Composite drill bit for submarine natural gas hydrate layer

A hydrate and layer composite technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of sticking, formation of mud bags, and difficulty in inhaling hydrate recovery channels, so as to prevent sticking and improve rock breaking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

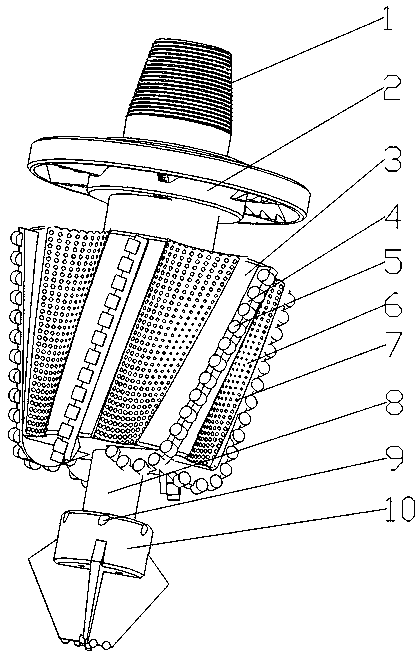

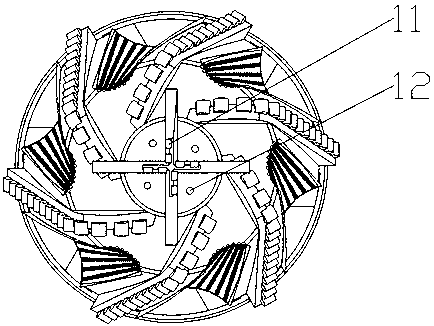

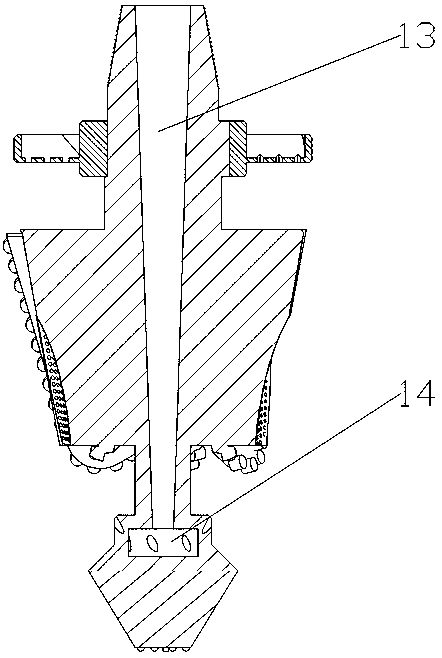

[0031] Such as Figure 1~3As shown, the present invention relates to a composite drill bit for a subsea natural gas hydrate layer. Its main structure is divided into three layers. The first layer is a collar hole drill body. Connecting, the drill body 10 of the collar hole drill body is cylindrical, and its cutting part includes a pyramid-shaped scraping edge 22 integrated with the drill body and a cylindrical drill tooth 11 inlaid at the bottom of the structure. There are tapered flow channel 13, diffuser cavity 14, drilling fluid injection hole one 12, and drilling fluid injection hole two 9 inside the drill bit. The tapered flow channel 13 extends from the top to the top of the diffuser cavity 14. The pressure chamber 14 is cylindrical and is located inside the drill body 10 of the collar bit body. The first drilling fluid injection hole 12 and the second injection hole 9 are respectively located at the bottom and side of the diffuser chamber 14 . The second layer is the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com