High-load helium compressor cascade structure with self-suction function

A compressor and high-load technology, applied in the field of compressors, can solve the problems of low compression efficiency, low pressure ratio, difficult compression, etc., and achieve the effects of preventing suction surface separation, increasing load, good economy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

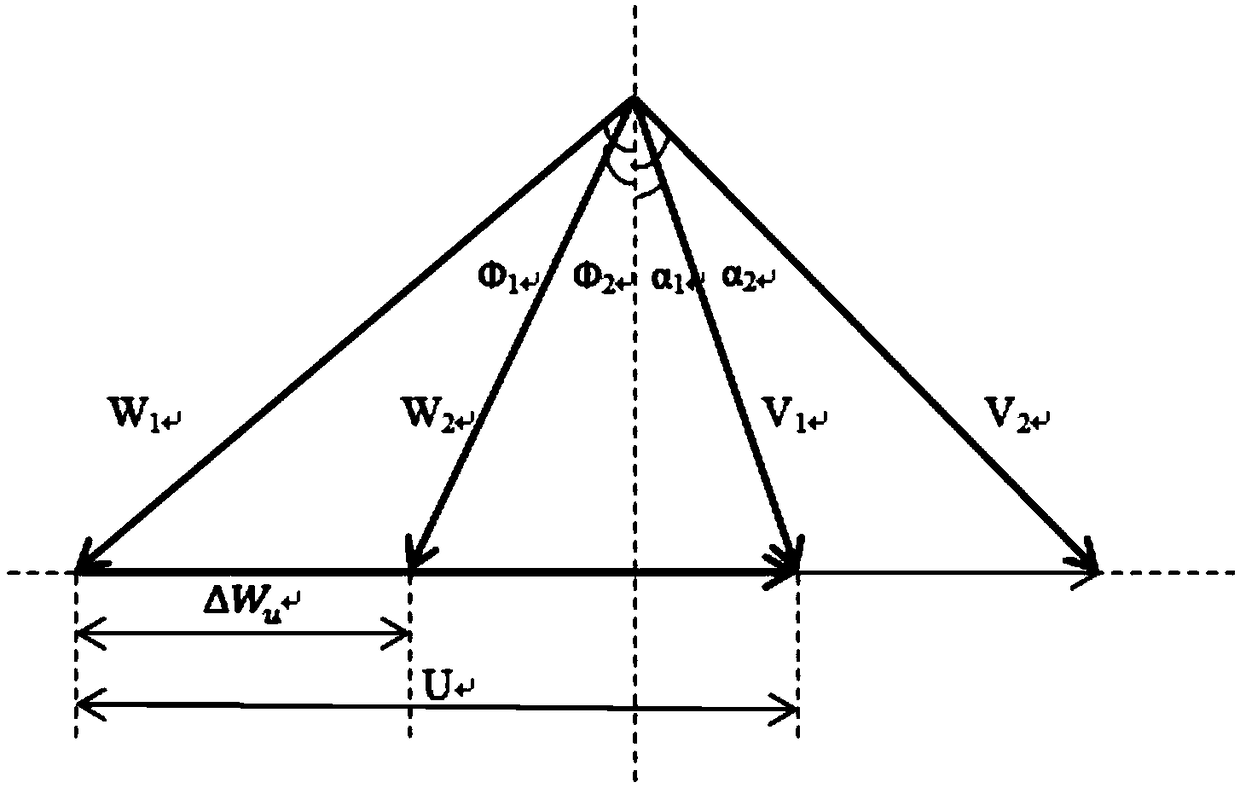

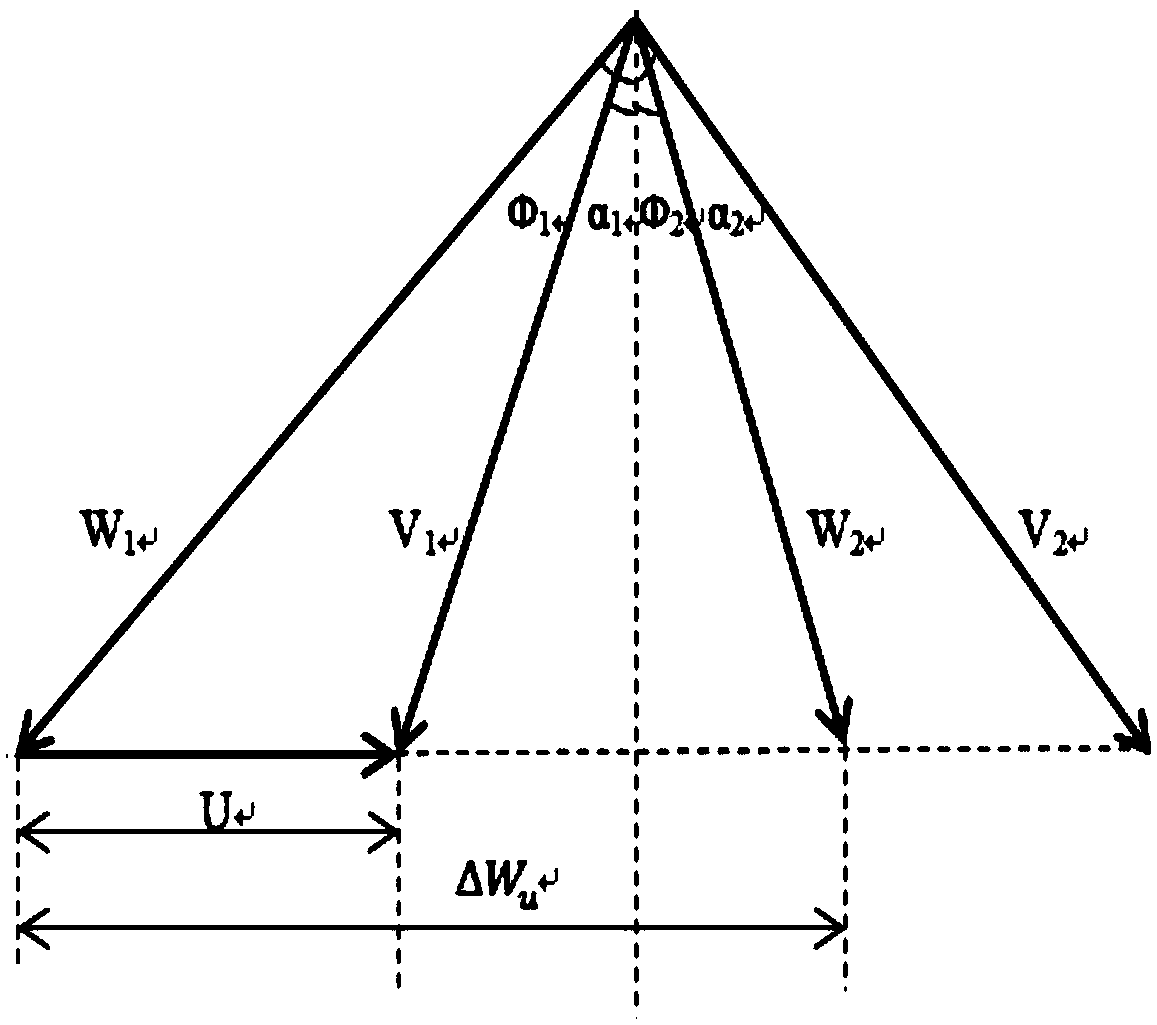

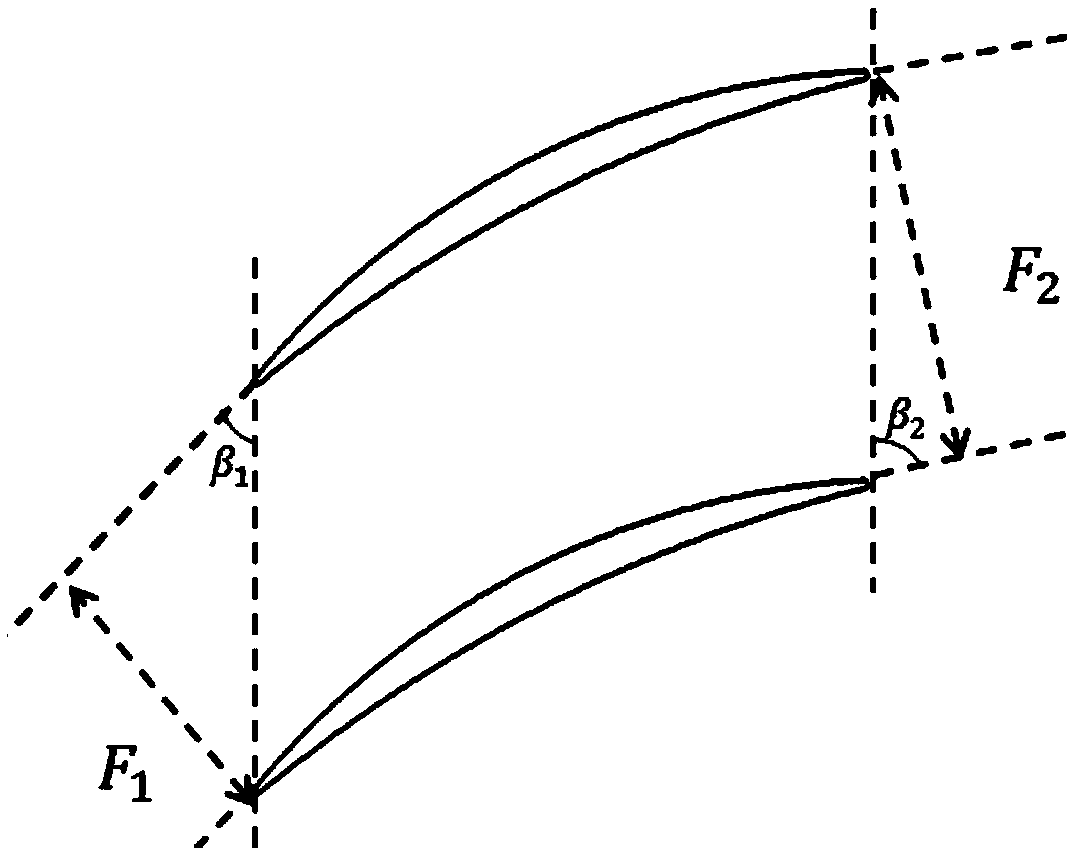

[0015] combine Figure 1-7 , the structure of the compressor cascade is an expansion-shrinking cascade, that is, the inlet of the cascade expands within the range of 70%-80% of the chord length and the last 20%-30% of the chord length shrinks to the outlet of the cascade (F3>F2> F1), applied to high-load helium compressors; the compressor increases the twisting speed by increasing the negative pre-swirl to increase the processing capacity of the compressor; the contraction structure of the compressor is generally located at the last 20% of the chord length of the cascade- In the range of 30%, the airflow accelerates in the constriction channel to produce a self-suction effect, thereby inhibiting the further development of the boundary layer, and achieving the purpose of improving the efficiency and stability of the compressor.

[0016] From Euler's basic equation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com