Electric pile gas-liquid distribution device and fuel cell applying same

A gas-liquid distribution and distribution device technology, applied in fuel cells, fuel cell additives, electrical components, etc., can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

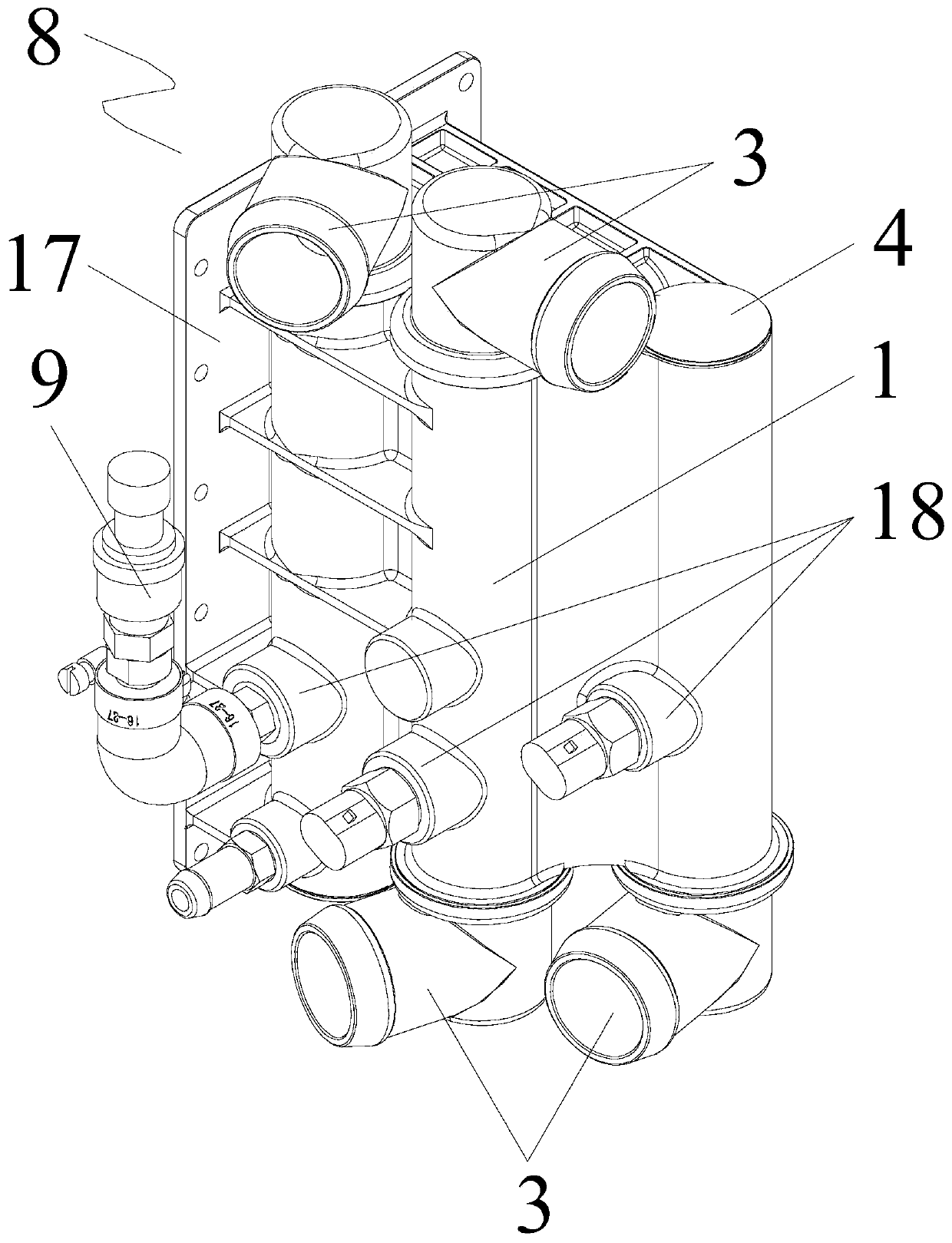

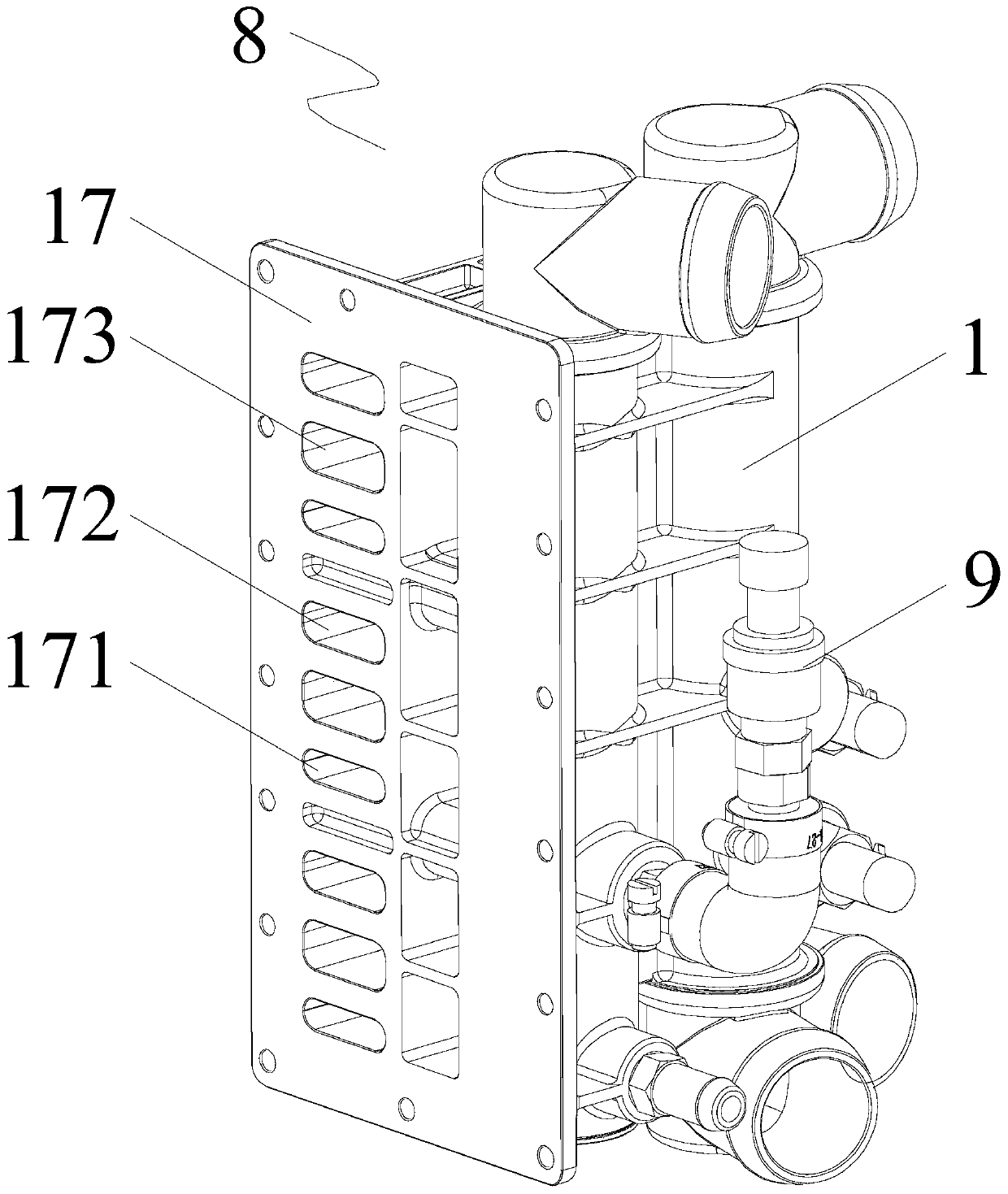

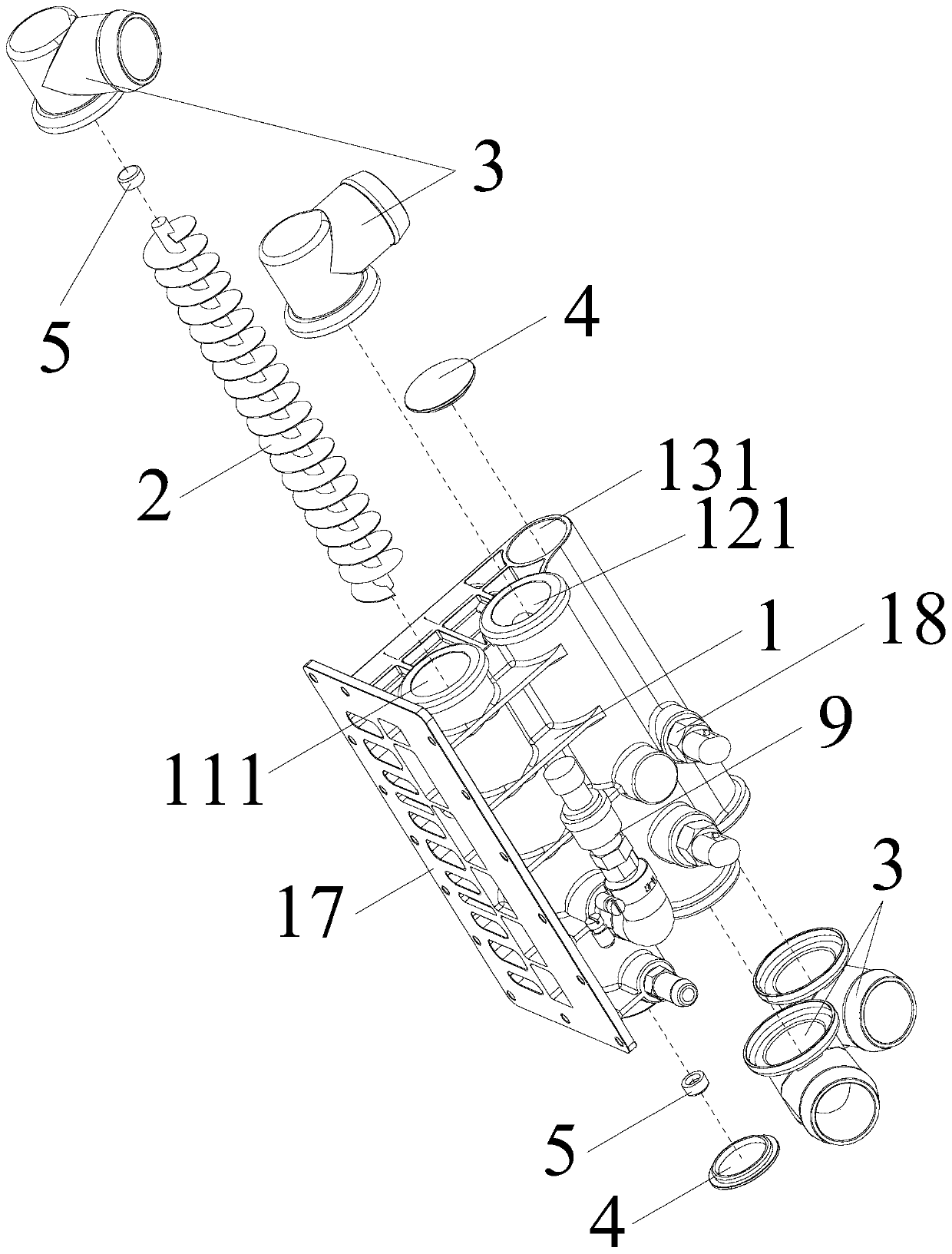

[0032] Such as Figure 1 to Figure 10 As shown, what this embodiment provides is a stack gas-liquid distribution device, including a block main body 1, and the main block body 1 is provided with a hydrogen main channel 11 for hydrogen circulation, an air main channel 12 for air circulation, and The cooling liquid main channel 13 for cooling liquid circulation, the hydrogen main channel 11, the air main channel 12 and the cooling liquid main channel 13 are vertically facing and separated from each other, a gas-liquid separation device is installed in the hydrogen main channel 11, and the gas-liquid separation device It is the spiral reamer blade 2. After the moist hydrogen gas mixture enters the main hydrogen channel 11, it will flow upwards in a spiral shape along the helical reamer blade 2 to form an outer swirling air flow; the outer swirling air flow will generate centrifugal force during the rotation process, and the hydrogen in the outer swirling air flow will rotate and ...

Embodiment 2

[0041] Such as Figure 11As shown, what this embodiment provides is a fuel cell, including a stack module 6, an input stack gas-liquid distribution device 7 and an output stack distribution device 8, and the stack module 6 is composed of several fuel cell units 60 are stacked from bottom to top, and one side of each fuel cell unit 60 is provided with a hydrogen input port, an air input port and a cooling liquid input port, and the hydrogen gas input port, the air input port and the cooling liquid input port The outlets are distributed from top to bottom, and the other side is provided with hydrogen outlets, air outlets and coolant outlets, the hydrogen outlets, air outlets and coolant outlets are respectively distributed from top to bottom, so The hydrogen input port, the air input port and the cooling liquid input port are connected to the input stack gas-liquid distribution device 7, and the hydrogen output port, the air output port and the cooling liquid output port are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com