Denitrifying low-NOx circulating fluidized bed boiler and denitrifying low-NOx emission control process

A circulating fluidized bed and emission control technology, which is applied to fluidized bed combustion equipment, fuel burned in a molten state, lighting and heating equipment, etc., can solve problems such as boiler economic impact, heavy metal pollution, and high input costs, and achieve Reduce daily operating costs, improve load carrying capacity, and reduce material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

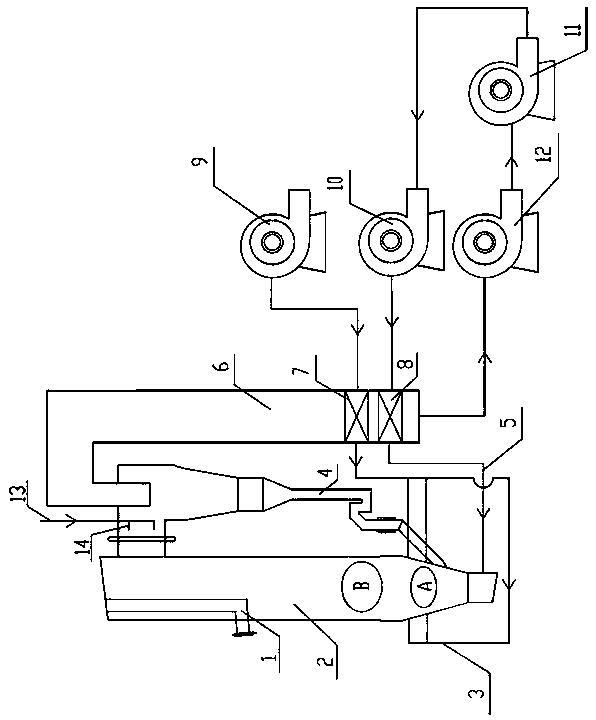

[0039] Such as figure 1 As shown, a denitration and low NOx emission control process suitable for circulating fluidized bed boilers of the present invention includes the following control processes:

[0040] Measure one, increase the area of the evaporation heating surface in the boiler to change the heat absorption of the evaporation heating surface of the boiler furnace, and control the heat absorption of the furnace by increasing the evaporation heating surface in the furnace. According to different boiler parameters, adjust the heat absorption to control the heating surface area according to the bed temperature before the transformation, and finally control the bed temperature after the transformation between 820~900℃;

[0041] The second measure is to adjust the size of the small holes of the air distribution plate and increase the slag discharge hole of the air distribution plate and the opening size of the hood at the surrounding wall;

[0042] The third measure is to impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com