Emulsion flow optimization method for inhibiting vibration of cold continuous rolling unit

A cold tandem rolling unit and flow optimization technology, applied in the field of cold tandem rolling, can solve problems that are not the main treatment objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] In order to further illustrate the application process of the related technology described in the present invention, take the cold rolling mill 1730 tandem cold rolling unit as an example, the application process of the emulsion flow optimization method aimed at vibration suppression in the tandem cold rolling mill.

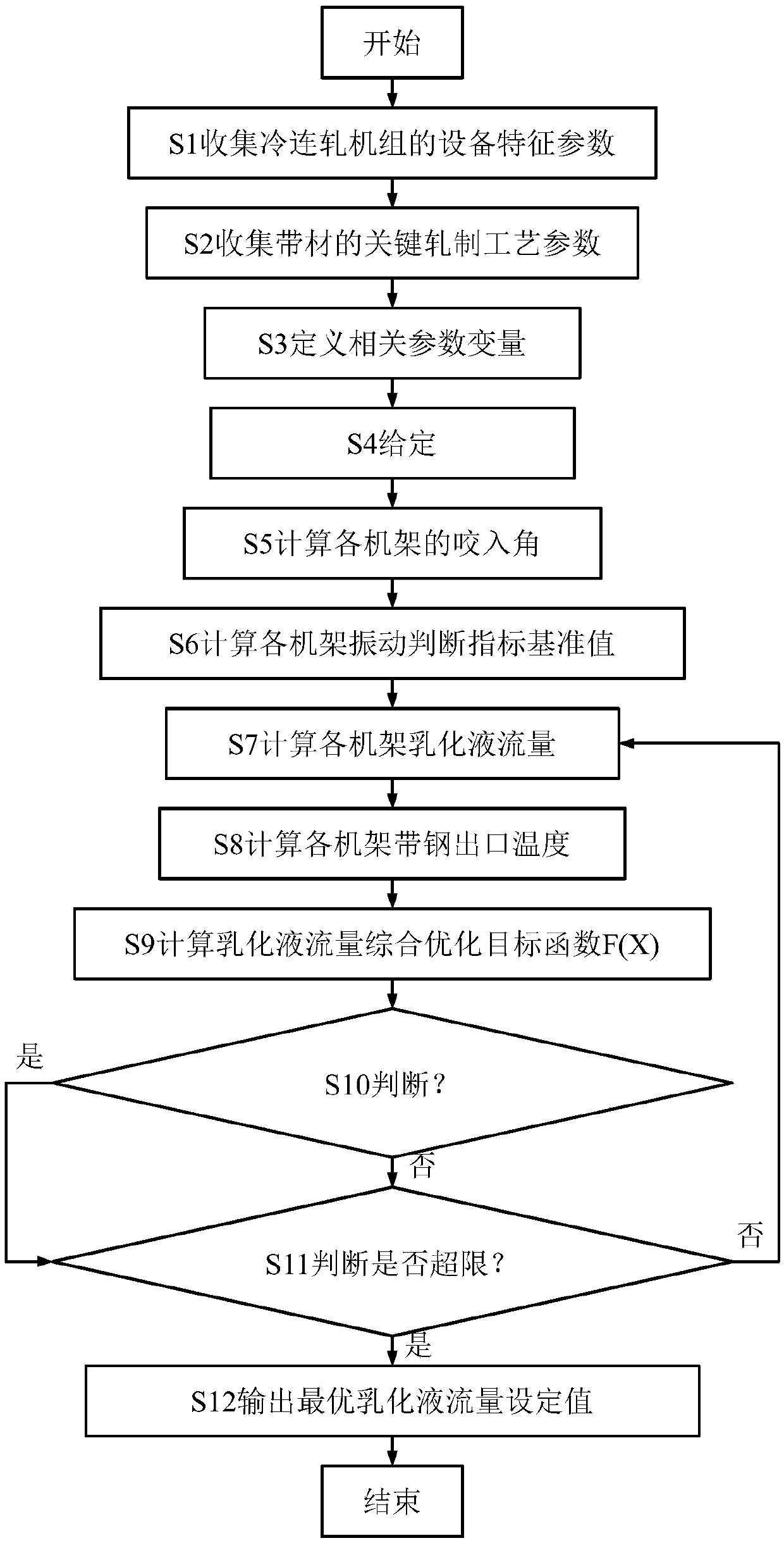

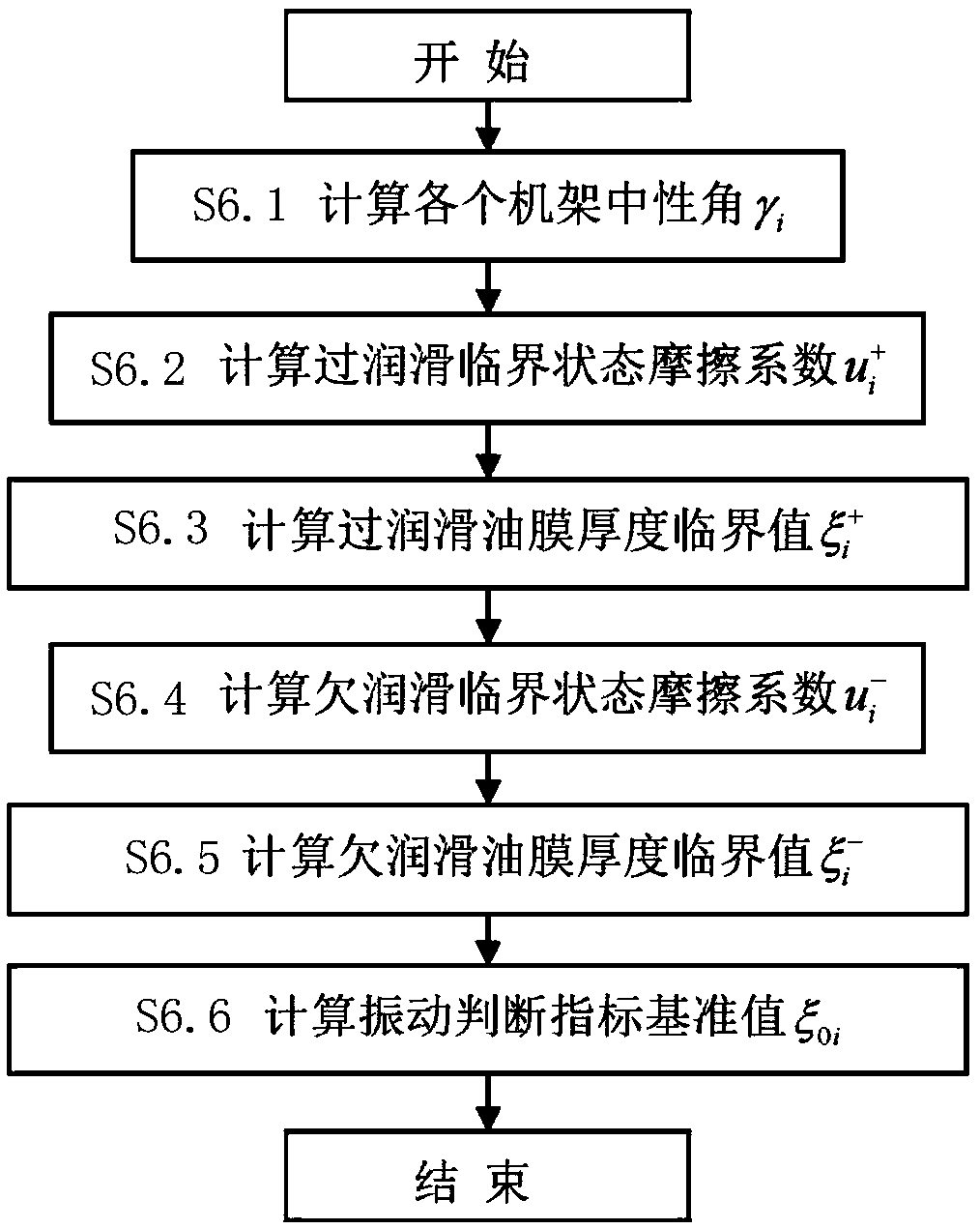

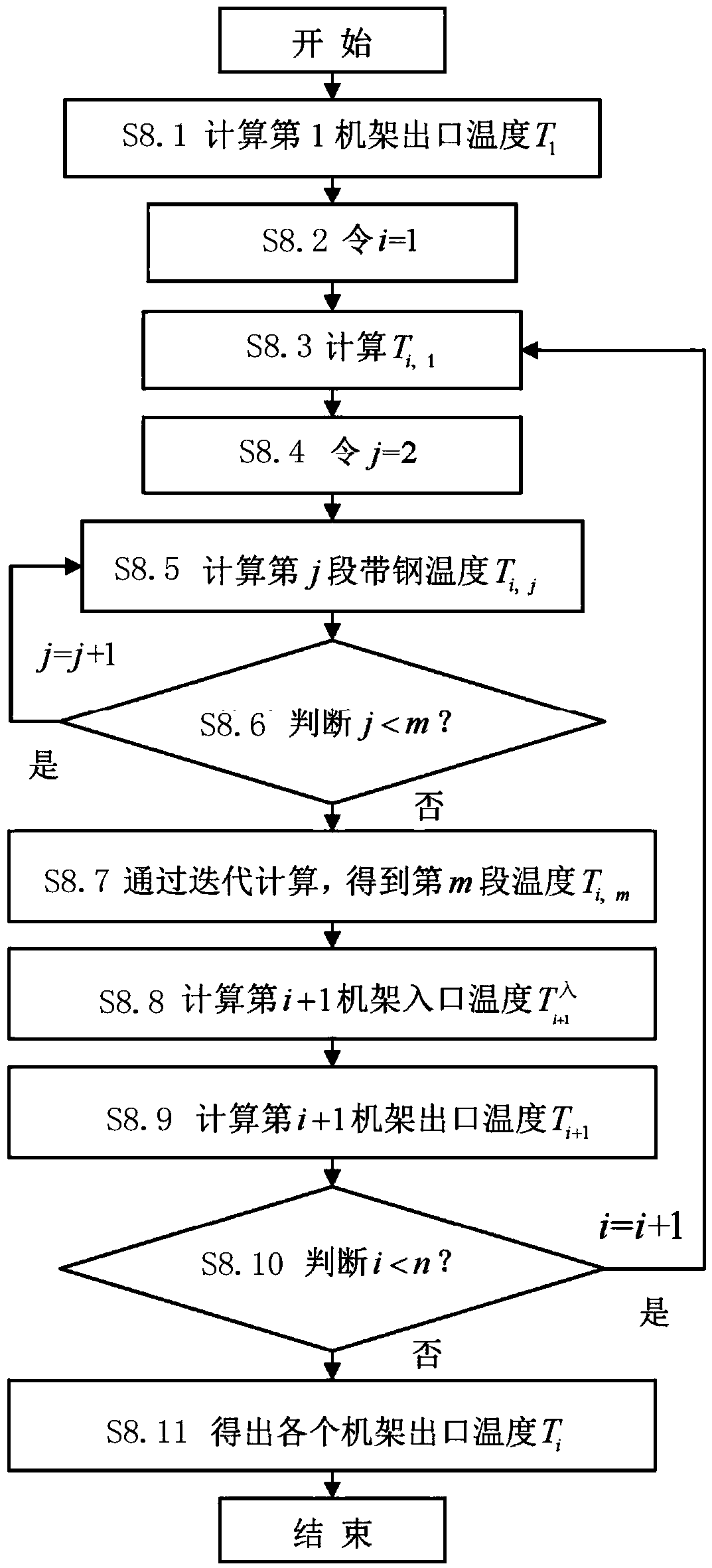

[0104] An emulsion flow optimization method for suppressing vibration of a cold tandem rolling mill, comprising the following steps:

[0105] S1. Collect the equipment characteristic parameters of the tandem cold rolling mill. The 1730 tandem cold rolling mill in the cold rolling plant has 5 stands in total, mainly including: the radius R of the work roll of each stand i ={210,212,230,230,228}mm, surface speed v of each stand roll ri ={180,320,500,800,1150}m / min, original roughness Ra of work rolls of each frame ir0 ={1.0,1.0,0.8,0.8,1.0}um, work roll roughness attenuation coefficient B L =0.01, the distance between stands l=2700mm, the rolling kilometer...

Embodiment 2

[0145] In order to further illustrate the application process of the related technology described in the present invention, take the cold rolling mill 1420 as an example, the application process of the emulsion flow optimization method aimed at vibration suppression in the cold rolling mill.

[0146] An emulsion flow optimization method for suppressing vibration of a cold tandem rolling mill, comprising the following steps:

[0147] S1. Collect the equipment characteristic parameters of the tandem cold rolling mill. The 1420 tandem cold rolling mill in the cold rolling plant has 5 stands in total, mainly including: the radius R of the work roll of each stand i ={211,213,233,233,229}mm, surface speed v of each stand roll ri ={182,322,504,805,1153}m / min, original roughness Ra of work rolls of each frame ir0 ={1.0,1.0,0.9,0.9,1.0}um, work roll roughness attenuation coefficient B L =0.015, the distance between the stands l=2750mm, the number of rolling kilometers L after the wor...

Embodiment 3

[0188] In order to further illustrate the application process of the related technology described in the present invention, take the cold rolling mill 1220 as an example, the application process of the emulsion flow optimization method aimed at vibration suppression in the cold rolling mill.

[0189] An emulsion flow optimization method for suppressing vibration of a cold tandem rolling mill, comprising the following steps:

[0190] S1. Collect the equipment characteristic parameters of the tandem cold rolling mill. The 1220 tandem cold rolling mill in the cold rolling plant has 5 stands in total, mainly including: the radius R of the work roll of each stand i ={208,210,227,226,225}mm, the surface speed v of each stand roll ri ={176,317,495,789,1146}m / min, original roughness Ra of working rolls of each frame ir0 ={0.9,0.9,0.7,0.7,0.8}um, work roll roughness attenuation coefficient B L =0.01, the distance between stands l=2700mm, the rolling kilometers L of each stand after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com