Rolling control apparatus and rolling control method

A control device and control method technology, which is applied to the operation end and the field of feedback selection, can solve the problems of speed change, outlet side plate thickness change, speed change, etc., and achieve the effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

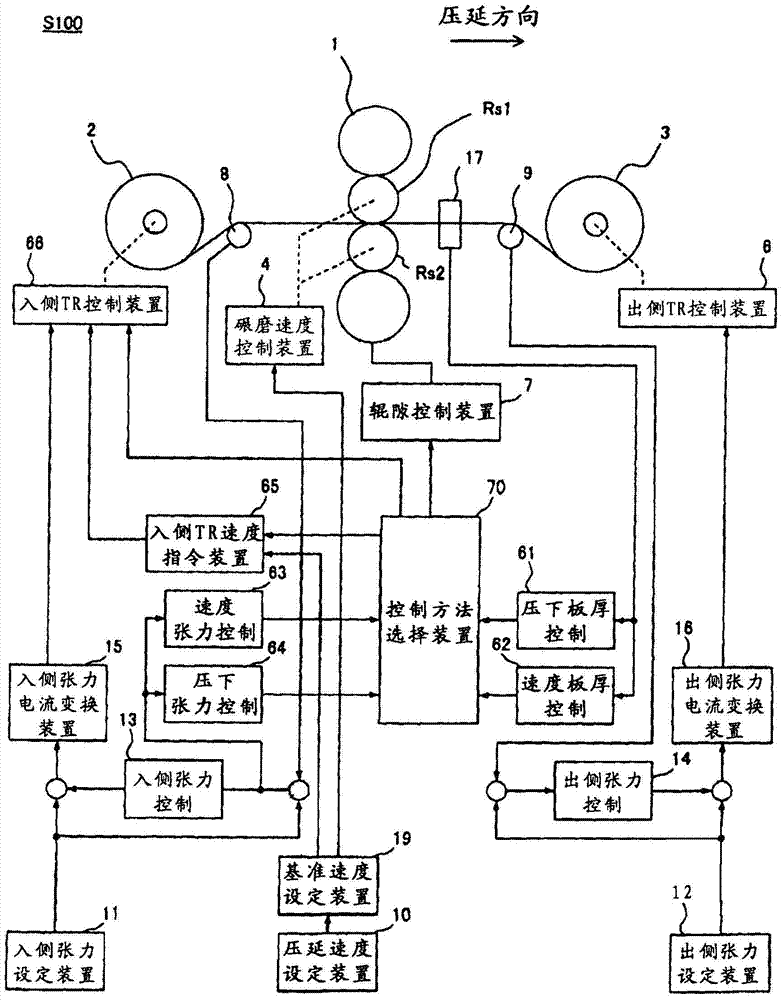

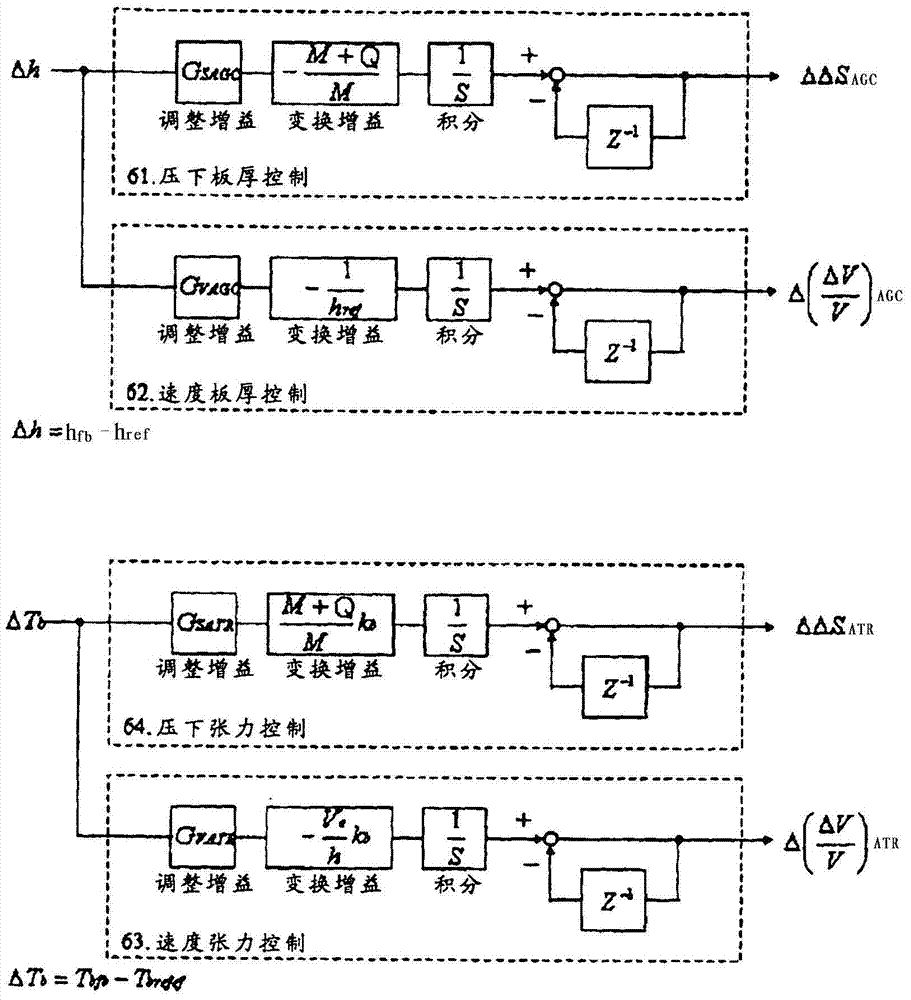

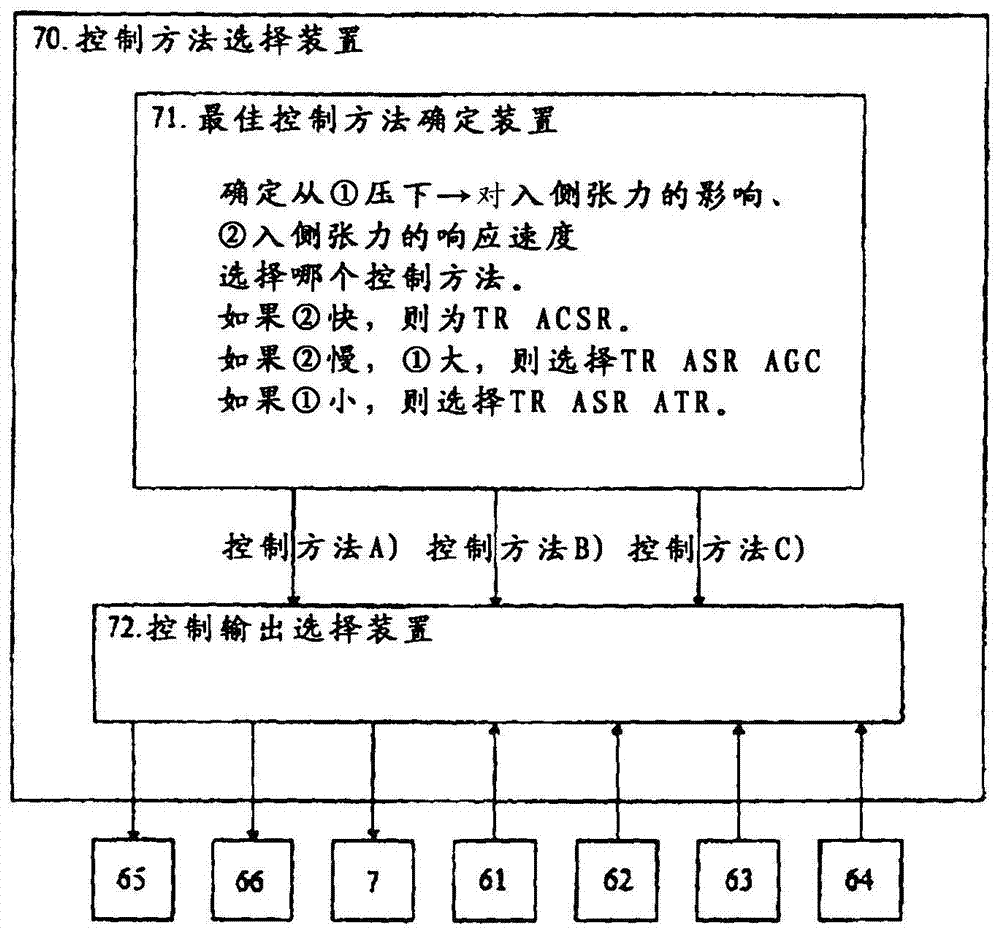

[0040] Hereinafter, the present invention will be described in detail by taking, as an example, a single-stand calender which is a typical calender using a tension roll for unwinding and winding of a material to be calendered. Figure 10 It is a figure which shows the control structure of the single stand calender S100. The rolling direction of the single-support calender S100 relative to the calender 1 (in Figure 10Indicated by the arrow in the middle), there is an entry tension reel 2 (hereinafter referred to as the entry side TR2) on the entry side of the calender 1 that releases the calendered material u, and on the exit side, there is a roll that is rolled by the calender 1. The exit side tension reel 3 (hereinafter referred to as exit side TR3) of the rolled material u.

[0041] The entry-side TR2 and the exit-side TR3 are respectively driven by electric motors, and the entry-side TR control device 5 and the exit-side TR control device 6 are respectively provided as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com