Patents

Literature

56results about "Vibration control device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

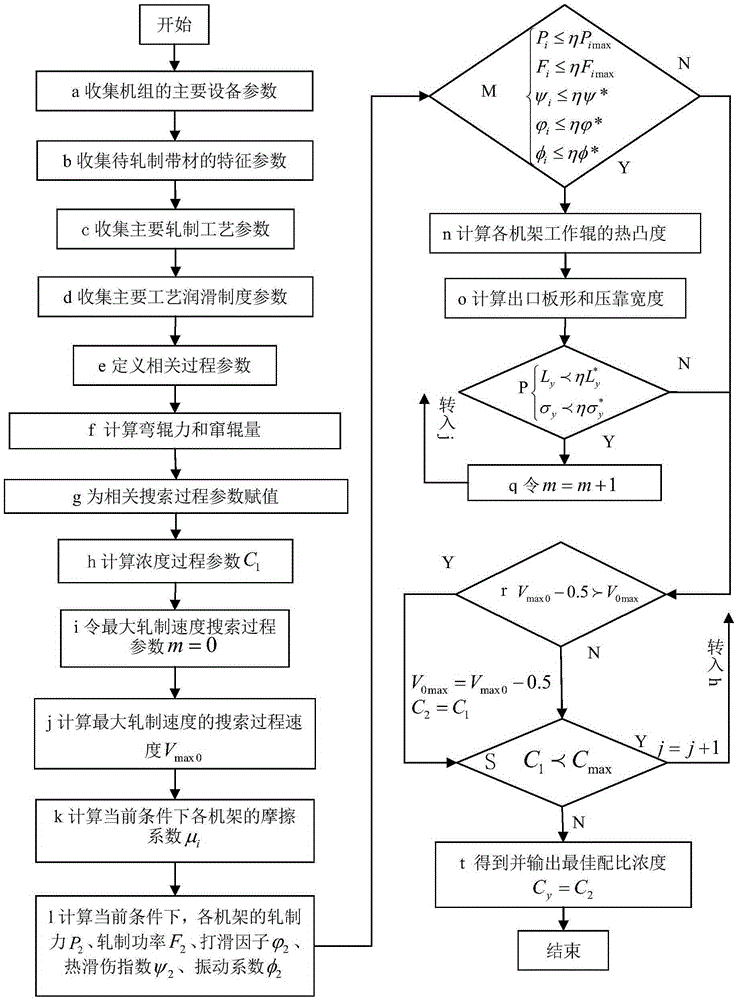

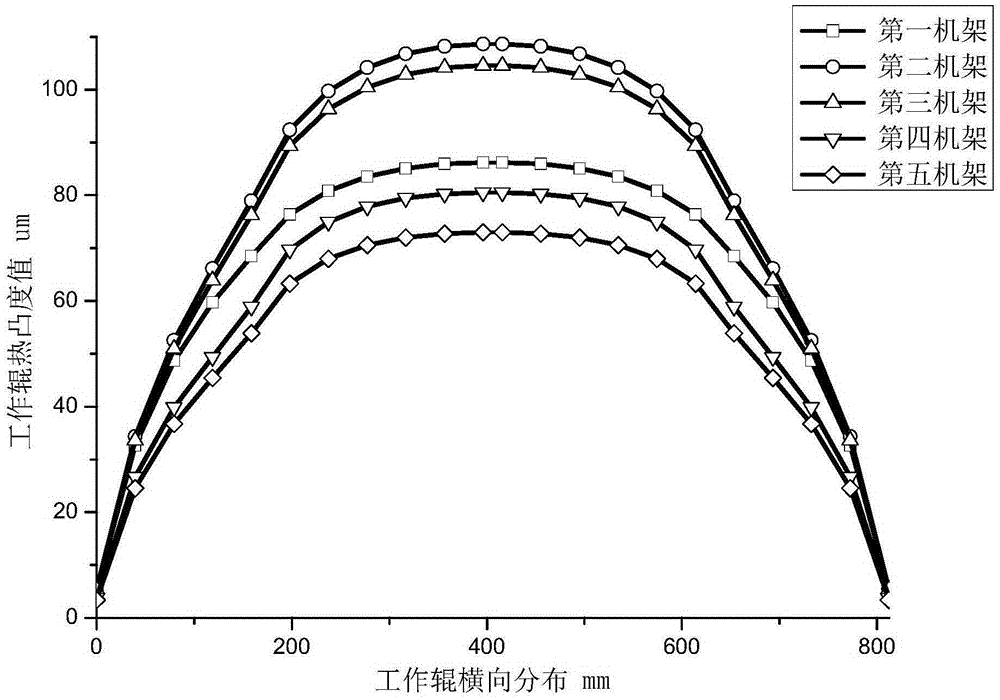

Method for setting concentration of emulsion in rolling of five-rack cold continuous rolling unit extremely thin band

InactiveCN103544340AIncrease rolling speedGuaranteed rolling efficiencyVibration control deviceSpecial data processing applicationsEmulsionBending force

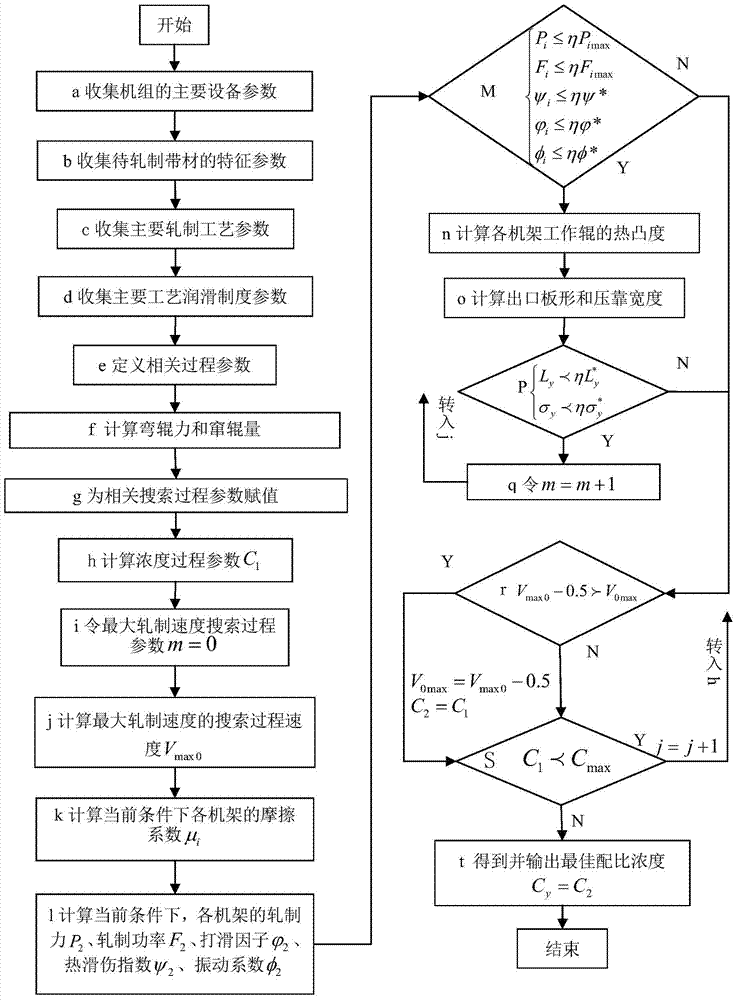

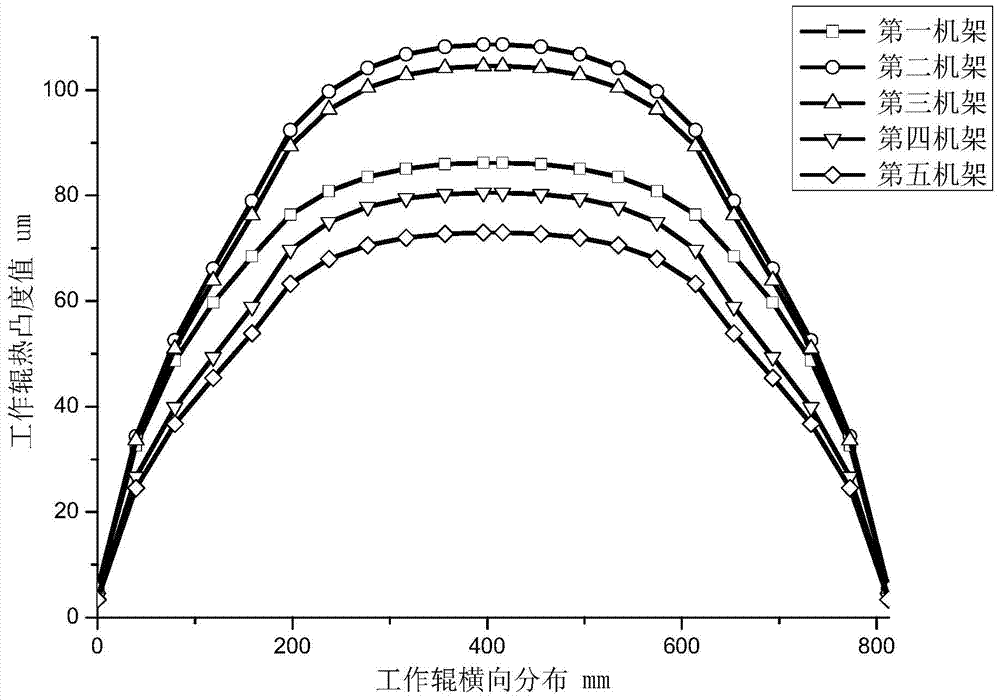

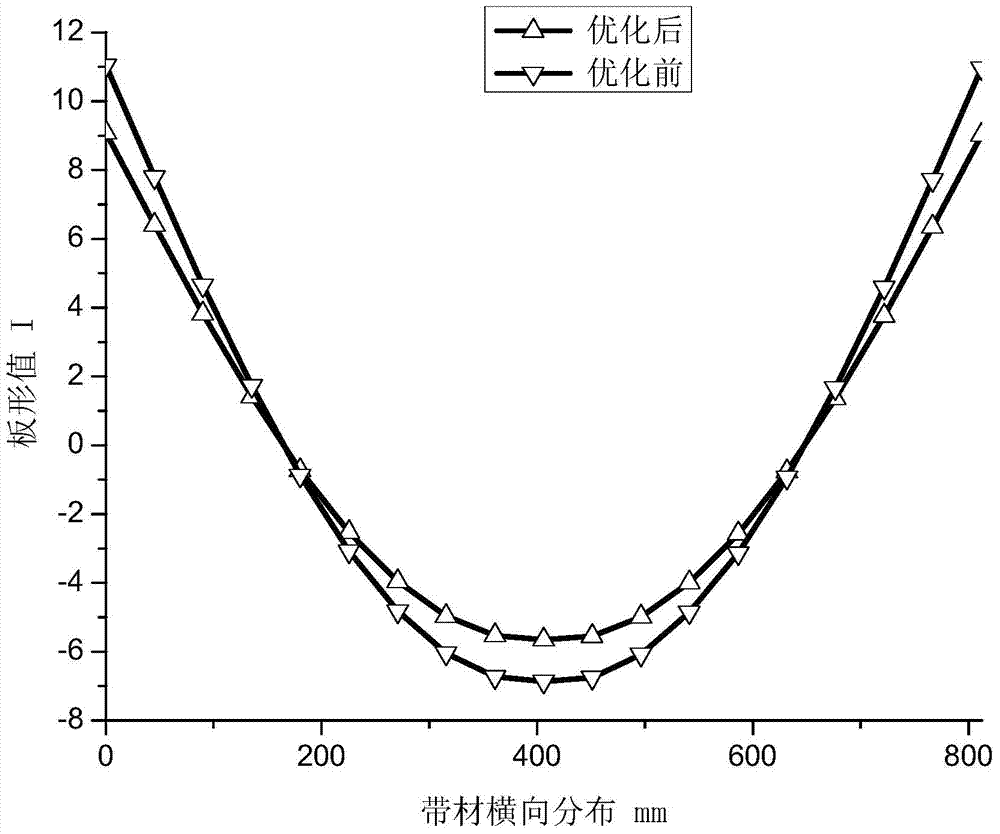

The invention discloses a method for setting concentration of emulsion in rolling of a five-rack cold continuous rolling unit extremely thin band. The method includes the following steps: (1) collecting characteristic parameters of main devices of a unit and to-be-rolled bands, main rolling process parameters and process lubricating system parameters, (2) defining related process parameters, (3) computing roll bending force and the roll channeling amount, (4) assigning related search process parameters, (6) computing concentration process parameters, (6) computing the search process speed of the highest rolling speed, (7) computing friction coefficients of various racks under the current condition, (8) computing rolling force, rolling power, slip factors, heat slip damage indexes and vibration coefficients of the various racks under the current condition, (9) computing heat convexity degrees of working rollers of the various racks, (10) computing an exit plate shape and the pressing width, and (11) obtaining and outputting the optimum proportion concentration. The steps are executed by a computer. According to the method, the rolling speed can be quickened, the rolling efficiency can be guaranteed, slip, heat slip damage and vibration are avoided, and it is guaranteed that the exit plate shape of the final rack and the pressing width of the roller ends of the working rollers are the smallest.

Owner:唐山扬邦钢铁技术研究院有限公司

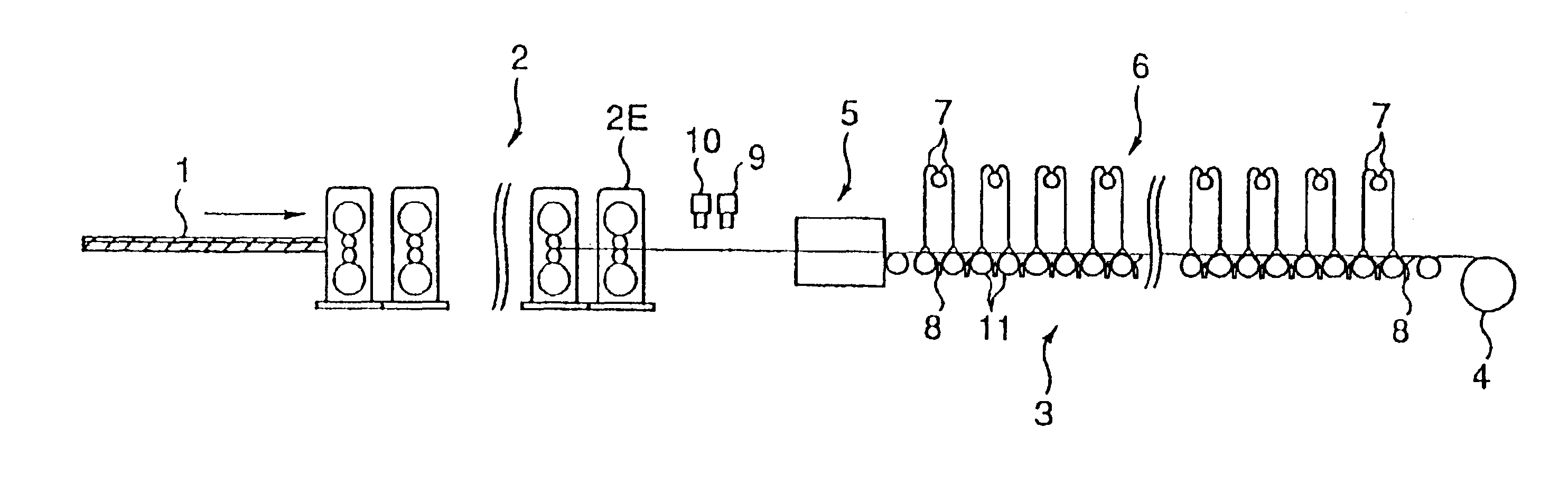

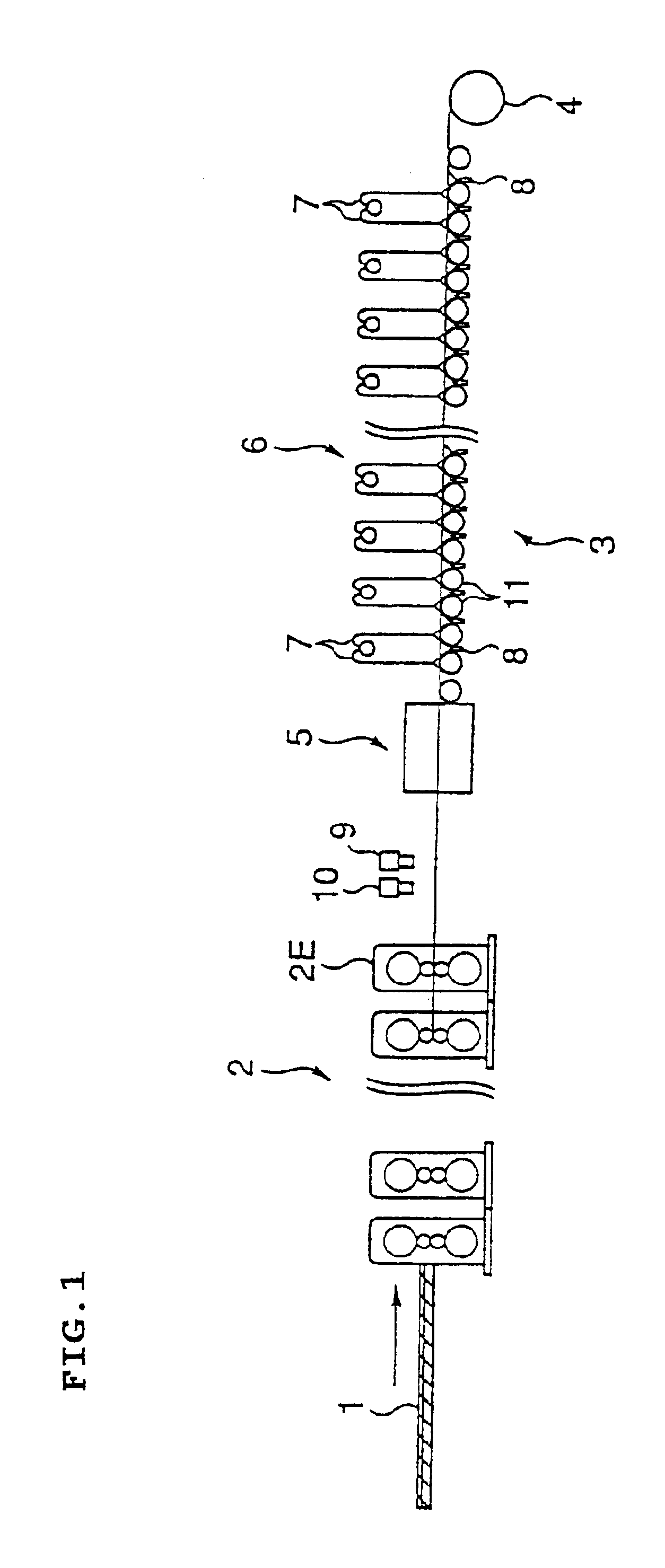

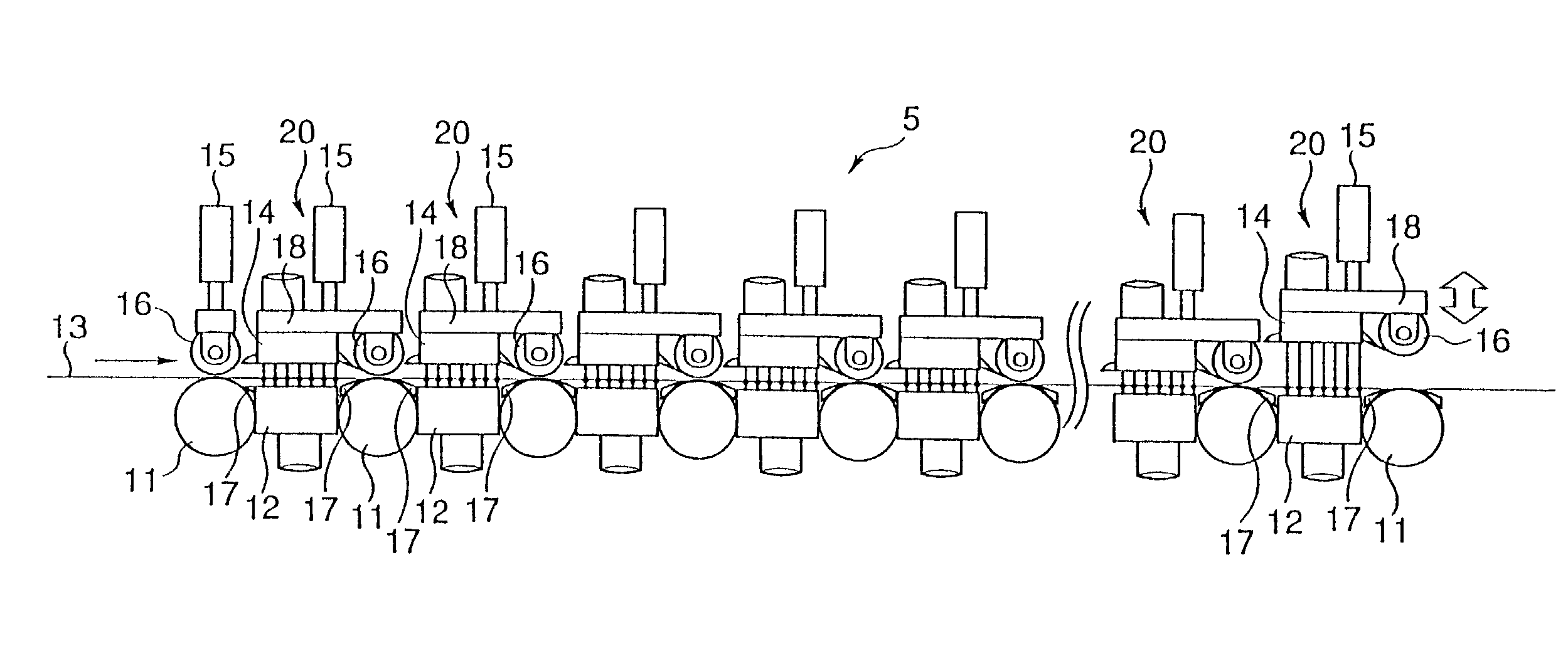

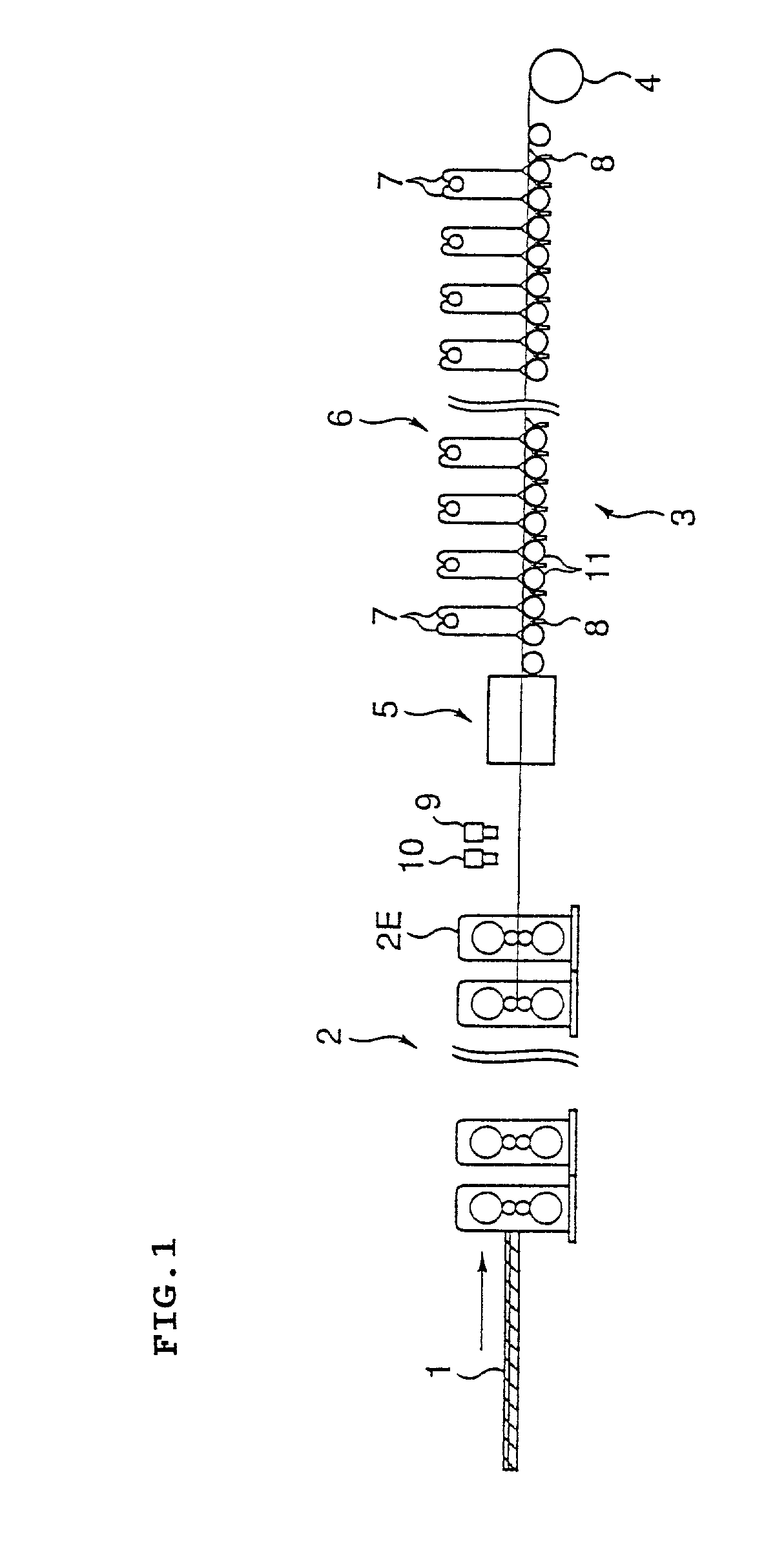

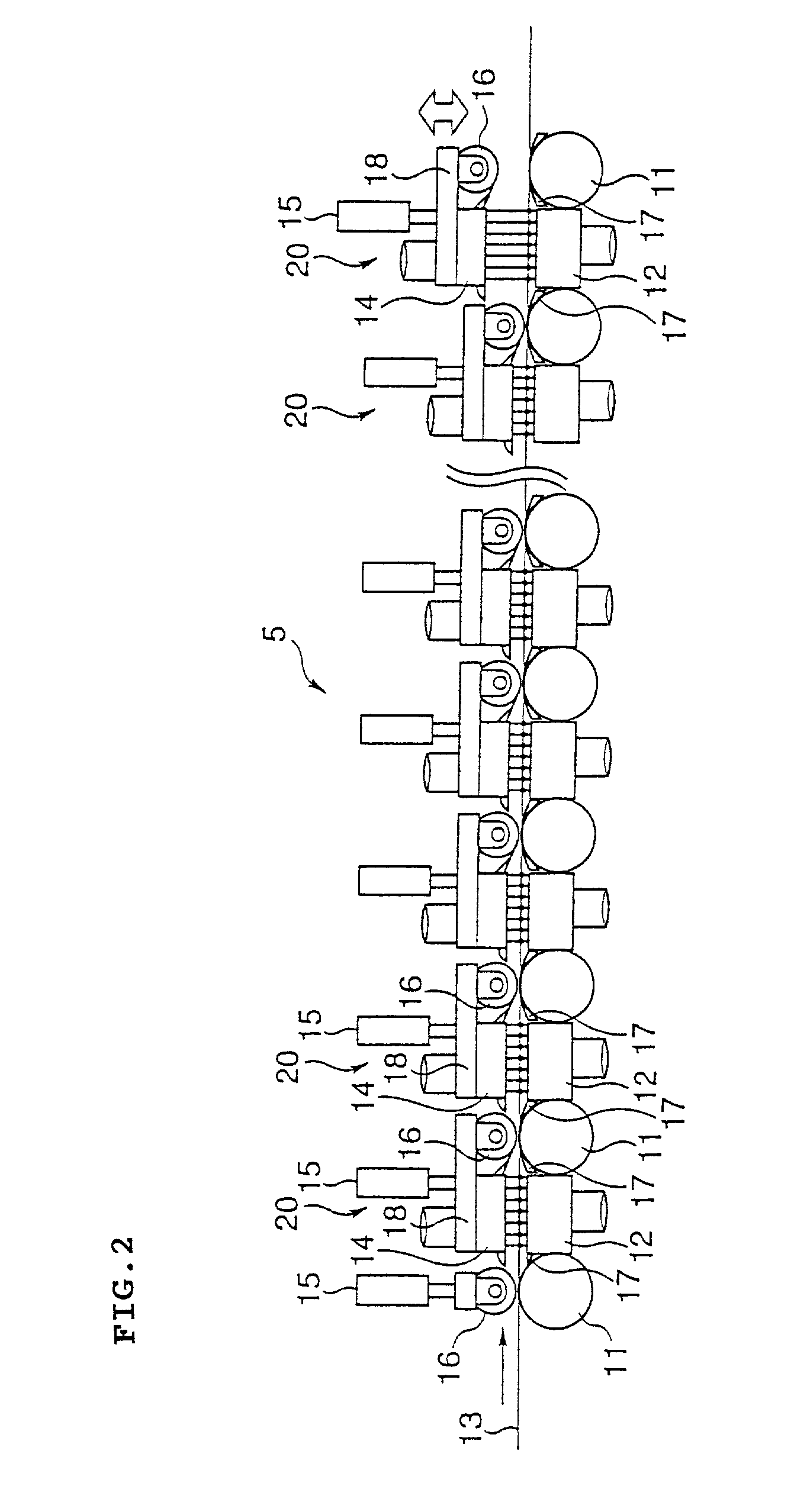

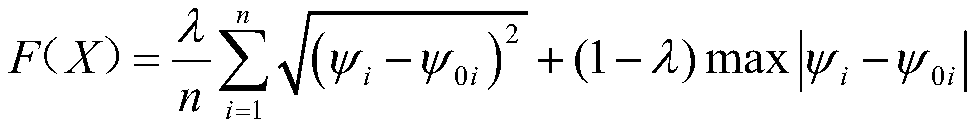

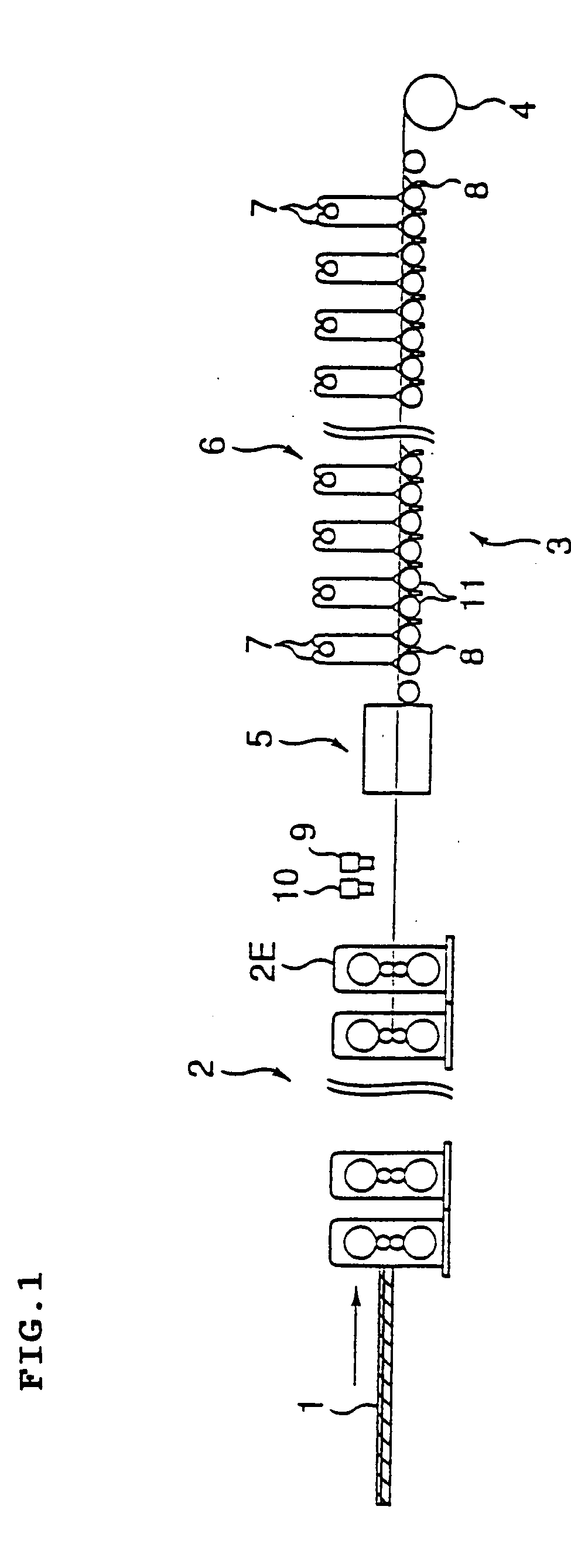

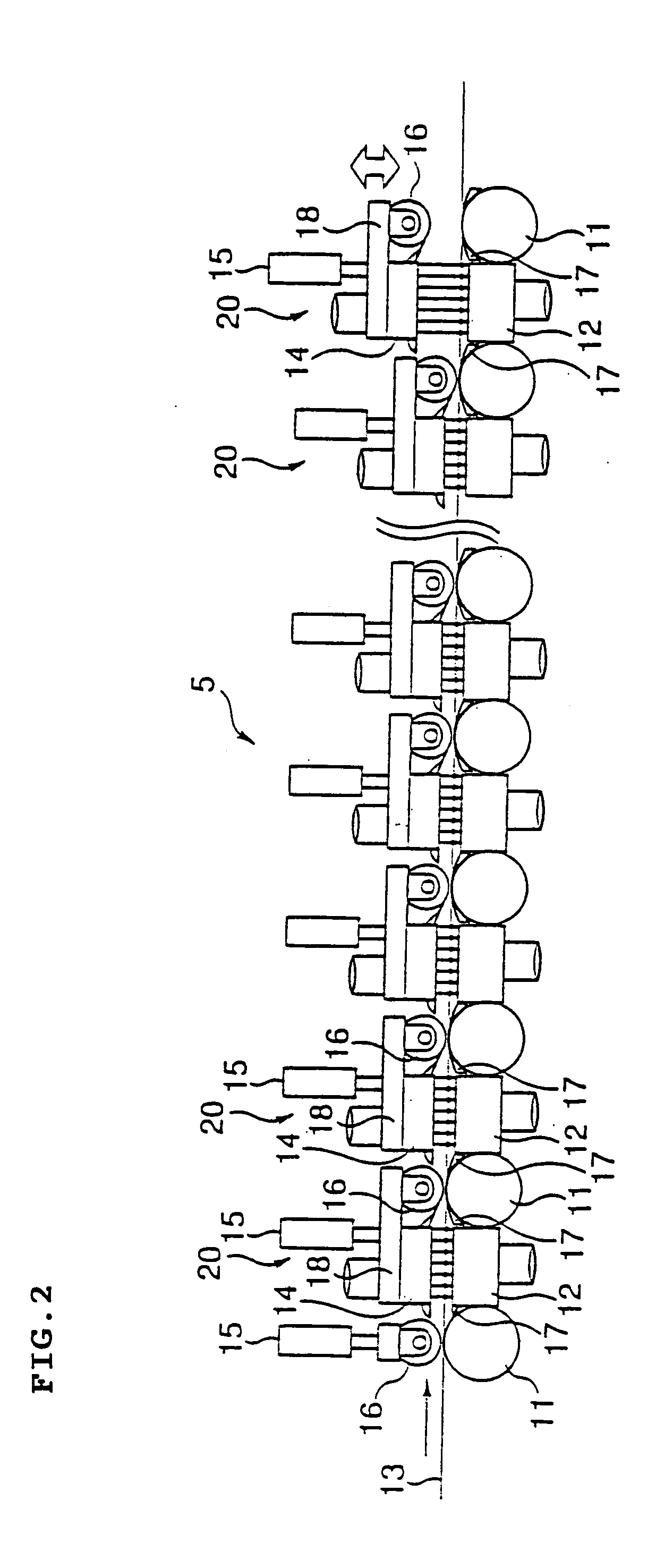

Method and apparatus for cooling hot rolled steel strip, and method for manufacturing hot rolled steel strip

InactiveUS6733720B2Efficient dischargeFine granularityBlast furnace detailsCooling devicesSurface coolingSteel belt

A lower surface cooling box 12 is arranged between transfer rolls 11 on a runout table 3 and an upper cooling box 14 moving freely is arranged at a position corresponding to the cooling box 12 to eject cooling water to the steel strip symmetrically in the vertical direction. The steel strip passes the center of converge of cooling water from upper and lower surfaces of the steel strip. A water breaking roll 16 is provided elevating freely at least at the outlet side rotating at the same peripheral speed as the transfer rolls and is rotated to lower concurrently with passing of the steel strip top at the cooling apparatus. The upper cooling box is also lowered concurrently to cool the steel strip.

Owner:JFE STEEL CORP

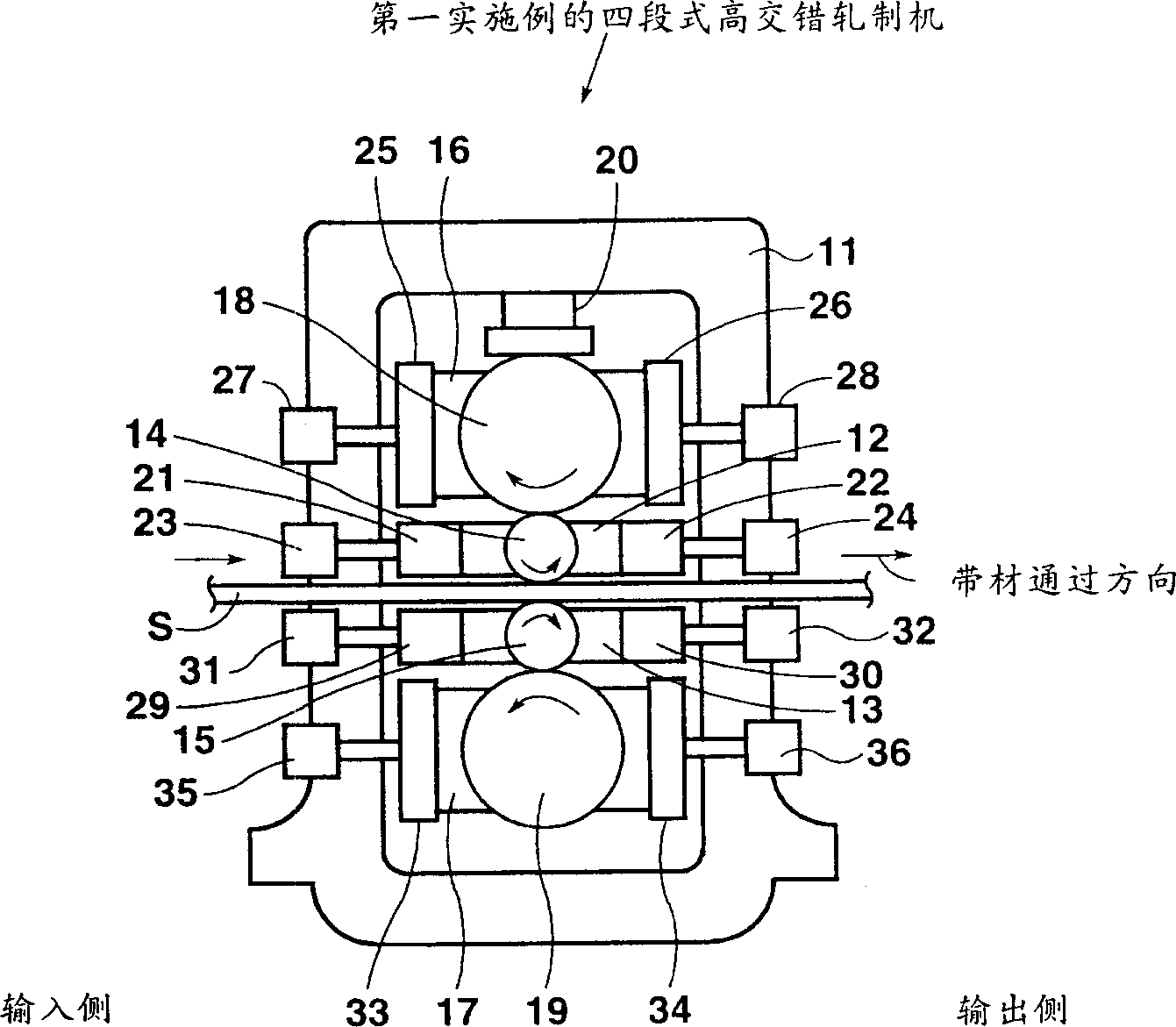

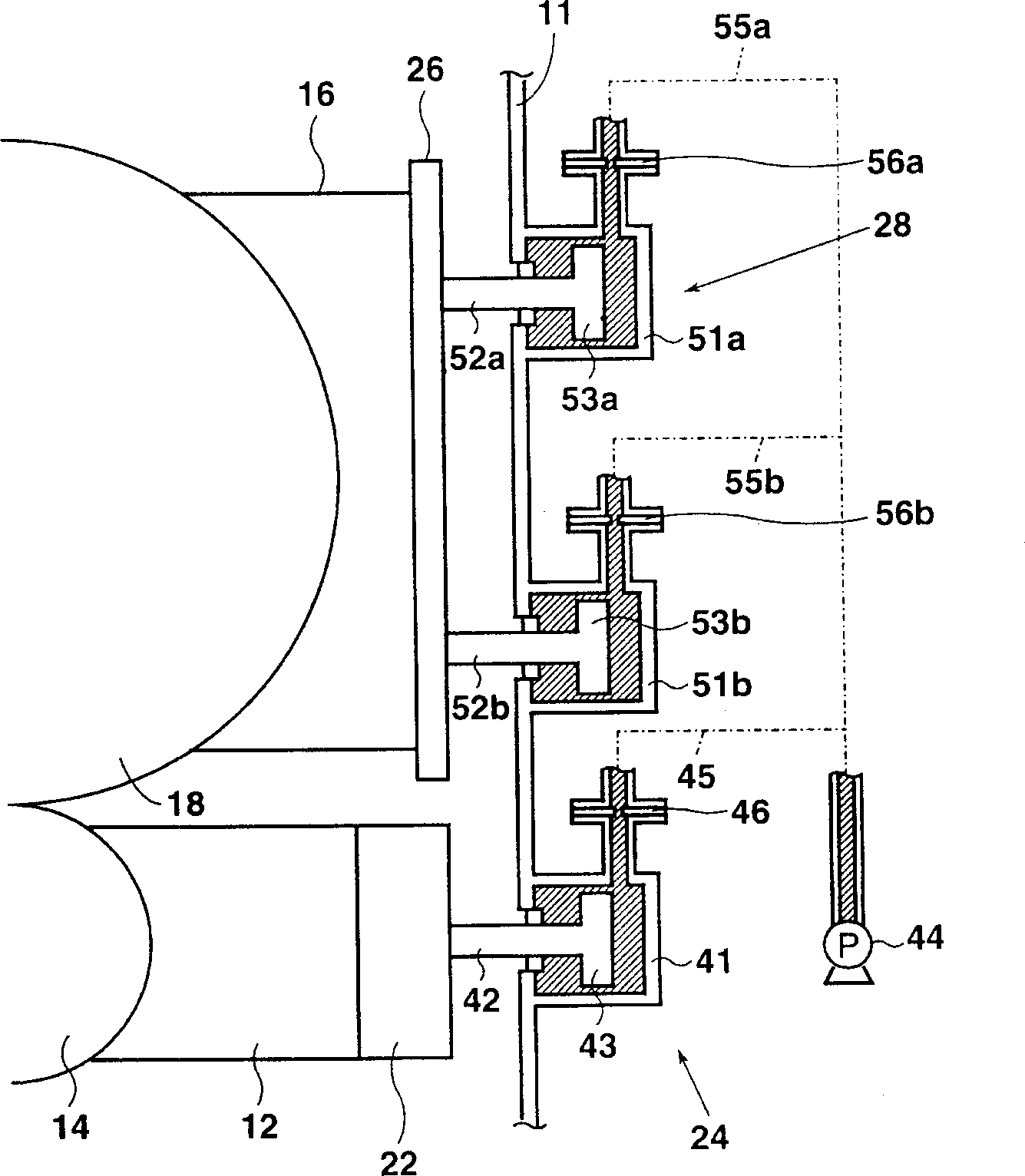

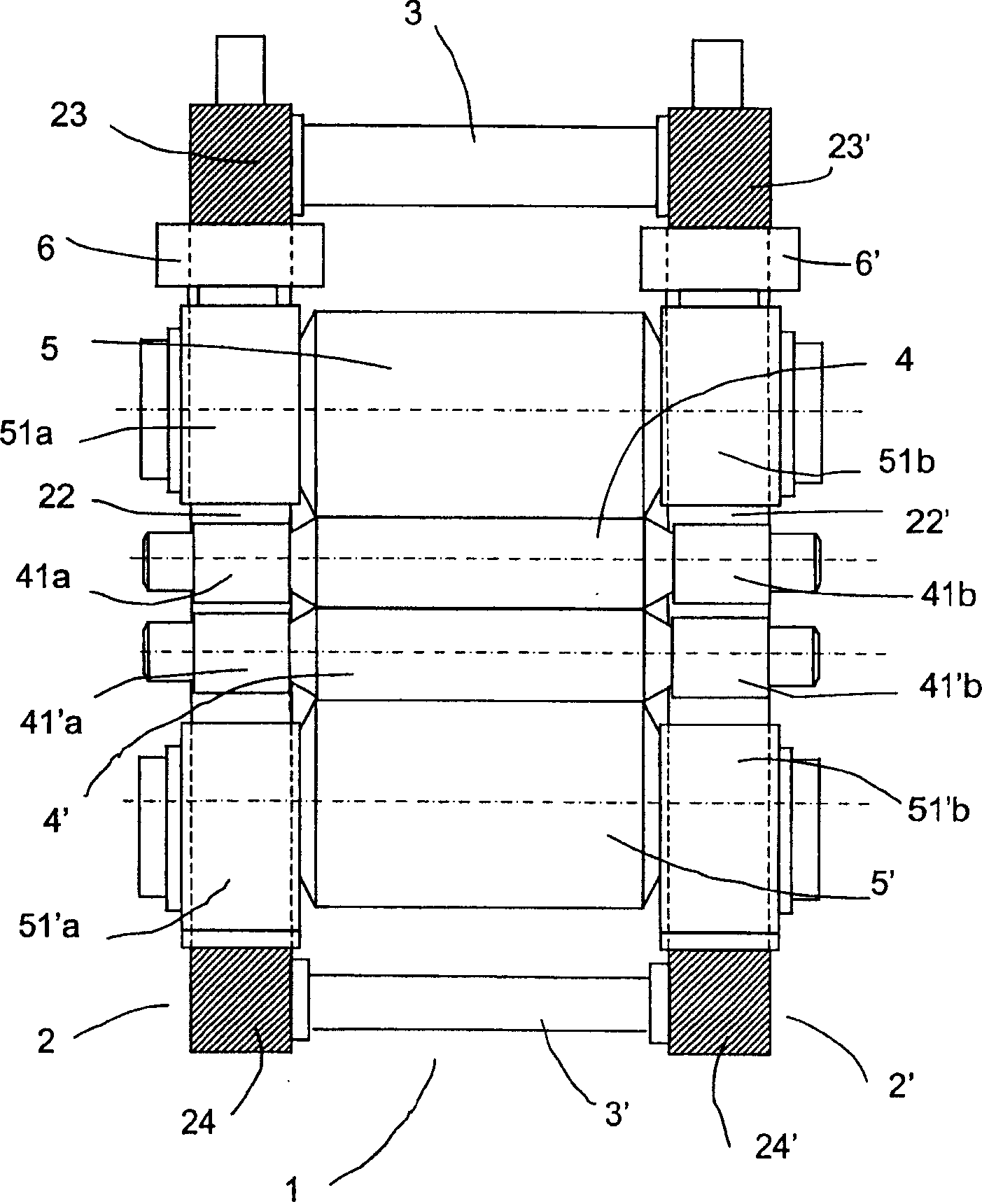

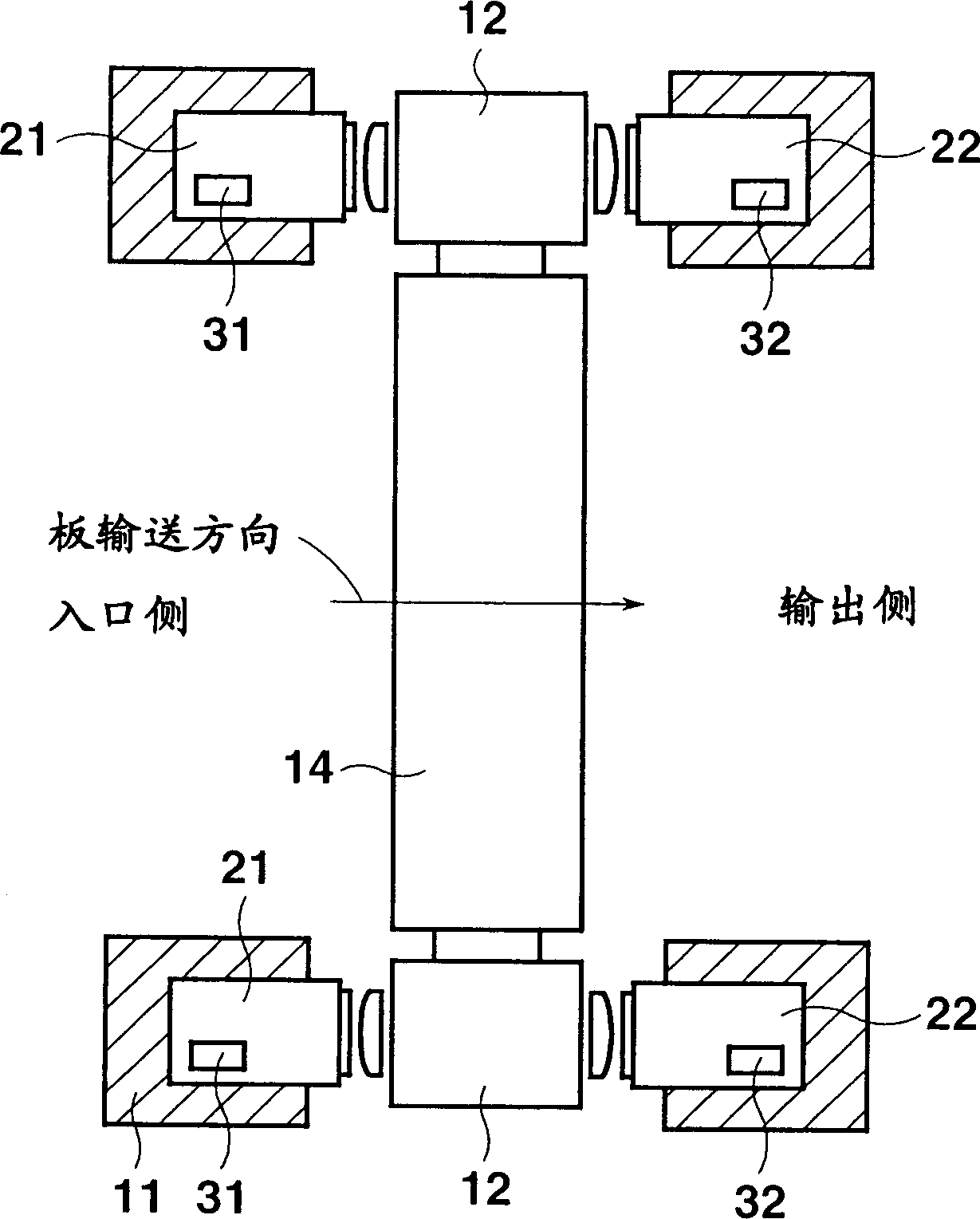

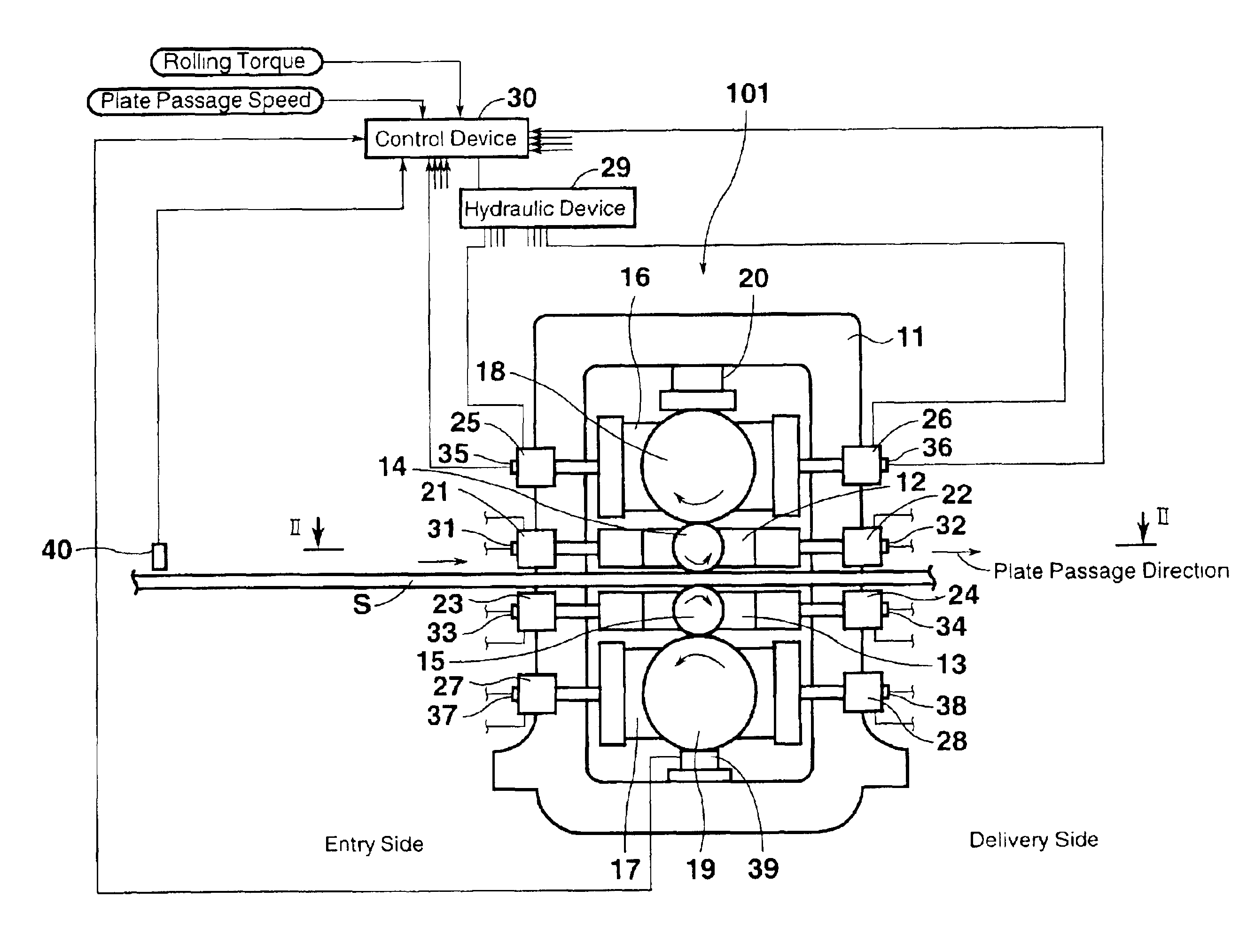

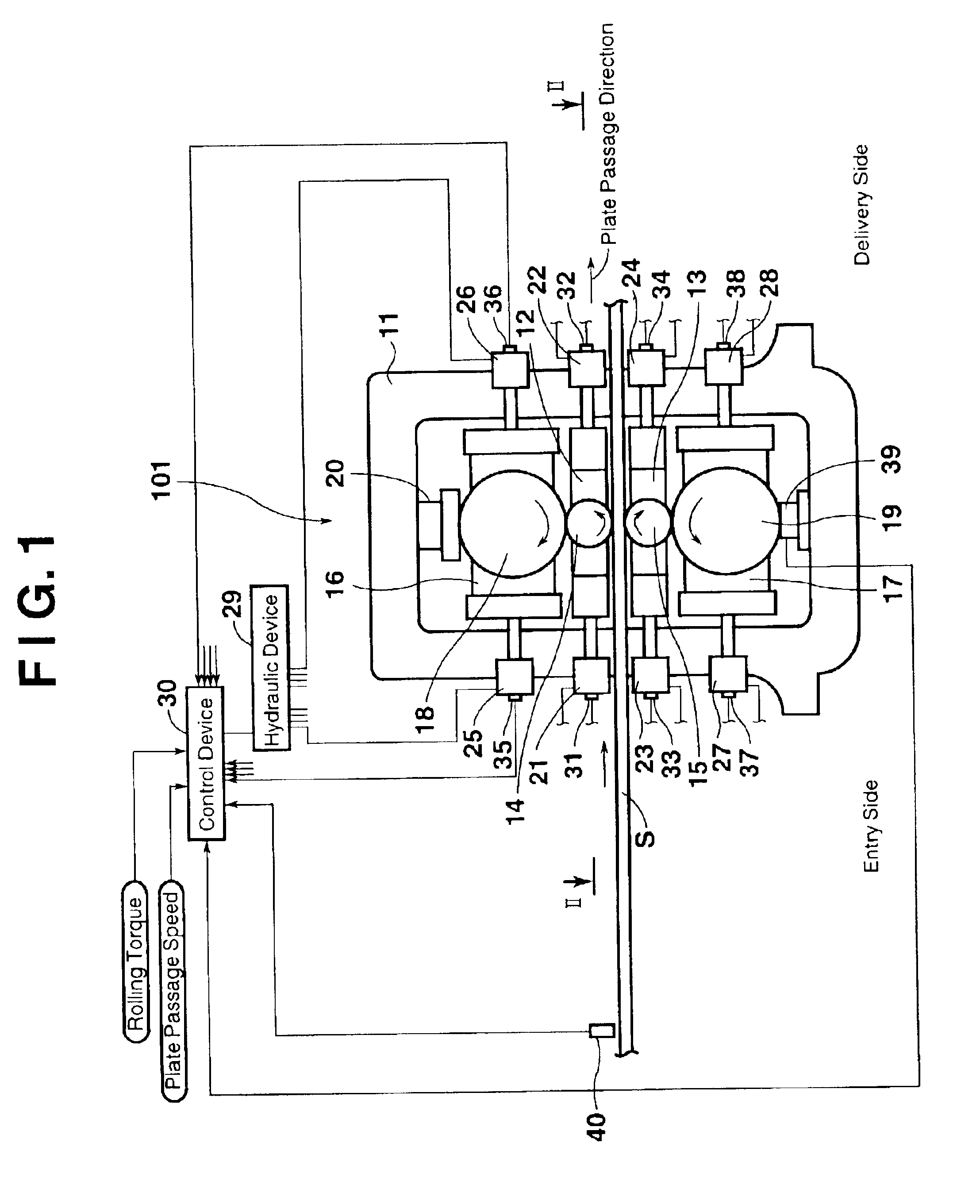

Rolling mill

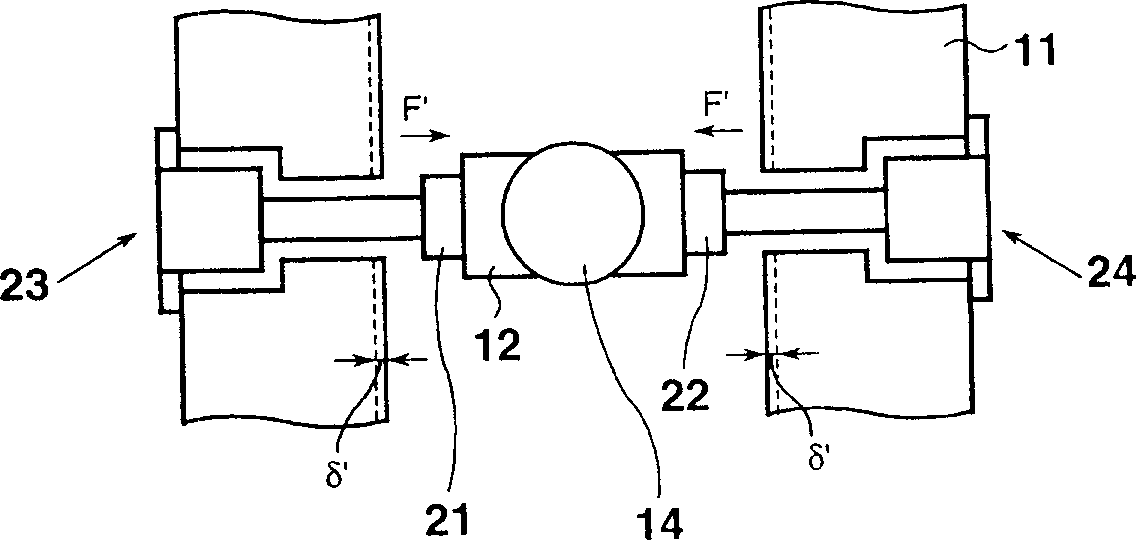

InactiveCN1320064AReduce vibrationEliminate gapsMetal rolling stand detailsVibration control deviceHydraulic cylinderWork roll

Work rolls (14, 15) opposed to each other have shafts rotatably supported by upper and lower work roll chocks (12, 13) of a housing (11), a screw down device (20) for applying a predetermined pressure to the upper work roll (14) is provided in an upper portion of the housing (11), screw mechanisms (23, 31) capable of thrusting the work roll chocks (12, 13) in a horizontal direction are provided on an entry side or a delivery side of the housing (11), hydraulic cylinder mechanisms (24, 32) capable of thrusting the work roll chocks (12, 13) in the horizontal direction are provided on the other side, and contraction portions (46) are provided in hydraulic supply and discharge pipes (45) of the hydraulic cylinder mechanisms (24, 32).

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

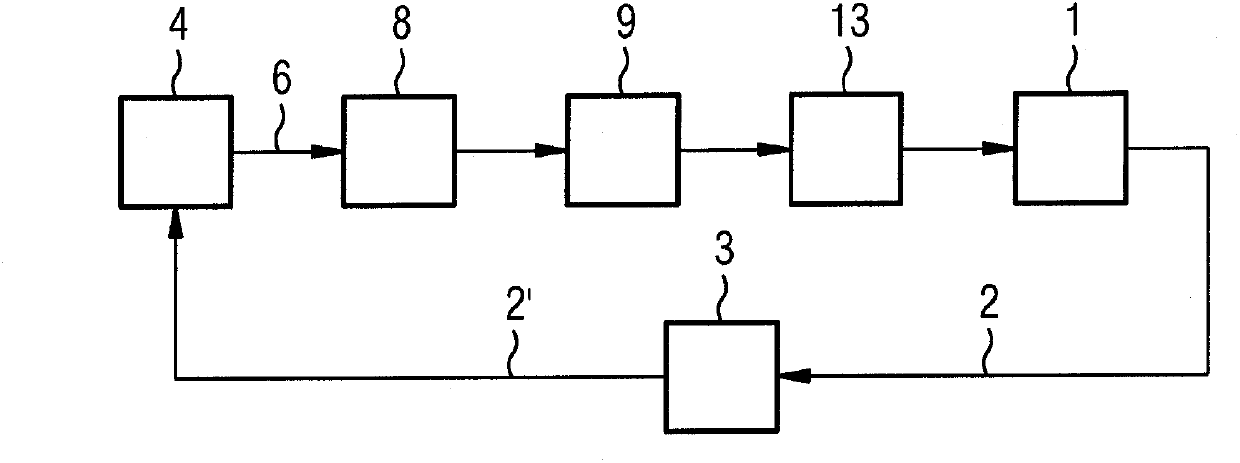

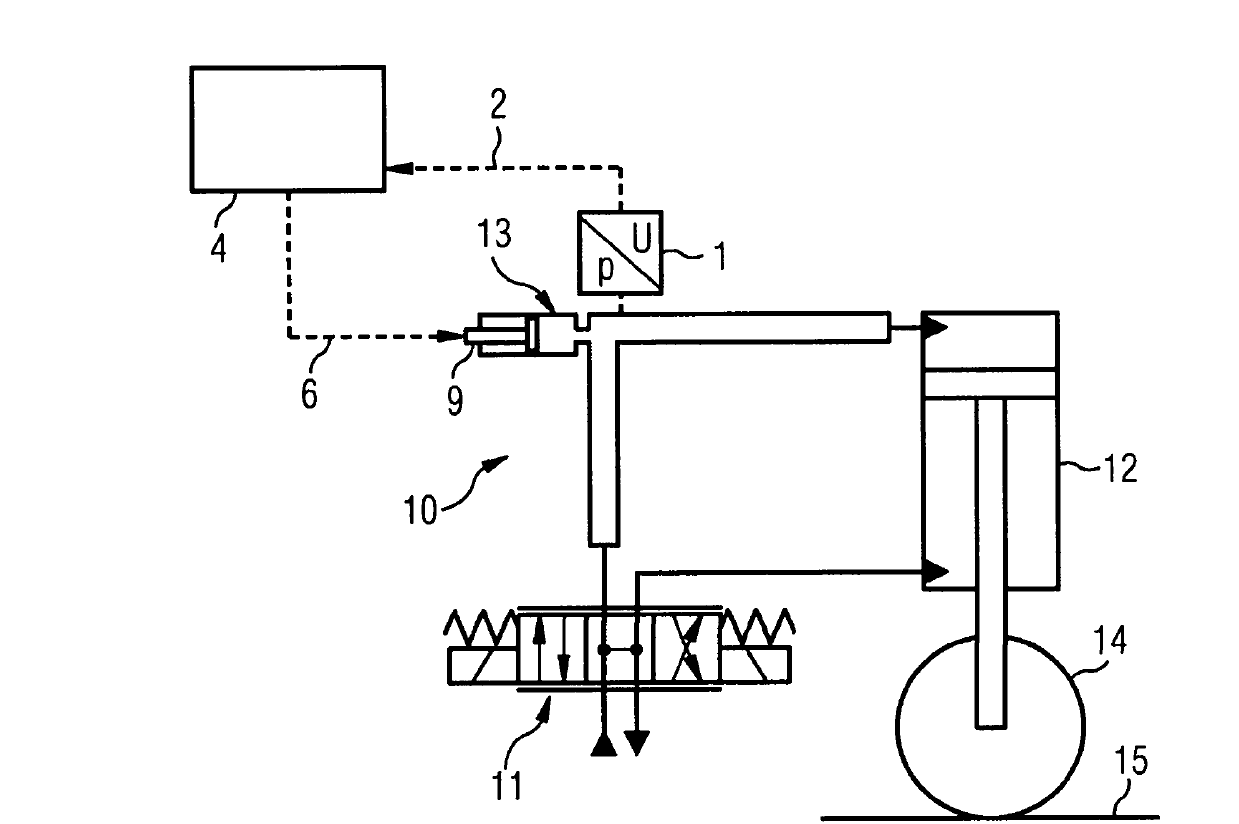

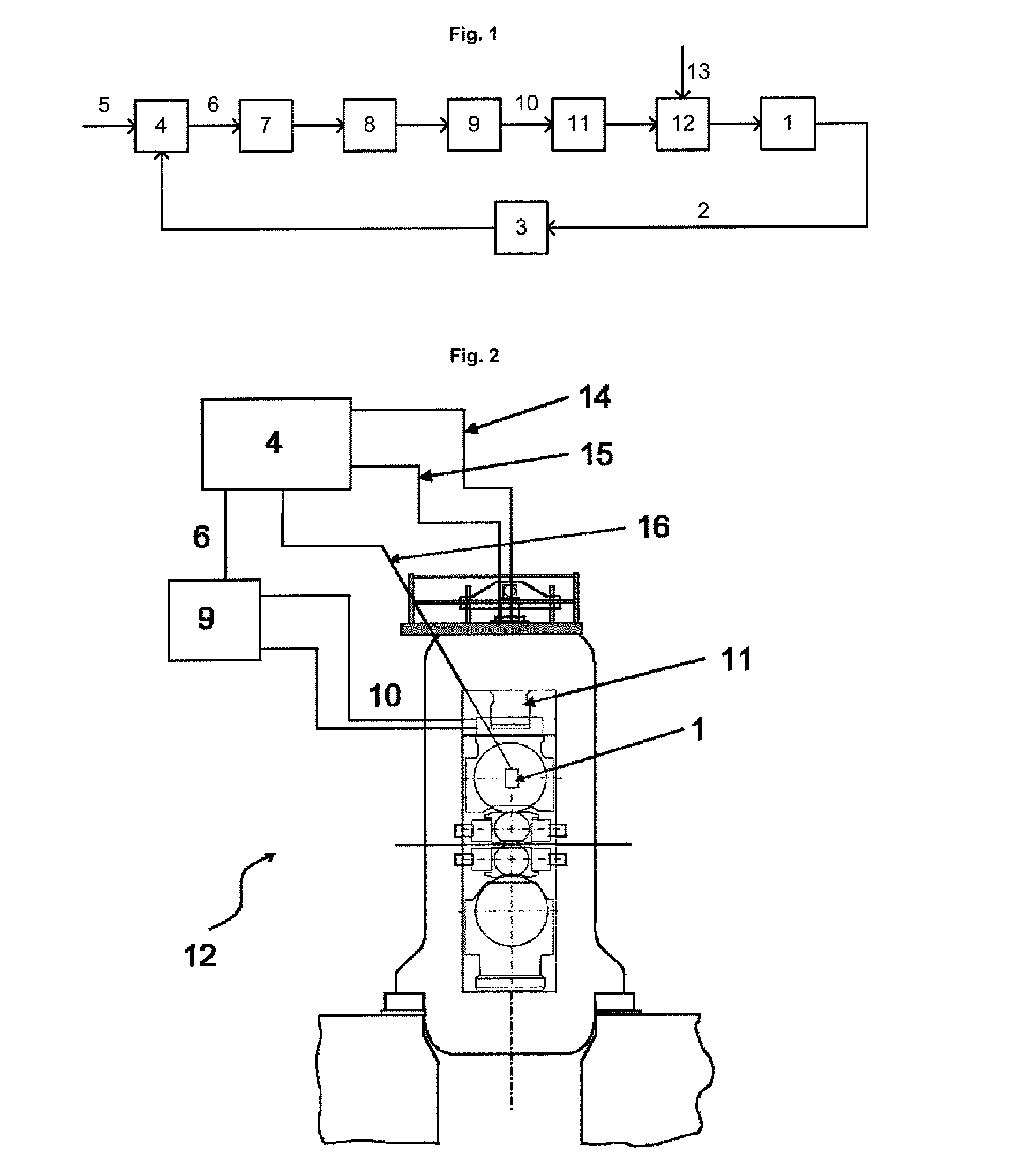

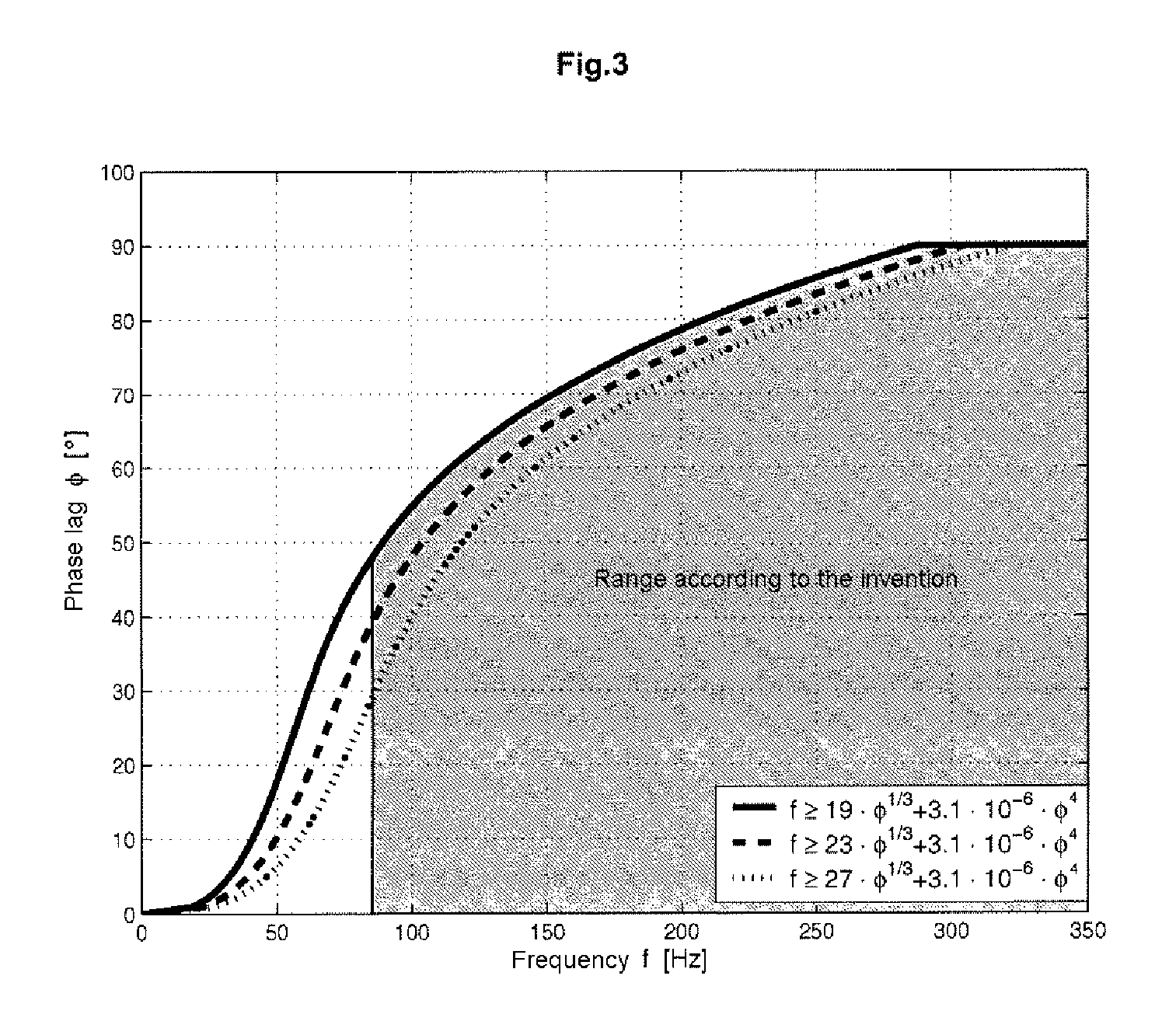

Method and apparatus to suppress vibrations in a rolling mill

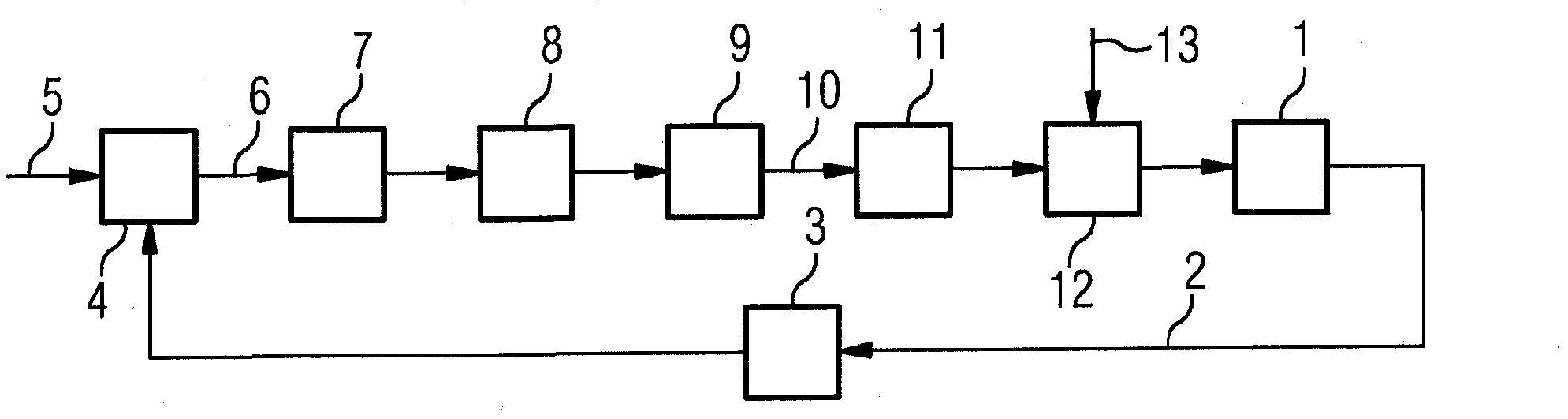

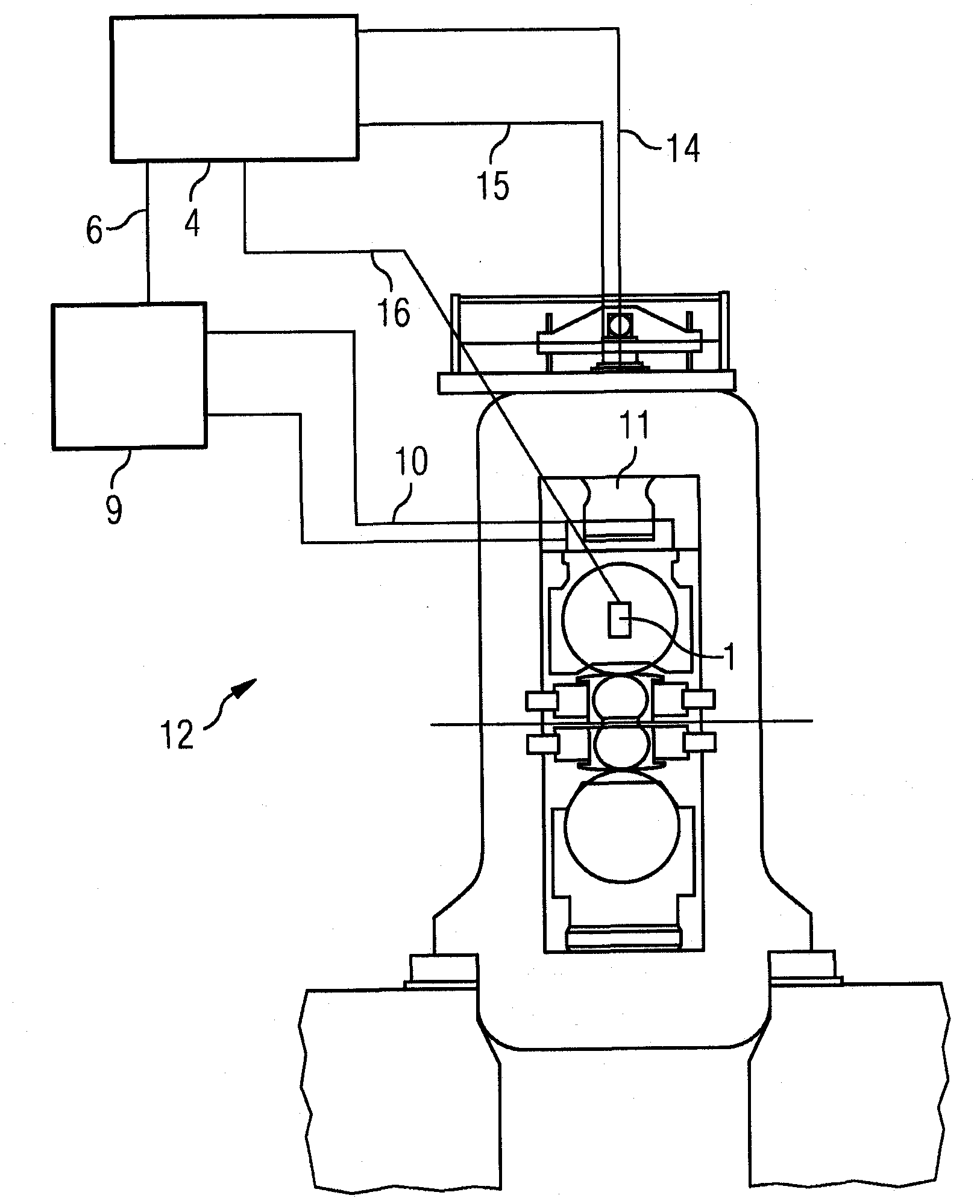

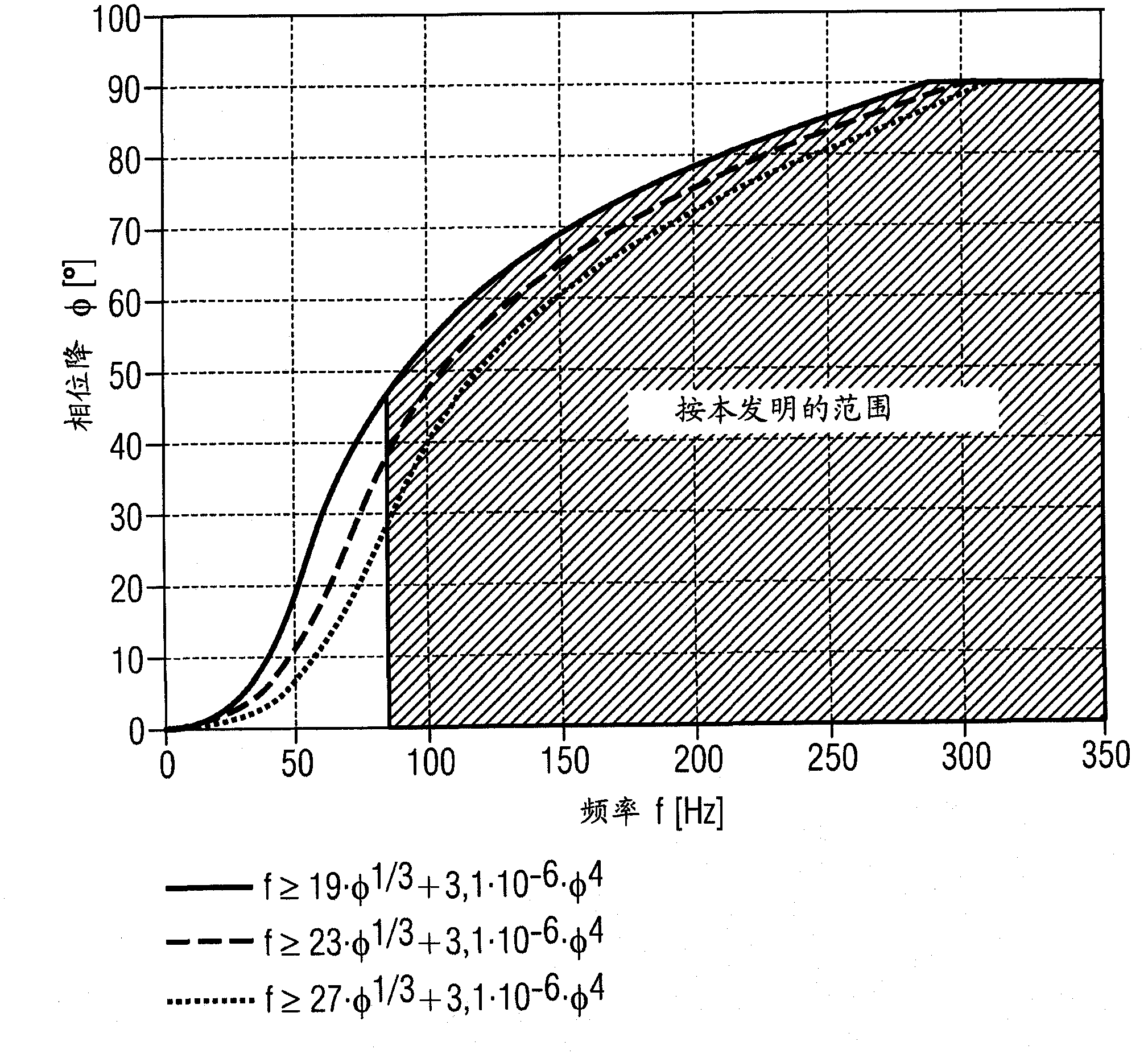

ActiveCN102083560AReduce non-linearityStrong nonlinearityVibration control deviceMetal rolling arrangementsProduction rateElectro hydraulic

The present invention relates to a method and to an apparatus for suppression of vibrations in a rolling mill. The problem of the invention is to create a method and an apparatus having a hydraulic roller actuator for the suppression of vibrations in a rolling mill, with which in particular the third-octave vibrations can be effectively suppressed and thereby the quality of the rolled material and / or the productivity of the rolling mill can be improved. This problem is solved by a method in which the control variable is supplied to an electro-hydraulic actuating unit and then due to this actuating unit at least one hydraulic actuator for the roller setting is actuated, wherein the electro-hydraulic actuating unit has a nominal rate of flow >= 50 l / min and at least a portion of the frequency response at frequencies f >= 80 Hz is characterized by a drop in value of <= 3 dB, and in this frequency range, the phase drop Phi satisfies the conditions (I) and Phi < 90 DEG.

Owner:PRIMETALS TECH AUSTRIA GMBH

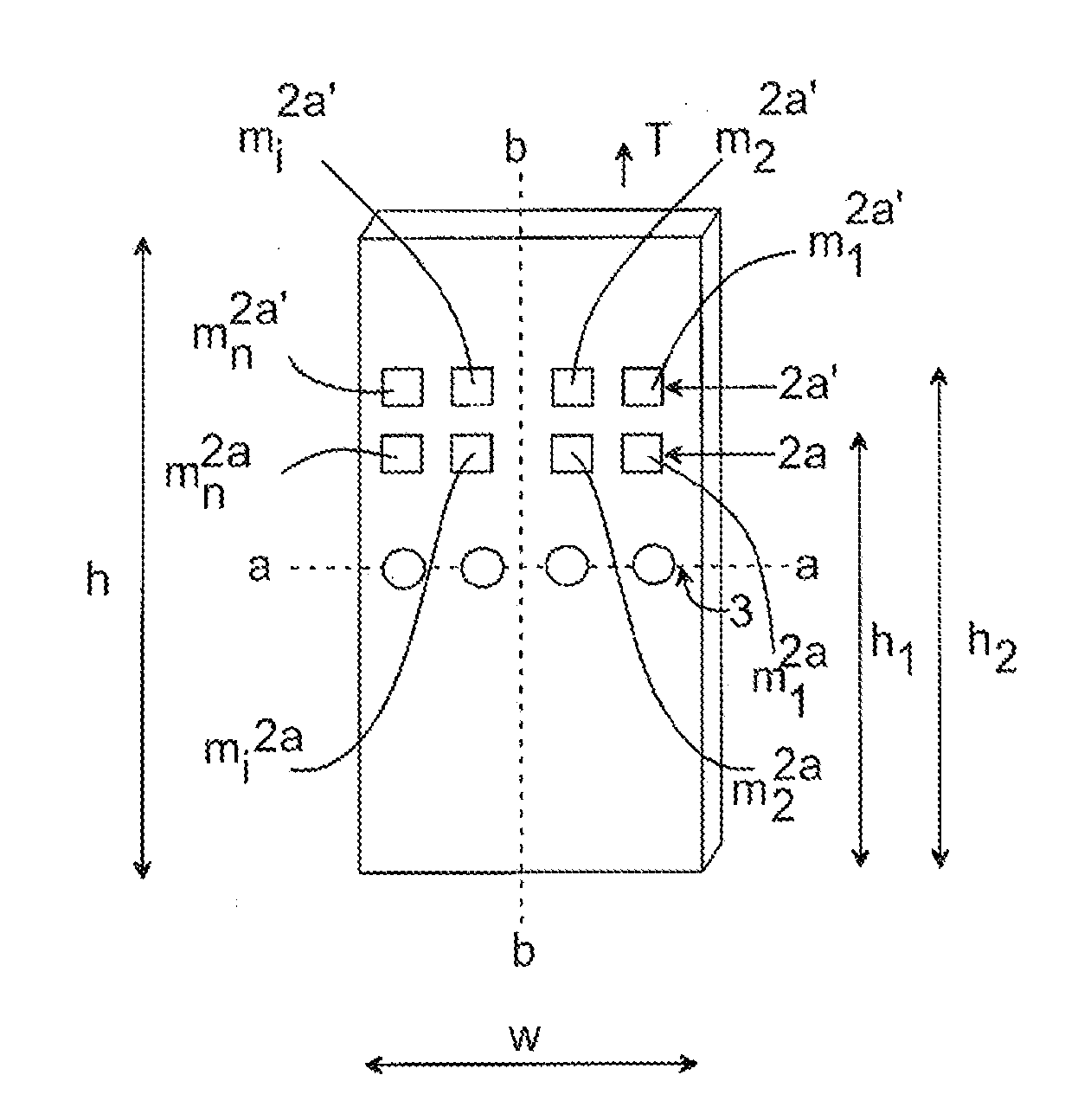

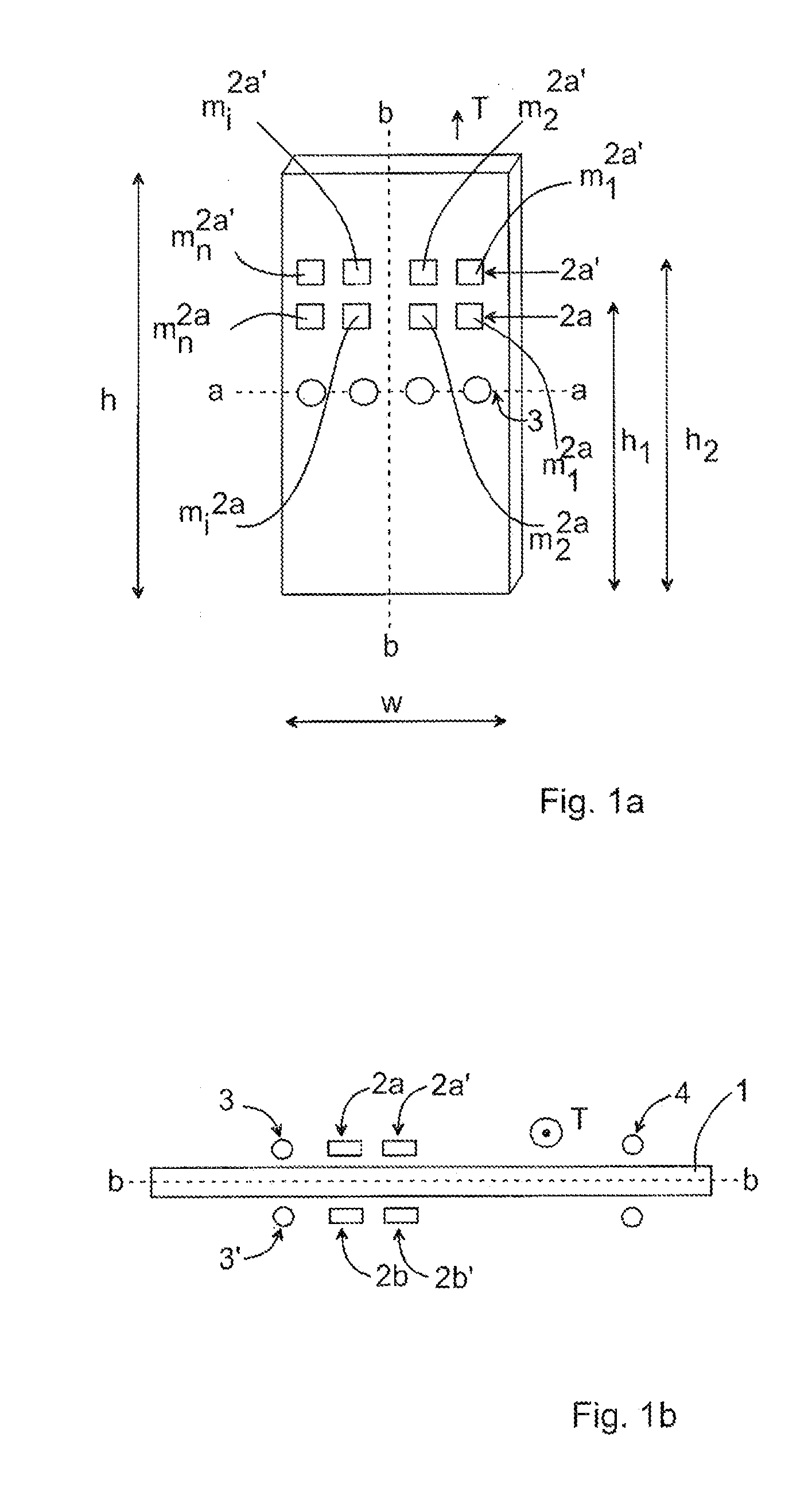

Mode Based Metal Strip Stabilizer

ActiveUS20100161104A1Damper of strip vibrationReduce exerciseHot-dipping/immersion processesMeasuring devicesEngineeringActuator

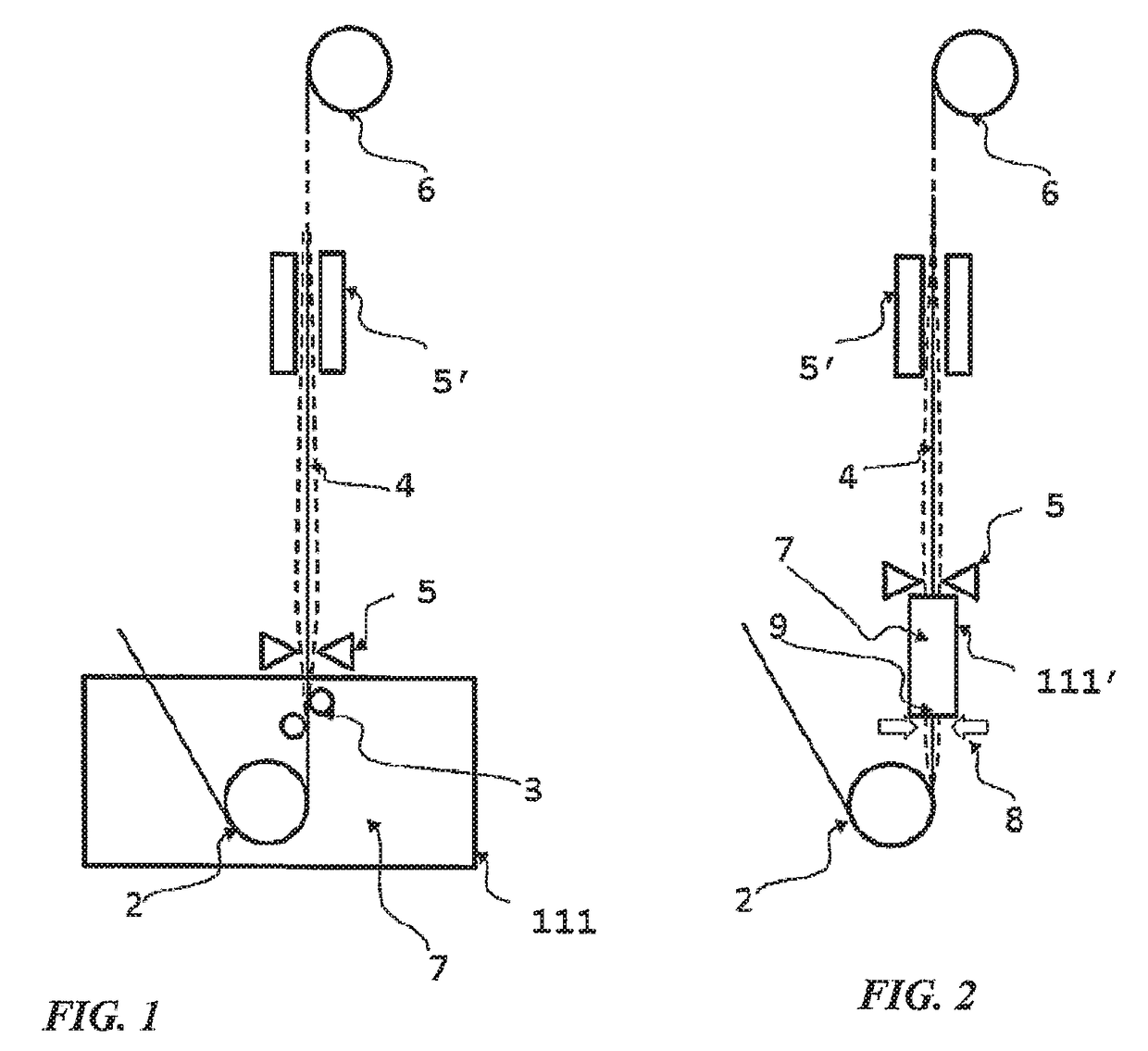

A method for vibration damping and shape control of a suspended metal strip during continuous transport in a processing facility in a steel rolling line or surface treating line in a steel mill, where the method comprises the steps: measuring distance to the strip by a plurality of non-contact sensors; and generating a strip profile from distance measurements; decomposing the strip profile to a combination of mode shapes; determining coefficients for the contribution from each mode shape to the total strip profile; and controlling the strip profile by a plurality of non-contact actuators based on a combination of mode shapes.

Owner:ABB (SCHWEIZ) AG

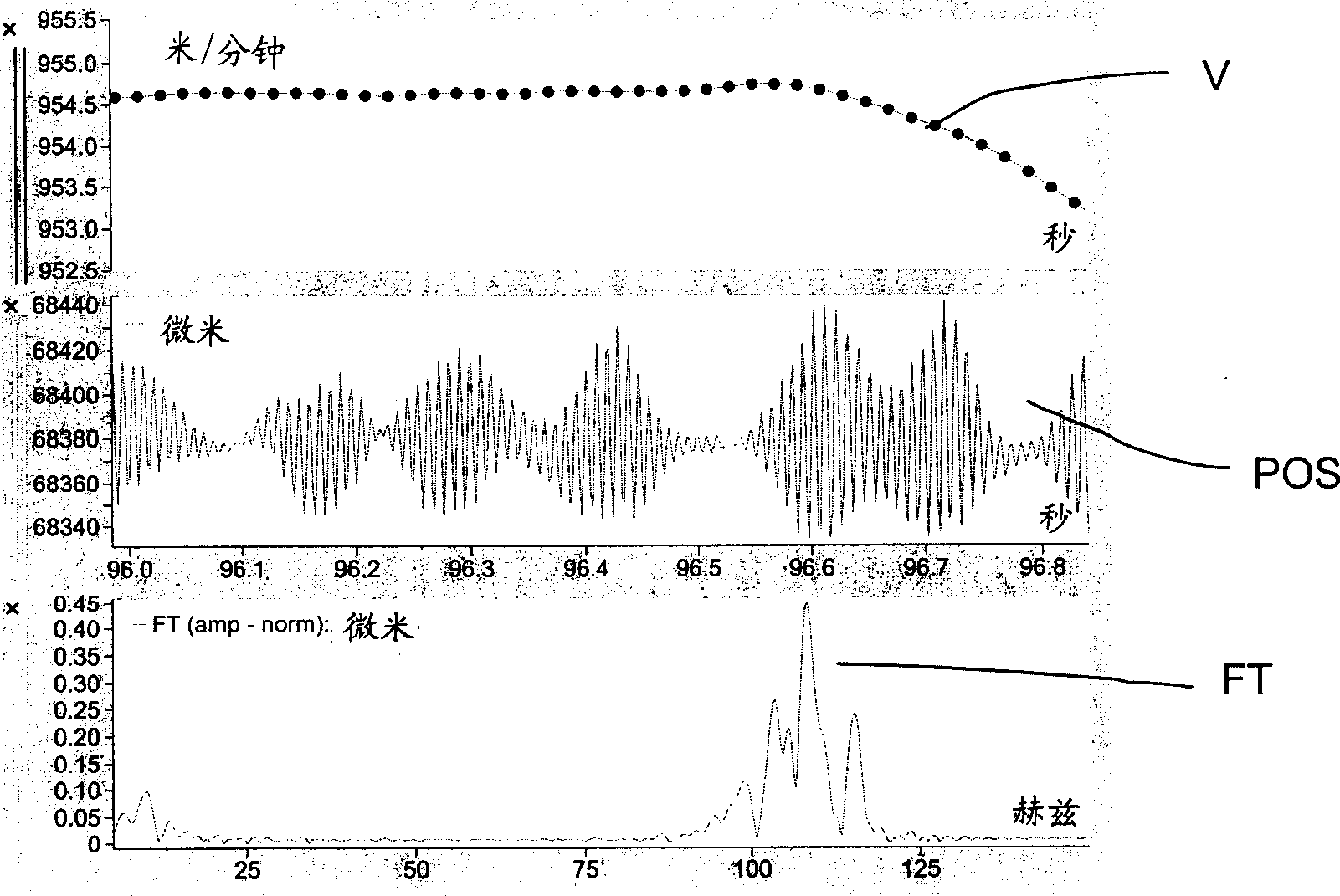

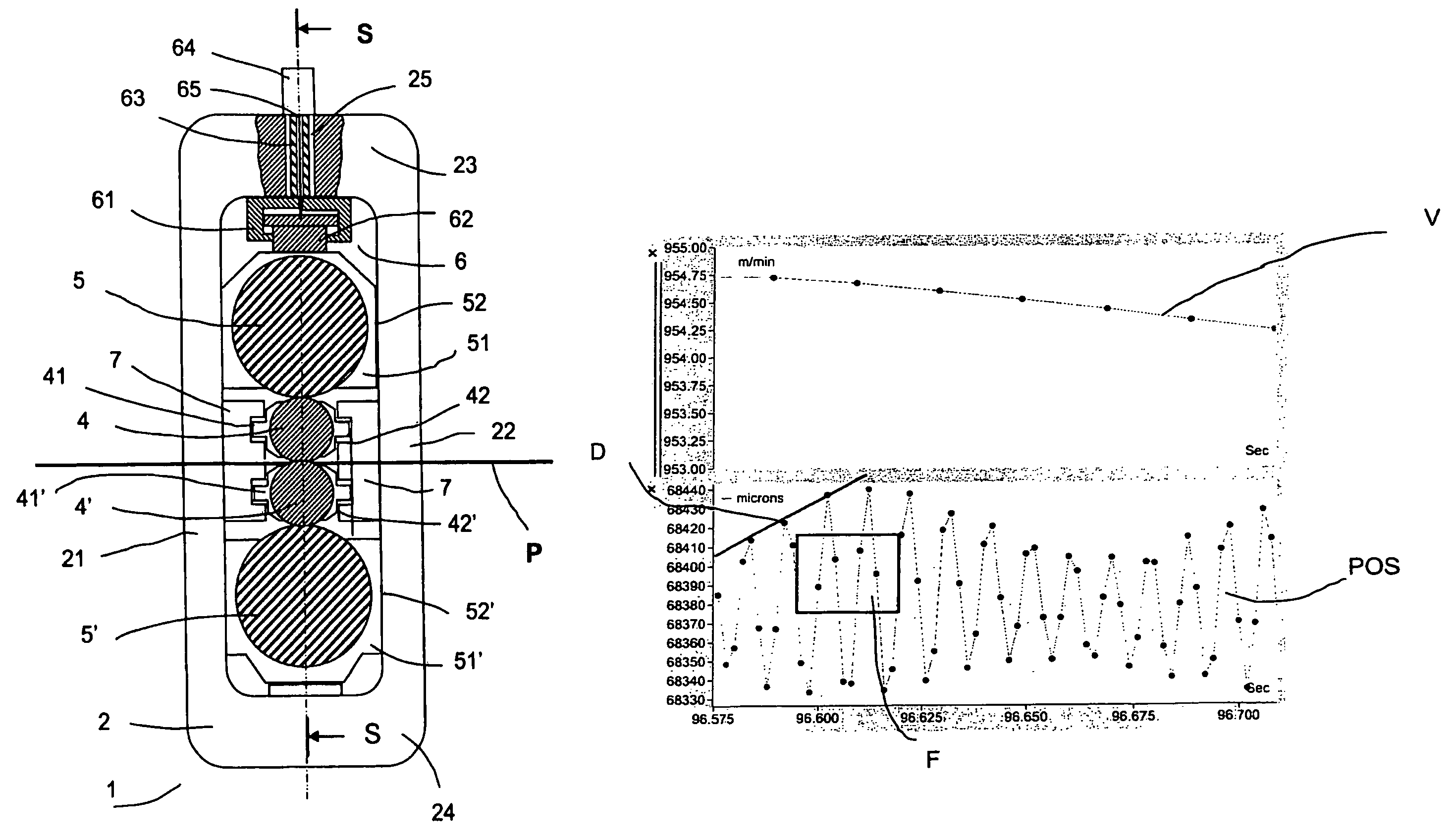

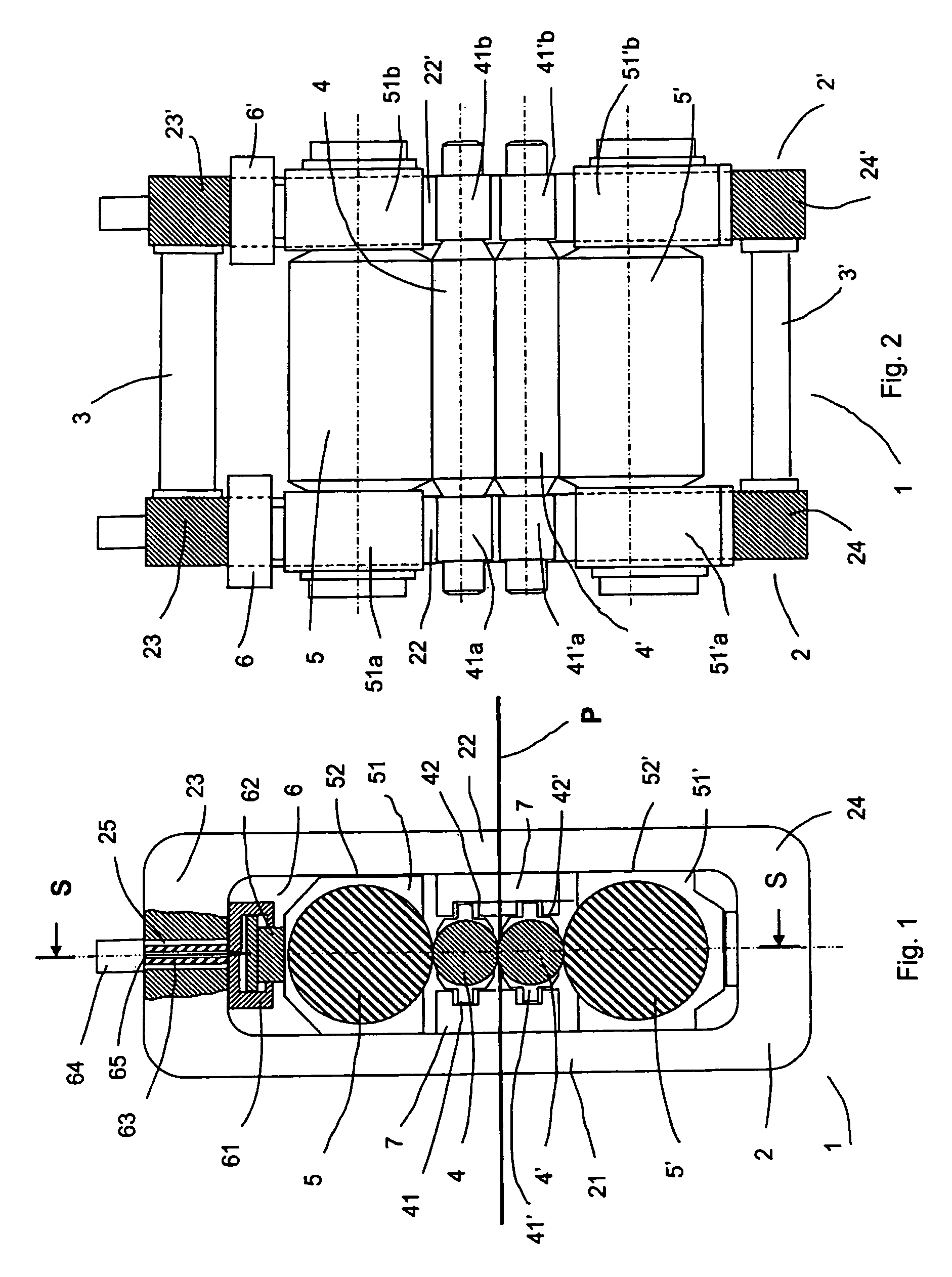

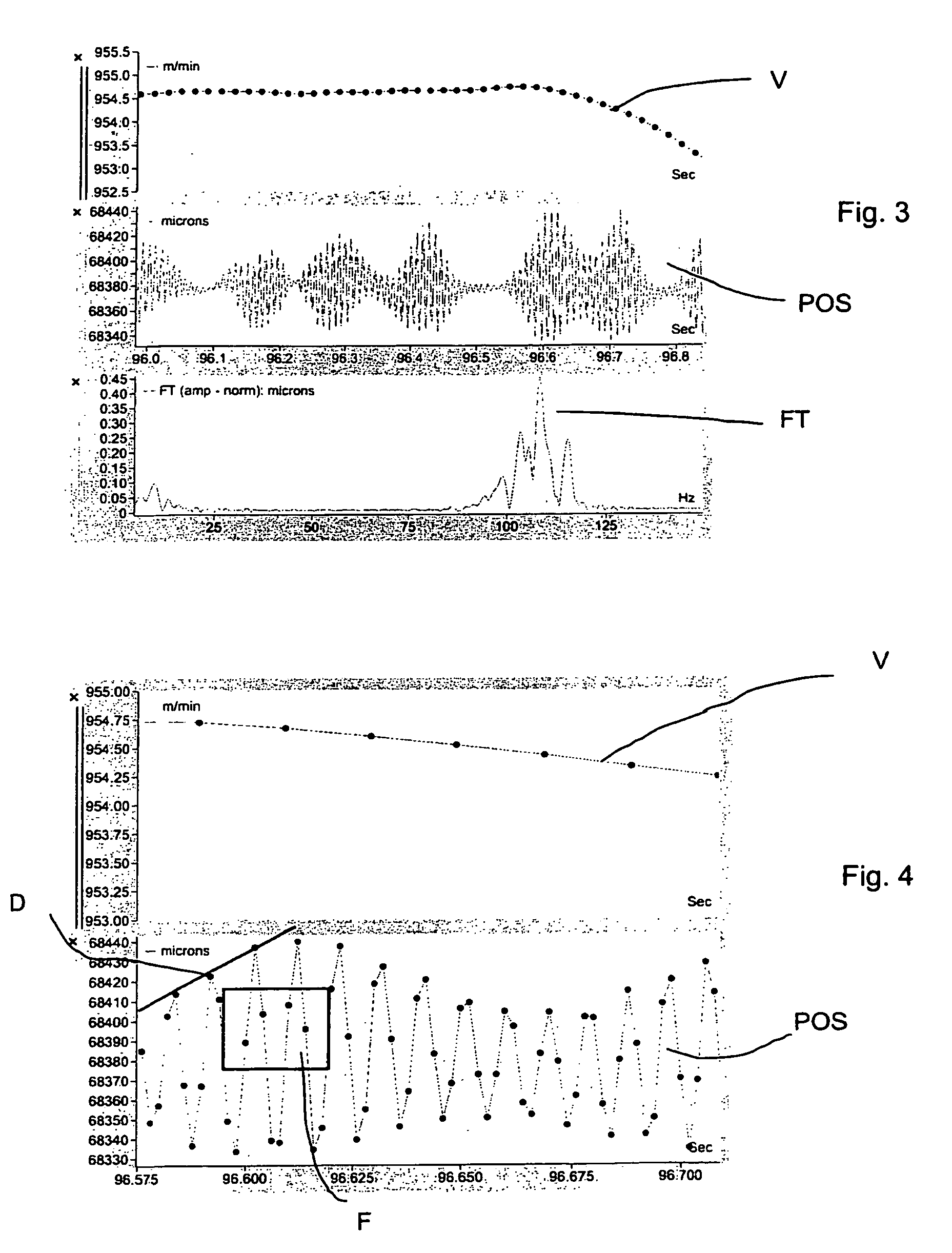

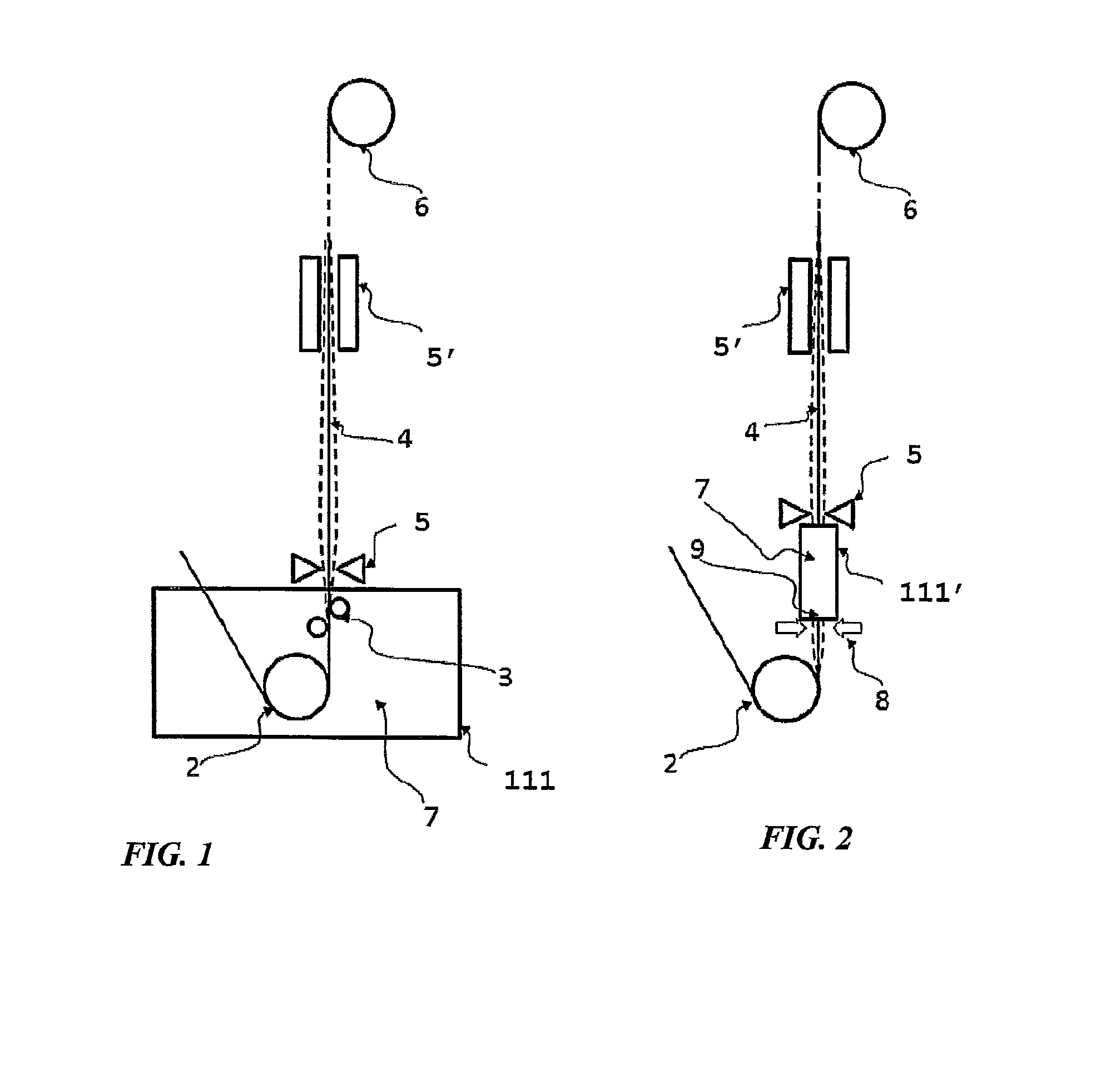

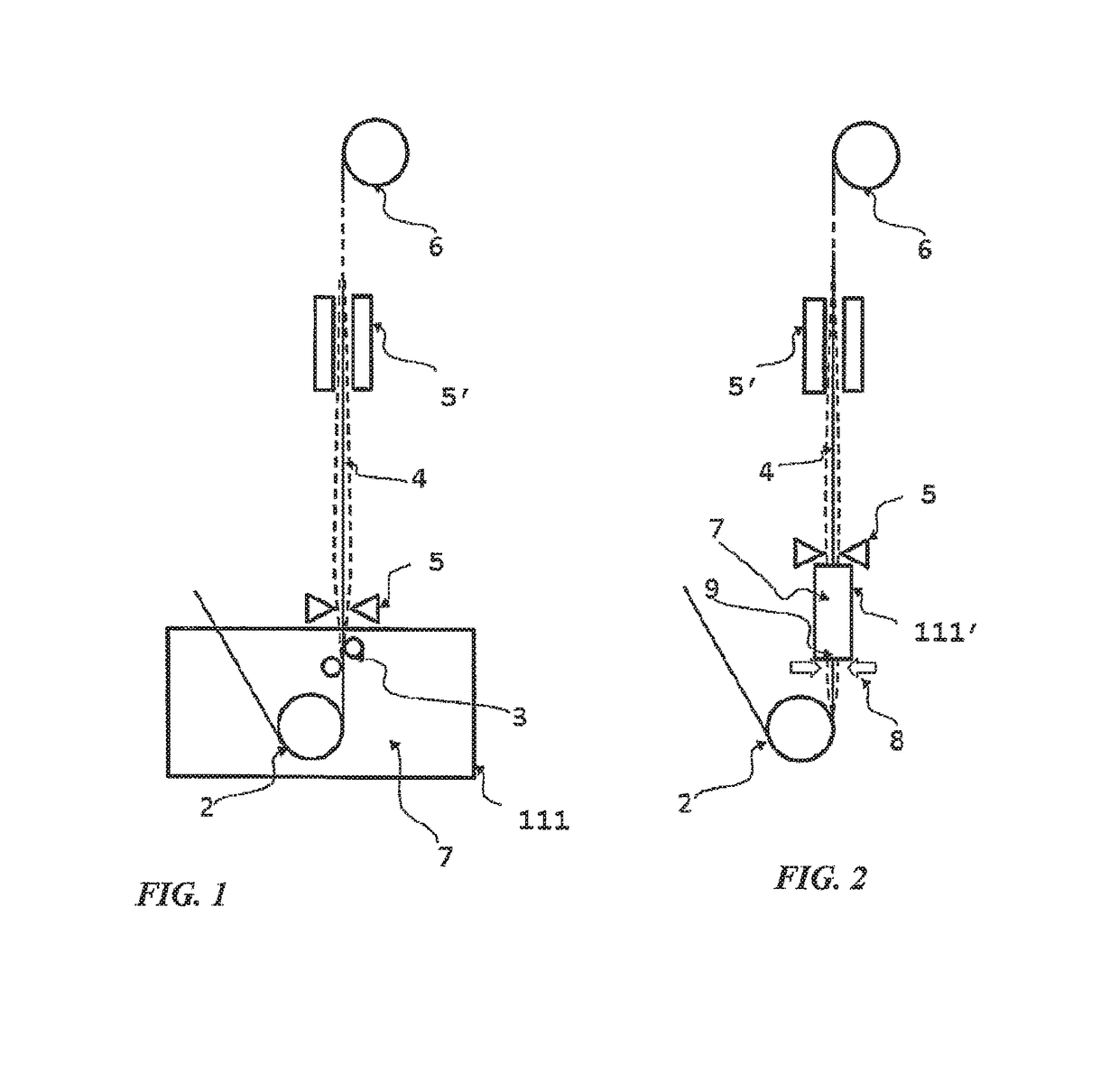

Process for the detection of vibrations of a roll stand

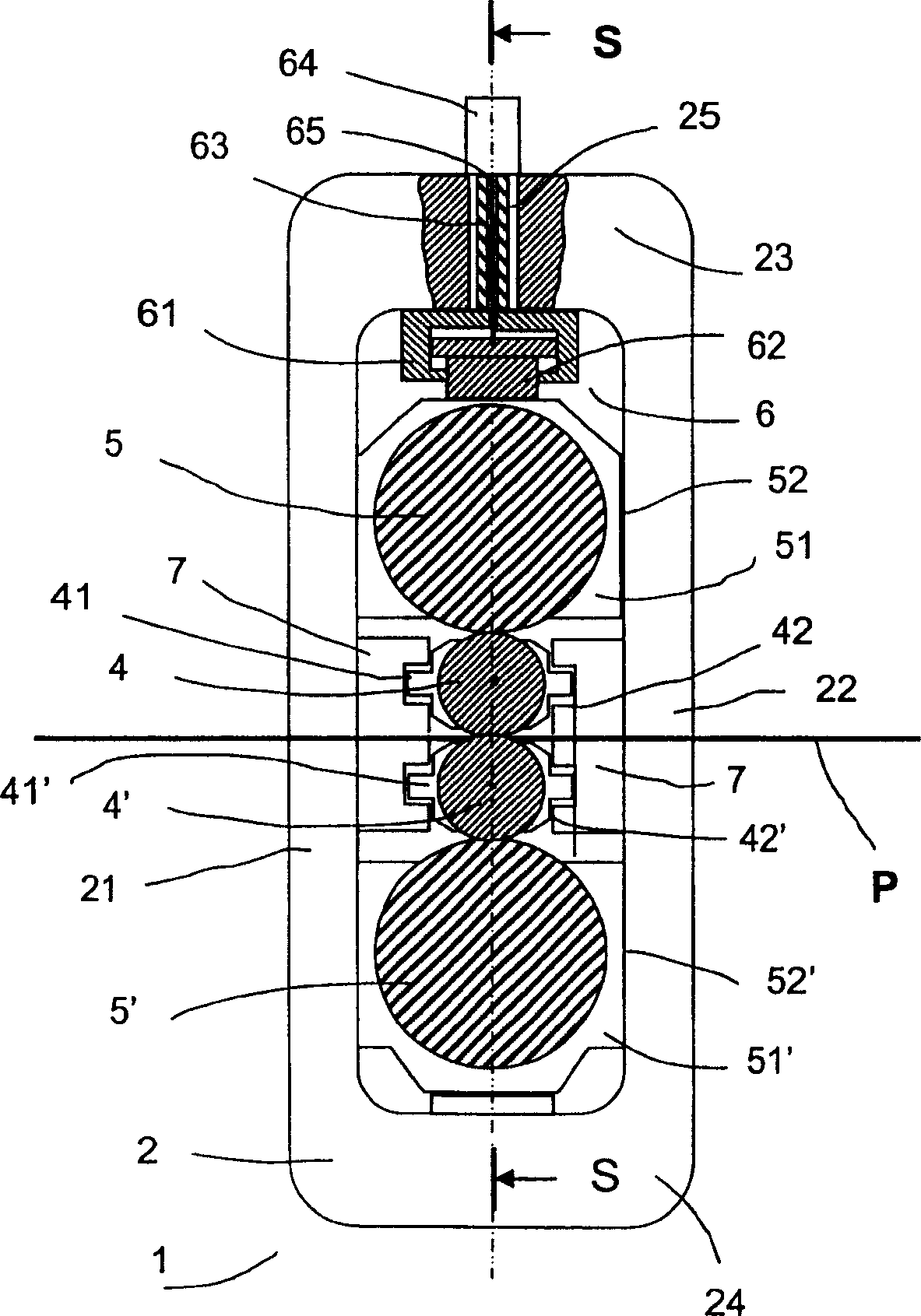

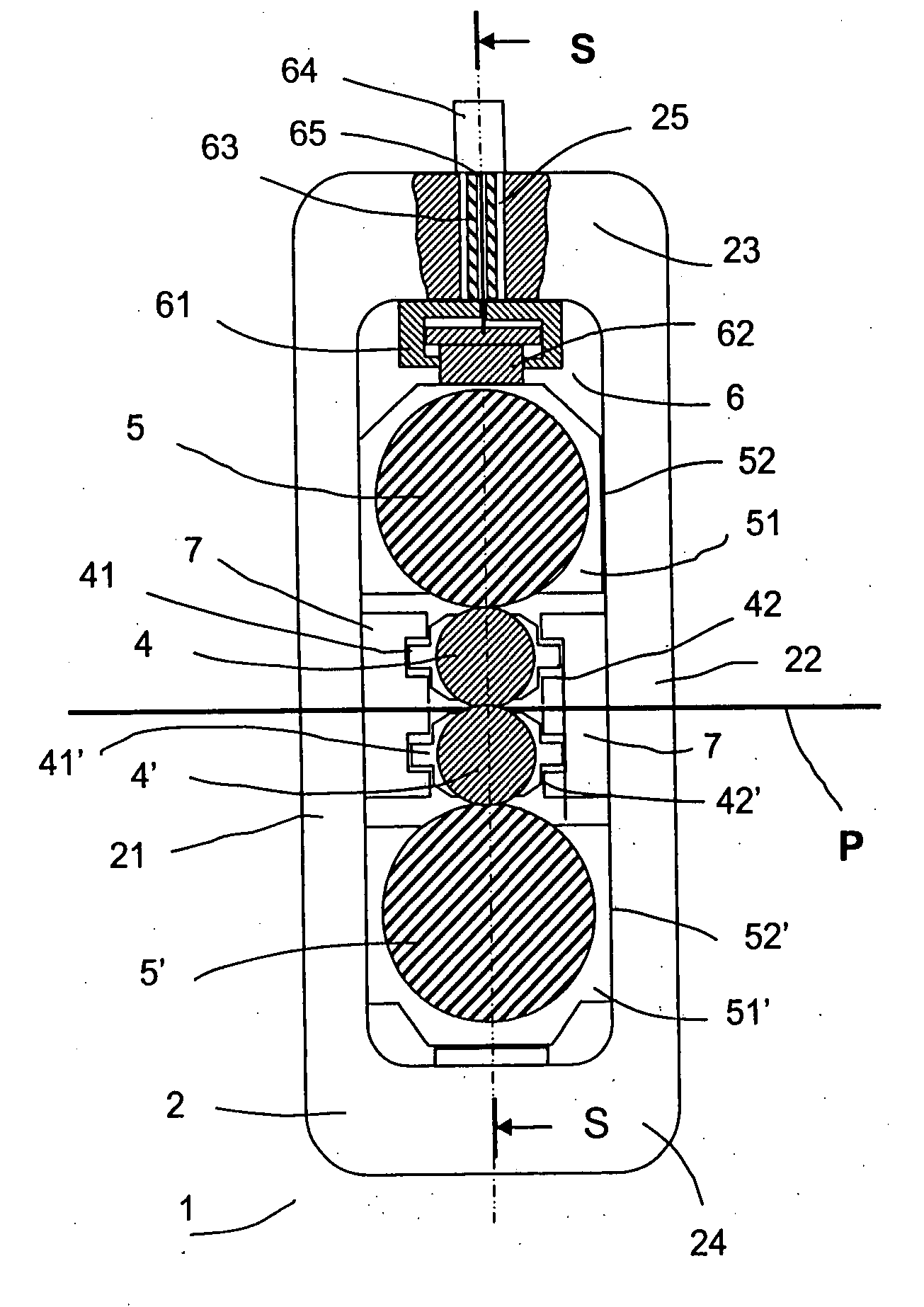

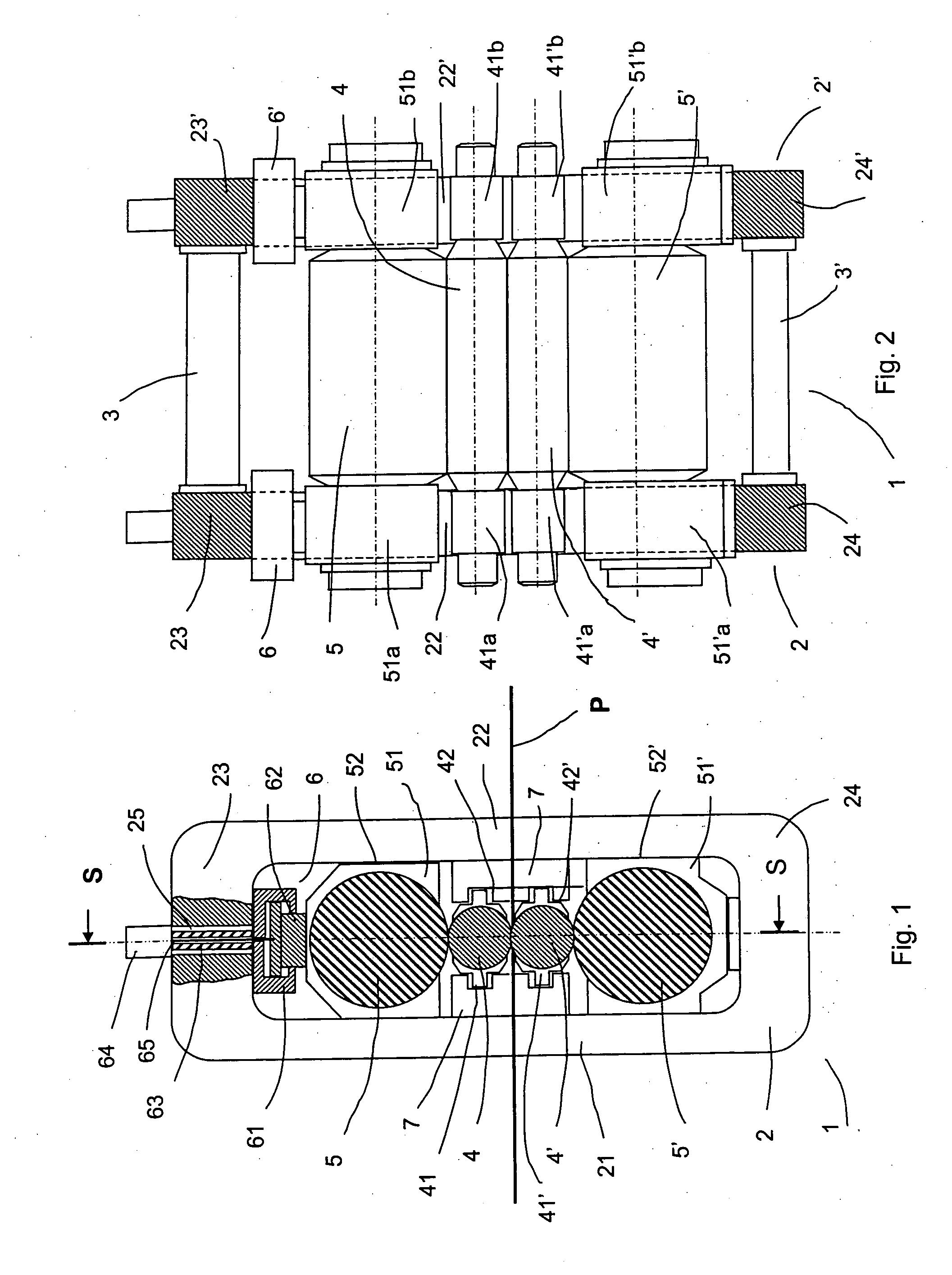

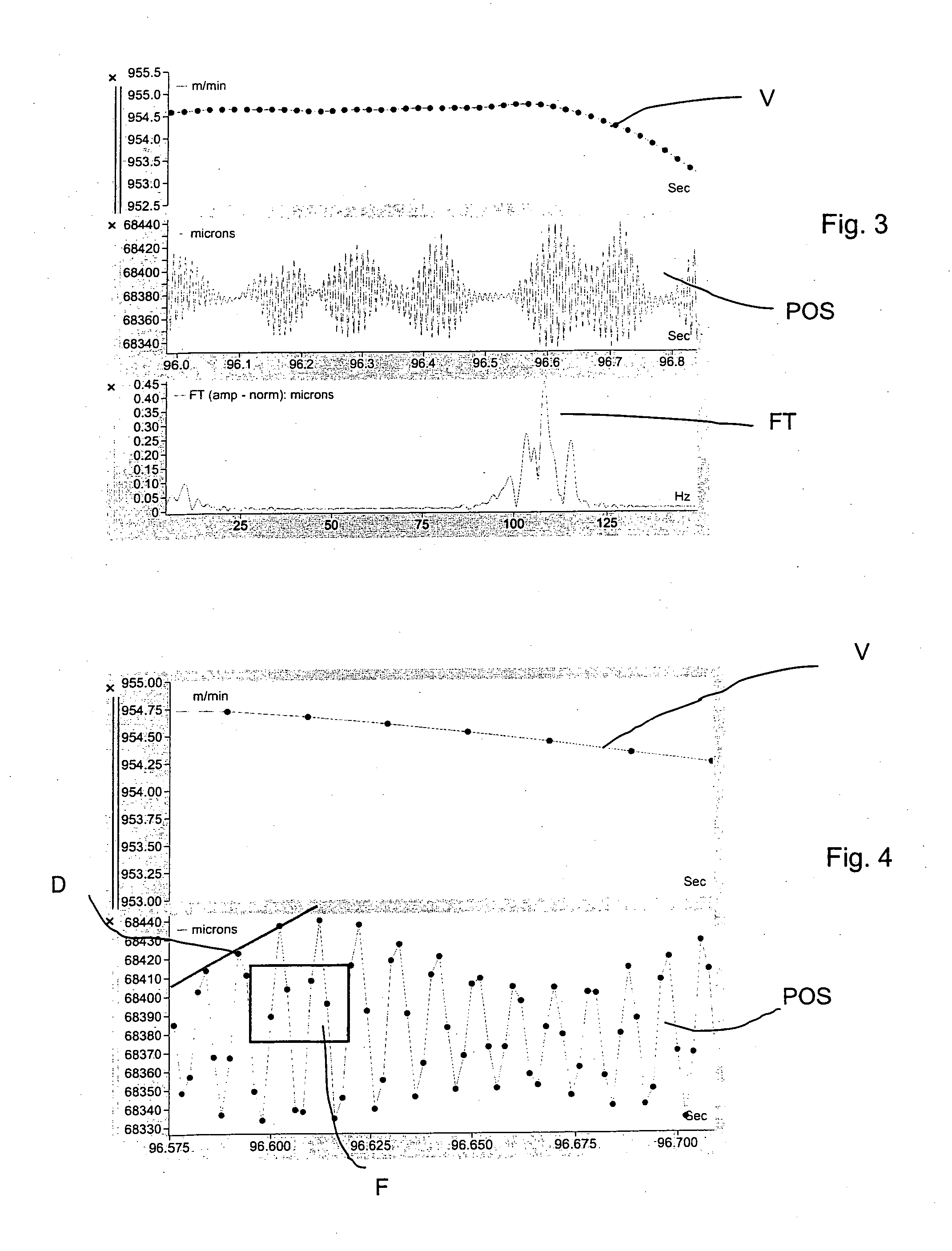

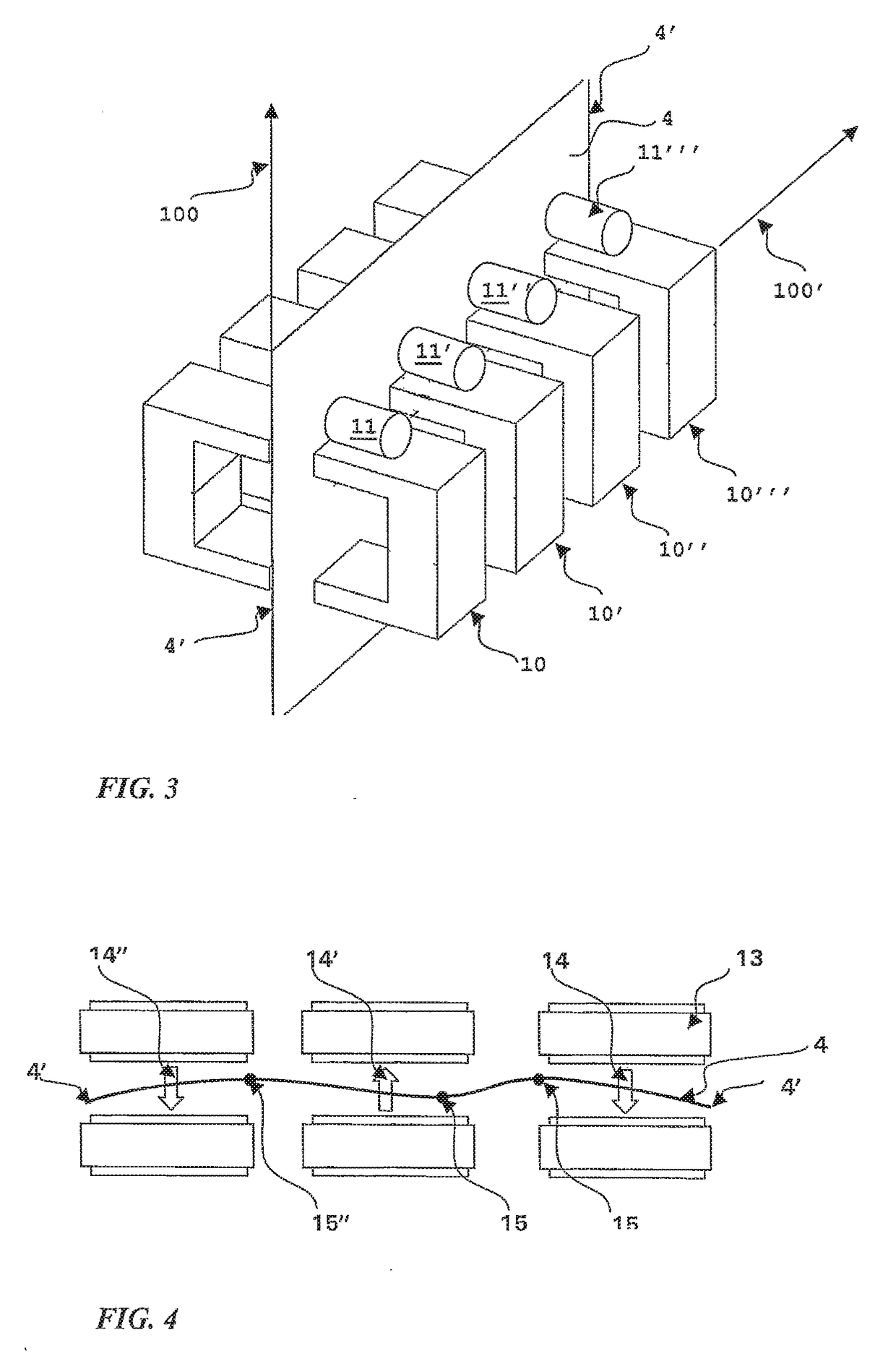

InactiveCN1772405AReal-time and permanent storageRoll force/gap control deviceMeasuring devicesClassical mechanicsJackscrew

The invention relates to a method for detecting vibrations of a roll stand (1). The roll stand (1) is equipped with a hydraulic jack (6) as a device for adjusting the rolls (4, 5). The hydraulic jack includes a sensor (64) providing a digital signal (POS) that measures the position of the movable part relative to the fixed part. According to the invention, vibrations are detected by directly observing the position signal (POS) and comparing it with a spatio-temporal window (F), the size of which is determined as a function of the frequency to be measured. According to the present invention, different observation windows (F) suitable for detecting different vibration phenomena can be determined. In a continuous rolling mill, the method of the invention makes it possible to observe the position signal (POS) of the hydraulic jacks (6) of each roll stand (1) and thus to detect the onset of vibration in each stand and to determine from which stand the phenomenon started .

Owner:CLECIM SAS

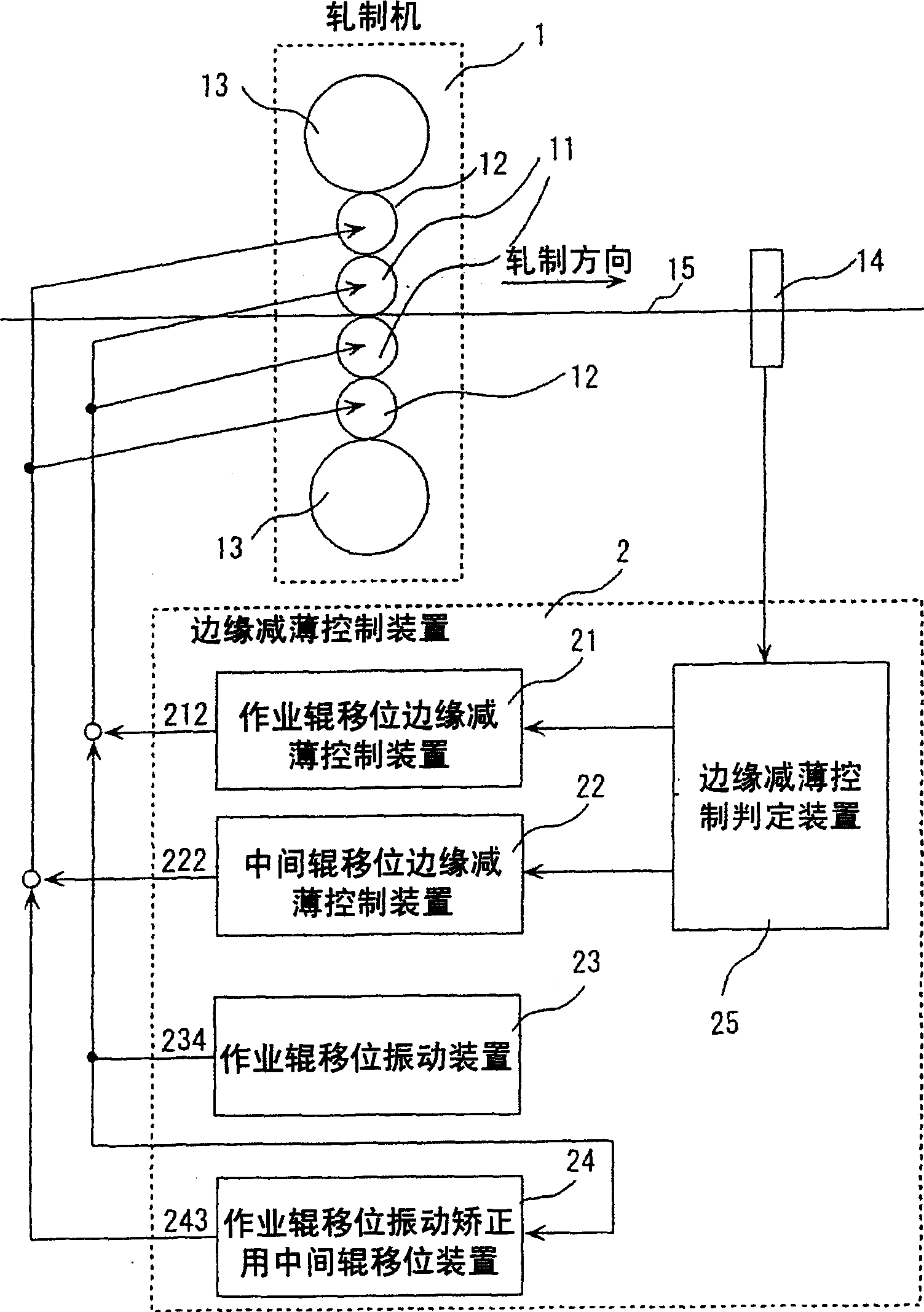

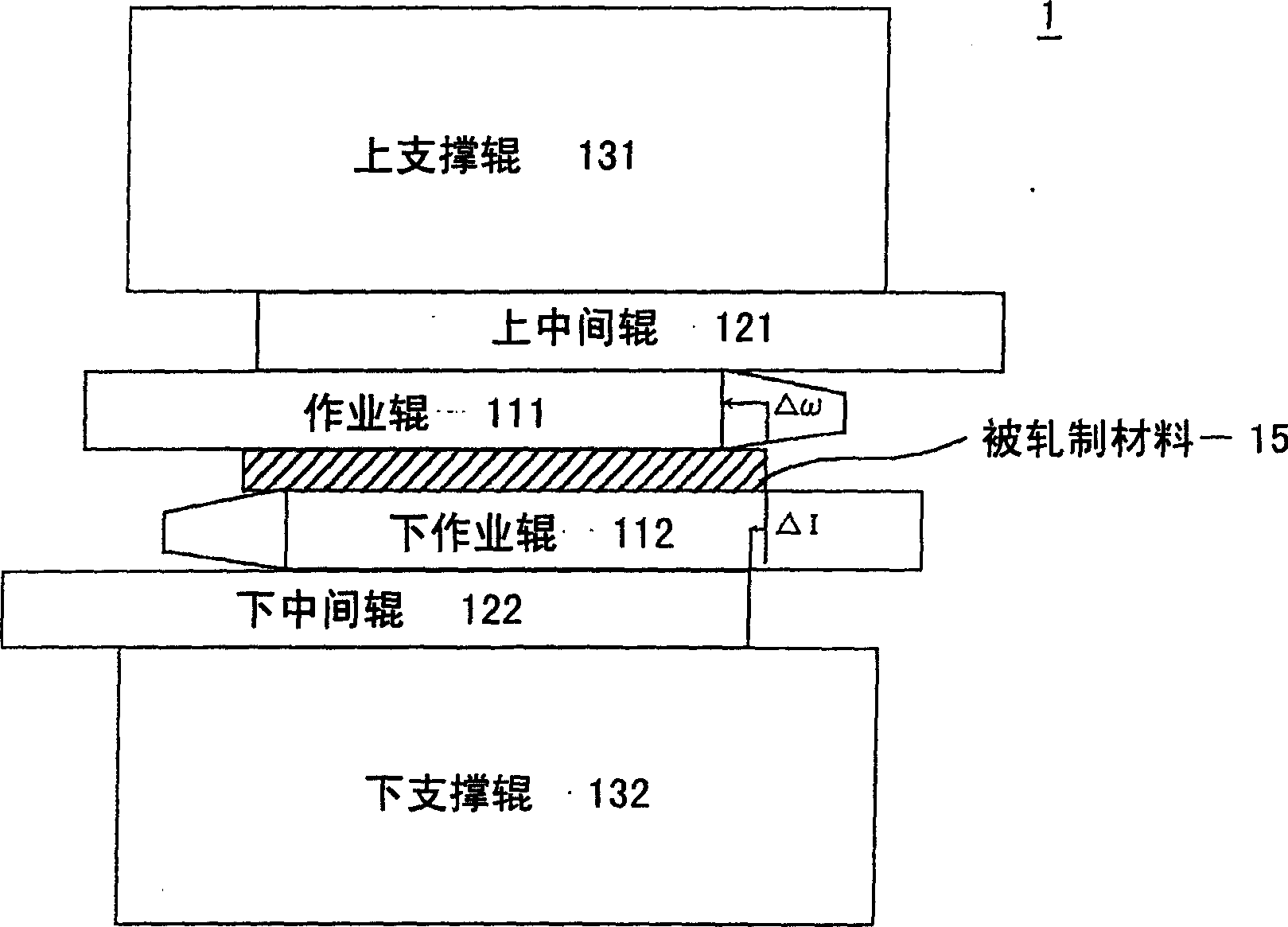

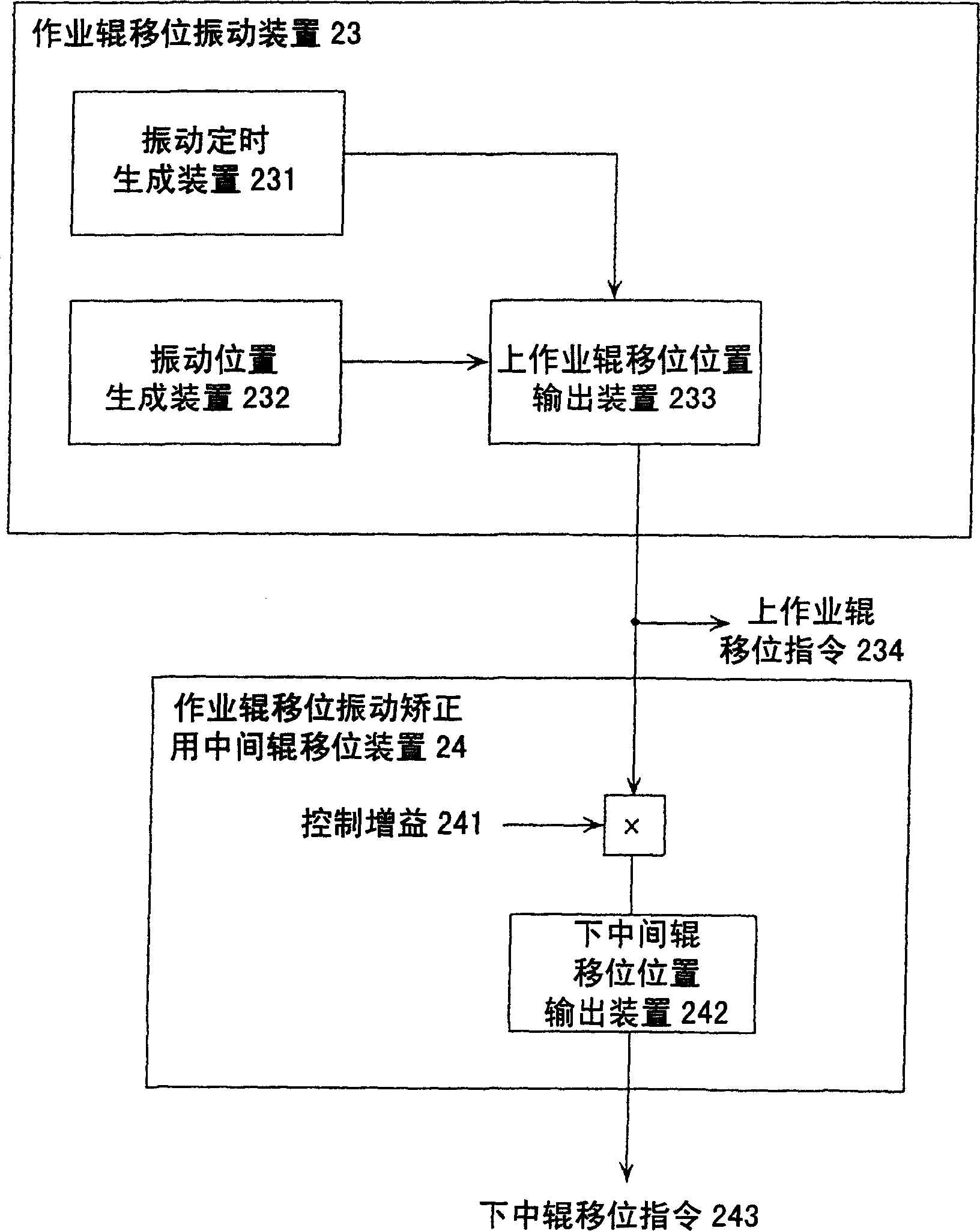

Rolling control method and device

InactiveCN1718299AImprove plate thickness control accuracyVibration control deviceMetal rolling arrangementsWork rollEngineering

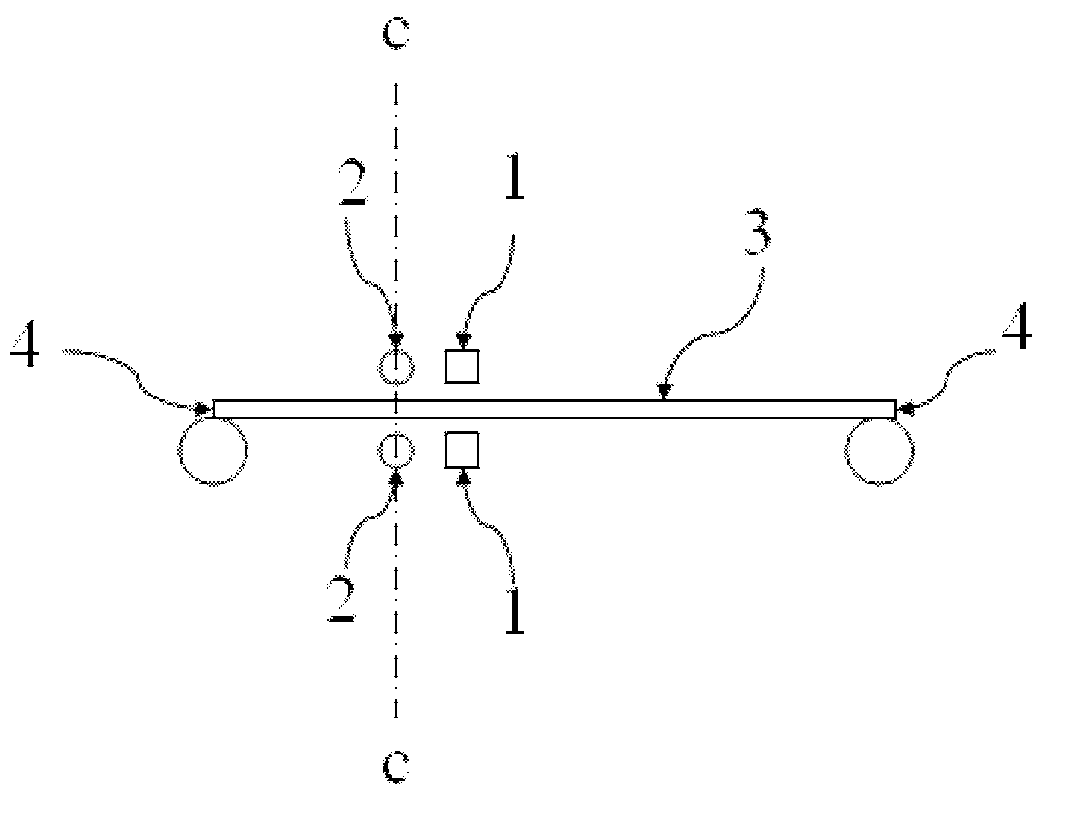

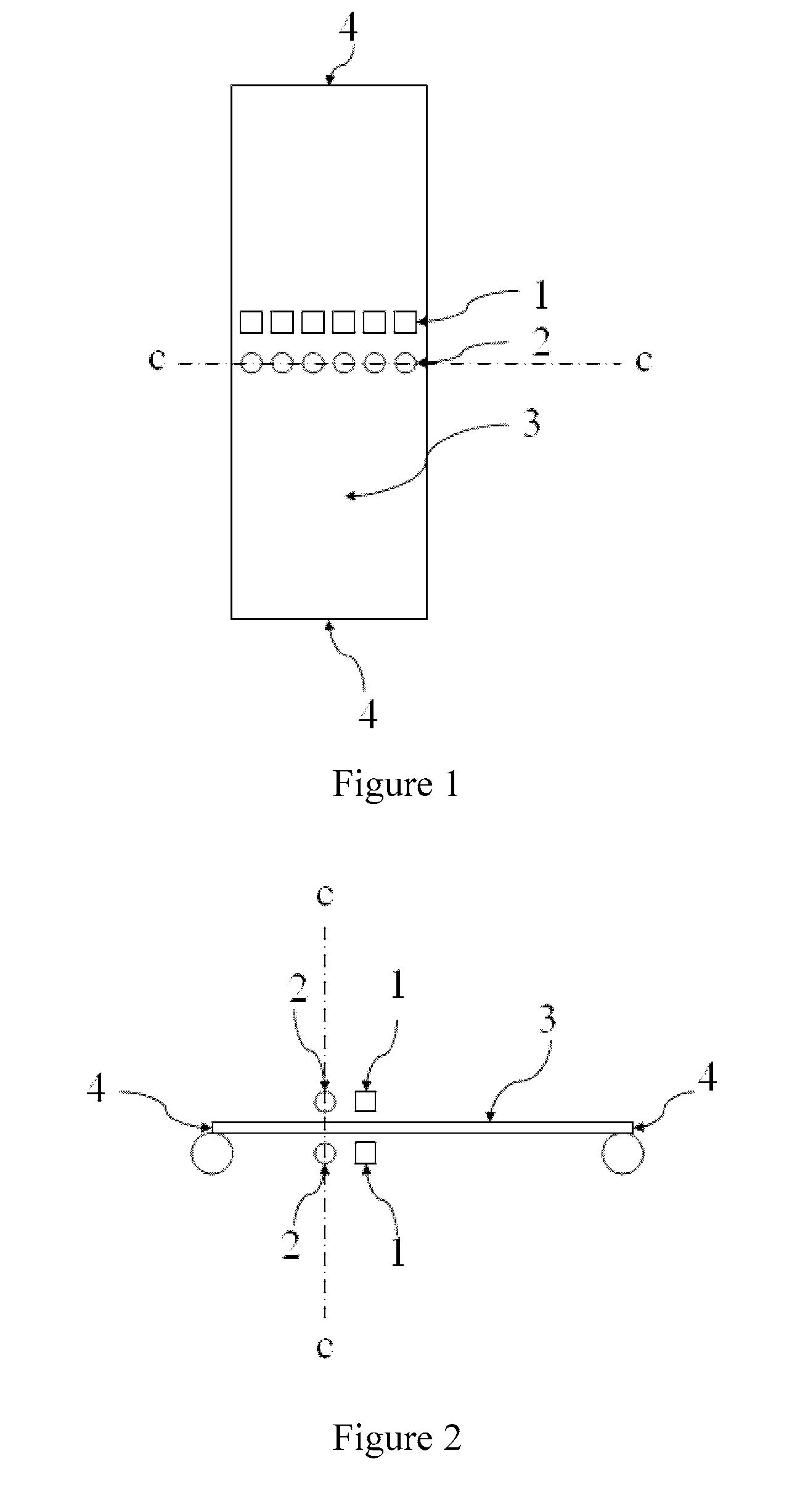

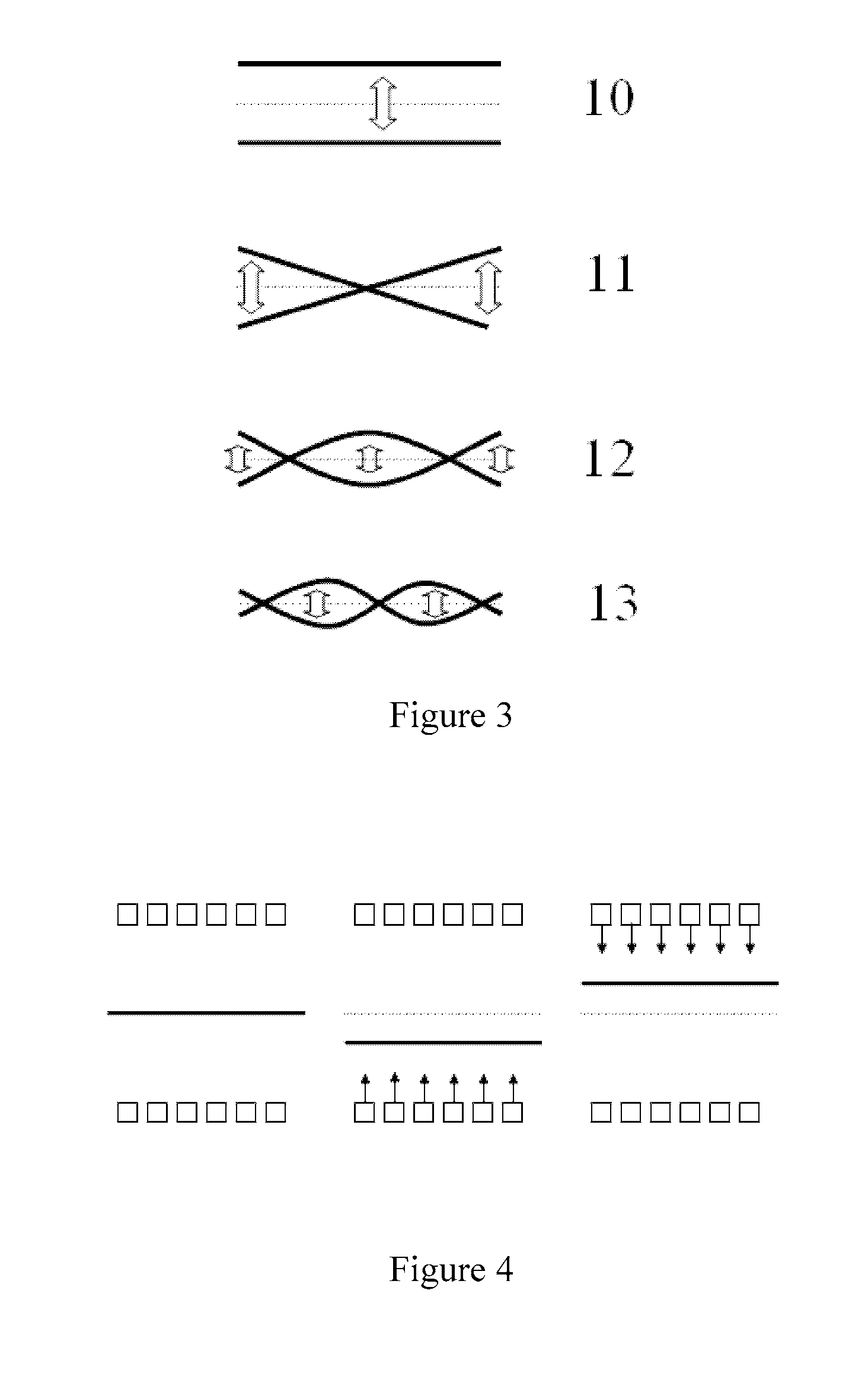

The present invention provides a method and an apparatus for controlling a rolling operation, which method and apparatus can carry out a highly accurate control of the edge drop while suppressing surface defects caused by a roll shift. In a six-high rolling mill, the highly accurate control of the edge drop is carried out by combining a working roll shift and an intermediate roll shift. In addition, a shift oscillation and the control of the edge drop by shifting the intermediate roll are carried out during the rolling operation of the working roll. Further, when the amount of the edge drop cannot be fully controlled by the control of the edge drop by shifting the intermediate roll, the control of the edge drop is carried out by shifting the working roll. By this method, the deviation of the edge drop can be controlled to a minimum while suppressing the generation of the defects on the surface of a strip to be rolled as much as possible.

Owner:HITACHI LTD

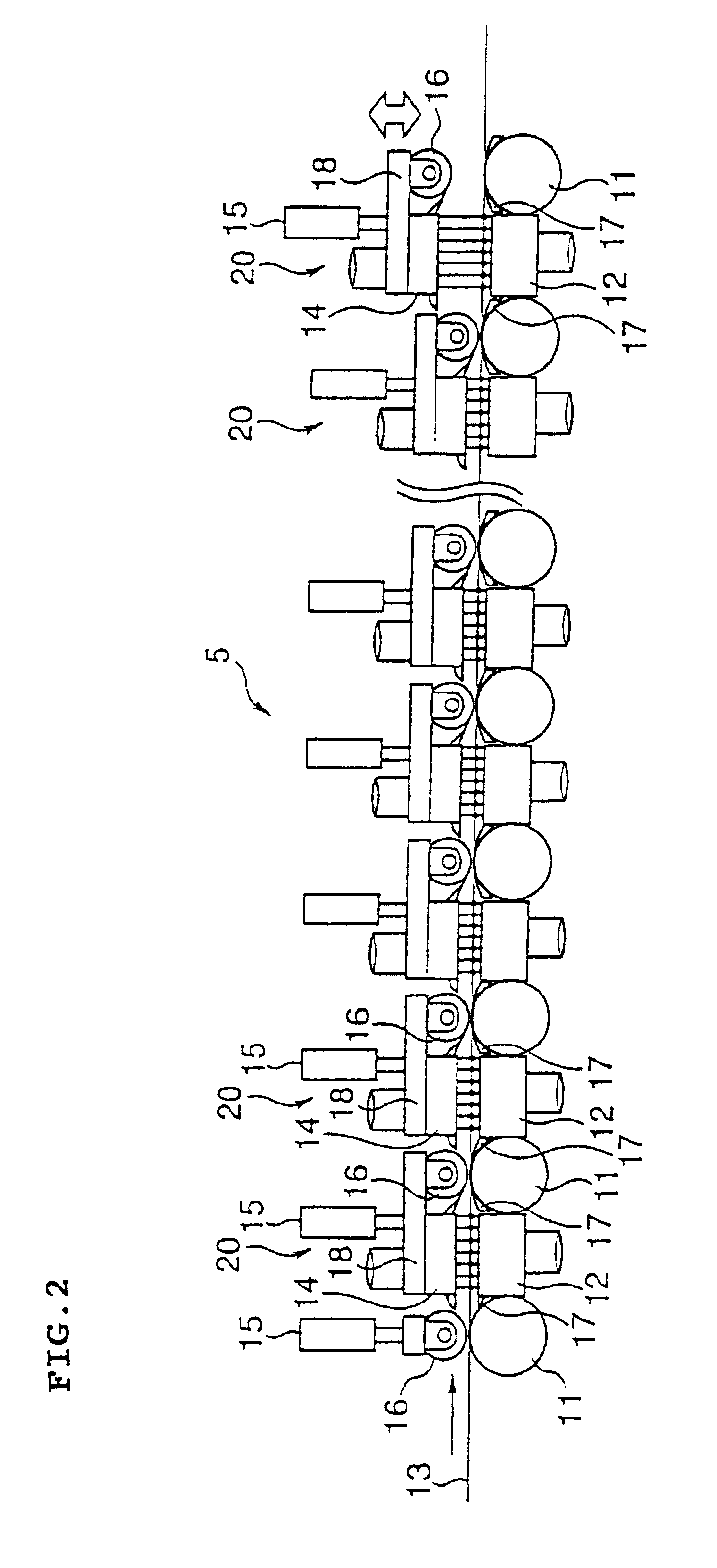

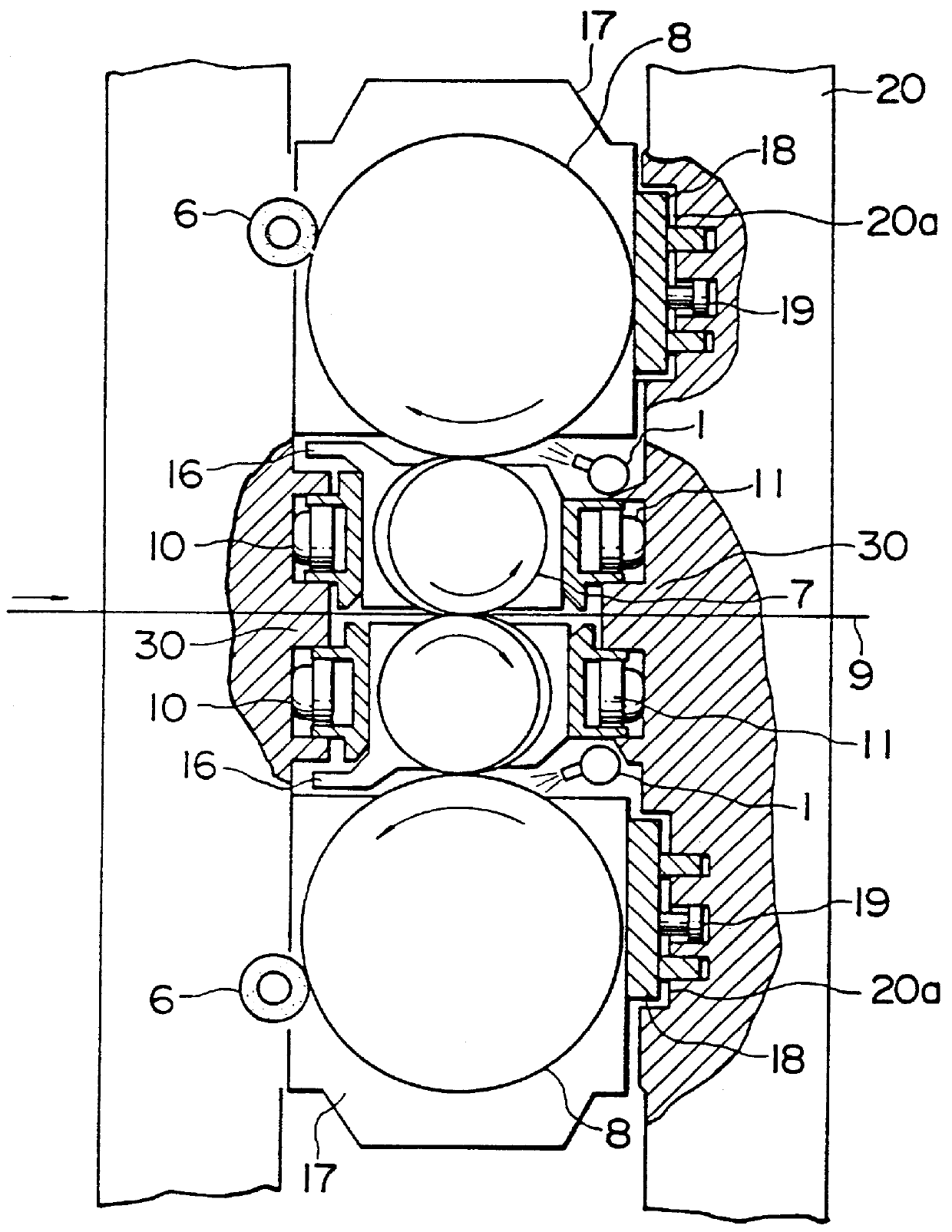

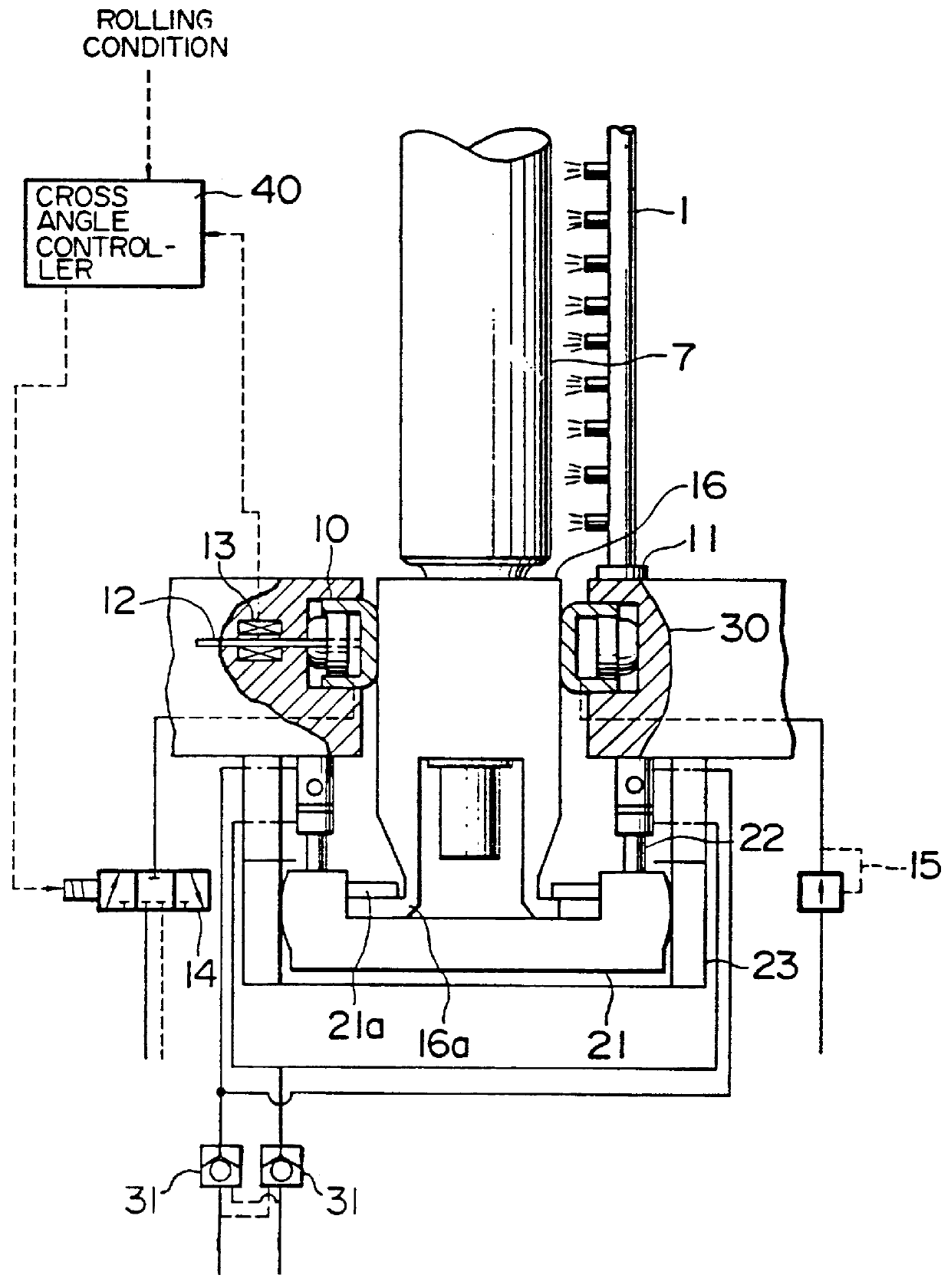

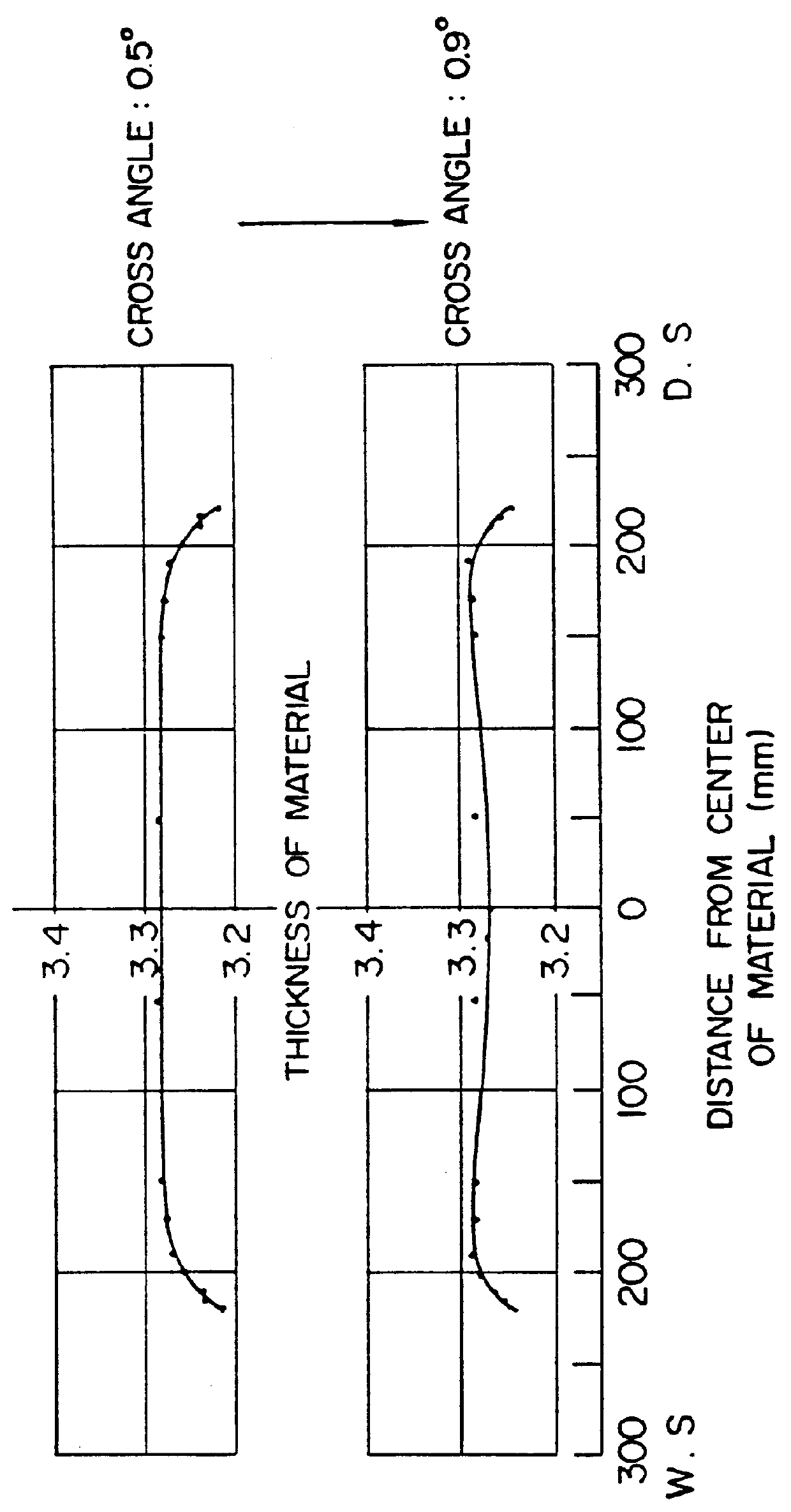

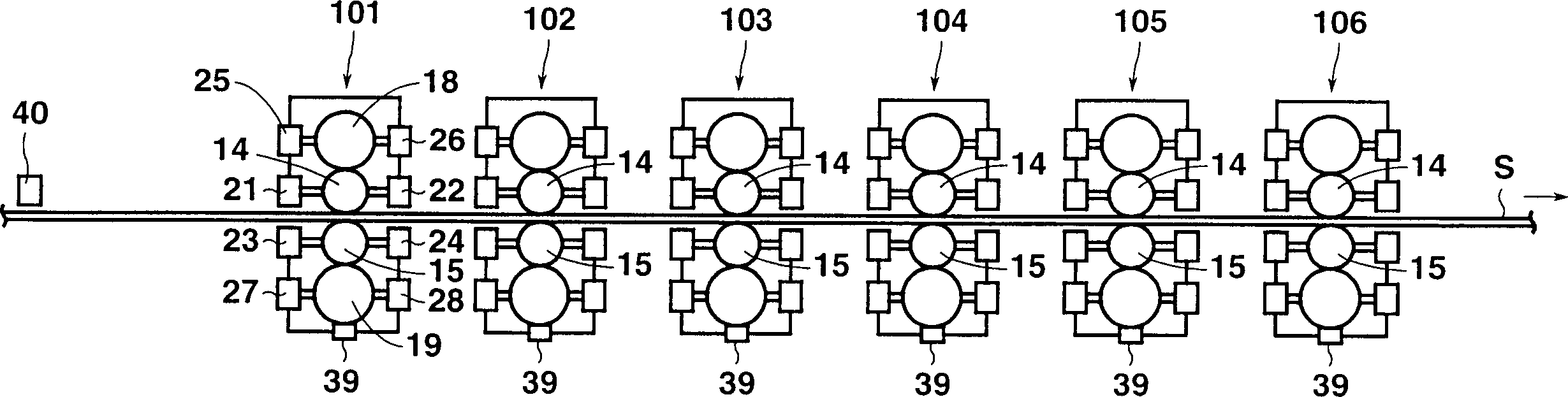

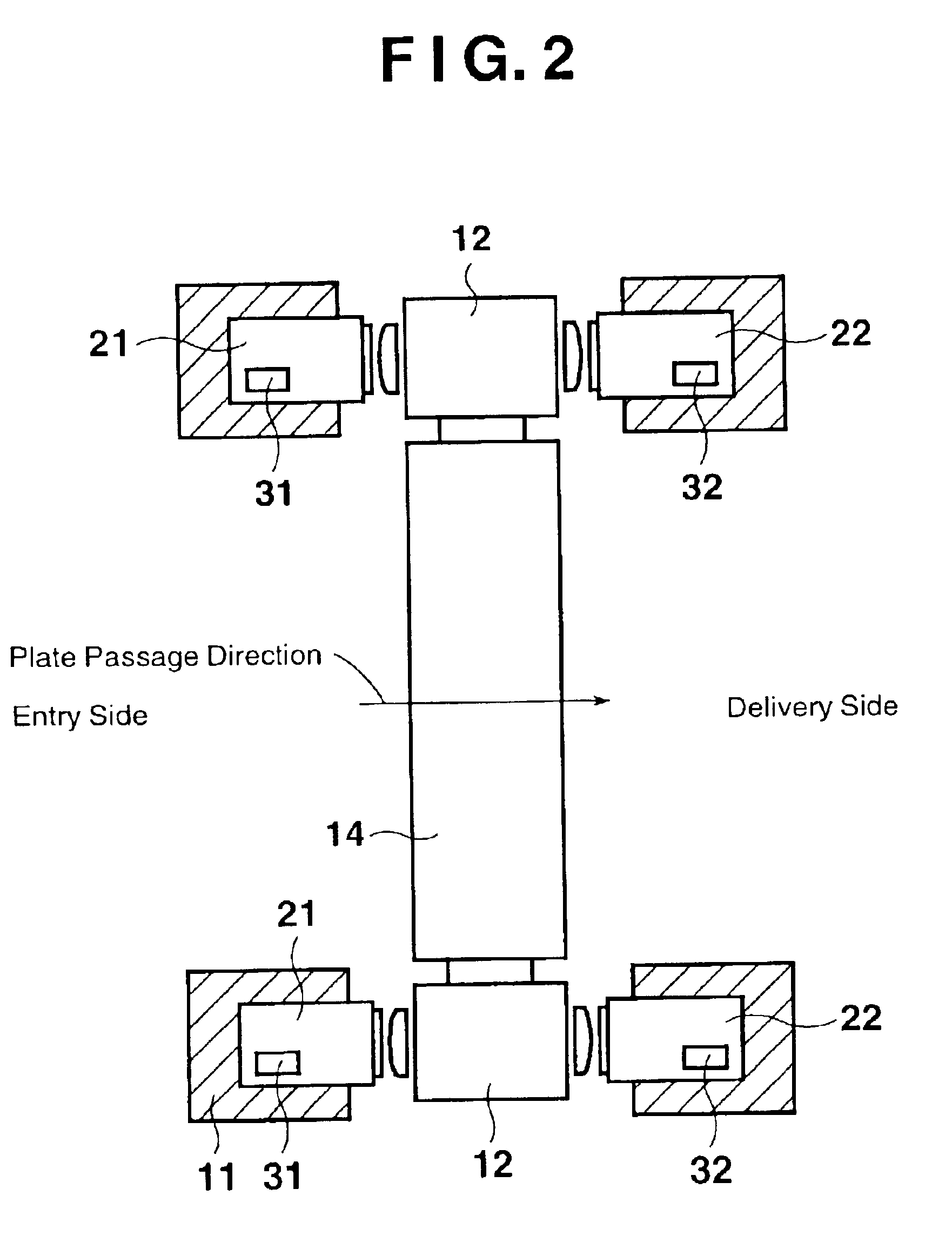

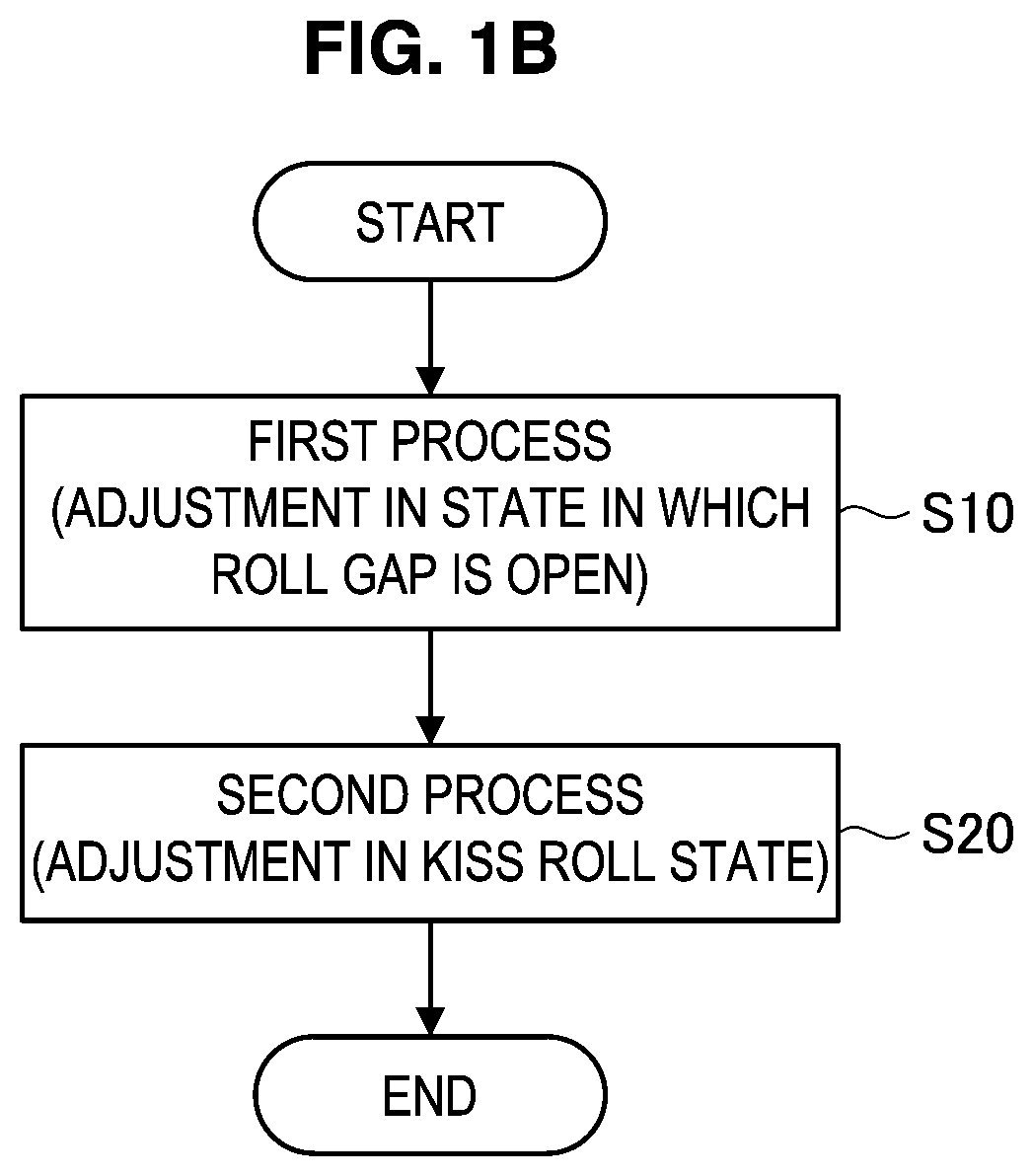

Rolling mill, hot rolling system, rolling method and rolling mill revamping method

InactiveUS6076388AImprove abilitiesReduce thrustMetal rolling stand detailsRolling equipment maintainenceWork rollEngineering

A work roll crossing type rolling mill has back-up rolls arranged in such a manner that their axes are not inclined in a horizontal plane. Work rolls are constructed in such a manner that their axes can be inclined in a horizontal plane relative to the backup rolls such that the axes of the work rolls cross the axes of the back-up rolls and such that the axes of the work rolls cross each other. A lubricant supply device is provided for supplying a lubricant between each work roll and each back-up roll combination to greatly reduce the thrust exerted to the work rolls, whereby the rolling mill is given an excellent ability of controlling the crown of the material to be rolled.

Owner:HITACHI LTD

Method for detecting the vibrations of a roll stand

ActiveUS20060236736A1Disturbed signalRoll force/gap control deviceMetal rolling stand detailsDirect observationEngineering

The invention relates to a method for detecting the vibrations of a roll stand (1) equipped with a hydraulic jack (6) as a device for adjusting the rolling rolls (4, 5). The hydraulic jack comprises a sensor (64) for measuring the position of the mobile portion relative to the fixed portion, this sensor supplying a digital signal (POS). In the method of the invention, the vibrations are detected by direct observation of the position signal (POS) and a comparison thereof relative to a spatio-temporal window (F) whose dimensions are determined as a function of the frequency to be detected. In accordance with the invention, it is possible to define different observation windows (F) suitable for the detection of different vibratory phenomena. In a tandem mill, the position signal (POS) of the hydraulic jack (6) of each roll stand (1) is observed in accordance with the method of the invention, which enables the commencement of vibration on each of the stands to be detected and the stand on which the phenomenon started to be determined.

Owner:CLECIM SAS

Rolling mill and method for operating same

The invention relates to a rolling mill and method for operating same. Hydraulic cylinders are provided in a housing so as to be opposed to work rolls and backup rolls. Before a front end portion of a rollable material is engaged between the work rolls, the working oil pressure of the hydraulic cylinders is set at a high pressure value to make a pressing force on roll chocks high. After the rollable material is completely engaged between the work rolls, the working oil pressure of the hydraulic cylinders is set at a low pressure value to make the pressing force on the roll chocks low.

Owner:MITSUBISHI HEAVY IND LTD

Rolling mill and method for operating same

InactiveUS6959571B2Improve accuracyRare end control deviceMetal rolling stand detailsHydraulic cylinderWork roll

Hydraulic cylinders are provided in a housing so as to be opposed to work rolls and backup rolls. Before a front end portion of a rollable material is engaged between the work rolls, the working oil pressure of the hydraulic cylinders is set at a high pressure value to make a pressing force on roll chocks high. After the rollable material is completely engaged between the work rolls, the working oil pressure of the hydraulic cylinders is set at a low pressure value to make the pressing force on the roll chocks low.

Owner:MITSUBISHI HEAVY IND LTD

Method for detecting the vibrations of a roll stand

ActiveUS7188496B2Disturbed signalRoll force/gap control deviceMetal rolling stand detailsDirect observationEngineering

The invention relates to a method for detecting the vibrations of a roll stand (1) equipped with a hydraulic jack (6) as a device for adjusting the rolling rolls (4, 5). The hydraulic jack comprises a sensor (64) for measuring the position of the mobile portion relative to the fixed portion, this sensor supplying a digital signal (POS). In the method of the invention, the vibrations are detected by direct observation of the position signal (POS) and a comparison thereof relative to a spatio-temporal window (F) whose dimensions are determined as a function of the frequency to be detected. In accordance with the invention, it is possible to define different observation windows (F) suitable for the detection of different vibratory phenomena. In a tandem mill, the position signal (POS) of the hydraulic jack (6) of each roll stand (1) is observed in accordance with the method of the invention, which enables the commencement of vibration on each of the stands to be detected and the stand on which the phenomenon started to be determined.

Owner:CLECIM SAS

Method and apparatus for cooling hot rolled steel strip, and method for manufacturing hot rolled steel strip

InactiveUS20020134473A1Efficient dischargeFine granularityBlast furnace detailsCooling devicesSurface coolingSteel belt

A lower surface cooling box 12 is arranged between transfer rolls 11 on a runout table 3 and an upper cooling box 14 moving freely is arranged at a position corresponding to the cooling box 12 to eject cooling water to the steel strip symmetrically in the vertical direction. The steel strip passes the center of convergence of cooling water from upper and lower surfaces of the steel strip. A water breaking roll 16 is provided elevating freely at least at the outlet side rotating at the same peripheral speed as the transfer rolls and is rotated to lower concurrently with passing of the steel strip top at the cooling apparatus. The upper cooling box is also lowered concurrently to cool the steel strip.

Owner:JFE STEEL CORP

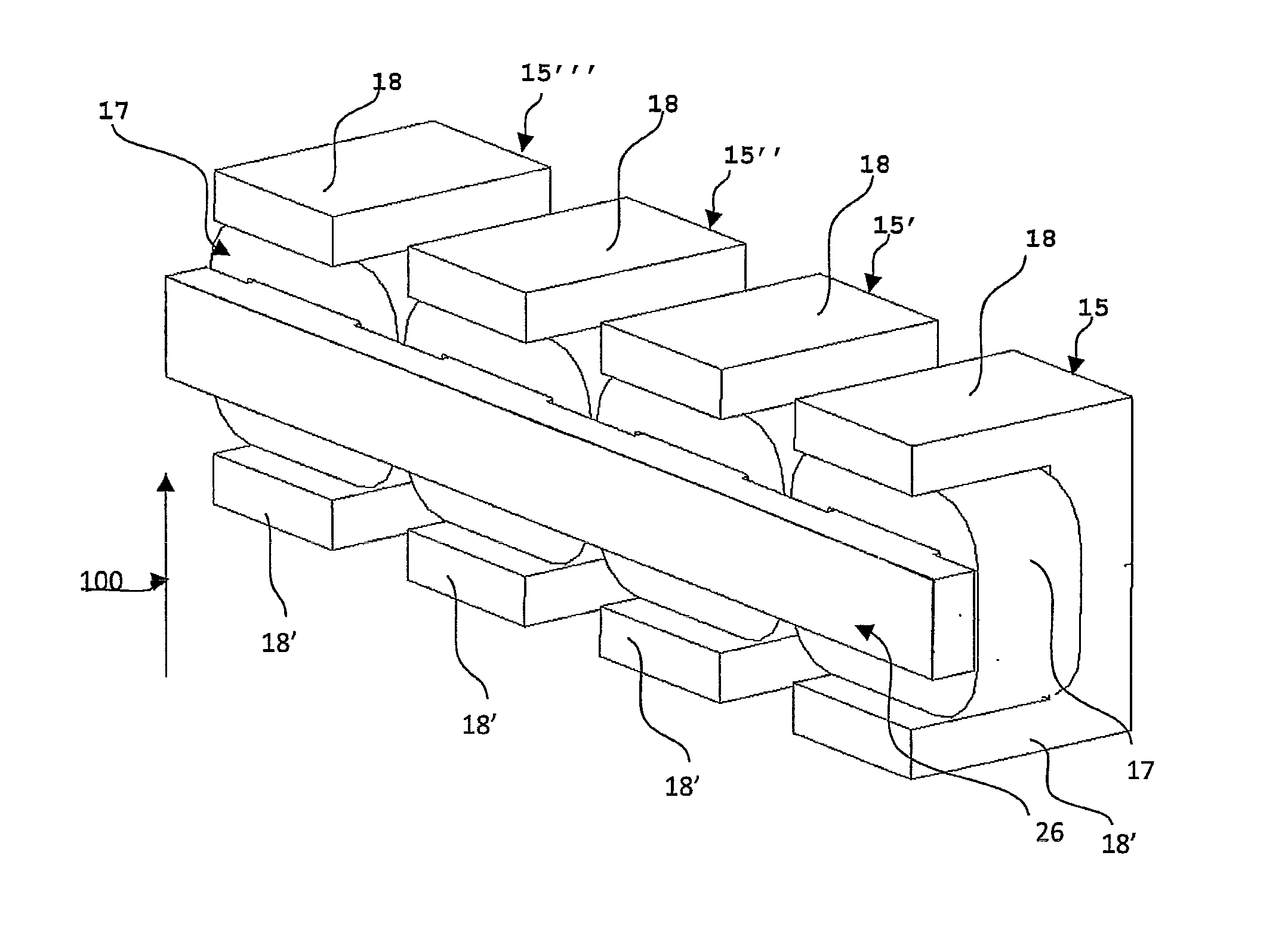

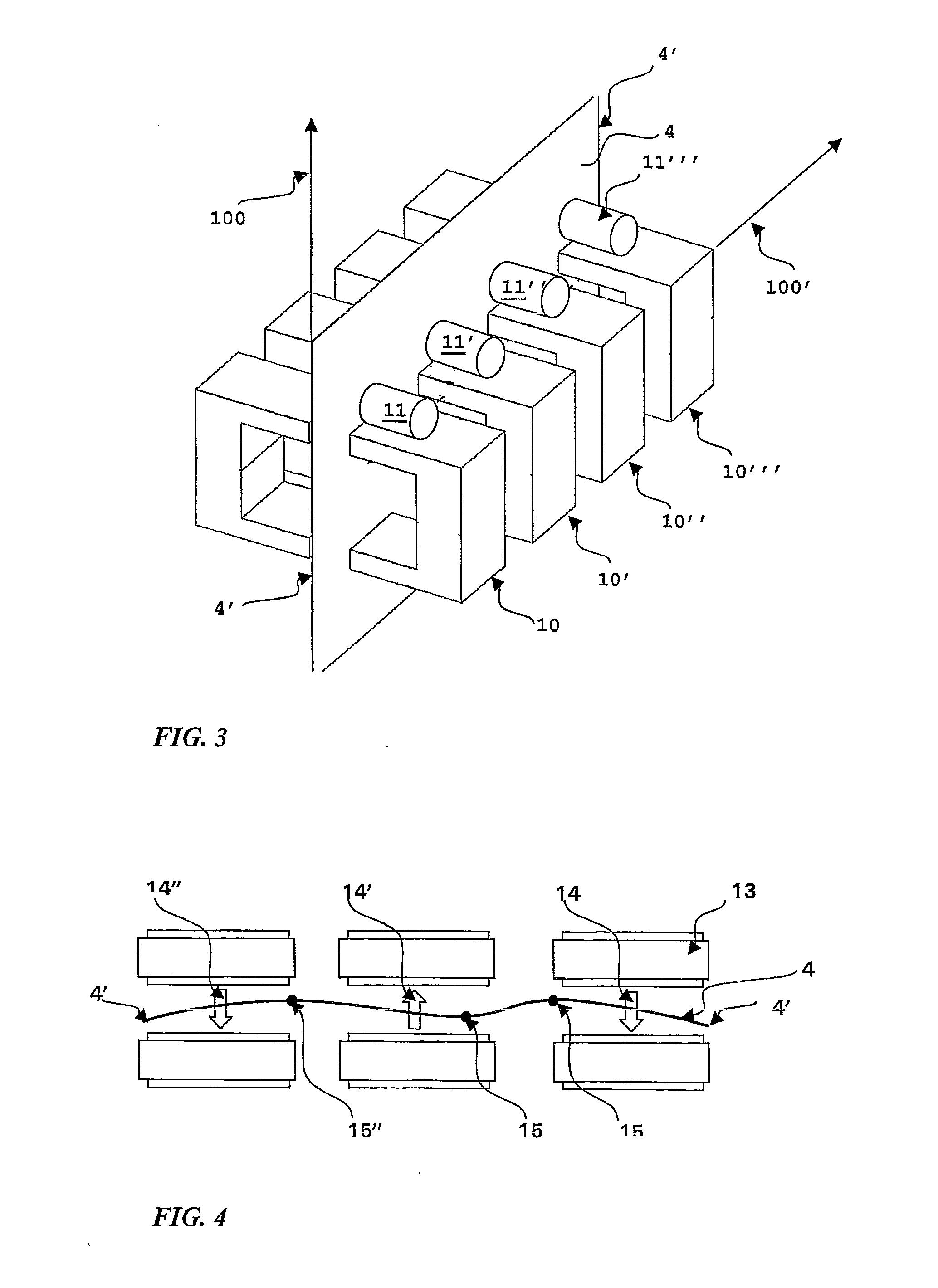

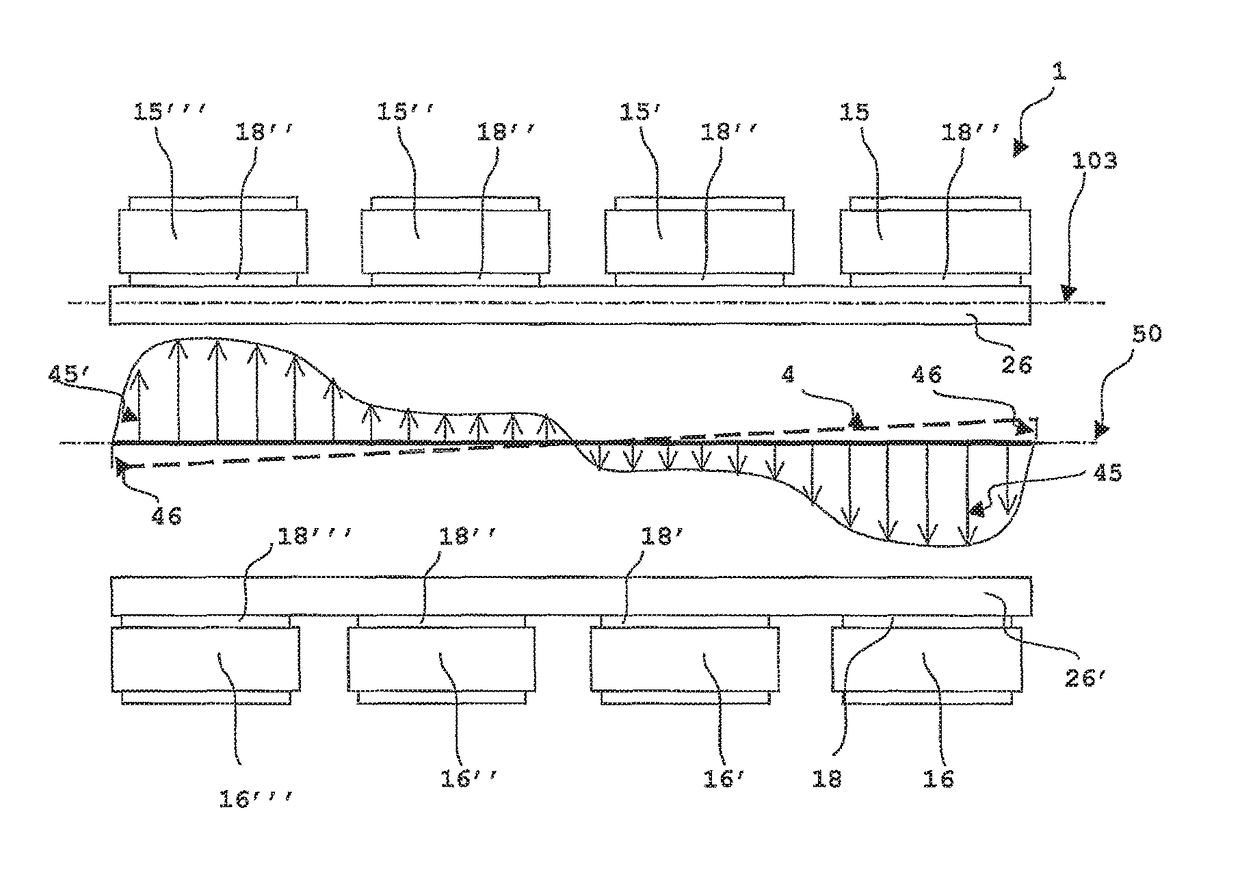

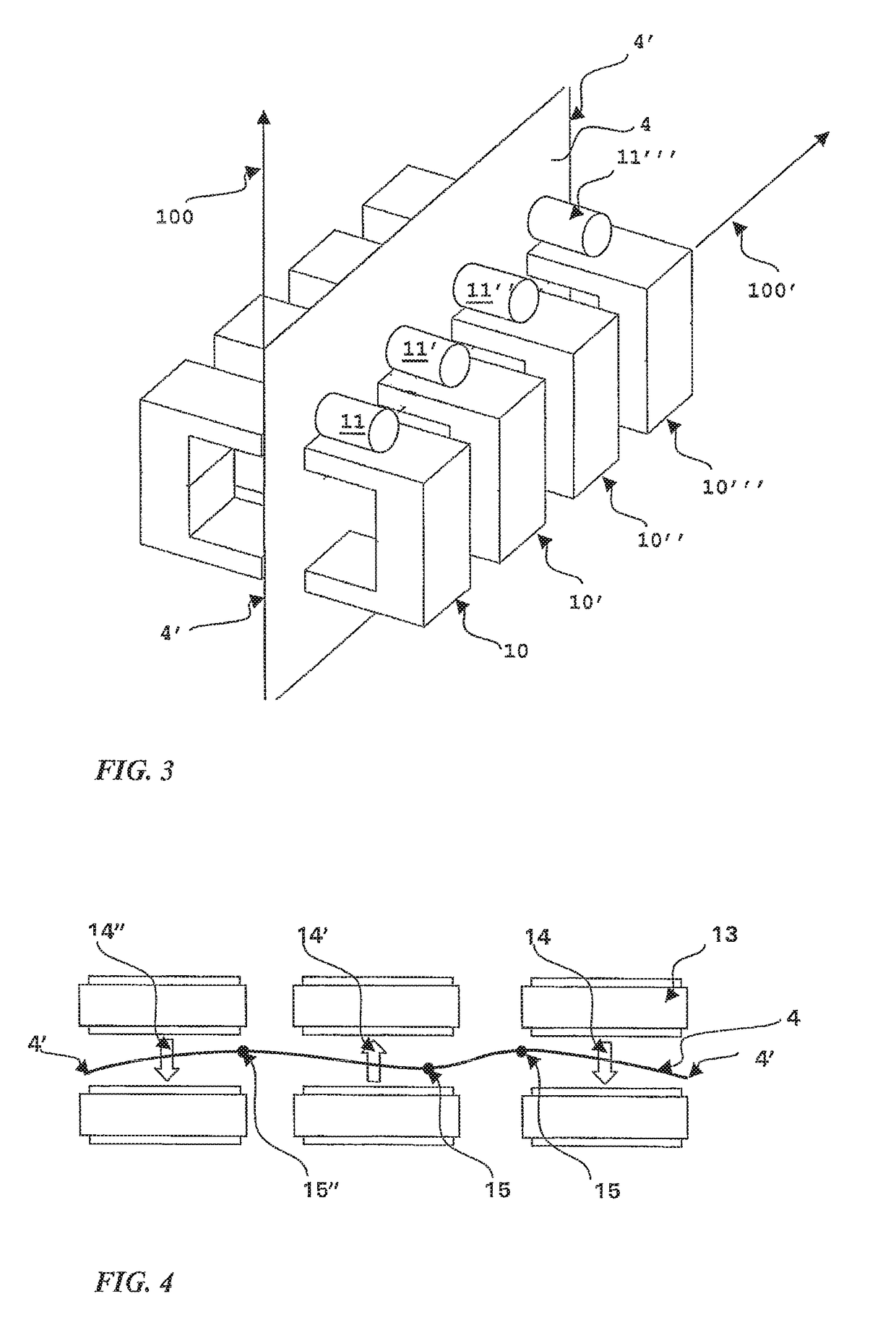

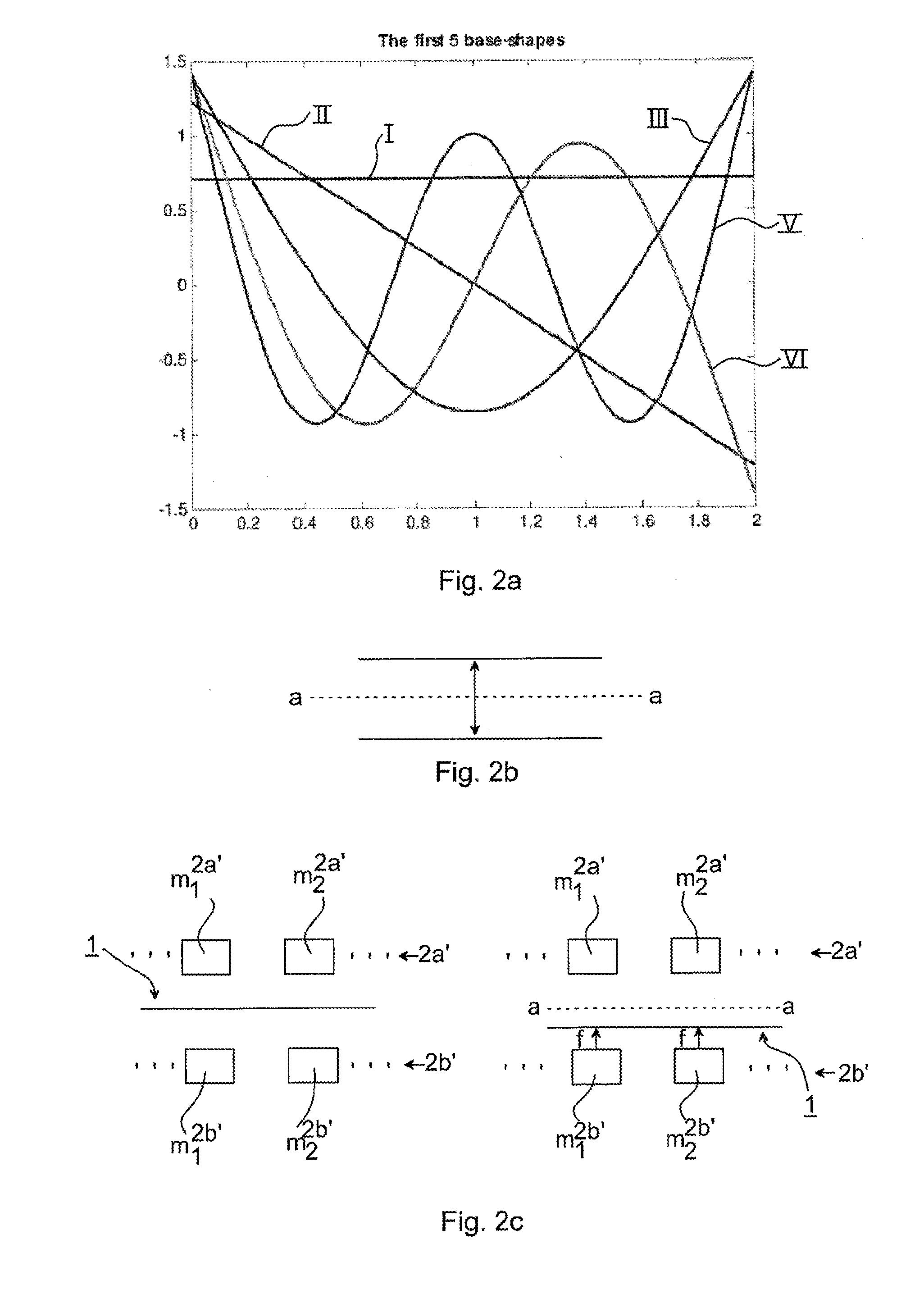

Electromagnetic device for stabilizing and reducing the deformation of a strip made of ferromagnetic material, and related process

ActiveUS20130319326A1Reduce productionEliminate leaksHot-dipping/immersion processesLiquid surface applicatorsEngineeringMirror image

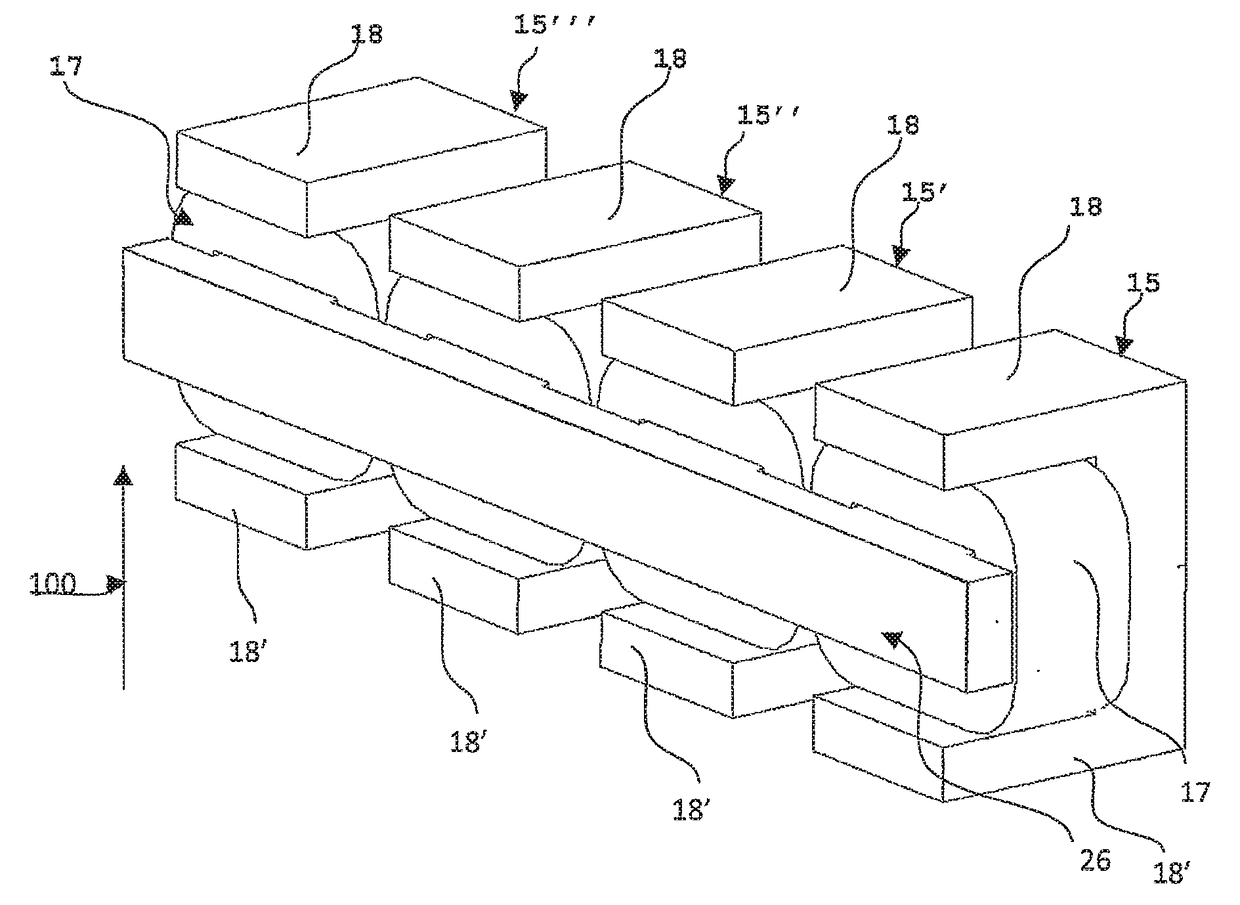

An electromagnetic device (1) for stabilizing and minimizing the deformation of a strip (4) made of ferromagnetic material during its feeding in a system for coating the same strip with molten metal, by applying a distribution of force which is continuous in the direction transversal to the strip regardless of the width thereof. The device comprises first electromagnets and second electromagnets mirroring the first electromagnets with respect to said theoretical pass-line (50) of said strip (4). Each electromagnet includes a core comprising one pole and one feeding coil wound about the pole. The electromagnetic device comprises a connection element (26) made of ferromagnetic material which connects the cores of the first electromagnets (15, 15′, 15″, 15″′) and a connection element (26′) made of ferromagnetic material which connects the cores of the second electromagnets (16, 16′, 16″, 16′). The connection elements (26, 26′) mirror the theoretical pass-line (50) of the strip (4).

Owner:DANIELI & C OFF MEC SPA

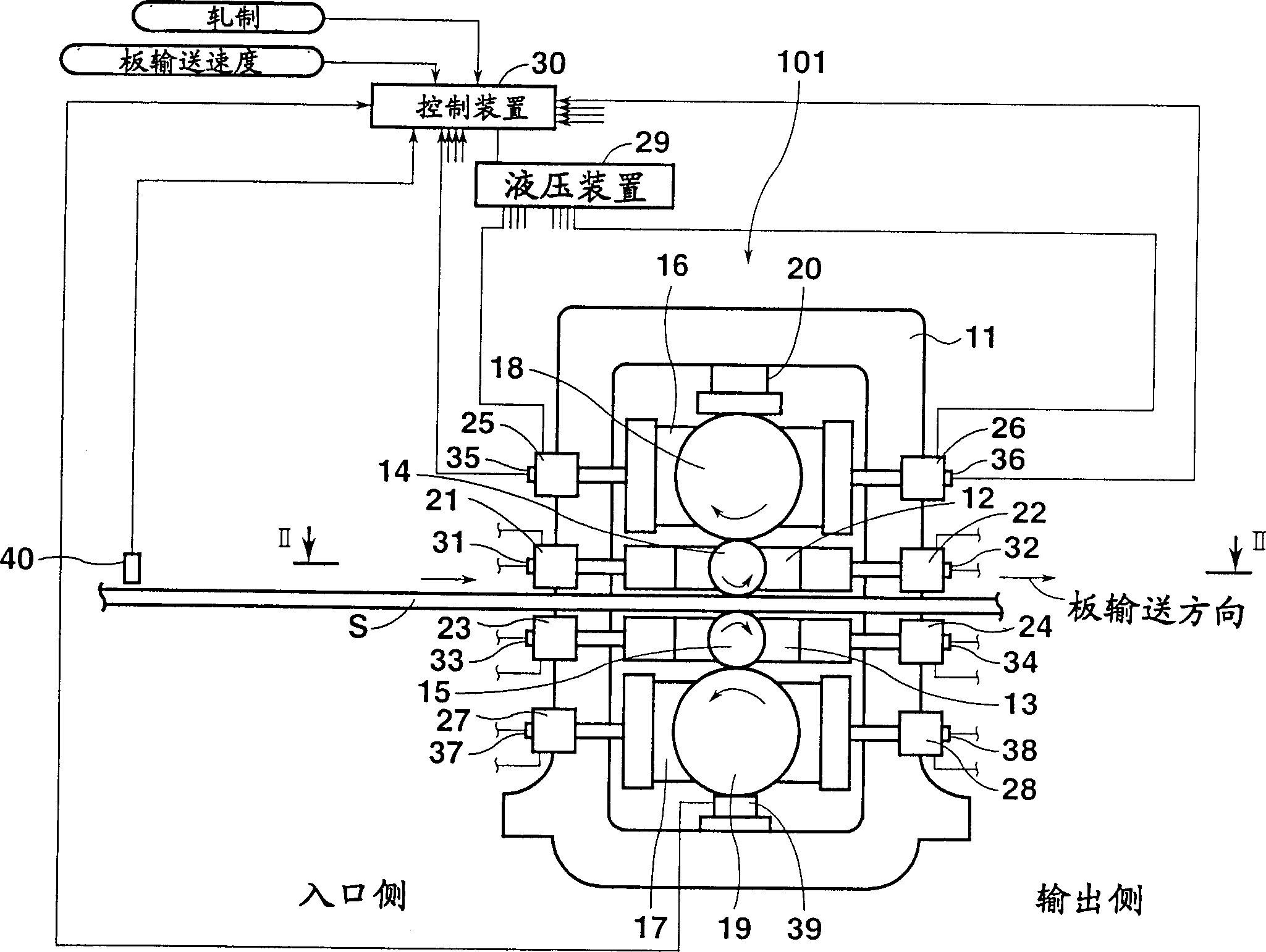

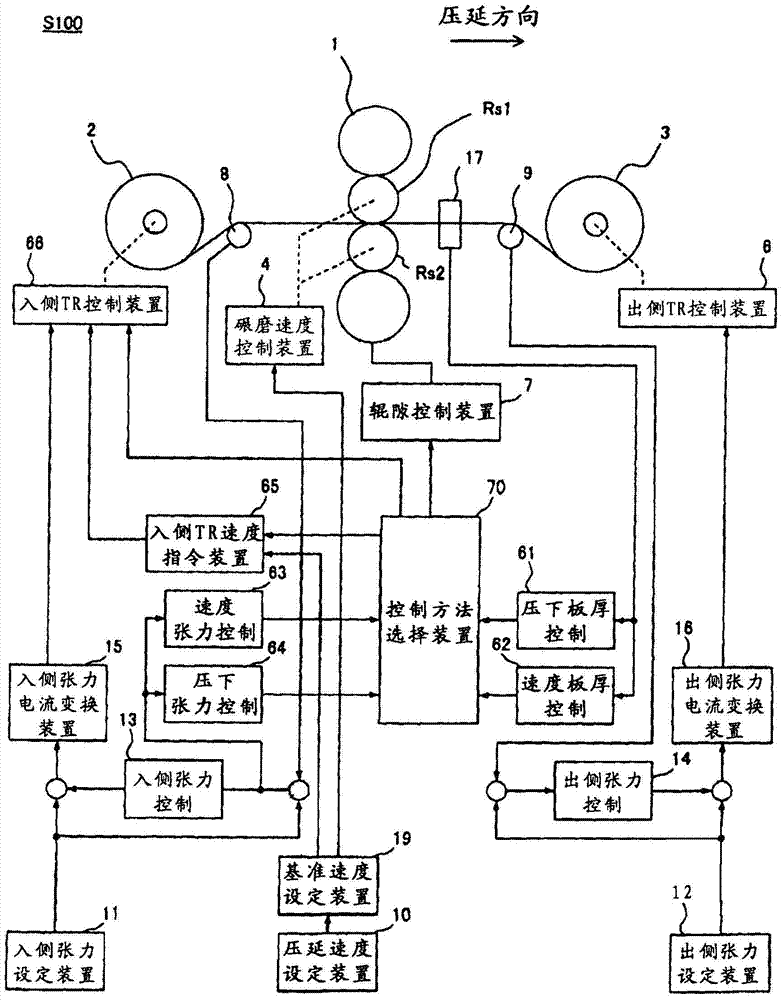

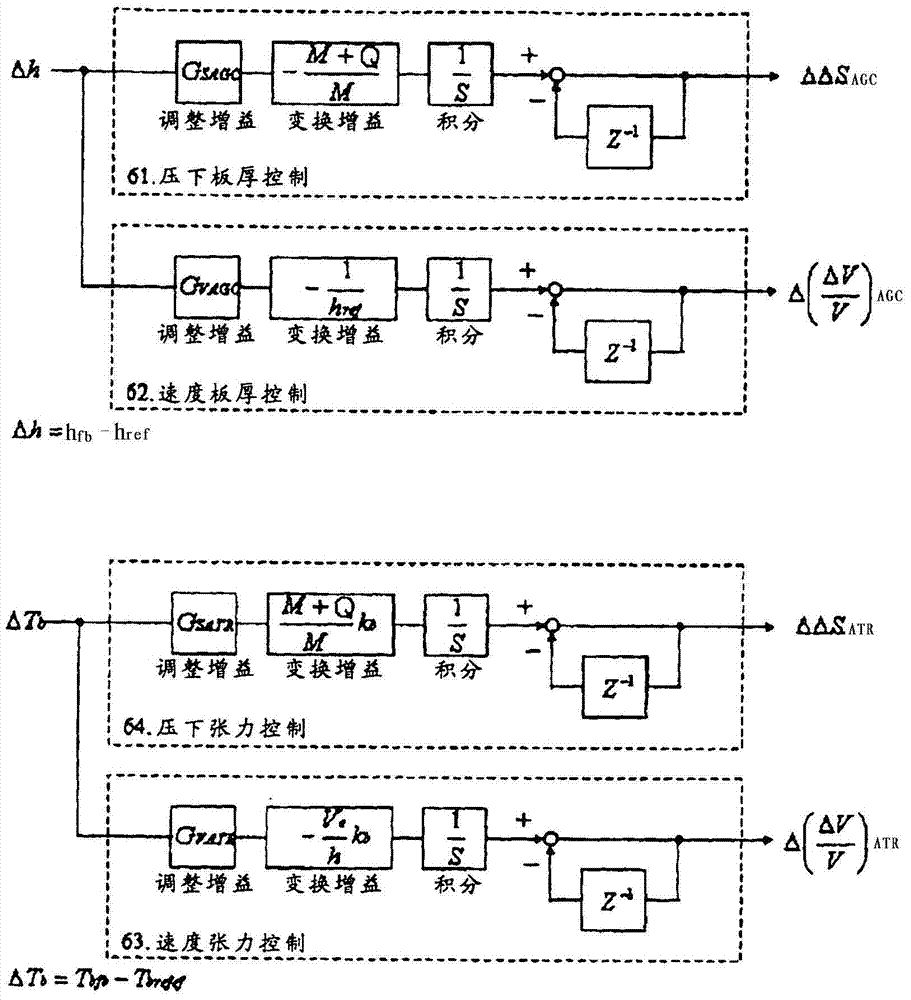

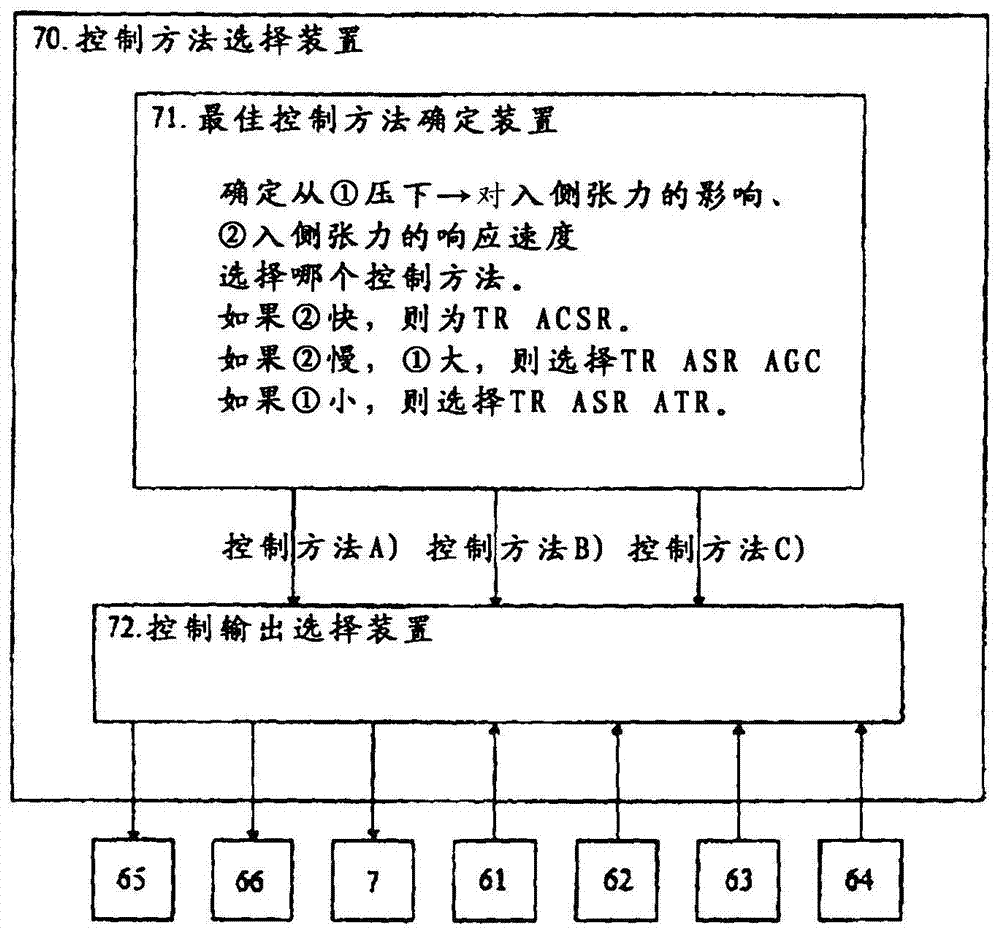

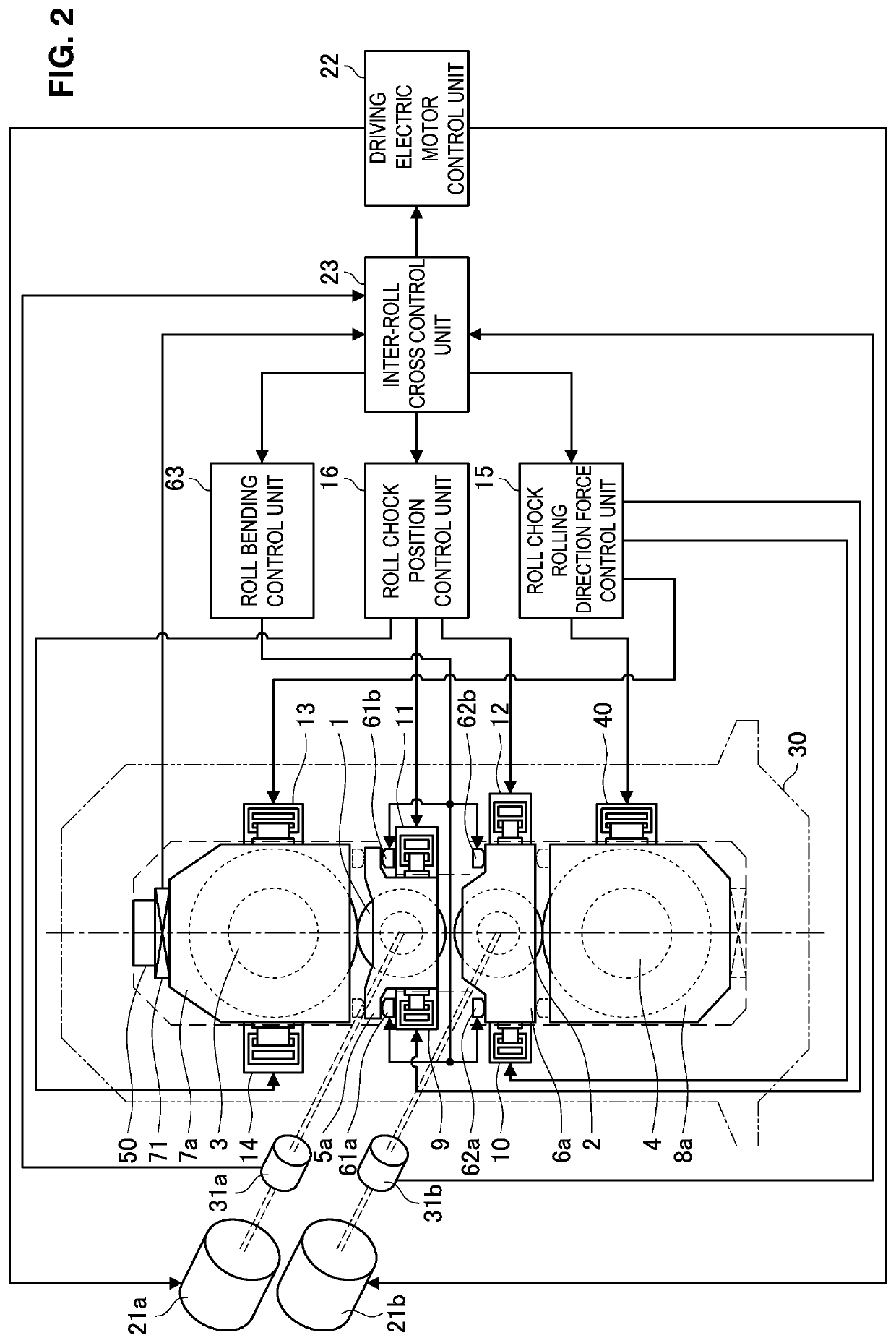

Rolling control apparatus and rolling control method

ActiveCN103861872AReduce vibrationRoll force/gap control deviceVibration control devicePlate pressureTension control

The invention relates to an apparatus for controlling the structure that generates tensile force on a rolled material in the inlet side and outlet side of a rolling machine so as to compress the vibaration of the plate pressure on the outlet side of the rolling machine. The invention provides a rolling control apparatus, namely a rolling machine which rolls a rolled material by controlling a roller pair. The rolling apparatus is characterized by comprising a roller gap control part, which is used to control the gap between the tensile force control rollers, wherein the tensile force control rollers are inserted into the rolling machine to roll the rolled material or roll the rolled material that is discharged from the rolling machine; and a speed control part, which is used to control the conveying speed that the rolled material is inserted into the rolling machine or the rolled material is discharged out of the rolling machine according to the plate thickness of the rolled material.

Owner:HITACHI LTD

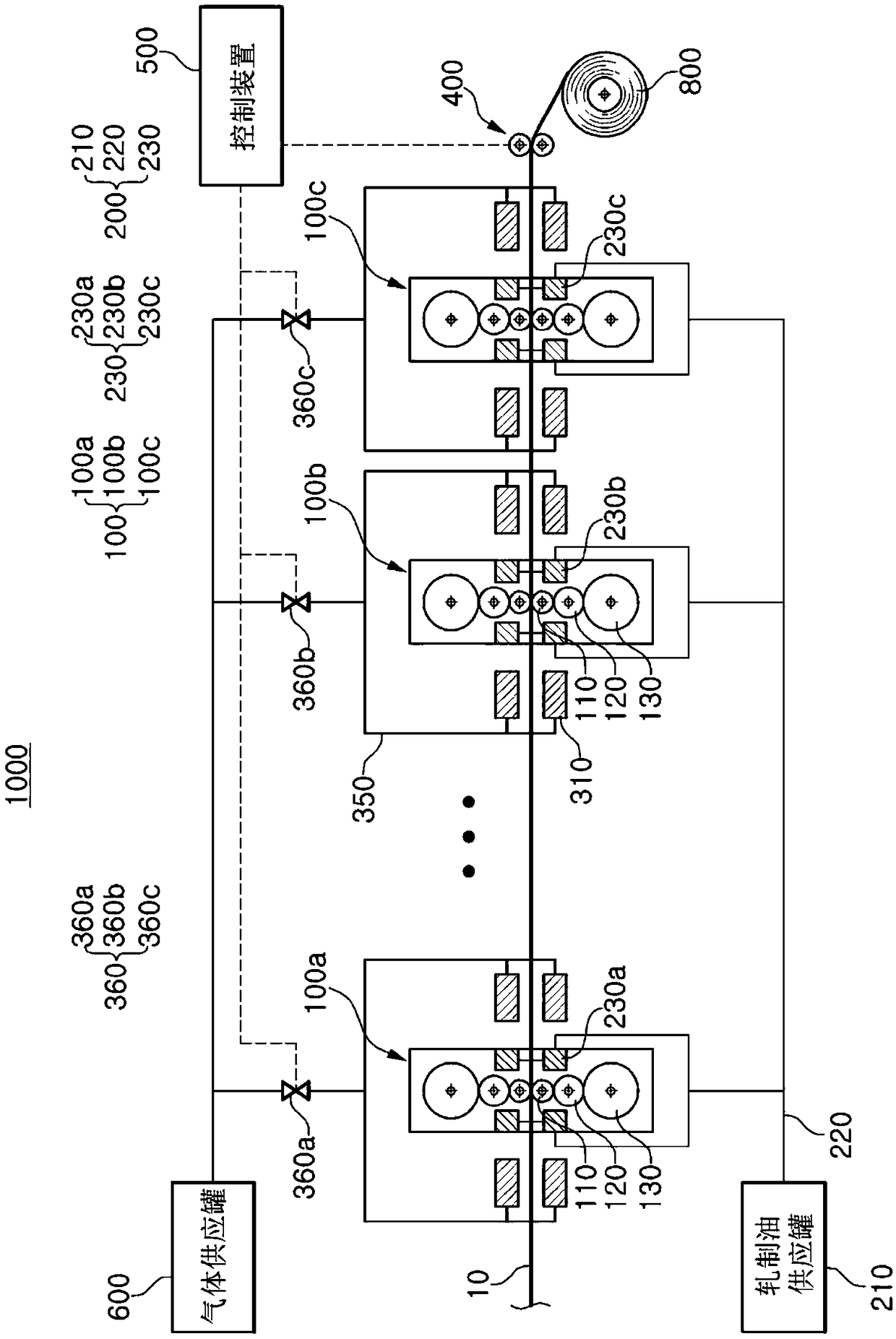

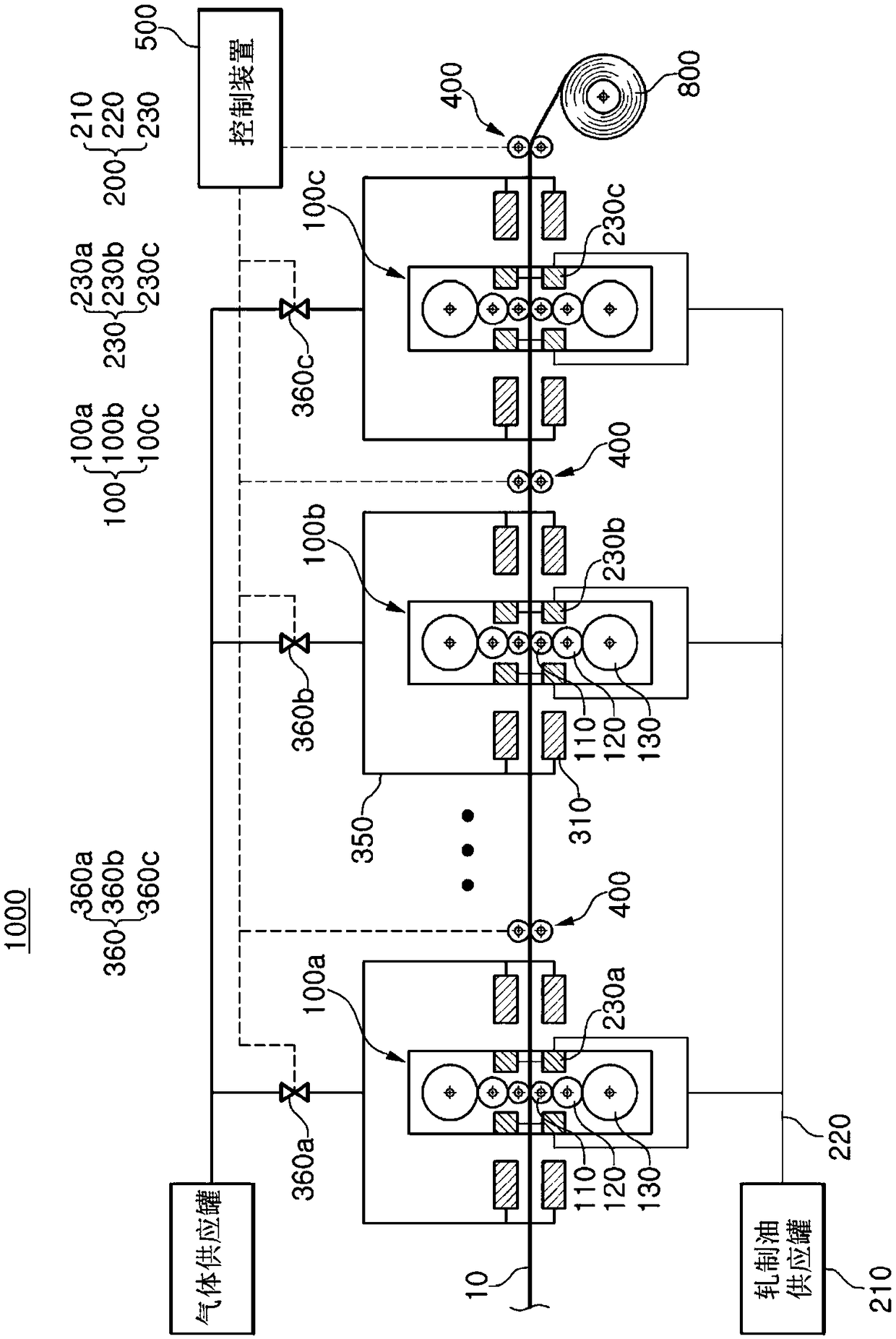

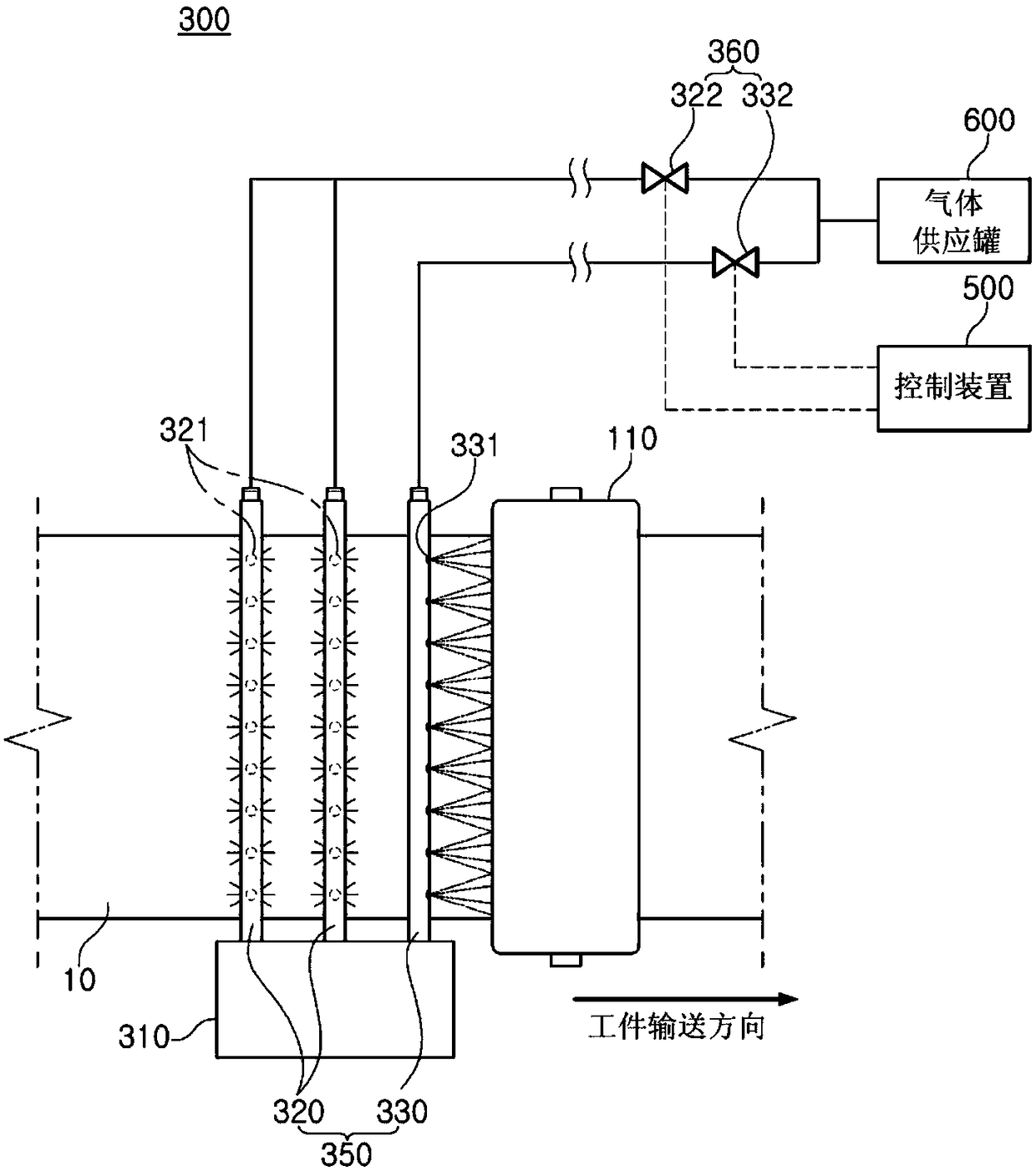

Rolling facility and rolling method of stainless steel plate

InactiveCN109475912AImprove productivityQuality improvementTemperature control deviceMetal rolling stand detailsEngineeringGas supply

The present invention relates to a rolling facility and a rolling method of a stainless steel plate. The rolling facility according to the present invention comprises: a plurality of rolling roll setswhich are composed of at least a pair of rolls facing each other with a workpiece being conveyed therebetween and are provided in a conveying direction of the workpiece; a plurality of rolling oil supply means, provided corresponding to each of the rolling roll sets, for supplying a rolling oil to the rolling roll sets; a plurality of cooling means, provided corresponding to each of the rolling roll sets, for supplying a gas to the workpiece and the rolling roll sets; a gloss measurement means, disposed between the rolling roll set most rearwardly disposed in the traveling direction of the workpiece and a winder for winding the workpiece, for measuring the surface gloss of the workpiece; and a control means, connected to the gloss measurement means and the plurality of cooling means, forcontrolling an amount of gas supplied by the plurality of cooling means according to the surface gloss measured by the gloss measurement means.

Owner:POHANG IRON & STEEL CO LTD

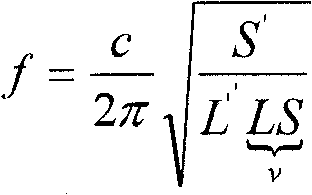

Method and apparatus for semi-active reduction of compression oscillations in a hydraulic system

InactiveCN102271832AVolume changeChange effective lengthRoll force/gap control deviceServometer circuitsSemi activeActuator

The invention relates to a method and a device for the semi-active reduction of pressure oscillations in a hydraulic system of a cold- or warm-rolling train or a strip conditioning installation for iron, steel or aluminum materials. The aim of the invention is to provide a method and a device by means of which occurring pressure oscillations can be effectively suppressed by means of a simple and cost-effective device. This aim is achieved by a method of the type mentioned above, comprising the following method steps in the sequence specified: a) detecting a pressure signal by means of a pressure sensor through permanent pressure measurement in the hydraulic system; b) determining an alternating component of the pressure signal; c) determining in real time at least one variable that changes over time with the aid of a controller while taking the alternating component into consideration; d) subjecting at least one actuator to the variable, wherein the actuator changes a natural frequency of an oscillation absorber that is connected to the hydraulic system, thereby reducing the amplitude of the pressure oscillations in the hydraulic system.

Owner:SIEMENS VAI METALS TECHNOLOGIES GMBH & CO

Electromagnetic device for stabilizing and reducing the deformation of a strip made of ferromagnetic material, and related process

ActiveUS9968958B2Reduce vibrationEliminate leaksHot-dipping/immersion processesLiquid surface applicatorsEngineeringMolten metal

An electromagnetic device (1) for stabilizing and minimizing the deformation of a strip (4) made of ferromagnetic material during its feeding in a system for coating the same strip with molten metal, by applying a distribution of force which is continuous in the direction transversal to the strip regardless of the width thereof. The device comprises first electromagnets and second electromagnets mirroring the tirst electromagnets with respect to said theoretical pass-line (50) of said strip (4). Each electromagnet includes a core comprising one pole and one feeding coil wound about the pole. The electromagnetic device comprises a connection element (26) made of ferromagnetic material which connects the cores of the first electromagnets (15, 15′, 15″, 15′″) and a connection element (26′) made of ferromagnetic material which connects the cores of the second electromagnets (16, 16′, 16″, 16′″). The connection elements (26, 26′) mirror the theoretical pass-line (50) of the strip (4).

Owner:DANIELI & C OFF MEC SPA

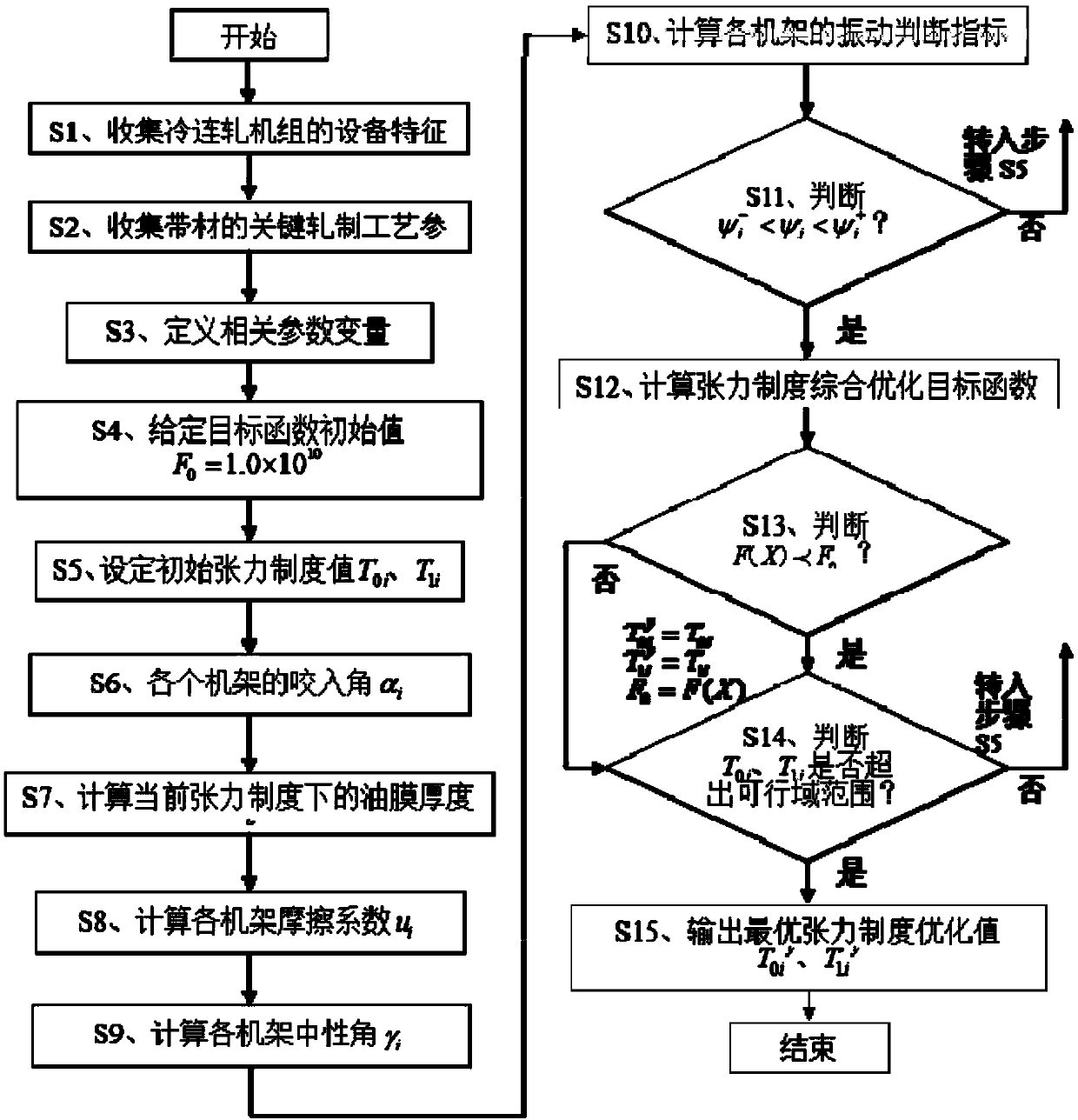

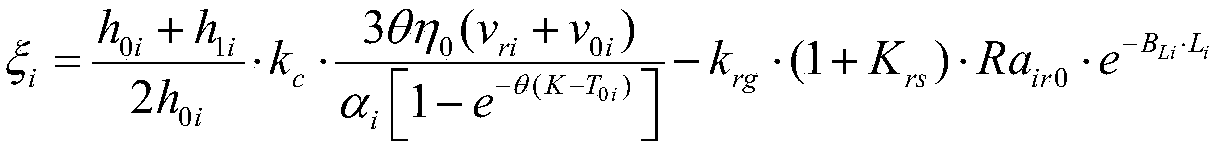

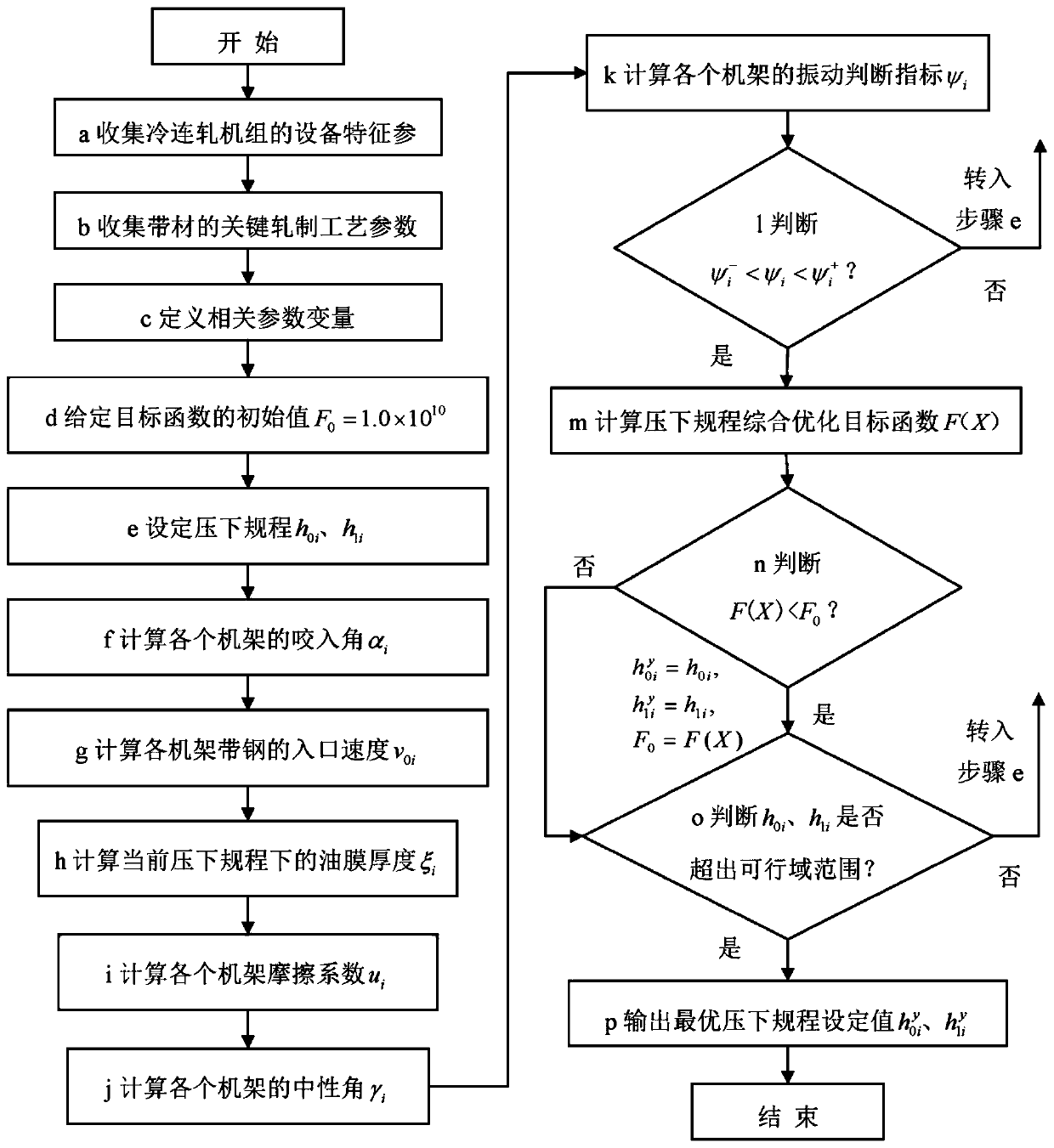

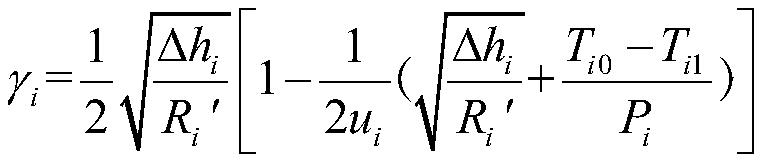

Tension system optimization method for inhibiting vibration of cold continuous rolling unit

ActiveCN110756593ASmooth rollingIncrease productivityVibration control deviceTension/compression control deviceClassical mechanicsEngineering

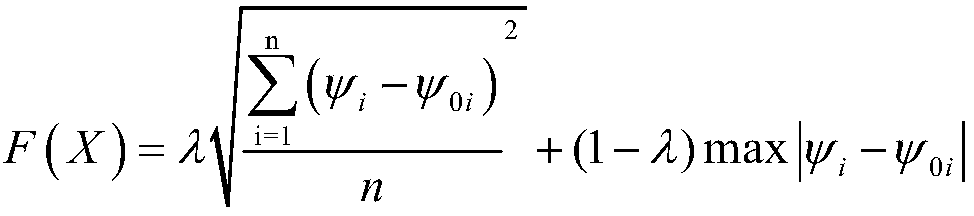

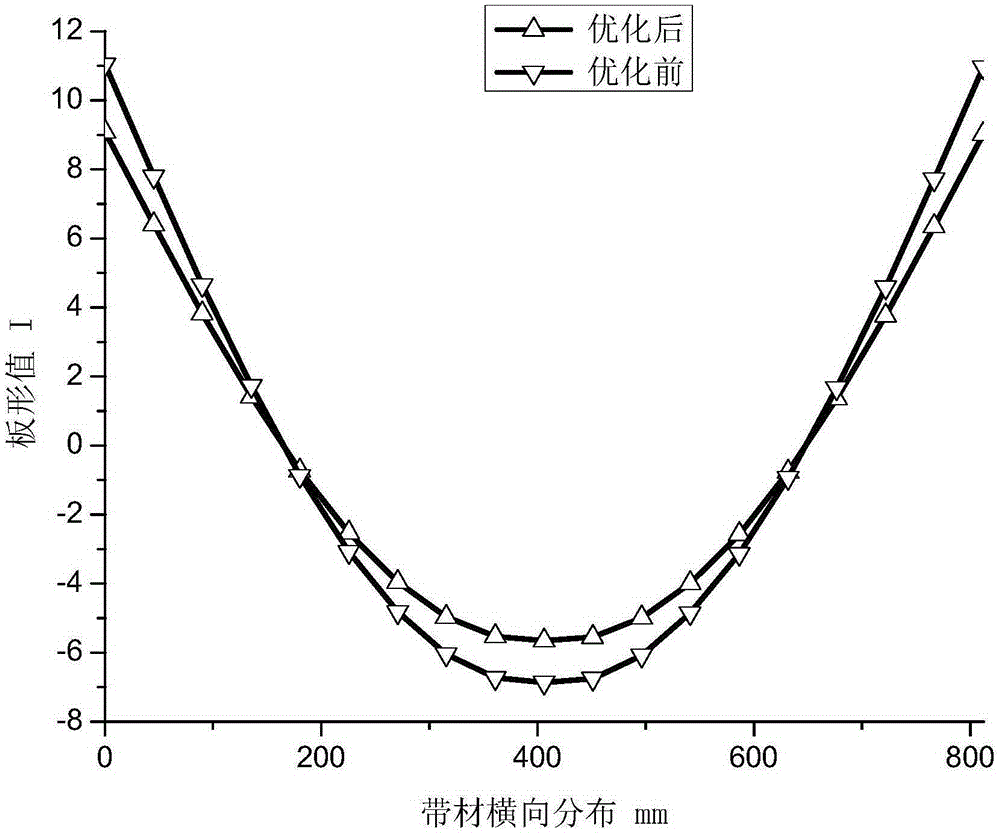

The invention discloses a tension system optimization method for inhibiting vibration of a cold continuous rolling unit. The method aims to inhibit the vibration defect in a high-speed rolling processof the cold continuous rolling unit, in order to effectively measure whether vibration appears in a rolling mill, a rolling mill vibration judgment index coefficient is proposed, the minimum mean square error between a rolling mill vibration judgment index coefficient optimal value and a rolling mill vibration judgment index coefficient value solved in an actual rolling process is taken as an optimization objective function taking that the maximum rolling mill vibration judgment index coefficient value of each individual rack is minimum in consideration, an upper threshold value, of an vibration judgment index, solved under an overlubricating state due to the fact that a neutral angle and a bite angle are overlapped in the rolling process and a lower threshold value, of the vibration judgment index, solved under an under-lubrication state due to the fact that the neutral angle is half of the bite angle in the rolling process are taken as constraint conditions, and finally the optimization of a tension system in the rolling process of the cold continuous rolling unit is realized.

Owner:BAOSHAN IRON & STEEL CO LTD

Electromagnetic device for stabilizing and reducing the deformation of a strip made of ferromagnetic material, and related process

ActiveUS20180085778A1Reduce vibrationEliminate leaksHot-dipping/immersion processesLiquid surface applicatorsEngineeringMirror image

An electromagnetic device (1) for stabilizing and minimizing the deformation of a strip (4) made of ferromagnetic material during its feeding in a system for coating the same strip with molten metal, by applying a distribution of force Which is continuous in the direction transversal to the strip regardless of the width thereof. The device comprises first electromagnets and second electromagnets mirroring the first electromagnets with respect to said theoretical pass-line (50) of said strip (4). Each electromagnet includes a core comprising one pole and one feeding coil wound about the pole. The electromagnetic device comprises a connection element (26) made of ferromagnetic material which connects the cores of the first electromagnets (15, 15′, 15″, 15′″) and a connection element (26′) made of ferromagnetic material which connects the cores of the second electromagnets (16, 16′, 16″, 16′″). The connection elements (26, 26′) mirror the theoretical pass-line (50) of the strip (4).

Owner:DANIELI & C OFF MEC SPA

Method And System For Vibration Damping and Shape Control Of A Suspended Metal Strip

ActiveUS20120067096A1Increased degrees of freedomEasy to shapeLiquid surface applicatorsMechanical oscillations controlEngineeringActuator

A method for vibration damping and shape control of a suspended metal strip is provided. The method includes the steps of: measuring distance to the metal strip by a plurality of non-contact sensors, providing distance measurements; generating a deflection profile based on the distance measurements; decomposing the deflection profile to a number of base shapes; and controlling the deflection profile by a plurality of non-contact actuators. The step of controlling includes providing for each of the base shapes a corresponding combination of force profiles.

Owner:ABB (SCHWEIZ) AG

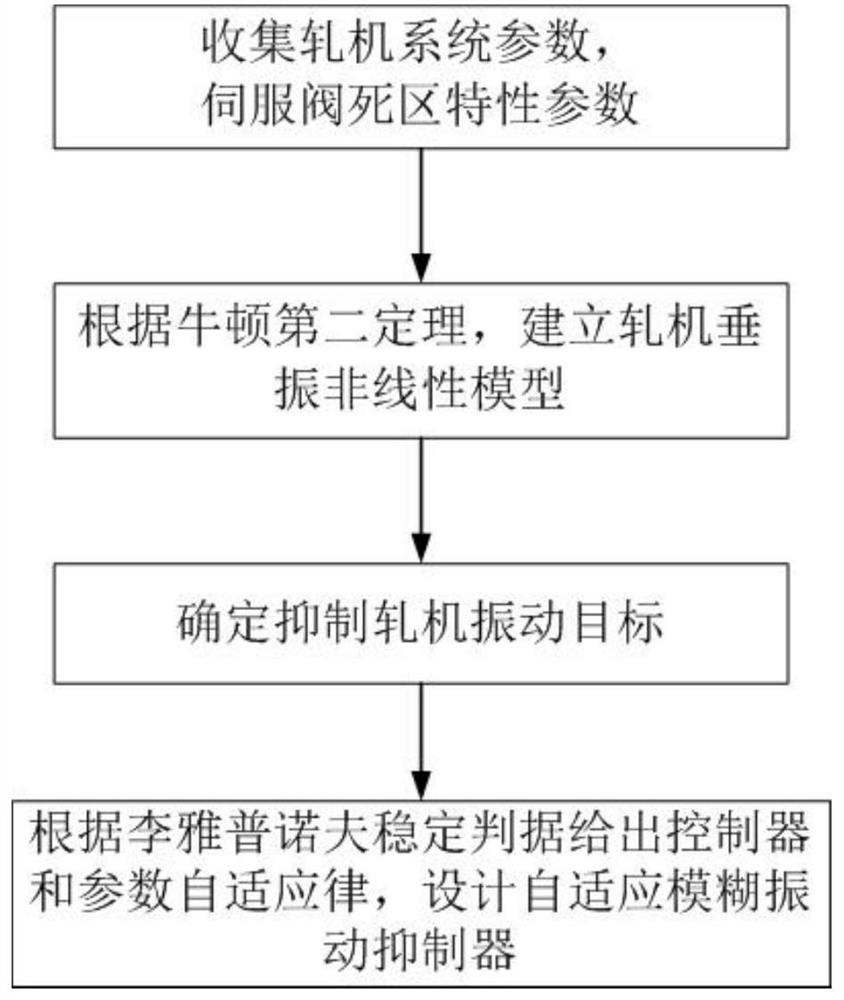

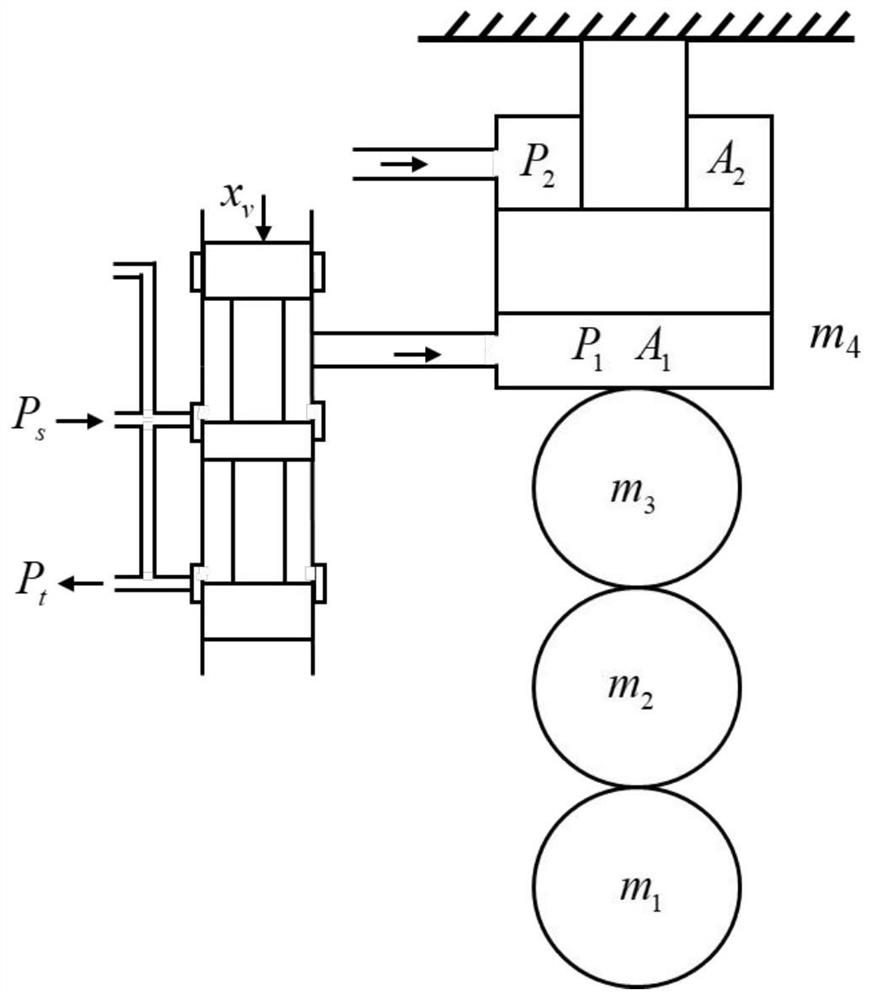

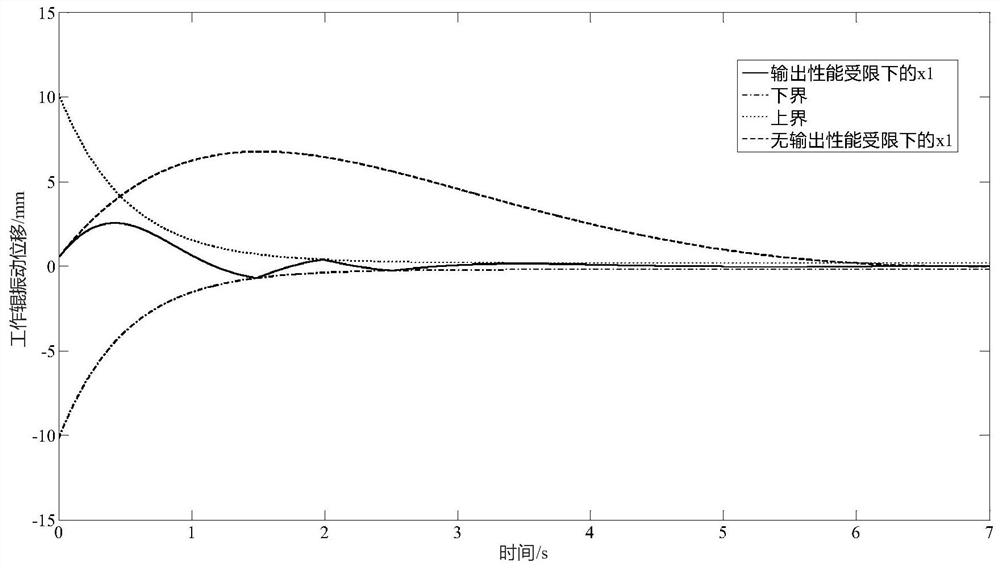

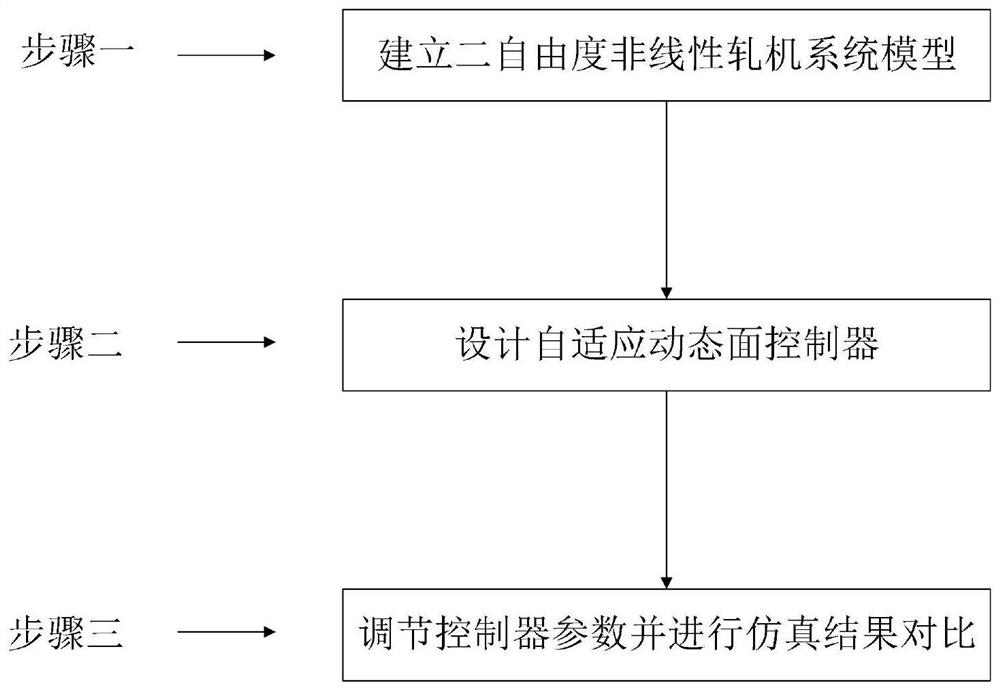

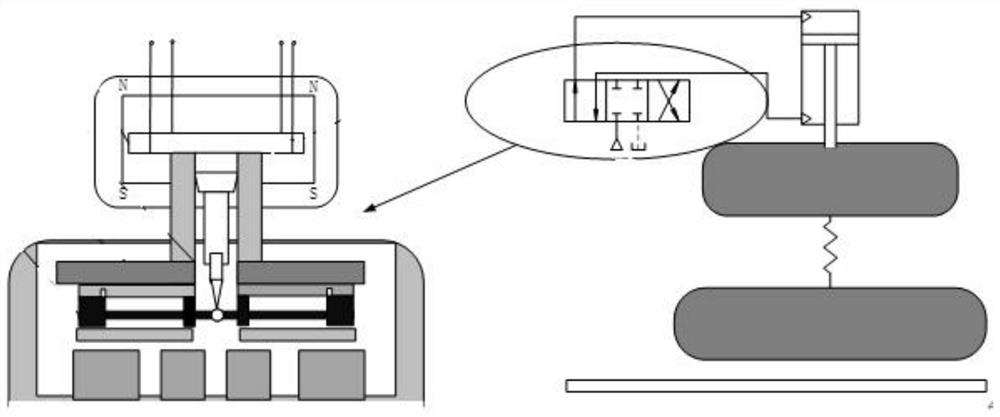

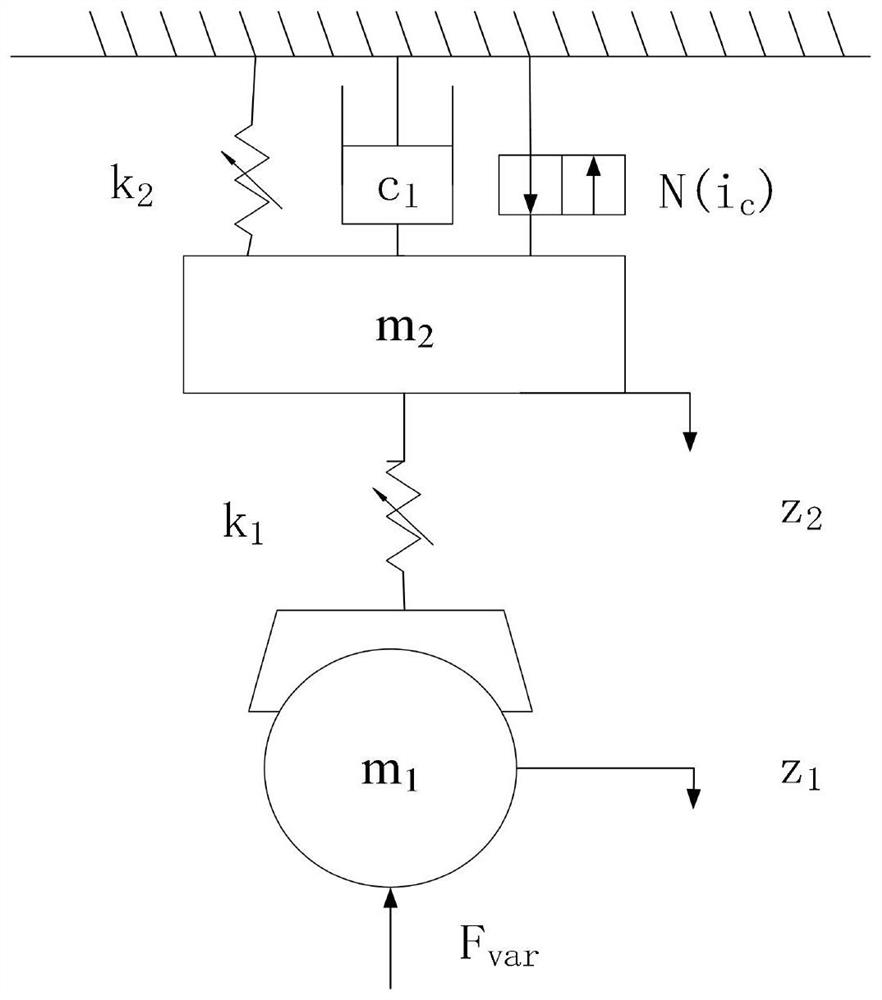

Design method of rolling mill vertical vibration suppression controller based on self-adaptive fuzzy backstepping

ActiveCN111723442AEnsure stabilityImprove the vibration damping effectGeometric CADVibration control deviceVertical vibrationBackstepping

The invention provides a method for designing a rolling mill vertical vibration suppression controller based on self-adaptive fuzzy backstepping, which comprises the following steps of: firstly, establishing a four-degree-of-freedom mechanical-hydraulic coupling nonlinear model of rolling mill vertical vibration according to a dynamic principle of a rolling mill vibration system; setting the vertical vibration displacement of the working roll of the rolling mill to be close to zero as a control target according to the condition that the vertical vibration of the rolling mill causes the workingroll to jump up and down; and finally, in combination with a nonlinear model of rolling mill vertical vibration, selecting a proper Lyapunov function, solving a virtual controller, an actual controller and an adaptive law which enable V (t) to tend to zero when t tends to be infinite, and finally obtaining the predetermined performance controller design method for suppressing rolling mill vertical vibration. According to the method, the rolling mill vertical vibration nonlinear model more conforming to the actual working condition is established, the characteristic that the servo valve has adead zone and the limitation on roller vibration displacement are considered, the rolling mill vertical vibration suppressor is designed, vertical vibration occurring in the high-speed rolling processis rapidly and actively suppressed, and the stability of the high-speed plate and strip rolling process is guaranteed.

Owner:YANSHAN UNIV

Setting method of emulsion concentration in ultra-thin strip rolling of five-stand cold tandem mill

InactiveCN103544340BIncrease rolling speedGuaranteed rolling efficiencyVibration control deviceSpecial data processing applicationsEmulsionEngineering

A method for setting the concentration of the emulsion in the ultra-thin strip rolling of a five-stand cold tandem rolling unit, comprising the following steps executed by a computer: 1. Collecting the main equipment of the unit, the characteristics of the strip to be rolled, the main rolling process and Process lubrication system parameters; 2. Define relevant process parameters; 3. Calculate roll bending force and roll shifting amount; 4. Assign values to relevant search process parameters; 5. Calculate concentration process parameters; 6. Calculate search process speed of maximum rolling speed; 7. Calculate the friction coefficient of each stand under the current conditions; 8. Calculate the rolling force, rolling power, slip factor, thermal slip index and vibration coefficient of each stand under the current conditions; 9. Calculate the working roll of each stand Thermal convexity; 10. Calculate the outlet plate shape and pressing width; 11. Obtain and output the optimal ratio concentration. The invention can increase the rolling speed, ensure the rolling efficiency, avoid slipping, thermal slipping and vibration, and ensure the minimum shape of the end stand exit and the pressing width of the work roll end.

Owner:唐山扬邦钢铁技术研究院有限公司

Emulsion flow optimization method for inhibiting vibration of cold continuous rolling unit

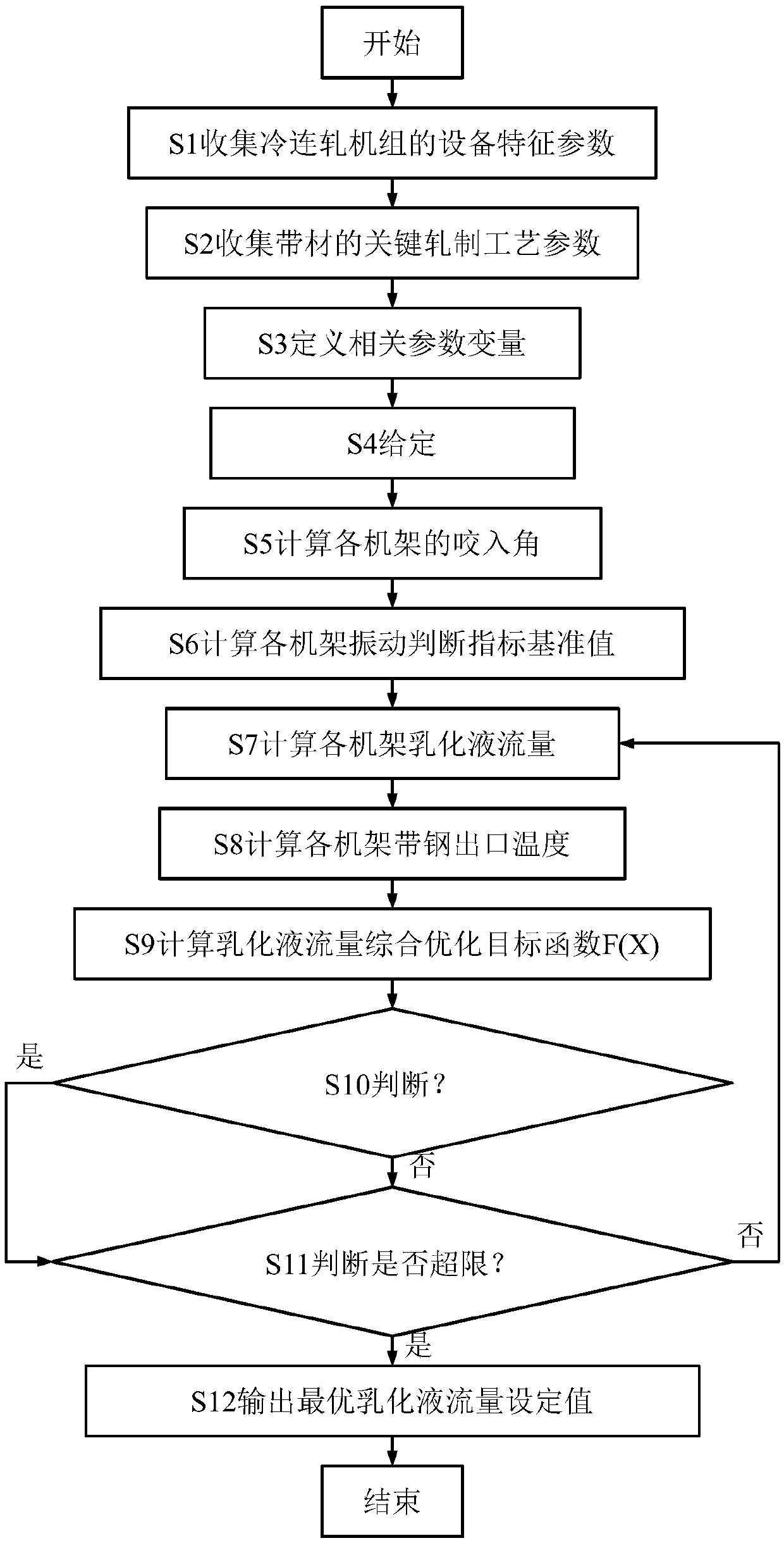

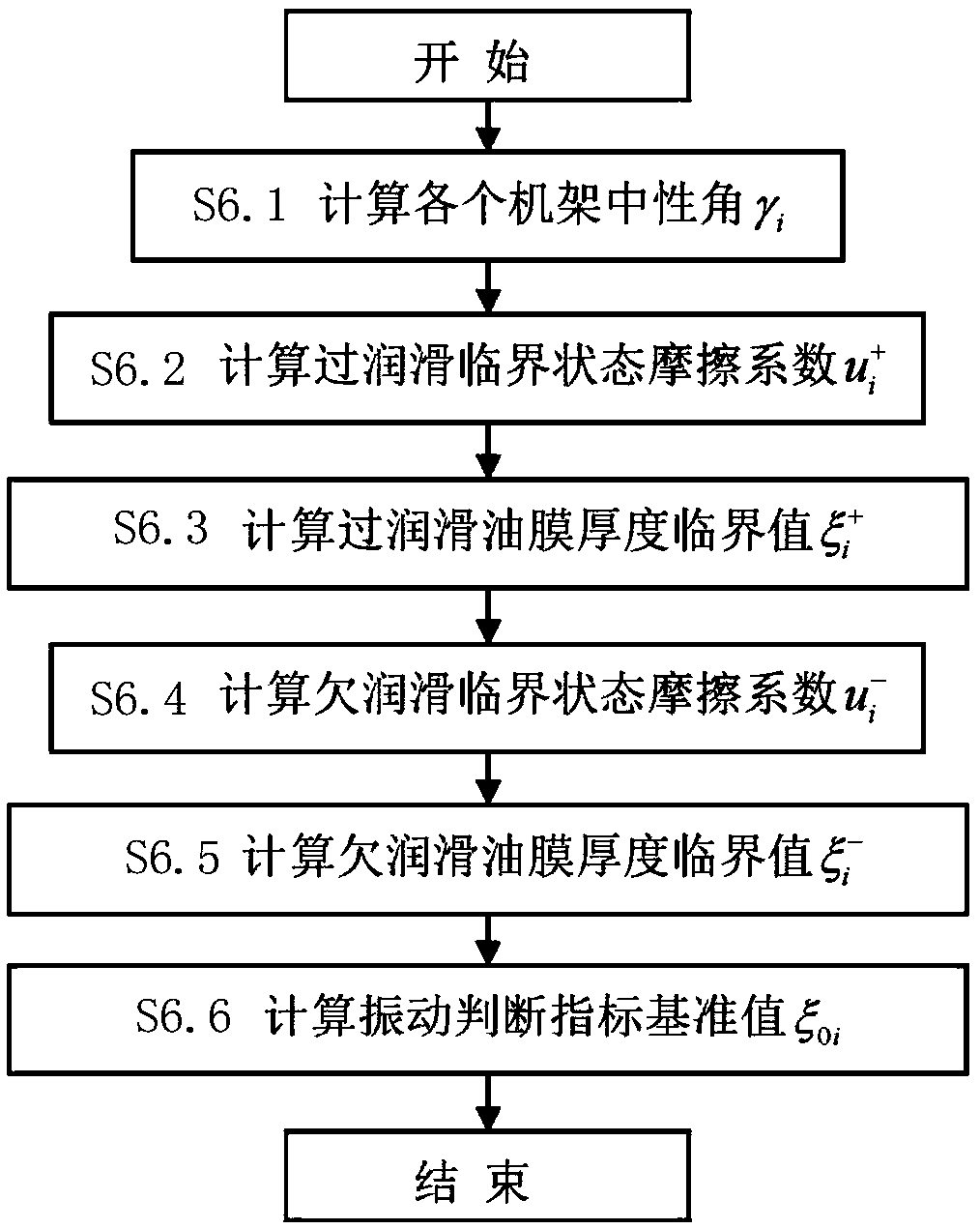

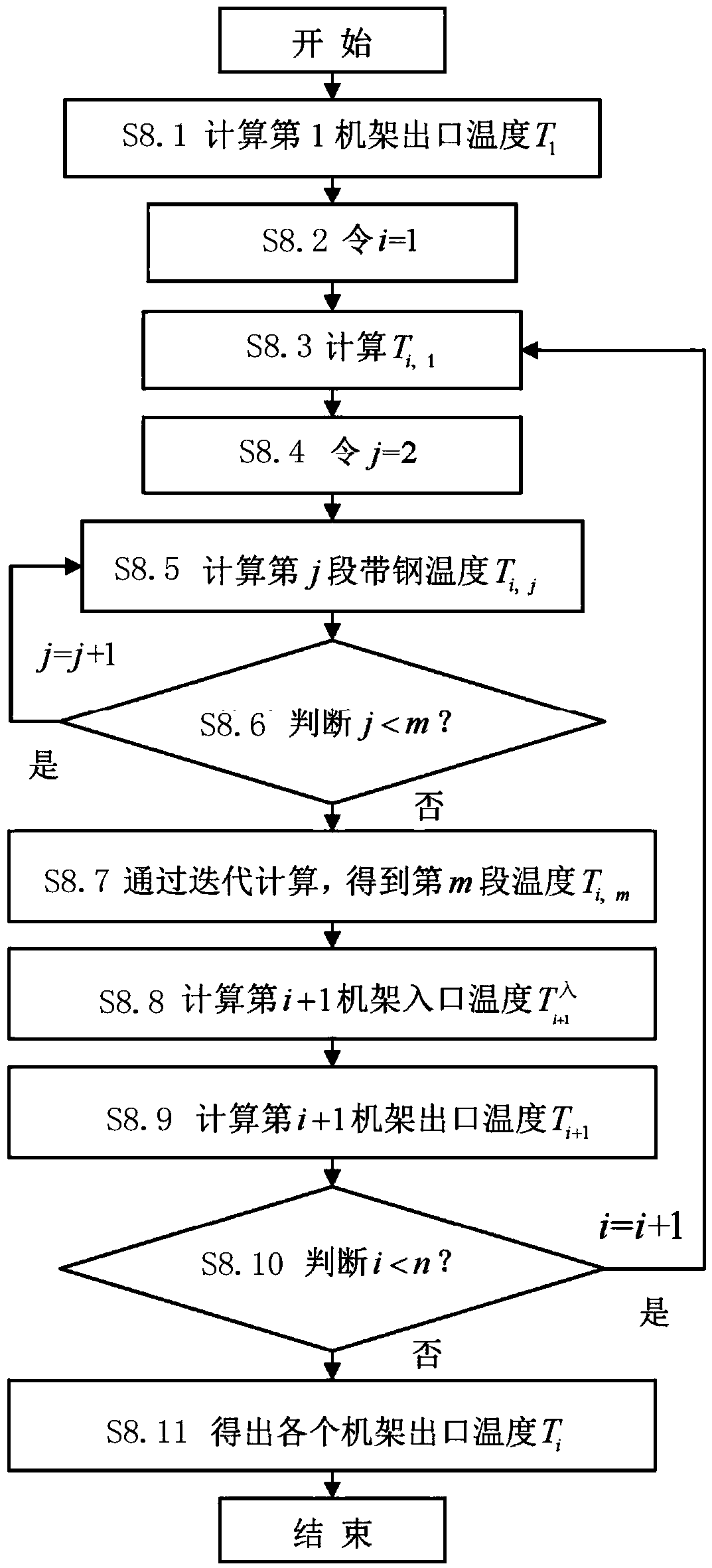

ActiveCN110842031AReduce incidenceAchieve governanceDesign optimisation/simulationVibration control deviceThermodynamicsEmulsion

The invention discloses an emulsion flow optimization method for inhibiting the vibration of a cold continuous rolling unit, relates to the technical field of cold continuous rolling, and particularlyrelates to the emulsion flow optimization method suitable for the cold continuous rolling unit and taking vibration inhibition as a target. The method is characterized in that the vibration inhibition is taken as a target, on the basis that the over-lubricating oil film thickness critical value and the under-lubricating oil film thickness critical value are provided, and through an oil film thickness model and a friction coefficient model, the emulsion flow optimal set values, taking the vibration inhibition as the target, of racks are obtained. According to the method, the occurrence rate ofvibration defects of a rolling mill is greatly reduced, the production efficiency and the product quality are improved, and great economic benefits are brought to enterprises; and the vibration defects of the rolling mill are overcome, and the surface quality and the rolling process stability of finished strip steel of the cold continuous rolling unit are improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Reduction schedule setting method of cold continuous rolling unit taking vibration abatement as target

ActiveCN111495980AAchieve governanceImprove quality stabilityVibration control deviceMetal rolling arrangementsStructural engineeringStrip steel

The invention relates to a reduction schedule setting method of a cold continuous rolling unit taking vibration abatement as a target and belongs to the field of rolling. The method comprises the following steps of collecting unit associated parameters and strip-rolling process parameters; defining vibration judging indexes of racks; giving a reduction schedule taking vibration abatement as the target to optimize an initial set value of a target function comprehensively; setting the reduction schedule; calculating bit angles of the racks, the inlet speeds and oil film thicknesses of strip steel of the racks, friction coefficients between working rollers of the racks and the strip steel and the neutral angles of the racks; calculating the vibration judging indexes of the racks; and by taking the minimum mean square errors of the rolling mill vibration judgment index optimum value and rolling mill vibration judging index values solved in an actual rolling process and the minimum value ofthe maximum rolling mill vibration judgment index values of the racks as the optimized target function and by taking a lower threshold value of the vibration judgment index solved as a rolling process is in a sub-lubricated state when the neutral angle is as half as the bit angle as a constraint condition, optimizing the reduction schedule of the rolling process of the cold continuous rolling unit finally.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and apparatus for suppression of oscillations in a rolling installation

ActiveUS8695391B2Increase productivityQuality improvementMetal rolling stand detailsVibration control deviceOctaveActuator

A method and an apparatus for suppression of oscillations in a rolling installation is described. By means of a hydraulic roller engagement third-octave oscillations are effectively suppressed, thus making it possible to improve the quality of the rolled material and / or the productivity of the rolling installation. A manipulated variable is supplied to an electrohydraulic actuating element that acts on at least one hydraulic actuator for the roller engagement and has a rated flow rate of ≧50 l / min. At least a portion of the frequency response at frequencies f≧80 Hz has a magnitude drop of ≦3 dB, and the phase lag φ in this frequency range satisfies the conditions f≧19·{square root over (φ)}+3.1·10−6·φ4 and φ<90°.

Owner:PRIMETALS TECH AUSTRIA GMBH

Method and apparatus for cooling hot rolled steel strip, and method for manufacturing hot rolled steel strip

InactiveUS20040201143A1Efficient dischargeFine granularityFurnace typesVibration control deviceSurface coolingEngineering

An apparatus for cooling a hot rolled steel strip comprising a transfer means arranged behind a final finishing mill, the transfer means comprising a plurality of transfer rolls for transferring the steel strip; at least one upper surface cooling means arranged at an upper surface side of the transfer means for cooling the steel strip by ejecting cooling water to an upper surface of the steel strip, the upper surface cooling means being capable of moving freely up and down and having a water breaking means at least at an outlet side of the cooling apparatus and at a position corresponding to the transfer rolls; and at least one lower surface cooling means arranged at a lower surface side of the transfer means relative to the upper surface cooling means and the steel strip to be transferred, for cooling the hot strip by ejecting cooling water at a lower surface of the steel strip.

Owner:JFE STEEL CORP

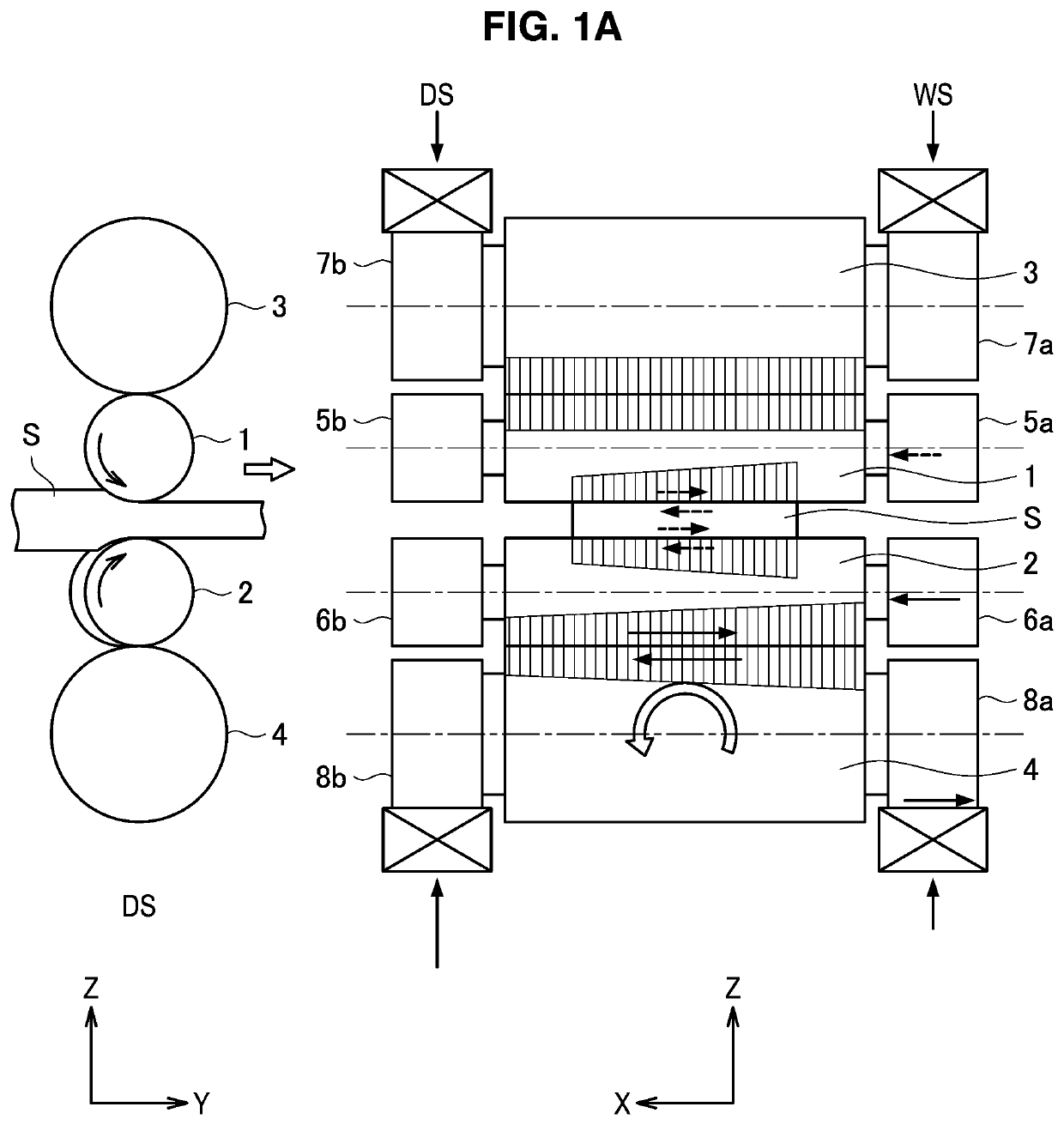

Method for setting rolling mill, and rolling mill

ActiveUS20210039148A1Thrust force generatedReduce thrustMetal rolling stand detailsMeasuring devicesWork rollControl theory

A method for setting a rolling mill, the method being executed before reduction position zero point adjustment or before the start of rolling, and including: a first process of setting rolls in an open state, and with respect to each of the upper roll assembly and the lower roll assembly, adjusting positions of roll chocks in a rolling direction based on a torque acting on the work roll or a vertical roll load difference; and a second process of, after the first process, setting rolls in a kiss roll state, measuring a vertical roll load in two rotational states on a work side and a drive side, and moving roll chocks of a roll assembly on the opposite side to a reference roll simultaneously and in a same direction so that the vertical roll load difference falls within an allowable range to thereby adjust the positions of the roll chocks.

Owner:NIPPON STEEL CORP

Anti-disturbance control method for vertical reduction system of rolling mill under typical working conditions

ActiveCN112742878AGuaranteed closed-loop stabilityVerify validityRoll force/gap control deviceVibration control deviceControl engineeringProcess engineering

The invention discloses an anti-disturbance control method for a vertical reduction system of a rolling mill under typical working conditions, which comprises the following steps of: under the condition of considering unknown model parameters and execution dead zone of a servo valve, using an anti-disturbance controller combining adaptive parameter estimation of an exponential reaching law and a backstepping control method to split the dead zone into a linear function and a piecewise function; and deducing an anti-disturbance controller capable of dealing with unknown system structure parameters and unknown asymmetric dead zones. Simulation shows that the controller can effectively restrain disturbance caused by sudden load change to a rolling mill screw-down system in the rolling process while guaranteeing the closed-loop stability of the system; and the anti-disturbance control method has important significance on high-precision rolling of plates and strips.

Owner:YANSHAN UNIV

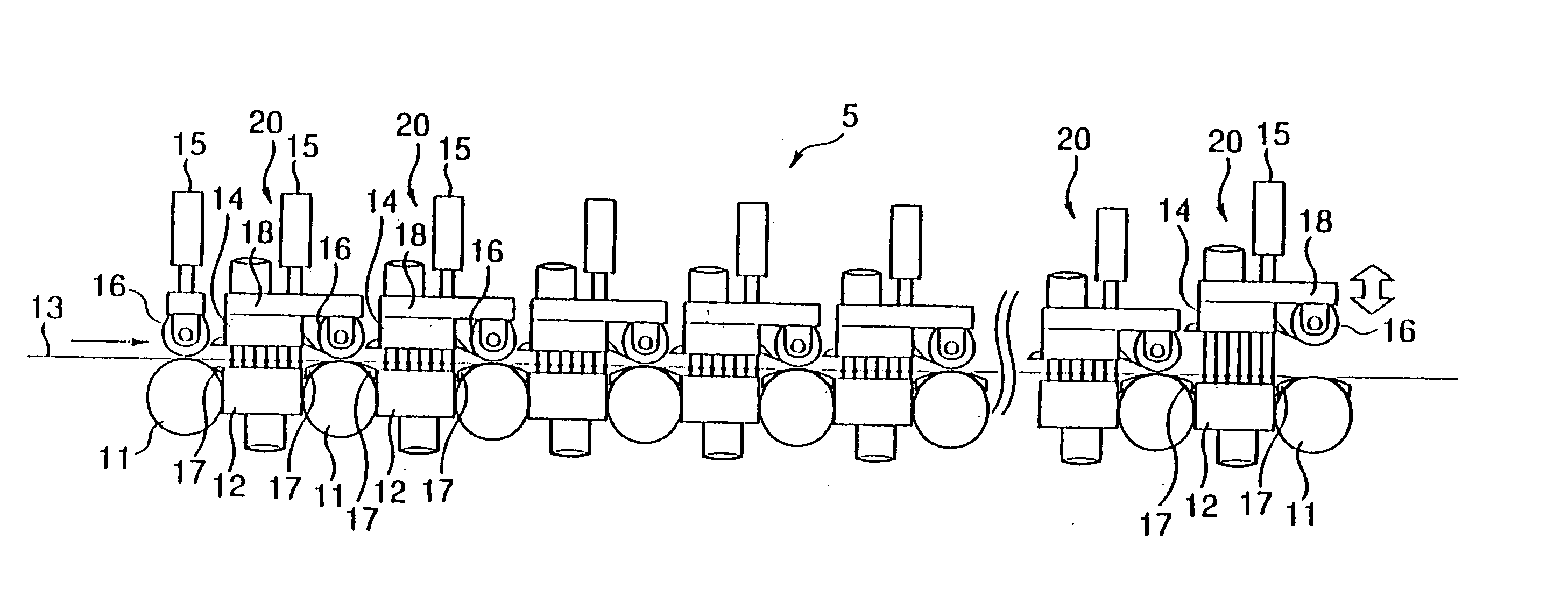

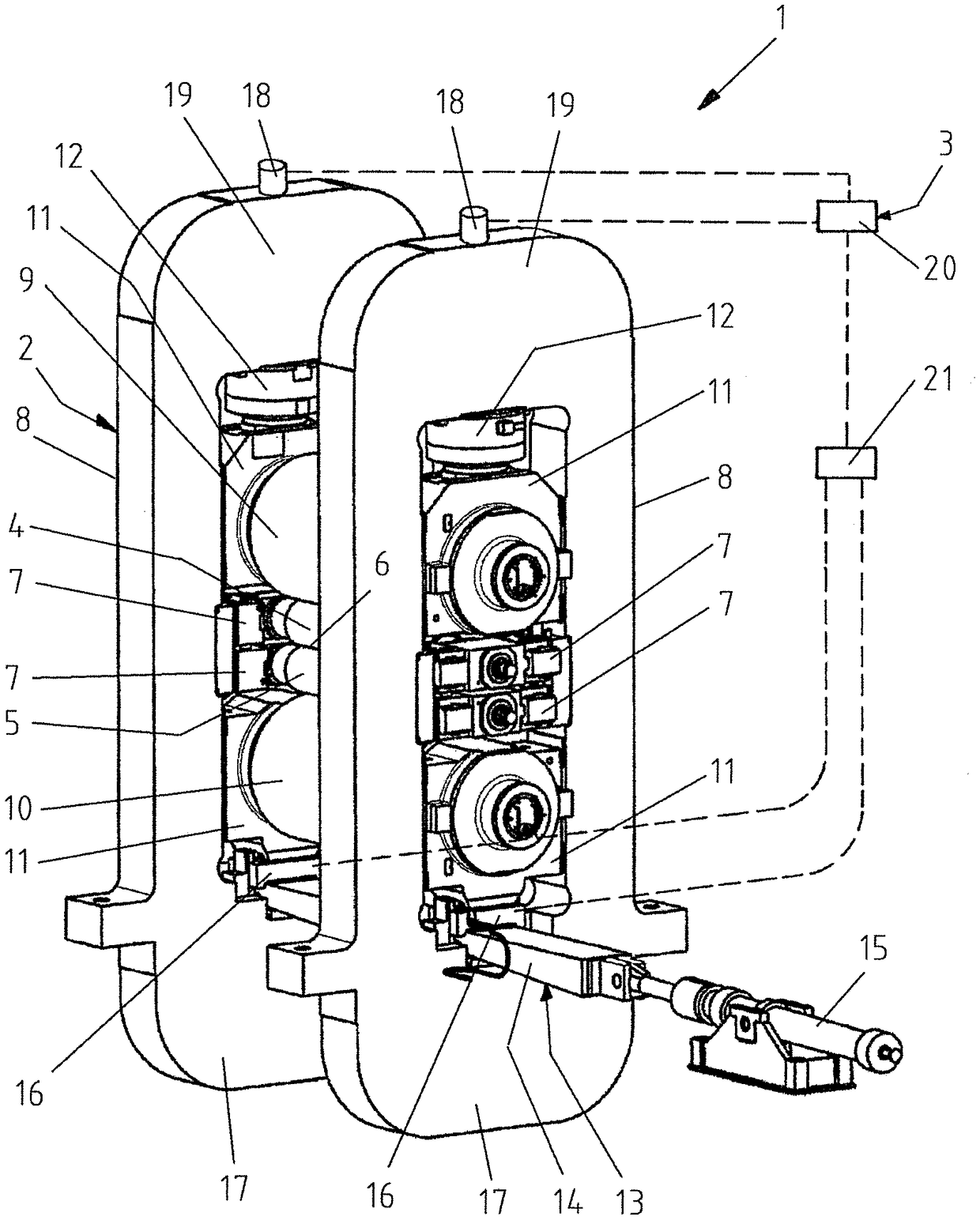

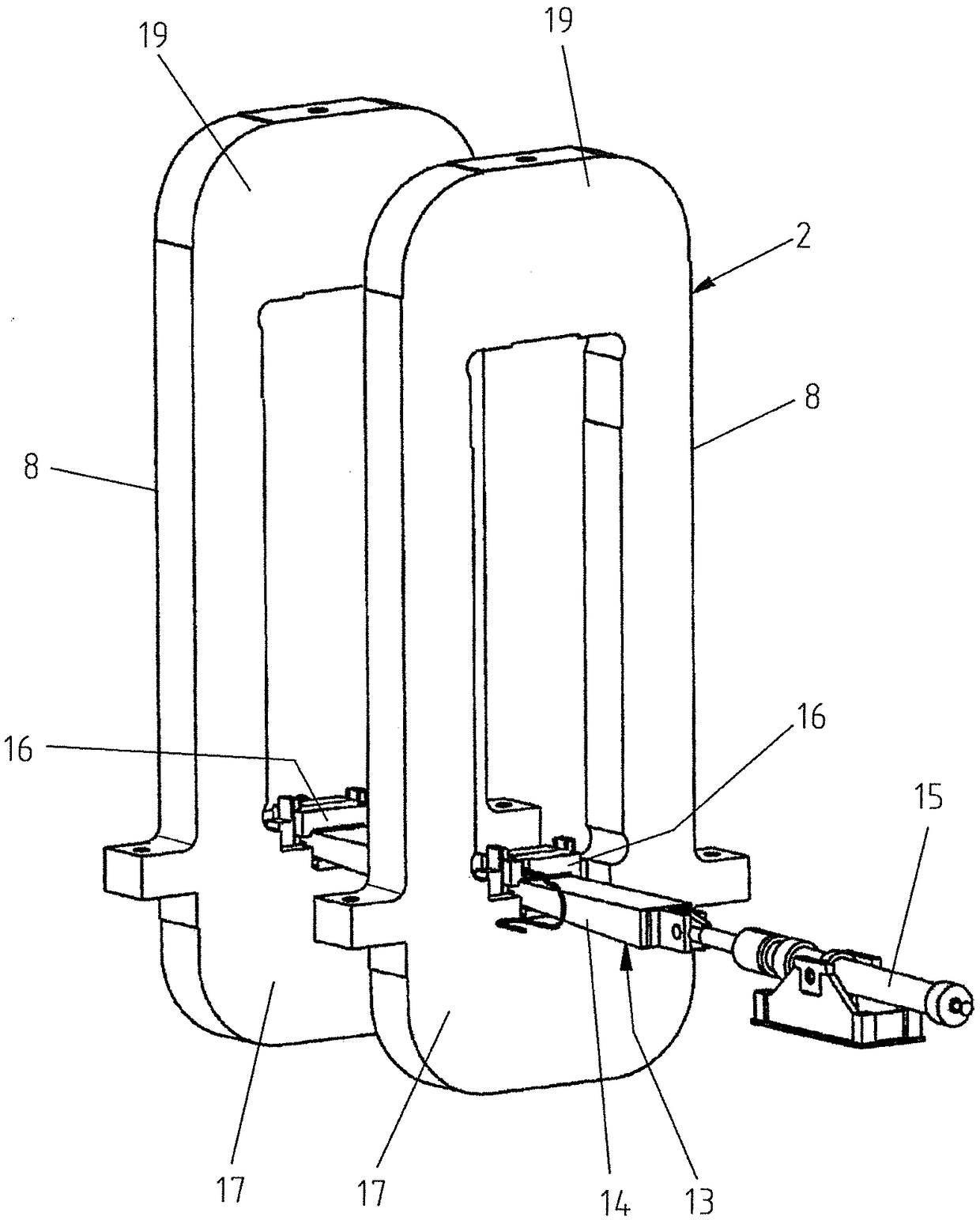

Roll stand, rolling system and method for actively damping vibrations in a roll stand

ActiveCN108136459AReduce vibrationReduce quality lossMetal rolling stand detailsMeasuring devicesEngineeringActuator

The invention relates to a roll stand (2) for rolling, in particular cold-rolling metal products, comprising at least one actuator (16) which can be actuated for actively damping vibrations in the roll stand (2), and at least one support roll (10), which is non-adjustable or can be adjusted exclusively via an adjuster for pass line adjustment (13) of the roll stand (2), for supporting a working roll (5) and / or intermediate roll of the roll stand (2), wherein the support roll (10) is guided at the ends via a respective bearing unit (11) on a rack (8) of the roll stand (2). According to the invention, in order to permit an optimal active damping of vibrations in a roll stand (2) of this type with low constructive effort, the support roll (10) is supported on the actuator (16) via at least one bearing unit (11), and the actuator (16) is supported on a section (17) of the rack (8) either directly or indirectly via at least one component (14) of the adjuster (13).

Owner:SMS GRP GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com