Oxygen-enriched top-blown copper smelting combined with a method for treating waste printed circuit boards

An oxygen-enriched top-blowing and waste printing technology, which is applied in the field of oxygen-enriched top-blowing copper smelting and processing of waste printed circuit boards, can solve the problems of high energy consumption, strict requirements on raw material particle size, composition, process conditions, and complex pretreatment process. , to achieve the effect of high reaction temperature, strong adaptability of raw materials, and inhibition of dioxin formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

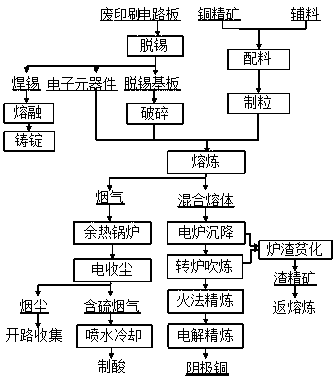

[0040] Referring to the accompanying drawings, the method for oxygen-enriched top-blown copper smelting combined with processing waste printed circuit boards is as follows:

[0041] (1) Heating detinning treatment: heat the waste printed circuit board at 200°C to remove the solder, obtain solder, detinned substrate and electronic components, melt the solder and cast ingots, screen and separate the electronic components, and send the detinned substrate into step (2);

[0042] (2) Crushing treatment: coarsely crush the detinned substrate to 50mm×50mm with a crusher;

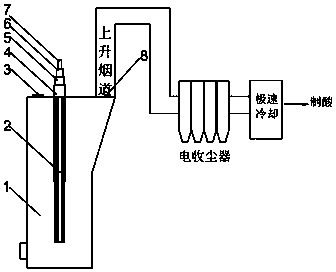

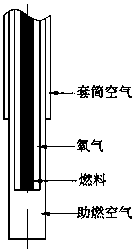

[0043] (3) Mixed smelting: send the crushed detinned substrate and electronic components to the furnace top feeding port 3 at a rate of 6 t / h with a belt conveyor, and continuously and evenly feed them into the oxygen-enriched top-blown furnace 1;

[0044] Using high-silicon river sand and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com