Rolling mill and method for operating same

A rolling mill and roll technology, applied in the field of operating the rolling mill, can solve the problems of low horizontal dynamic stiffness, hindering high-efficiency rolling, etc., and achieve the effects of improving accuracy, preventing rolling mill vibration, and reducing impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

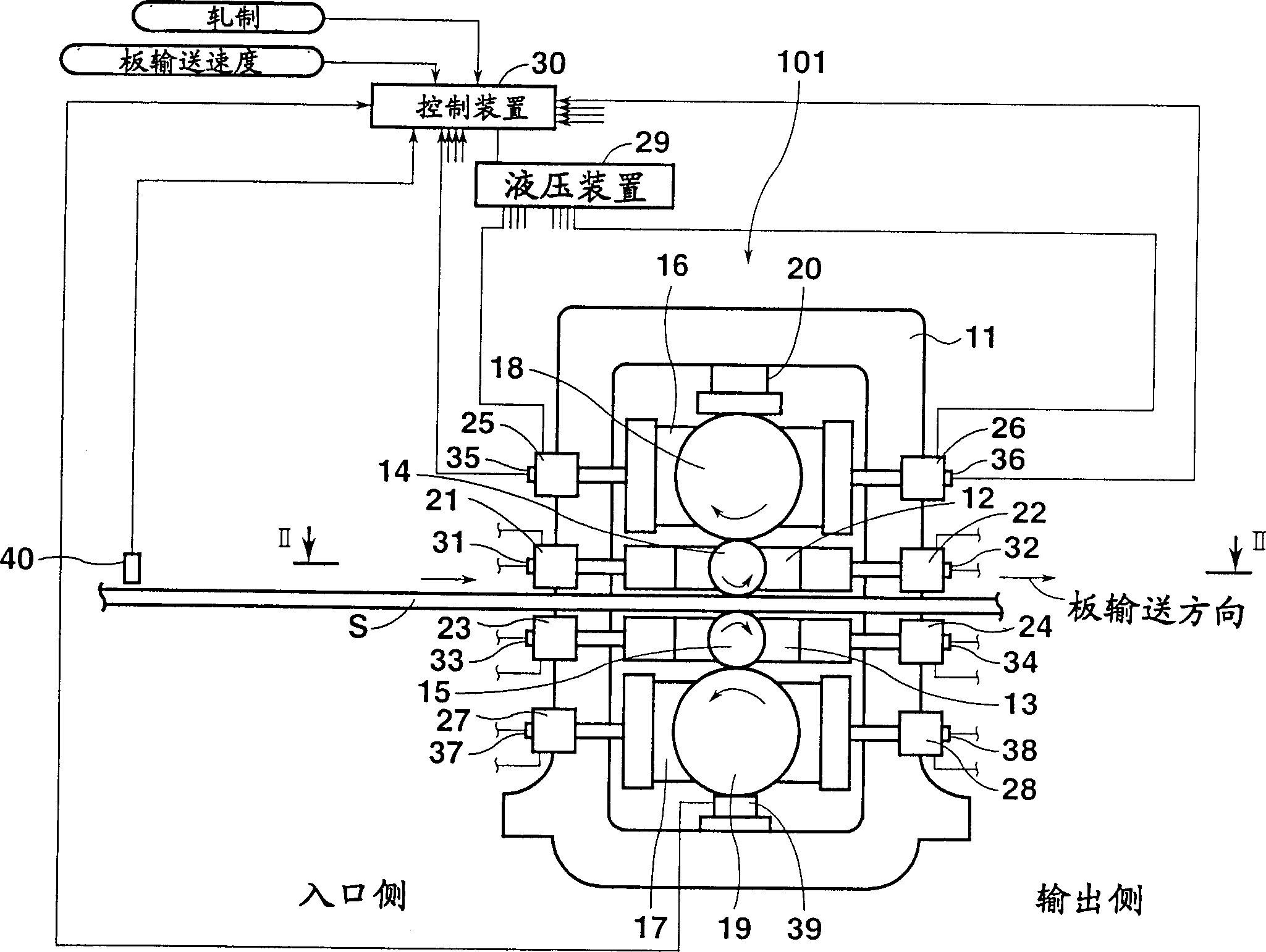

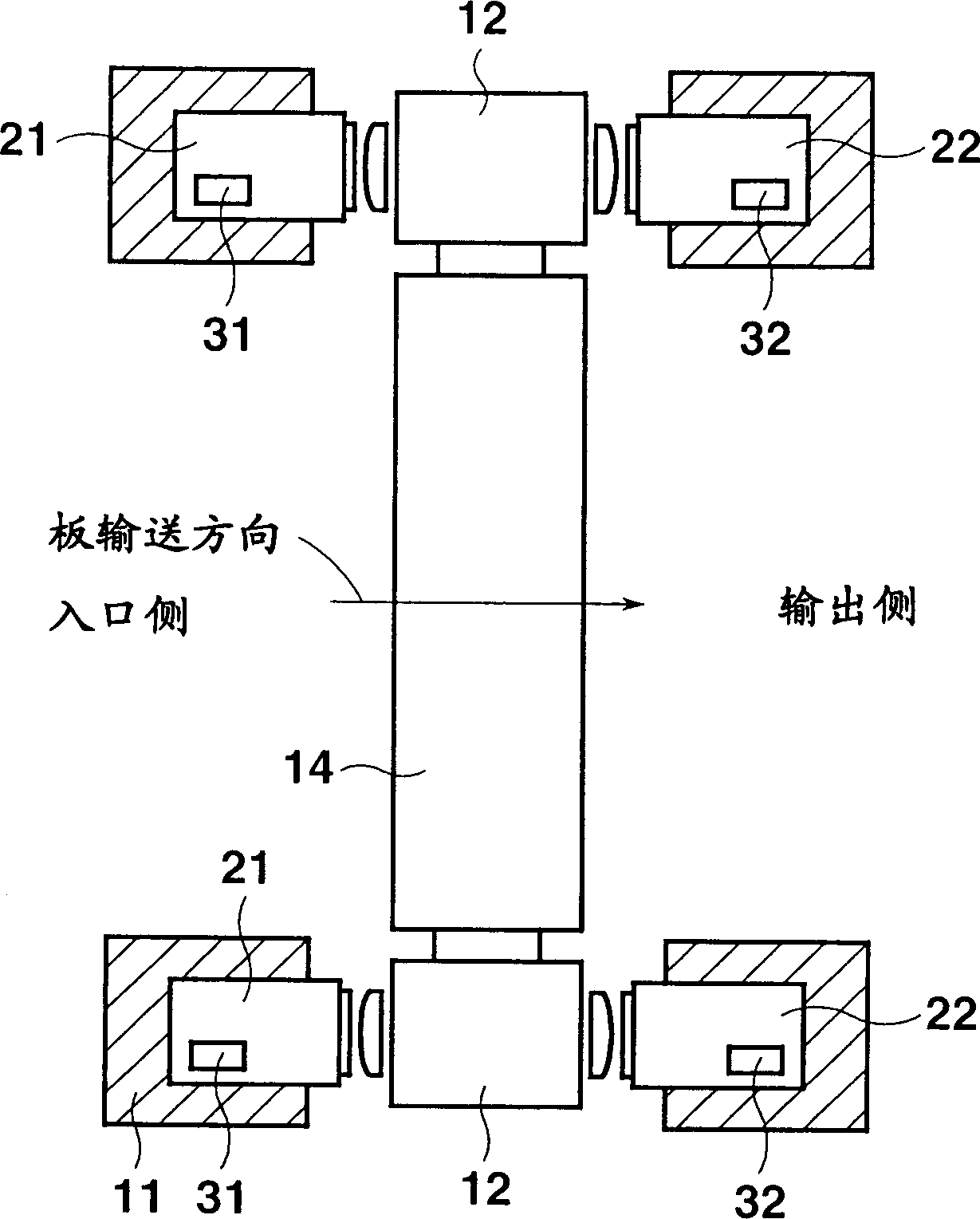

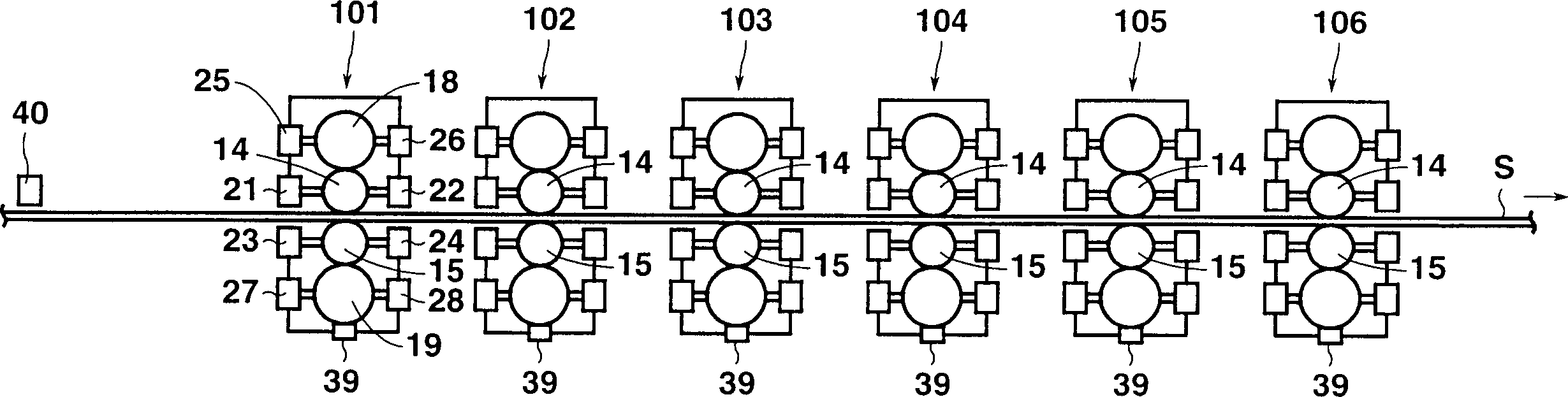

[0030] Such as figure 1 with 2 As shown in , in a rolling mill 101 according to the first embodiment, a pair of upper and lower work roll chocks 12 and 13 are supported in a housing 11 . Shaft portions of a pair of upper and lower work rolls 14 and 15 are rotatably supported by upper and lower work roll chocks 12 and 13, respectively, and the upper and lower work rolls 14 and 15 are opposed to each other. A pair of upper and lower backup roll chocks 16 and 17 are supported above and below the upper and lower work roll chocks 12 and 13 . Shaft portions of a pair of upper and lower backup rolls 18 and 19 are rotatably supported by upper and lower backup roll bearing housings 16 and 17, respectively. The upper backup roll 18 and the lower work roll 14 face each other, and the lower backup roll 19 and the lower work roll 15 face each other. In the upper part of the archway 11 there is a reduction device 20 for applying a rolling force on the upper work roll 14 by means of the u...

no. 2 approach

[0048] In the method for operating a rolling mill according to the second embodiment, the control device 30 controls the hydraulic device 29 such that before the tail end portion of the rollable material S passes between the work rolls 14 and 15, the hydraulic cylinders 21 to 28 will The pressure applied to the roll chocks 12 , 13 , 16 , 17 is set higher, and after the rollable material S passes between the work rolls 14 and 15 , the pressure is set lower.

[0049] That is, as in image 3 with 5 As shown in , the rolling of the rollable material S by the rolling mill 101 is nearly completed, and the end detection sensor 40 detects the tail end portion of the rollable material S. In this case, the control device 30 at time t 6 The hydraulic device 29 is controlled to increase the operating oil pressure of the hydraulic cylinders 21 to 28 at a predetermined time after detection by the end detection sensor 40 . at time t 7 , the working oil pressure of the hydraulic cylinders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com