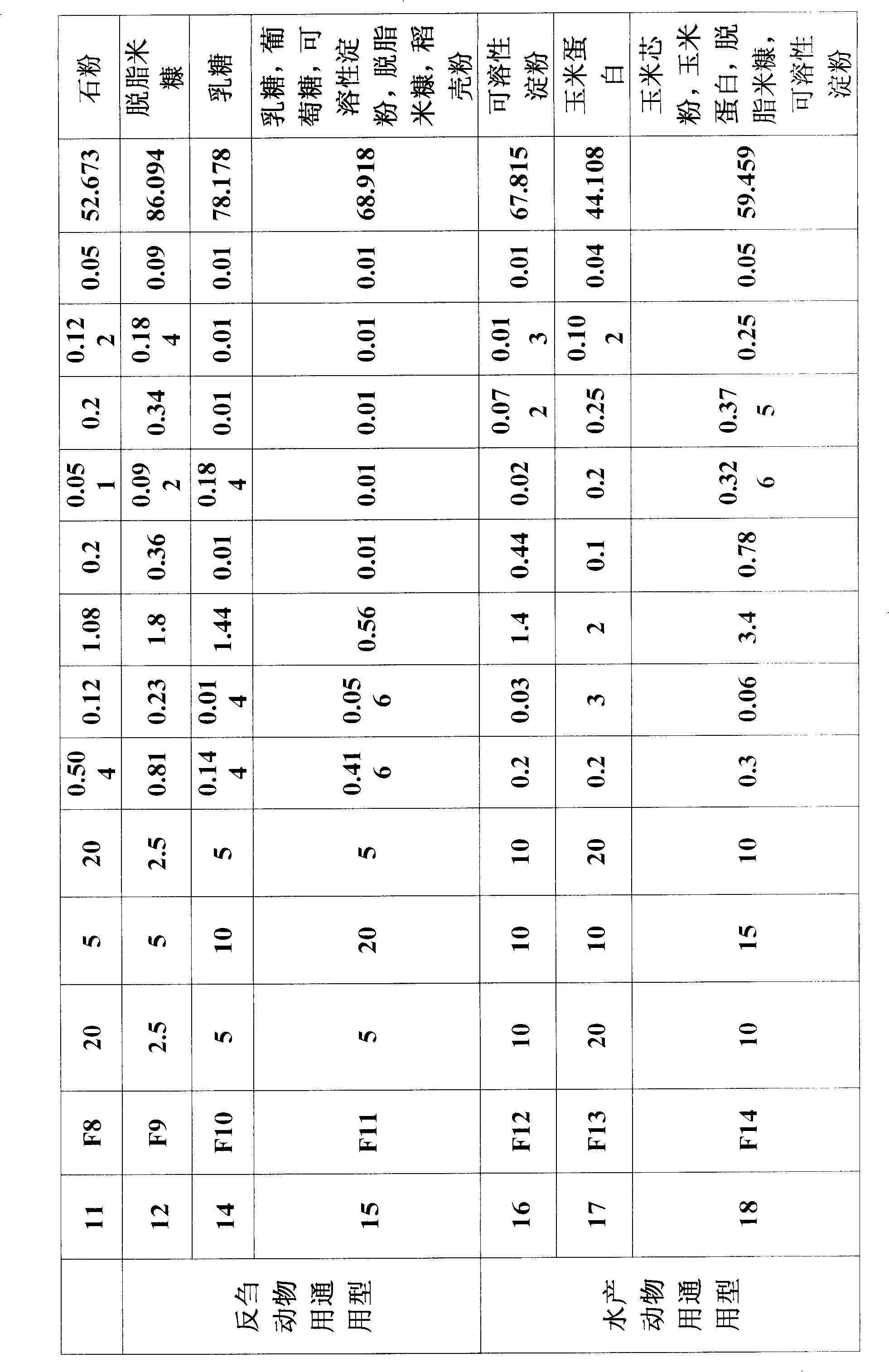

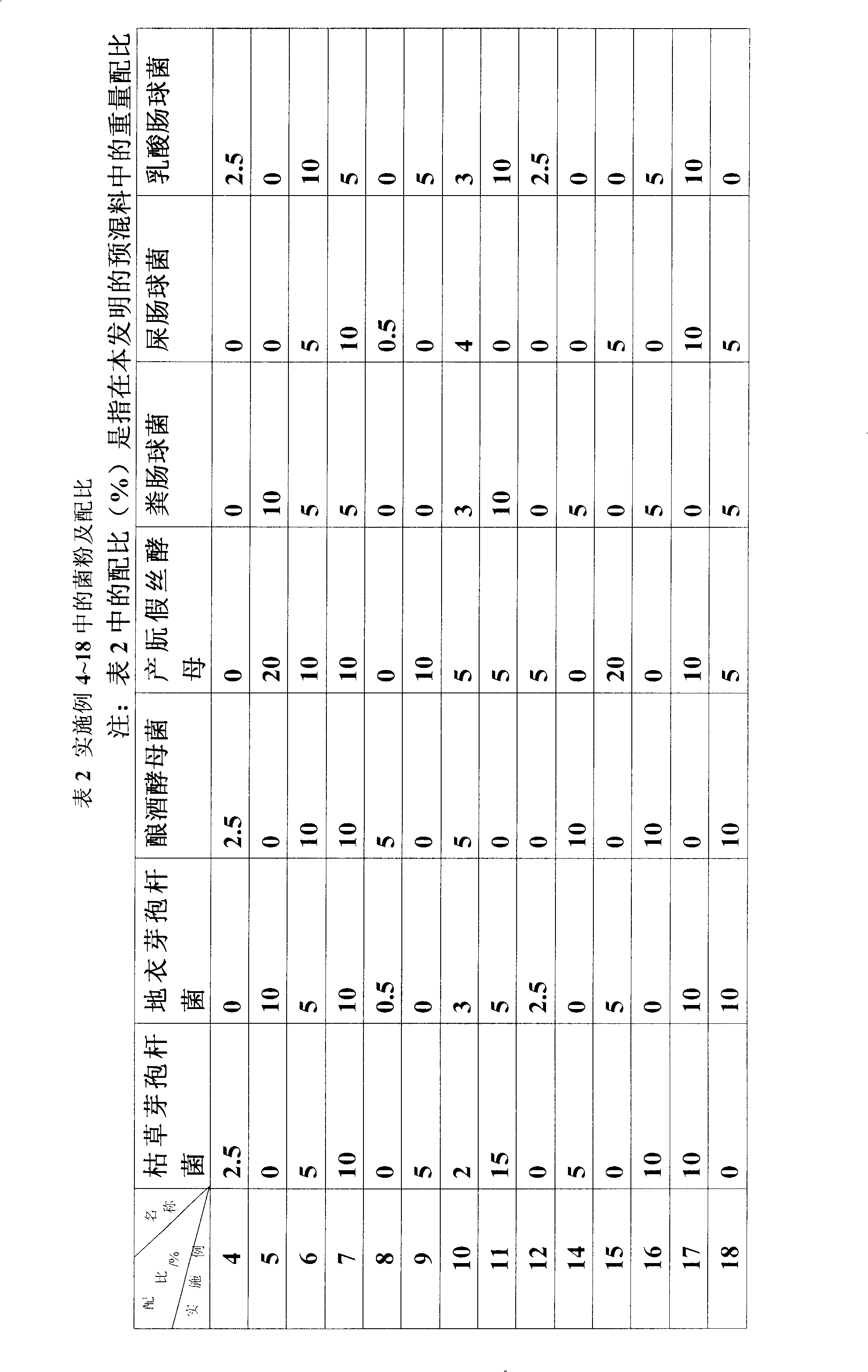

Examples

Embodiment 1

[0031] Embodiment 1: the preparation of bacillus

[0032] The seed medium is a mixed solution (g / L) prepared according to the following ratio: bran 50, fish meal 3.0, soybean meal 10, yeast extract 3.0, sodium hydroxide 2.0, boil water for 1 hour, and neutralize with hydrochloric acid to 6.8-7.0.

[0033] The fermentation medium is a mixed solution (g / L) prepared in the following proportions: bran 50, soybean meal 20, sodium carbonate 0.3, and antifoaming agent 0.4. Sterilized at 121°C for 30 minutes.

[0034] Liquid submerged aerated fermentation culture, seed culture for 8 hours, inoculum size 1%, culture temperature 36-37°C. The stirring speed is 280-300rpm, the tank pressure is 0.06MPa, the air flow rate is 1:0.4-0.6, the relative value of dissolved oxygen is controlled at 80%-90%, and the number of spores is detected after 16 hours of fermentation time. When a large number of spores are observed, put the tank. The fermented liquid is directly spray-dried to make bacillus...

Embodiment 2

[0035] Embodiment 2: the preparation of yeast

[0036] The seed medium is a mixed solution (g / L) prepared according to the following ratio: molasses 70-80, peptone 5-10, ammonium sulfate 1.0, magnesium sulfate heptahydrate 0.5; pH is natural pH, sterilized at 121°C for 30 minutes.

[0037] The fermentation medium is a mixed liquid (g / L) prepared according to the following ratio: molasses 70-80, urea 2-10, sodium chloride 1.0; pH is natural pH, sterilized at 121° C. for 30 minutes.

[0038] Liquid submerged fermentation culture, seed culture for 12 hours, inoculum size 3-6%, culture temperature 28-30°C. The stirring speed is 150-250rpm, the tank pressure is 0.06MPa, the air flow rate is 1:0.4-0.6, the relative value of dissolved oxygen is controlled at 80%-90%, and after 24 hours of fermentation time, the number of colonies is detected to be qualified and the tank is released.

[0039] The fermented liquid is vacuum-concentrated at low temperature to 40% of the original volume...

Embodiment 3

[0041] Embodiment 3: the preparation of enterococcus

[0042] The seed medium is a mixed solution (g / L) prepared according to the following ratio: glucose 10-30, yeast extract 5-15, dipotassium hydrogen phosphate 2.0-5.0; potassium dihydrogen phosphate 2.0-5.0; pH is natural pH , sterilized at 121°C for 30 minutes.

[0043] The fermentation medium is a mixed solution (g / L) prepared in the following proportions: glucose: 10-30, yeast extract 2.0-10, sodium chloride 1.0. The pH is natural pH, sterilized at 121°C for 30 minutes.

[0044] For fermentation culture, seeds are cultivated for 12 hours, the inoculum size is 3-6%, and the culture temperature is 30-35°C. The fermentation time is 24 to 50 hours, and after the fermentation time is 24 hours, the number of colonies is detected to be qualified, and then the tank is released.

[0045] The fermented liquid is vacuum-concentrated at low temperature to 30% to 60% of the original volume, and a carrier is added to the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com