Roll stand, rolling system and method for actively damping vibrations in a roll stand

A technology for rolling mill stands and rolling equipment, applied in the direction of rolling mill control devices, metal rolling stands, metal rolling stands, etc., can solve the problems of low rolling speed and failure to reach equipment speed, so as to improve productivity and avoid The effect of mass loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

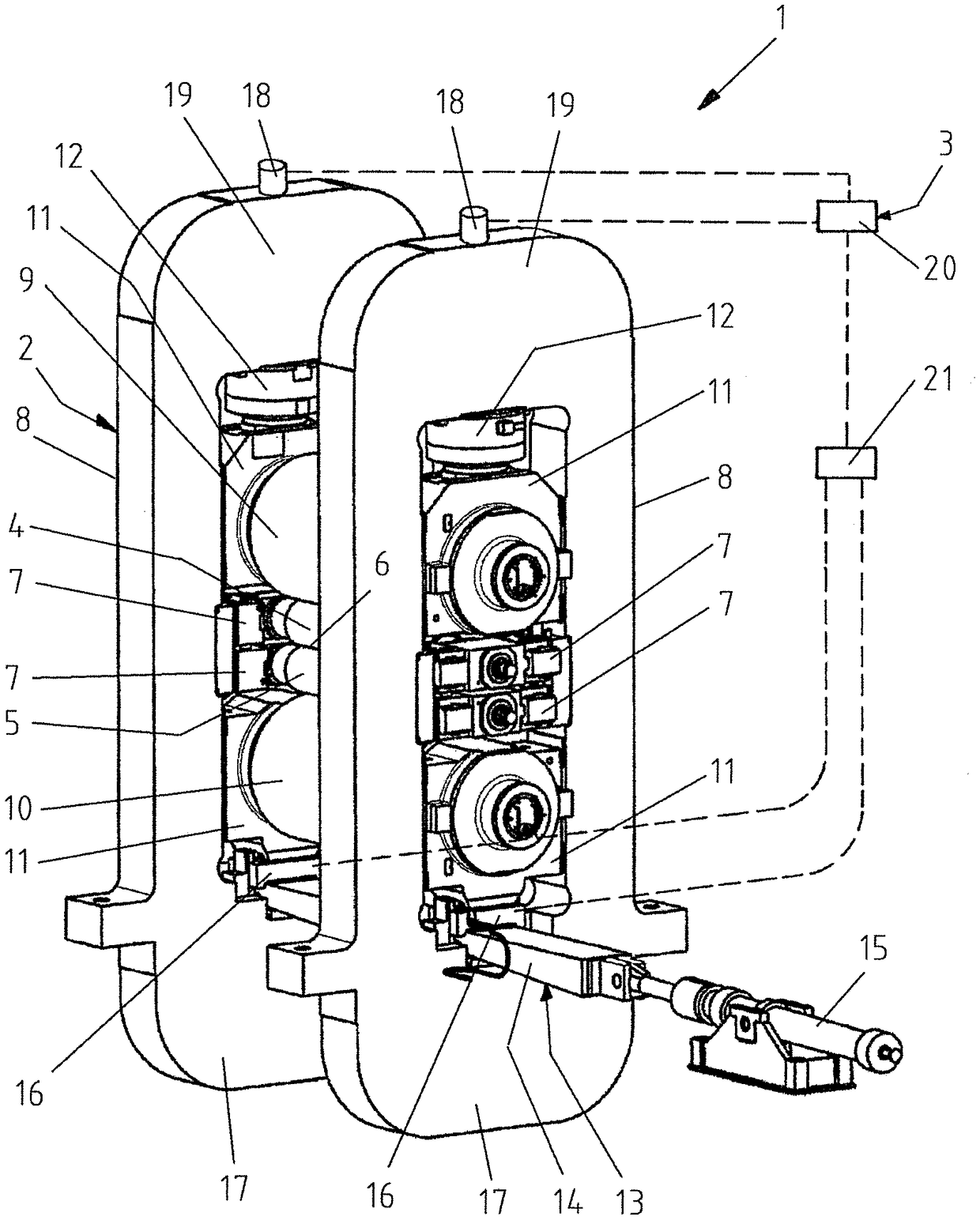

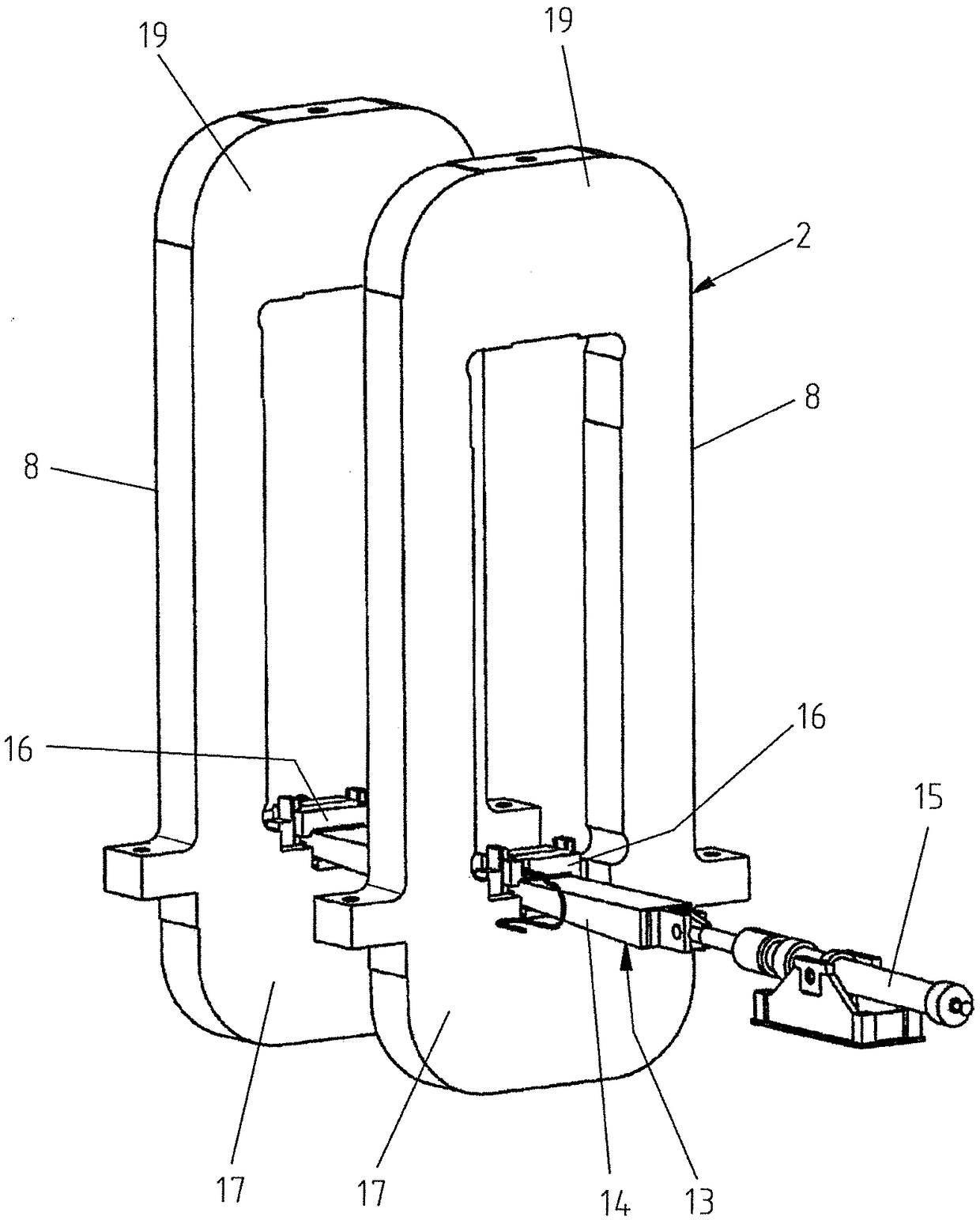

[0043] figure 1 A schematic perspective view of an embodiment of a rolling installation 1 for rolling, in particular cold rolling, metal objects according to the invention is shown. The rolling installation 1 comprises a rolling stand 2 and a system 3 for actively damping vibrations in the rolling stand 2 .

[0044] The rolling mill stand 2 comprises an upper work roll 4 and a lower work roll 5 cooperating therewith, forming a roll gap 6 between the upper work roll and the lower work roll. The work rolls 4 and 5 are respectively guided at the end sides via a bearing unit 7 on each column 8 of the rolling stand 2 . In addition, the rolling mill stand 2 includes an upper back-up roll 9 supporting the upper work roll 4 and a lower back-up roll 10 supporting the lower work roll 5 . The back-up rolls 9 and 10 are respectively guided at the end sides via a bearing unit 11 on each column 8 of the rolling stand 2 . In addition, the rolling stand 2 also includes two adjusting units ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com