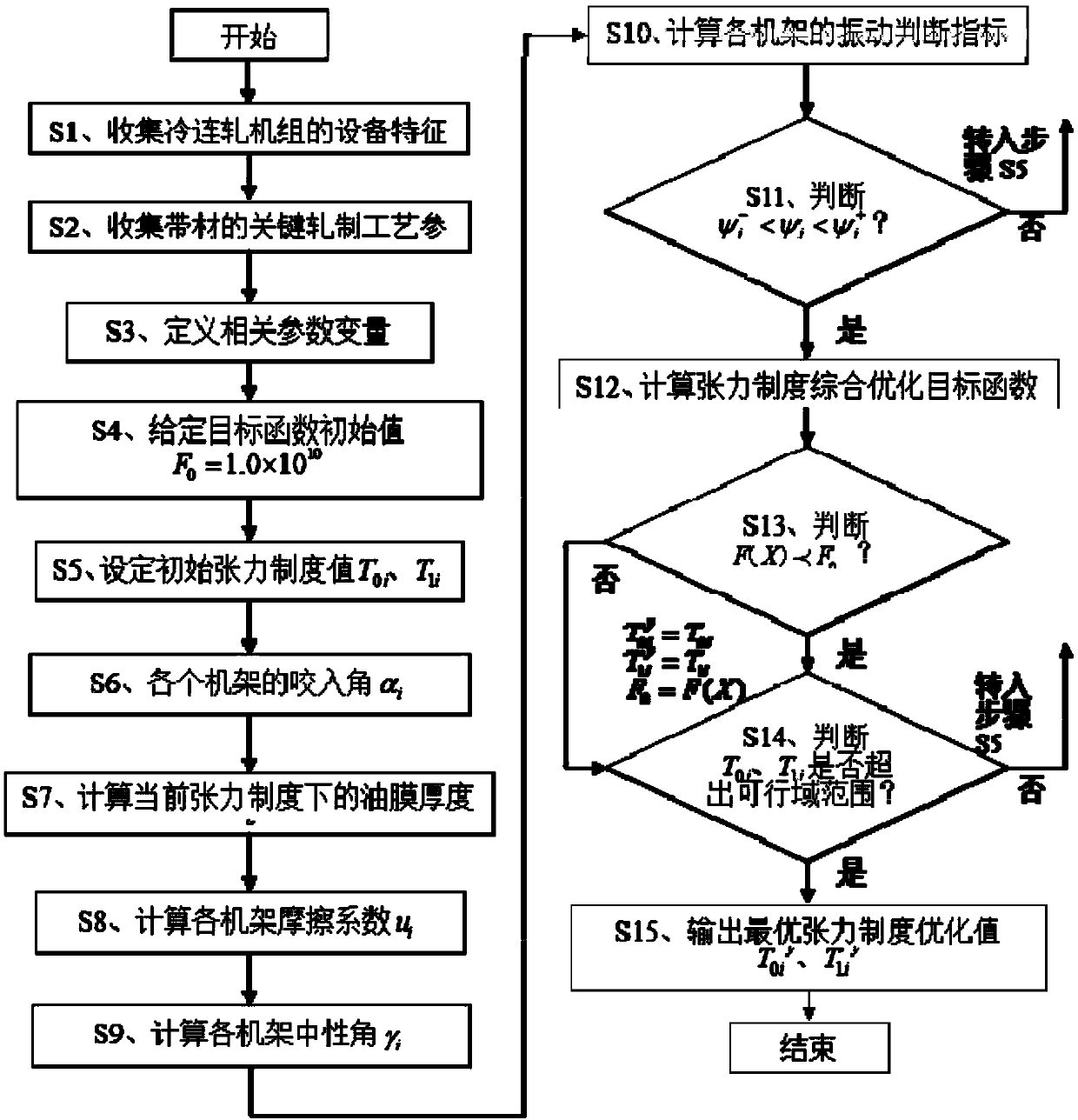

Tension system optimization method for inhibiting vibration of cold continuous rolling unit

A technology of cold tandem rolling unit and optimization method, which is applied in the field of metallurgical steel rolling, can solve the problems such as no cold tandem rolling unit is given, and achieve the effect of increasing economic benefits of enterprises, broad application prospects, and high-speed and stable rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

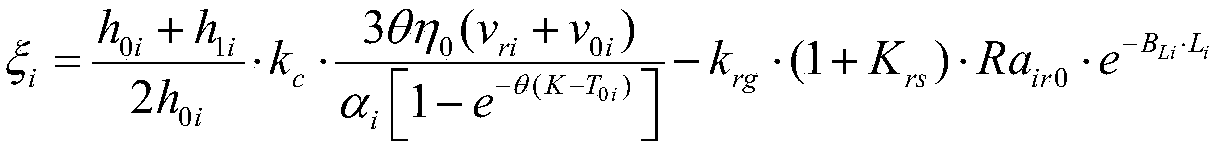

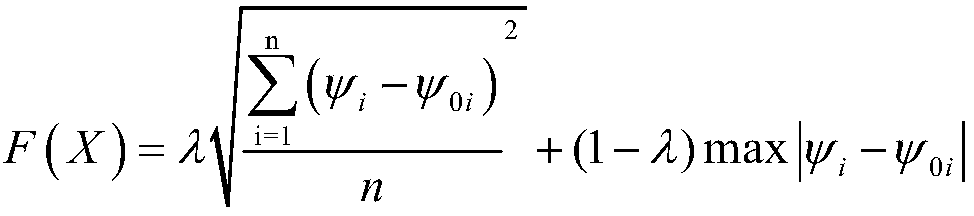

Method used

Image

Examples

Embodiment 1

[0057] S1, collect the equipment characteristic parameters of the cold tandem rolling mill, including: each stand (5) work roll radius R i ={1#217.5; 2#217.5; 3#217.5; 4#217.5; 5#217.5} (mm), each stand (5) roll surface linear velocity v ri ={1#149.6; 2#292.3; 3#328.3; 4#449.2; 5#585.5} (m / min), original roughness Ra of work rolls of each frame (5 pieces) ir0 ={1#0.53; 2#0.53; 3#0.53; 4#0.53; 5#0.53} (μm), the roughness attenuation coefficient B of each rack (5 pieces) work roll Li ={1#0.01; 2#0.0.1; 3#0.01; 4#0.01; 5#0.01}, the rolling kilometers L of each stand (5 pieces) after the work roll is changed i ={1#200; 2#180; 3#190; 4#220; 5#250}(km), wherein, i=1,2,...,5, representing the stand number of the cold tandem rolling mill;

[0058] S2, collect the key rolling process parameter of strip, comprise: elastic modulus E=206GPa of strip, Poisson's ratio ν=0.3 of strip, strip width B=812mm, each frame (5) strip Inlet thickness h 0i ={1#2.1; 2#1.17; 3#0.65; 4#0.4; 5#0.27} (...

Embodiment 2

[0082] S1, collect the equipment characteristic parameters of the cold tandem rolling mill, including: each stand (5) work roll radius R i ={1#217.5; 2#217.5; 3#217.5; 4#217.5; 5#217.5} (mm), each stand (5) roll surface linear velocity v ri ={1#149.6; 2#292.3; 3#328.3; 4#449.2; 5#585.5} (m / min), original roughness Ra of work rolls of each frame (5 pieces) ir0 ={1#0.53; 2#0.53; 3#0.53; 4#0.53; 5#0.53} (μm), the roughness attenuation coefficient B of each rack (5 pieces) work roll Li ={1#0.01; 2#0.0.1; 3#0.01; 4#0.01; 5#0.01}, the rolling kilometers L of each stand (5 pieces) after the work roll is changed i ={1#220; 2#190; 3#200; 4#240; 5#260}(km), wherein, i=1,2,...,5, representing the stand number of the cold tandem rolling mill;

[0083] S2, collect the key rolling process parameter of strip, comprise: elastic modulus E=210GPa of strip, Poisson's ratio ν=0.3 of strip, strip width B=826mm, each frame (5) strip Inlet thickness h 0i ={1#2.2; 2#1.27; 3#0.75; 4#0.5; 5#0.37} (...

Embodiment 3

[0107] S1, collect the equipment characteristic parameters of the cold tandem rolling mill, including: each stand (5) work roll radius R i ={1#217.5; 2#217.5; 3#217.5; 4#217.5; 5#217.5} (mm), each stand (5) roll surface linear velocity v ri ={1#149.6; 2#292.3; 3#328.3; 4#449.2; 5#585.5} (m / min), original roughness Ra of work rolls of each frame (5 pieces) ir0 ={1#0.53; 2#0.53; 3#0.53; 4#0.53; 5#0.53} (μm), the roughness attenuation coefficient B of each rack (5 pieces) work roll Li={1#0.01; 2#0.0.1; 3#0.01; 4#0.01; 5#0.01}, the rolling kilometers L of each stand (5 pieces) after the work roll is changed i ={1#190; 2#170; 3#180; 4#210; 5#230}(km), wherein, i=1,2,...,5, representing the stand number of the cold tandem rolling mill;

[0108] S2, collect the key rolling process parameter of strip, comprise: elastic modulus E=201GPa of strip, Poisson's ratio ν=0.3 of strip, strip width B=798mm, each frame (5) strip Inlet thickness h 0i ={1#2.0; 2#1.01; 3#0.55; 4#0.35; 5#0.25} (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com