Axial flow pump impeller and axial flow pump

A technology for axial flow pumps and impellers, applied in axial flow pumps, pumps, components of pumping devices for elastic fluids, etc., can solve the problems of reduced hydraulic performance, high construction costs, complex structures, etc., and achieve lift and efficiency Satisfy, increase the axial velocity, reduce the effect of impact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

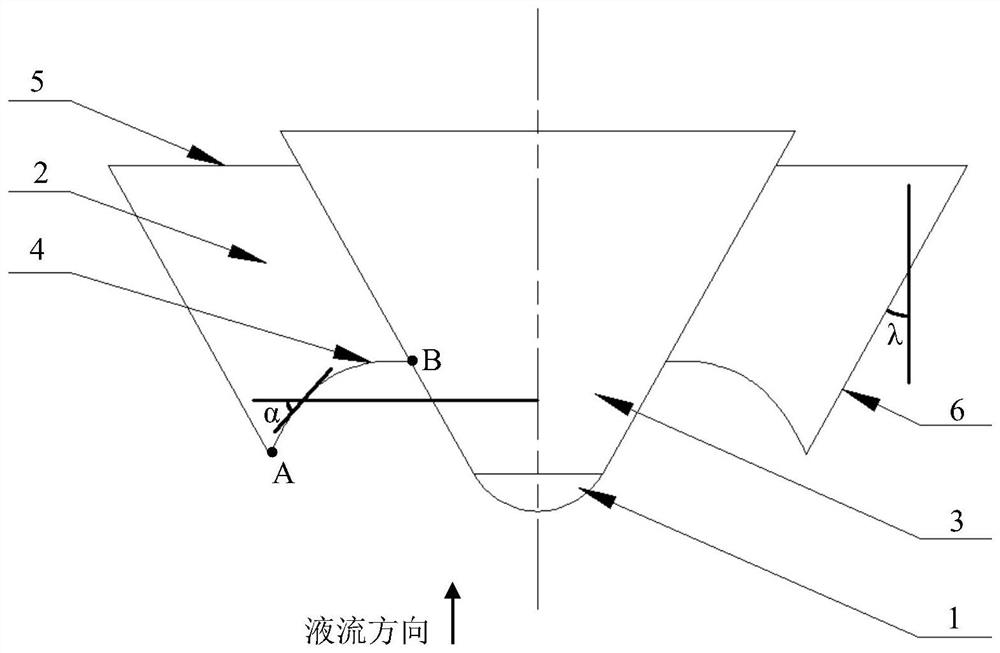

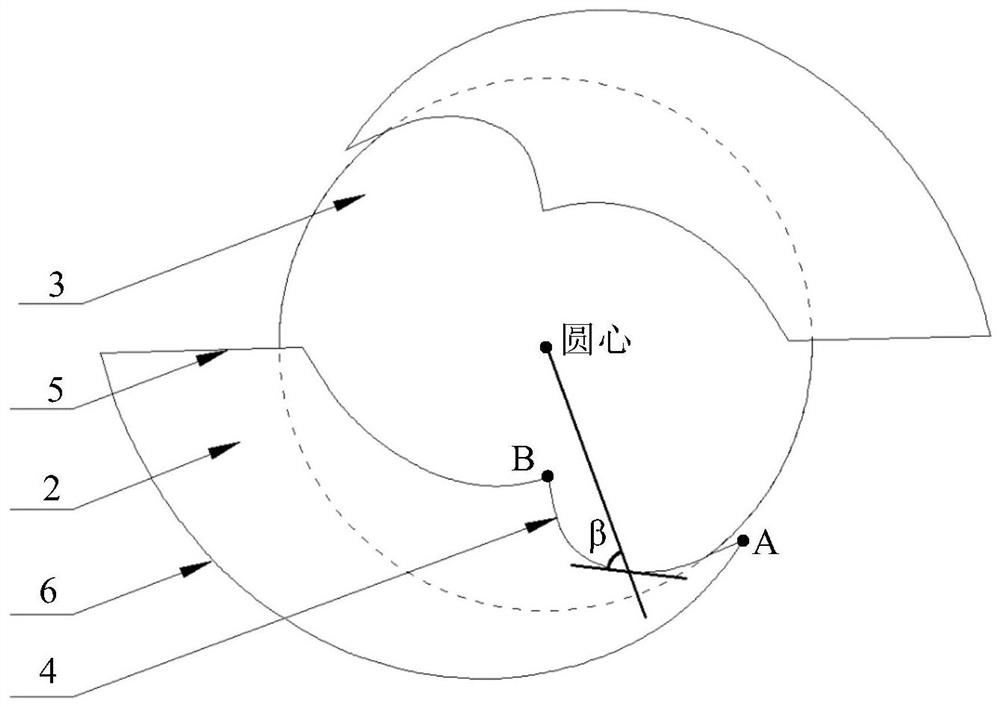

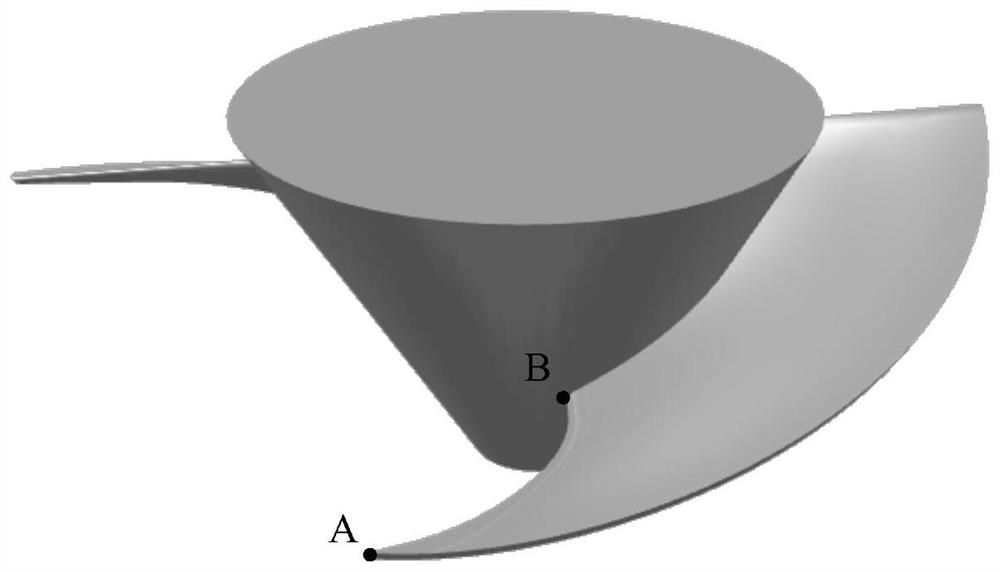

[0029] see figure 1 , figure 1 It is an axial view of an axial flow pump impeller provided by the embodiment of the present invention. The axial flow pump impeller is mostly used in large pumping stations, and its ND value is generally within 350, where N is the rotational speed (rpm), and D is the outer surface of the impeller. diameter (m). like figure 1 As shown, the impeller of the axial flow pump mainly includes a diversion cap 1, an impeller blade 2 and an impeller hub 3;

[0030] The diversion cap 1 is a partial structure of a sphere, the impeller hub 3 is a circular platform structure, the diversion cap 1 is connected to the bottom of the impeller hub 3, and the bus line of the impeller hub 3 is tangent to the outline of the partial structure of the sphere;

[0031] The impeller blade 2 is fixed on the impeller hub 3, and the impeller blade 2 includes a blade leading edge 4, a blade trailing edge 5 and a blade rim 6; the radius of the blade rim 6 gradually increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com