Preparation method of antibacterial and flame-retardant garment fabric

A fabric and clothing technology, applied in the field of special fabric textile production, can solve the problems of high synthesis cost and limited selection of fabric materials, and achieve the effects of prolonged antibacterial performance, less chemical waste, high production efficiency and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

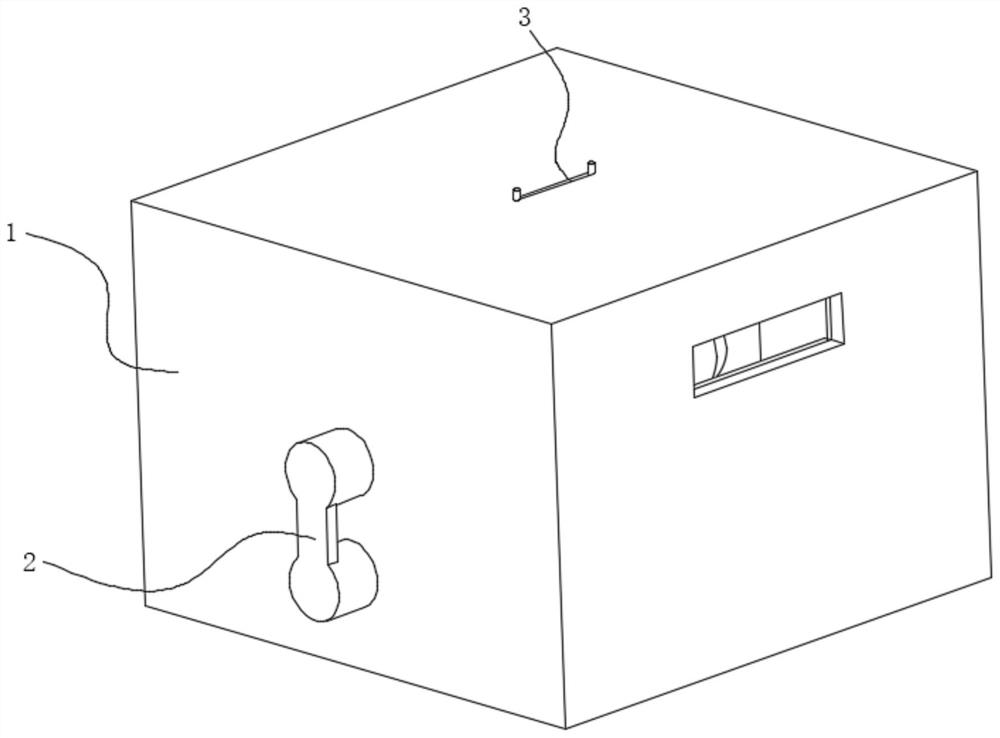

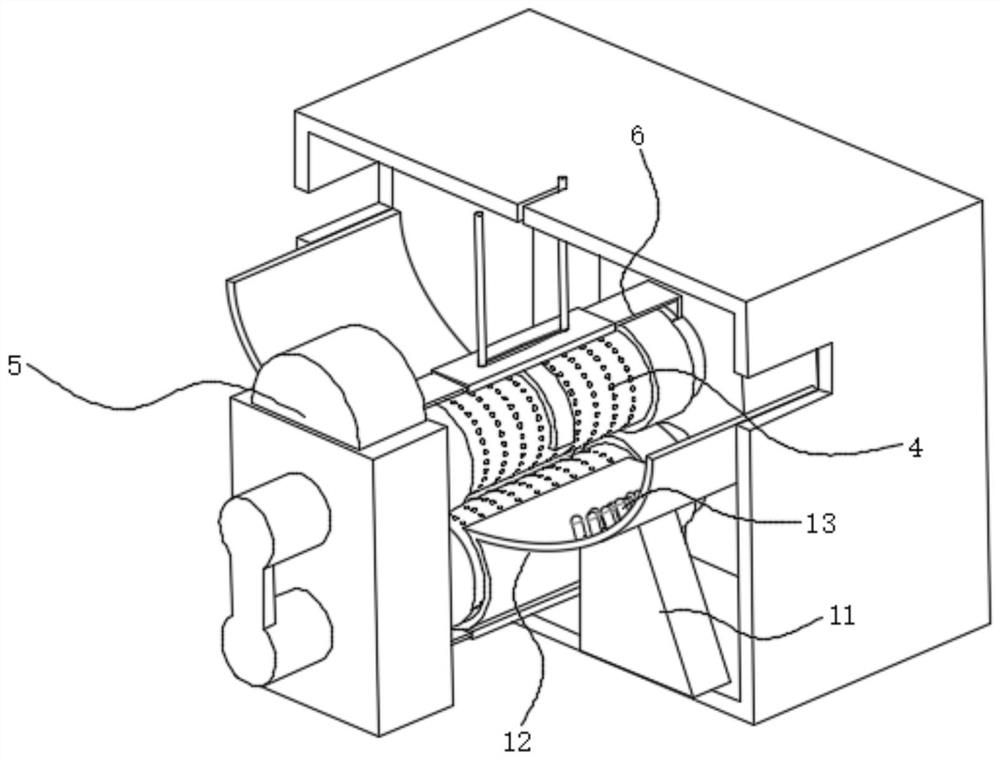

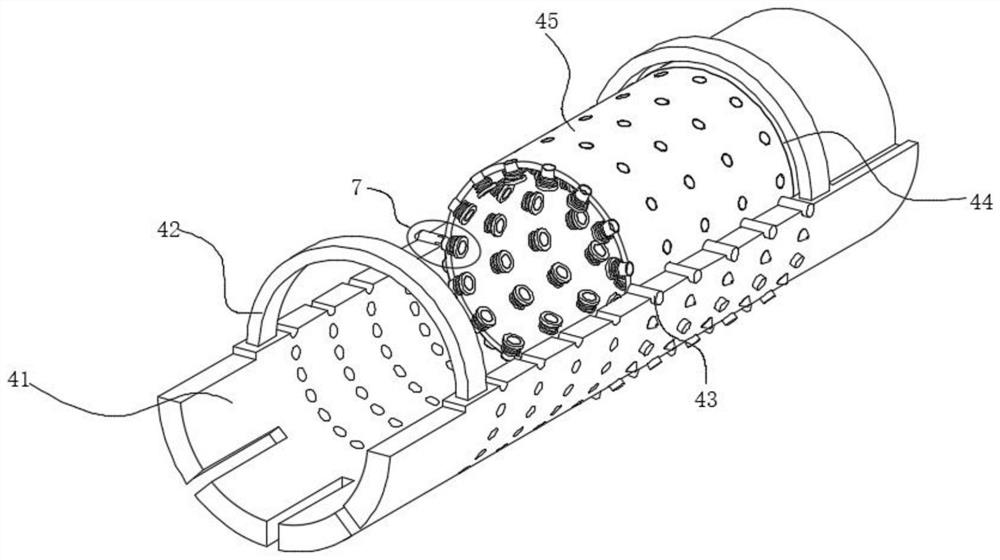

[0039] use Figure 1-Figure 7 The preparation method of an antibacterial and flame-retardant clothing fabric according to an embodiment of the present invention is described as follows.

[0040] Such as Figure 1-Figure 7 Shown, the preparation method of a kind of antibacterial flame-retardant clothing lining of the present invention, comprises the following steps:

[0041] S1: Prepare two cotton fabrics to be processed, stack the two cotton fabrics together, and evenly add polystyrene caprolactone solid particles between the fabrics;

[0042] S2: Use fine thread to sew two pieces of fabric together, and then put them into the fabric processing machine for processing;

[0043] S3: Inject a mixed solution of aluminum hydroxide and a silicon compound into the upper barrel, then seal the upper barrel and insert it into the fabric processing machine;

[0044] S4: Start the fabric processing machine to repeatedly press the inner fabric;

[0045] S5: After a period of processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com