Rolling facility and rolling method of stainless steel plate

A technology of steel plate and rolling oil, which is applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problem of the reduction of the surface gloss of the workpiece, so as to suppress the occurrence of defects, improve productivity and quality, and suppress the occurrence of surface defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to facilitate understanding of the description of the embodiments of the present disclosure, elements denoted by the same reference numerals in the drawings are used for the same elements, and related parts among parts having the same functions in the respective embodiments are denoted by the same drawings. Notation or extended reference notation.

[0039] To clarify the gist of the present disclosure, descriptions of elements and techniques known in the art will be omitted, and the present disclosure will be described in detail with reference to the accompanying drawings.

[0040] The spirit of the present disclosure is not limited to the proposed embodiments, and other elements may be added, changed, and deleted suggested by those skilled in the art, and these other elements are also included in the scope of the same concept as the concept of the present disclosure.

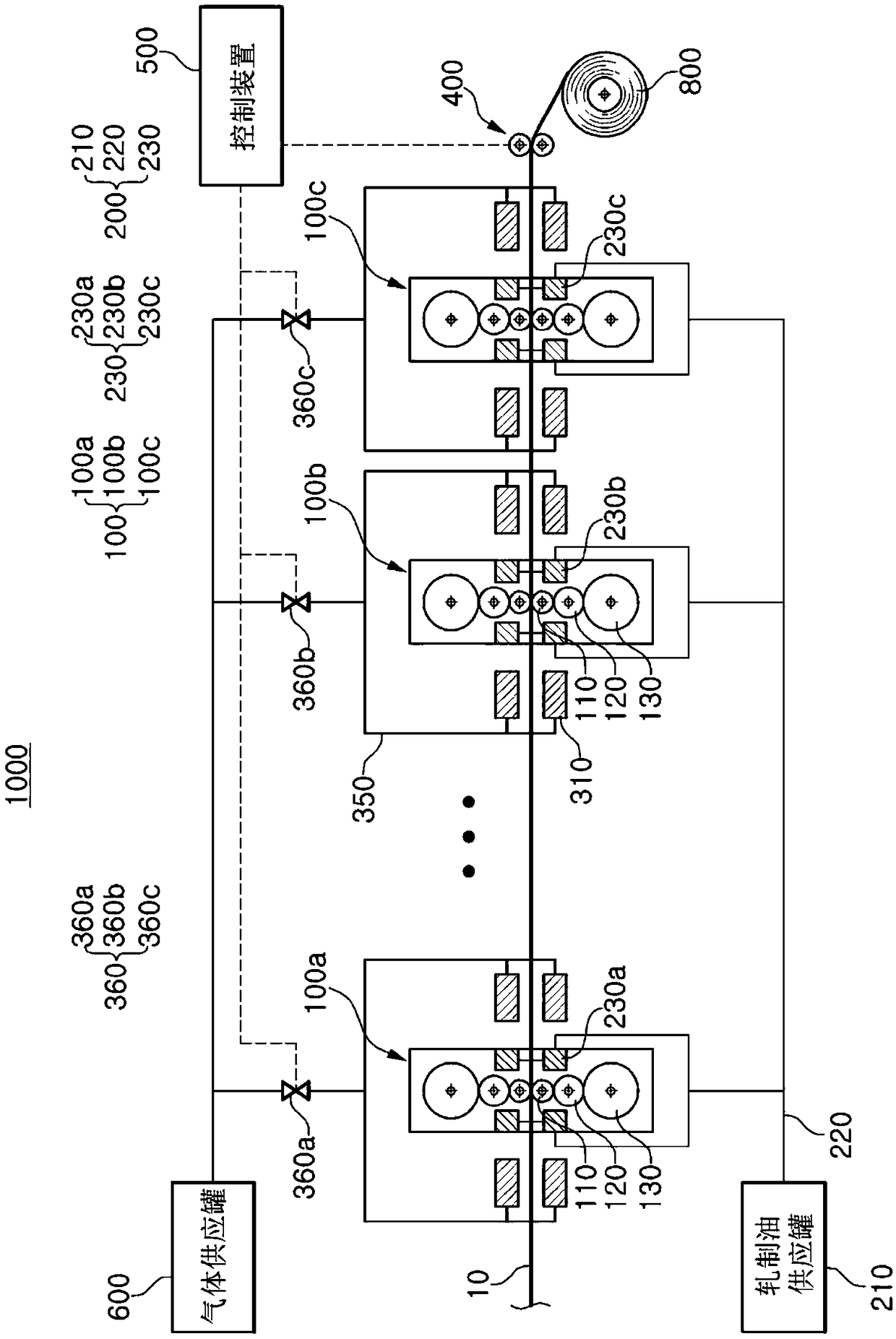

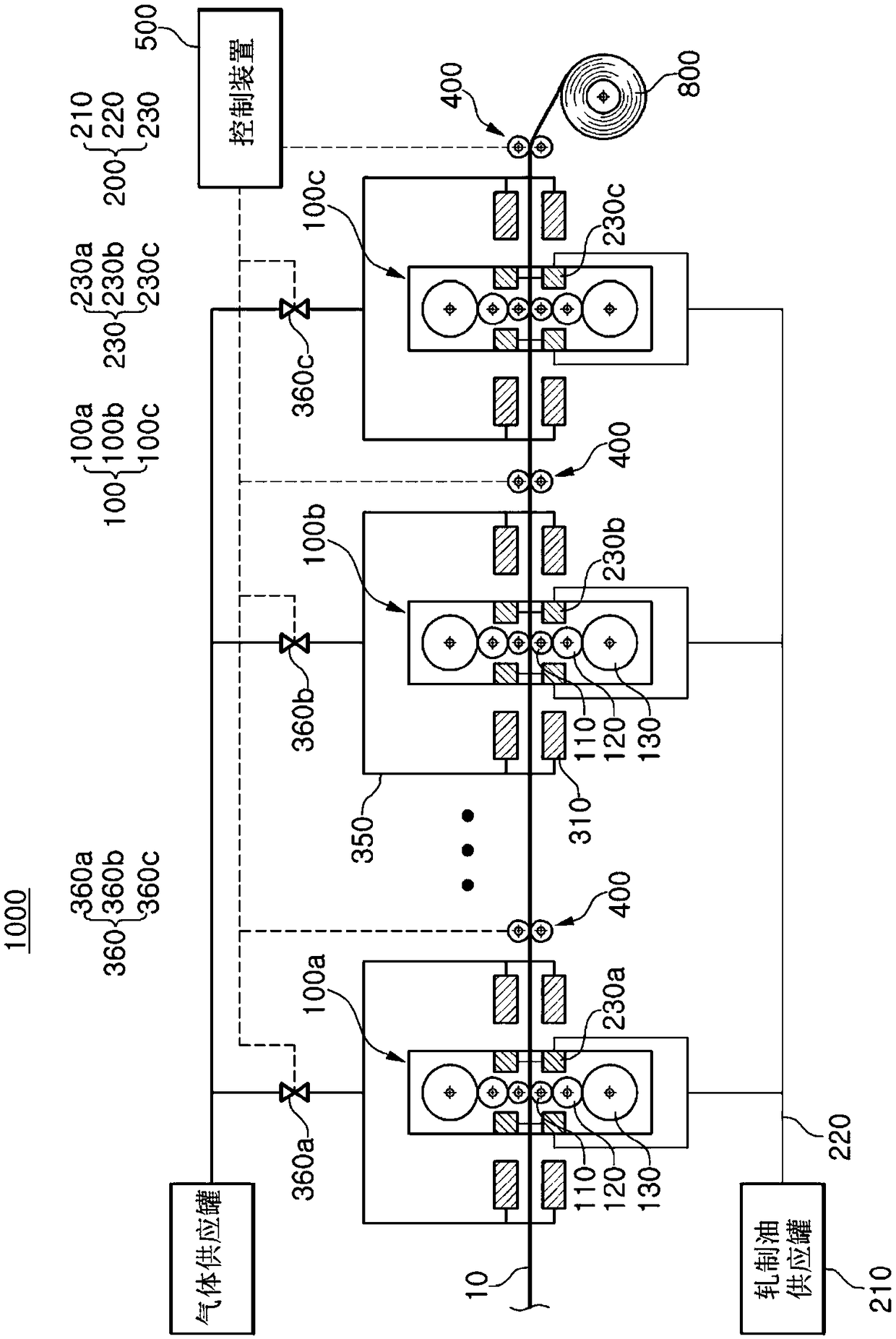

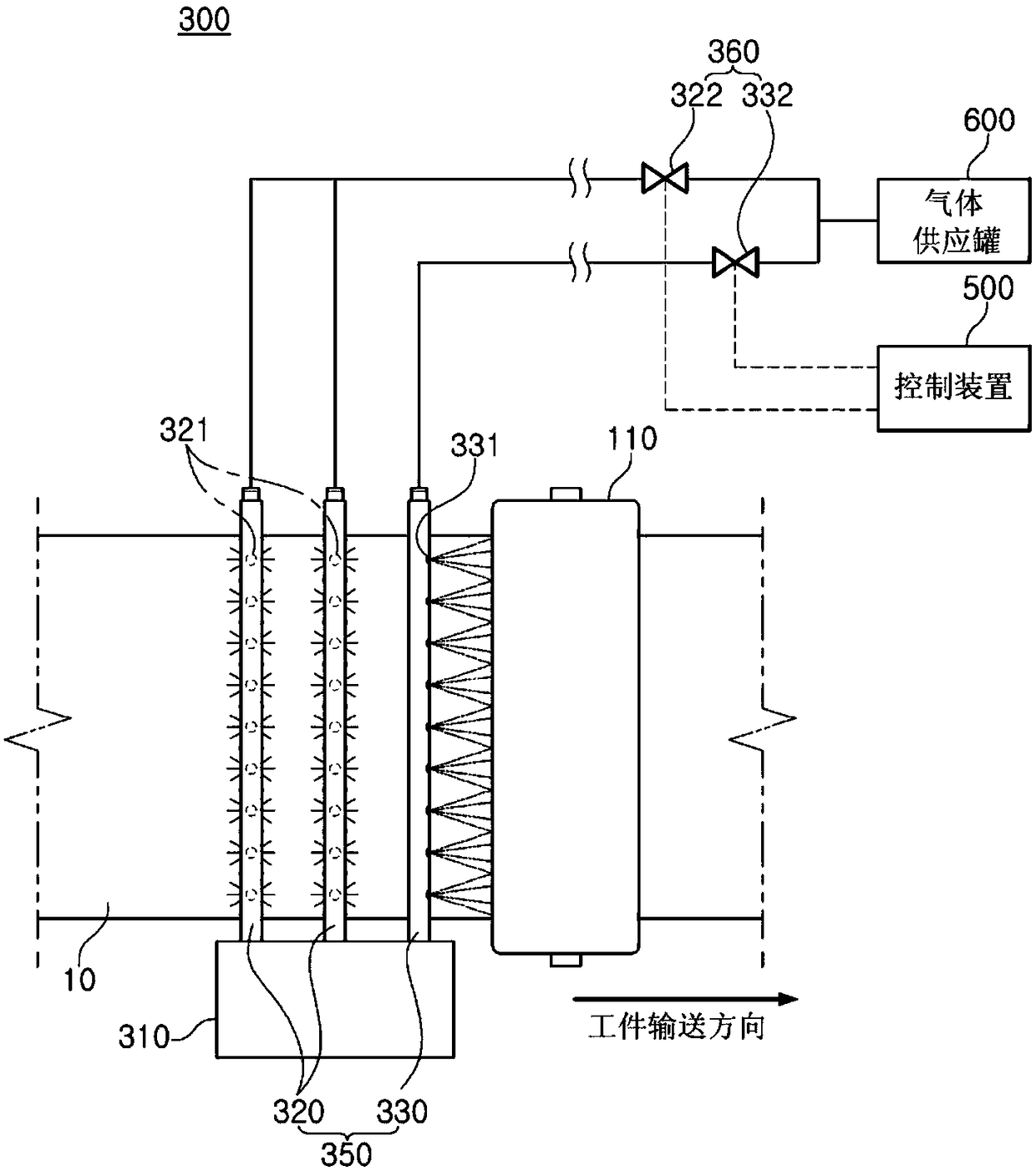

[0041] exist figure 1 In , a rolling mill 1000 according to an exemplary embodiment is illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com