A cavity air inlet flow velocity adjusting device

A flow rate adjustment and cavity technology, applied in valve devices, valve operation/release devices, valve details, etc., can solve problems such as affecting equipment production capacity and difficult to control air intake flow rate, so as to improve equipment production capacity and easy intake air volume. Control, smooth change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

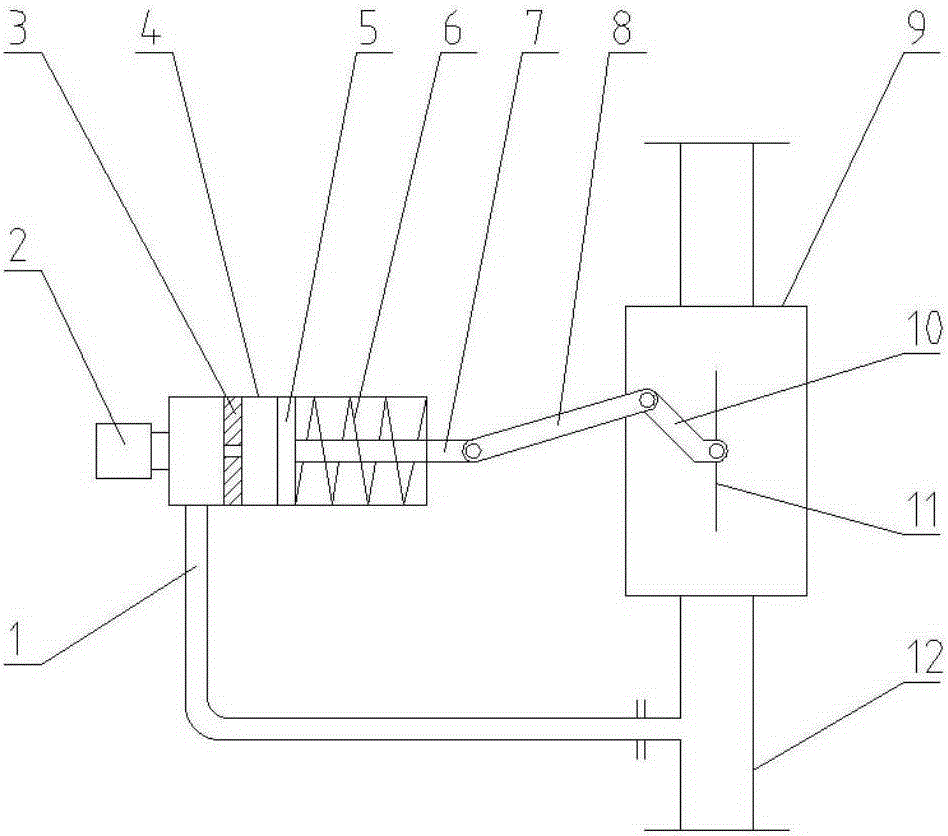

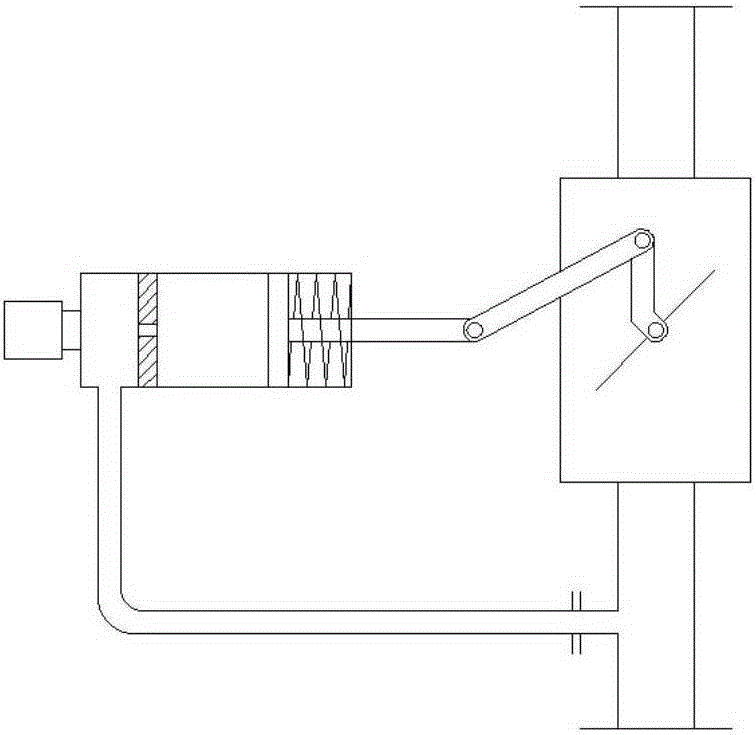

[0011] refer to figure 1 and figure 2 , a cavity intake flow rate regulator, including a cylinder intake pipe 1, a pressure regulating valve 2, a small hole baffle 3, a cylinder 4, a piston 5, a spring 6, a piston rod 7, a connecting rod 8, a valve body 9, a valve Sheet rod 10, valve sheet 11, intake pipe 12. The valve plate 11 is installed in the valve body 9 and can rotate around the pin on the valve body 9 in the valve body; the valve plate 11 is connected and fixed with the valve plate rod 10 . Described air intake pipe 12 is connected with valve body 9 intake ends; Cylinder air intake pipe 1 two ends are respectively connected with air intake pipe 12 and cylinder 4, and cylinder 4 is provided with piston 5, and piston 5 is connected with piston rod 7 and is fixed. Described spring 6 is positioned in cylinder 4, and one end is in contact with piston 5, and the other end is in contact with cylinder 4 inner end face, and the elastic force of spring 6 can act on piston 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com