Patents

Literature

46results about How to "No secondary hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

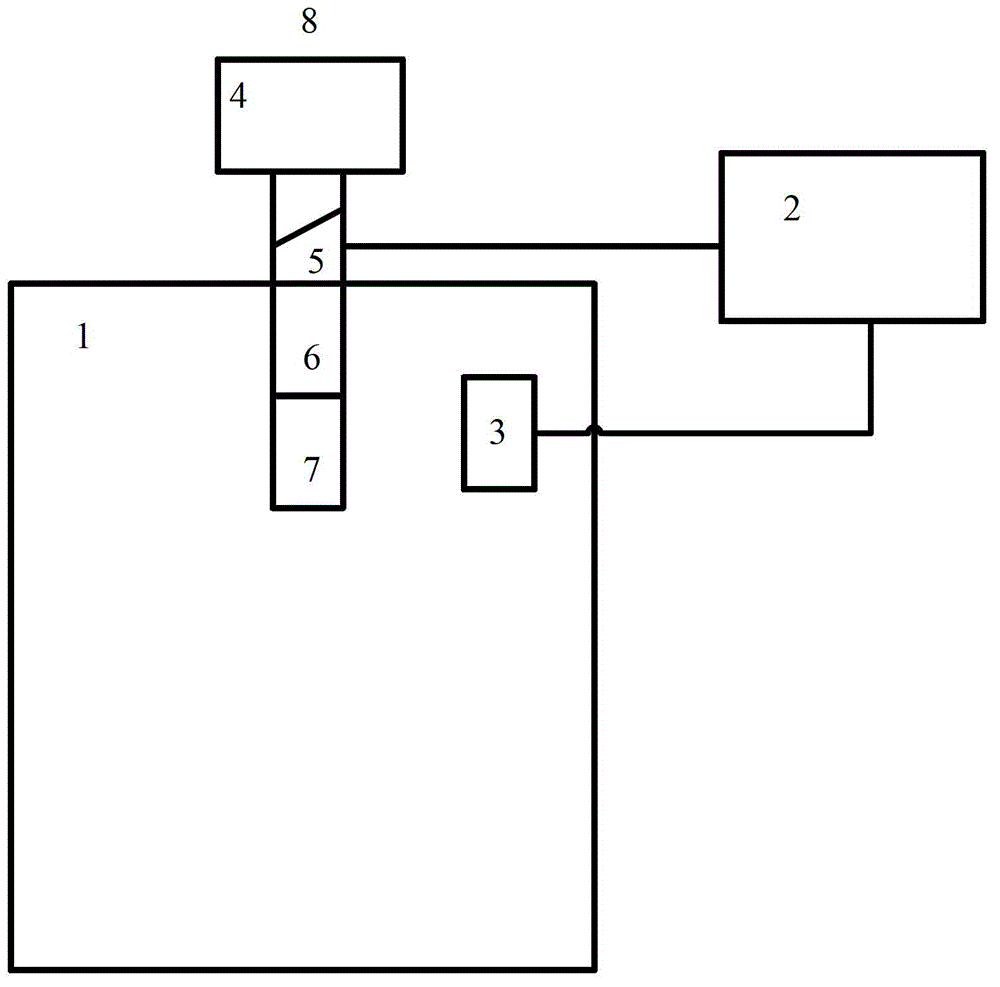

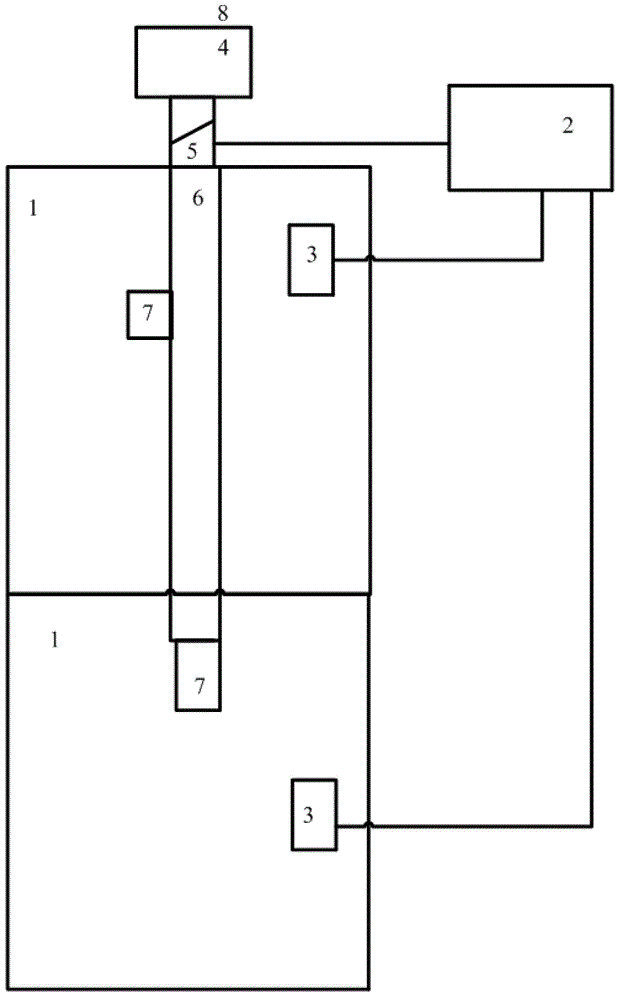

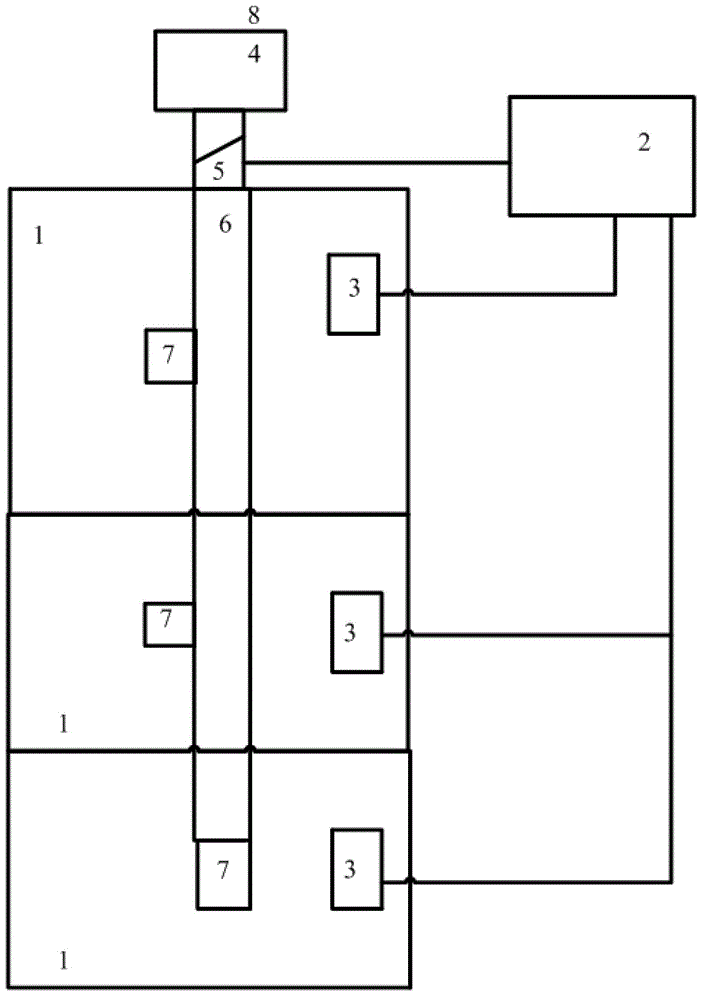

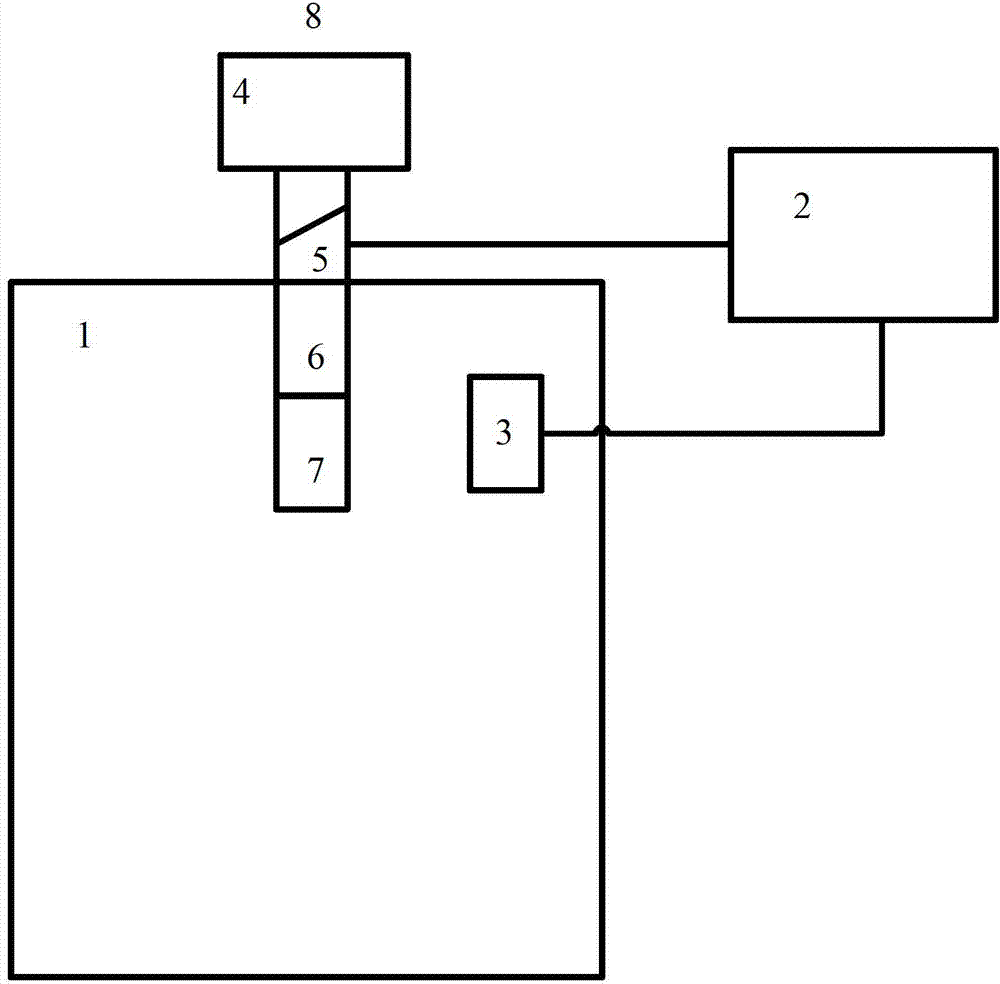

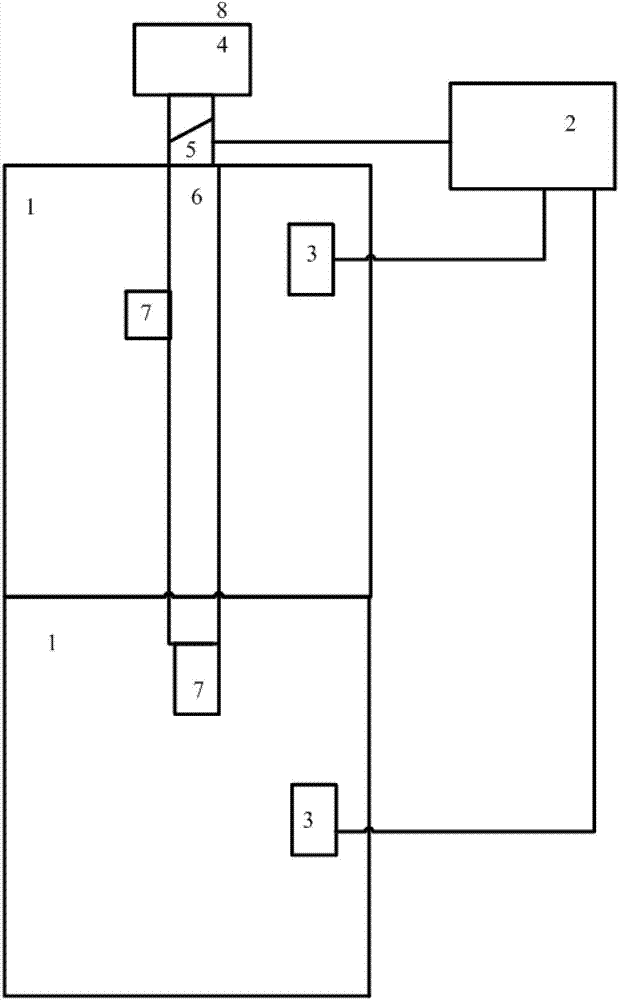

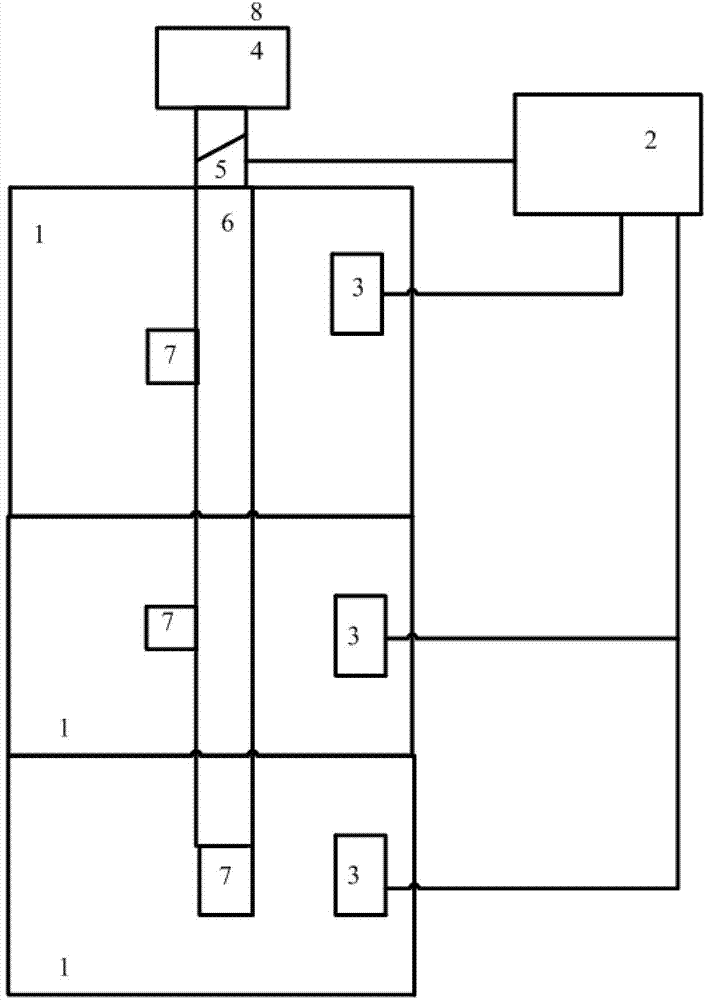

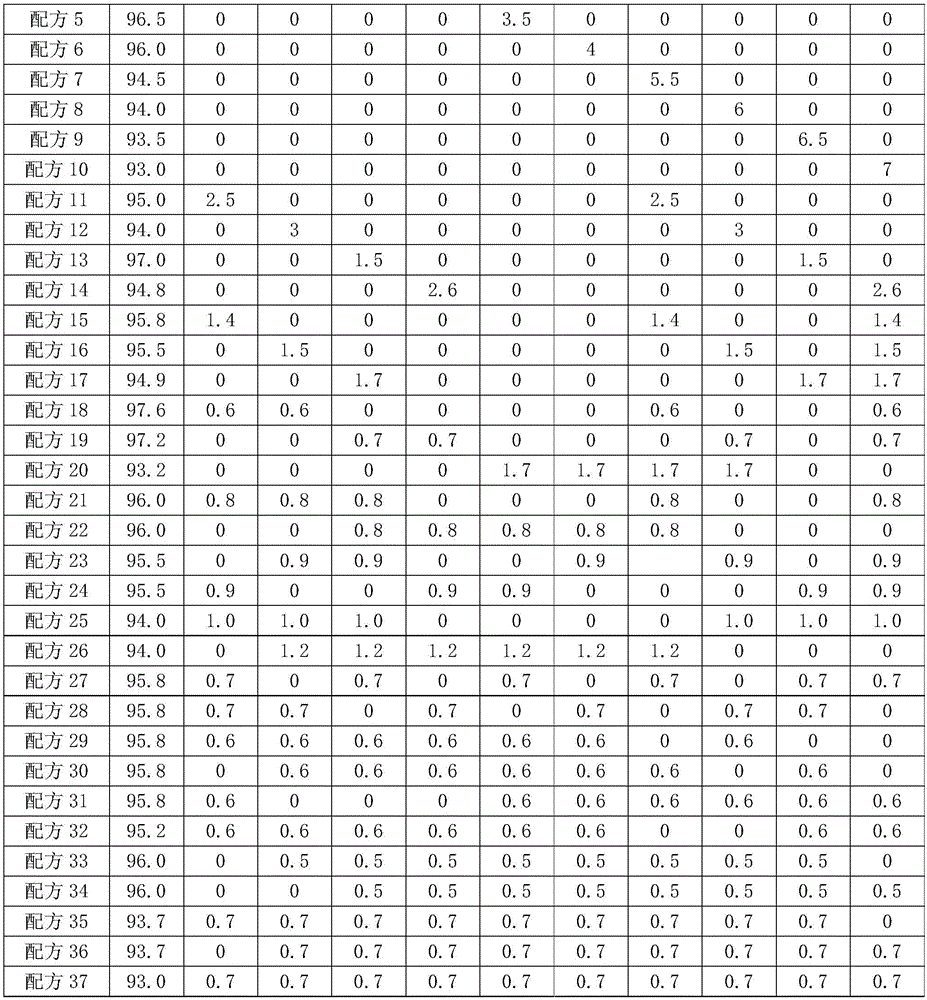

Automatic electric switch cabinet fire extinguishing system and fire recognition method

ActiveCN102743830ARealization of automatic fire extinguishingDoes not affect normal operationFire rescueFire alarmsEngineeringSwitchgear

The invention discloses an automatic electric switch cabinet fire extinguishing system and a fire recognition method, wherein the automatic electric switch cabinet fire extinguishing system comprises a fire extinguishing agent nozzle which is arranged in an electric switch cabinet; the fire extinguishing agent nozzle is connected with a storage device in which a non-conducting fire extinguishing agent is stored through a pipeline; an electromagnetic valve which is controlled by a central controller is arranged on a pipeline; a photoelectric sensor is also arranged in the electric switch cabinet; and the photoelectric sensor outputs a detection signal to the central controller and then the central controller judges whether to open the electromagnetic valve. The automatic electric switch cabinet fire extinguishing system is capable of responding sudden electric fire and reducing the loss caused thereby. Fire extinguishing agents such as heptafluoropropane and superfine dry powder are used and non-conducting, so that secondary danger caused by conduction of fire extinguishing agents does not occur; and the fire extinguishing agents are environmental-friendly, so that the damage to the environment caused by conduction of fire extinguishing agents also does not occur. The photoelectric sensor is used, so that the fire such as electric arc and the like in the switch cabinet can be rapidly and correctly detected.

Owner:XI AN JIAOTONG UNIV

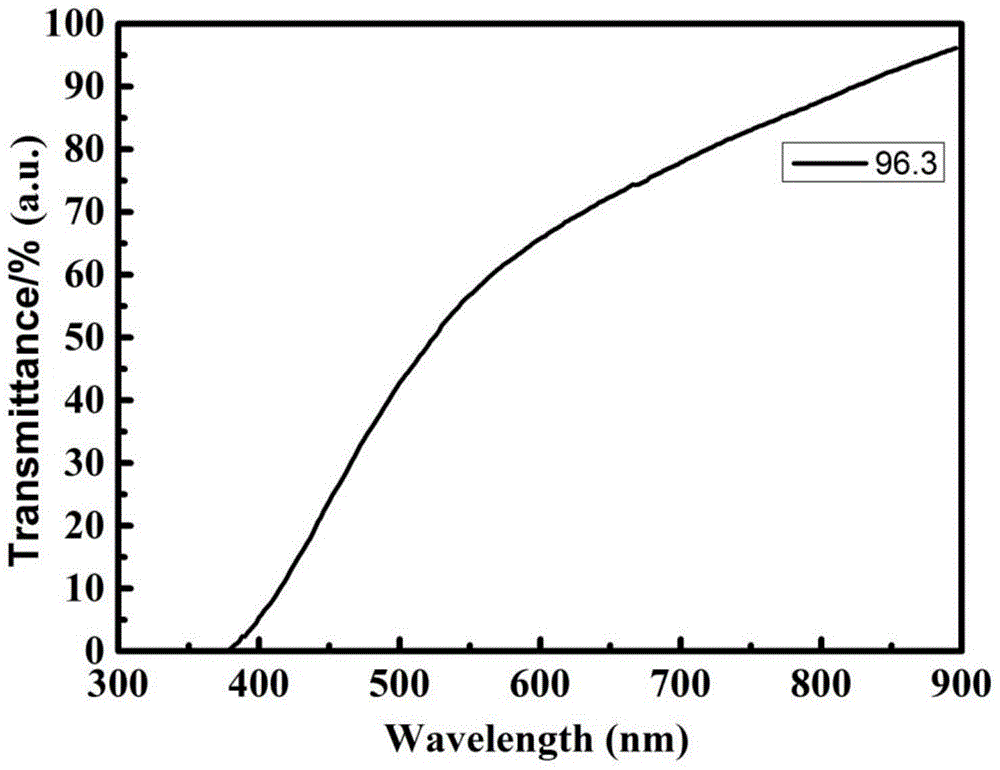

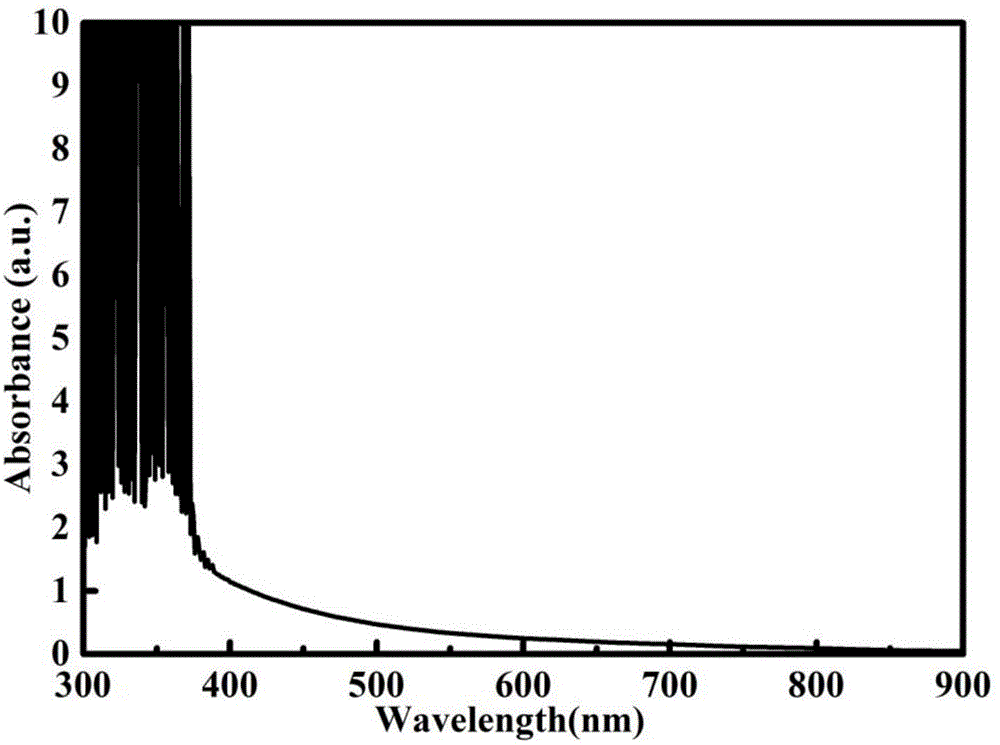

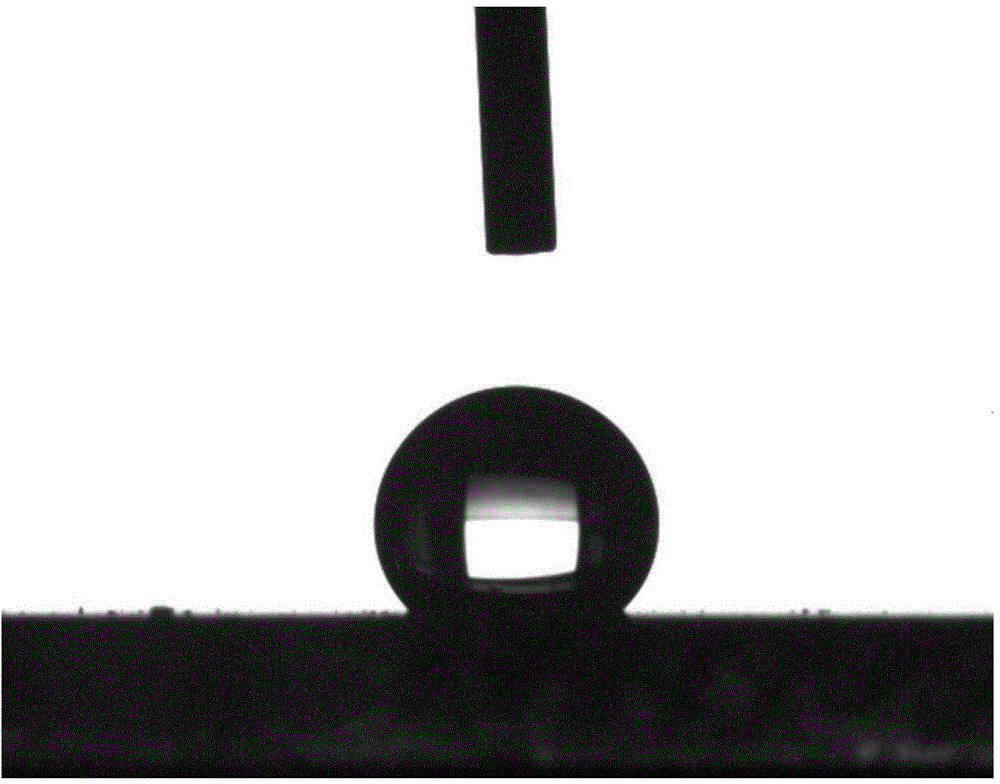

Preparation method of super-hydrophobic self-cleaning glass based on ZnO nano array coating

The invention discloses a preparation method of super-hydrophobic self-cleaning glass based on a ZnO nano array coating. The preparation method comprises the following steps: preparing ZnO seed layer sol by a sol-gel method; plating ITO glass with a ZnO seed layer by a dipping-pulling method; performing heat treatment and paving a layer of polystyrene spheres; performing hydrothermal treatment on the prepared ZnO seed layer / PS material in a ZnO growth solution to obtain a ZnO / PS nano rod array; and treating the ZnO / PS nano rod array with toluene for a period of time to obtain the super-hydrophobic self-cleaning glass. According to the super-hydrophobic self-cleaning glass based on a ZnO nano array coating prepared by the method disclosed by the invention, the transmittance of visible light can reach 96.3%, and both of the ultraviolet absorption efficiency and shielding efficiency can reach 90%; and according to the test by a contact angle meter (DSA series), the contact angle to water exceeds 152 degrees. The preparation method disclosed by the invention has the advantages of no secondary harm, low cost, easiness in implementation and convenience in control.

Owner:TIANJIN CHENGJIAN UNIV

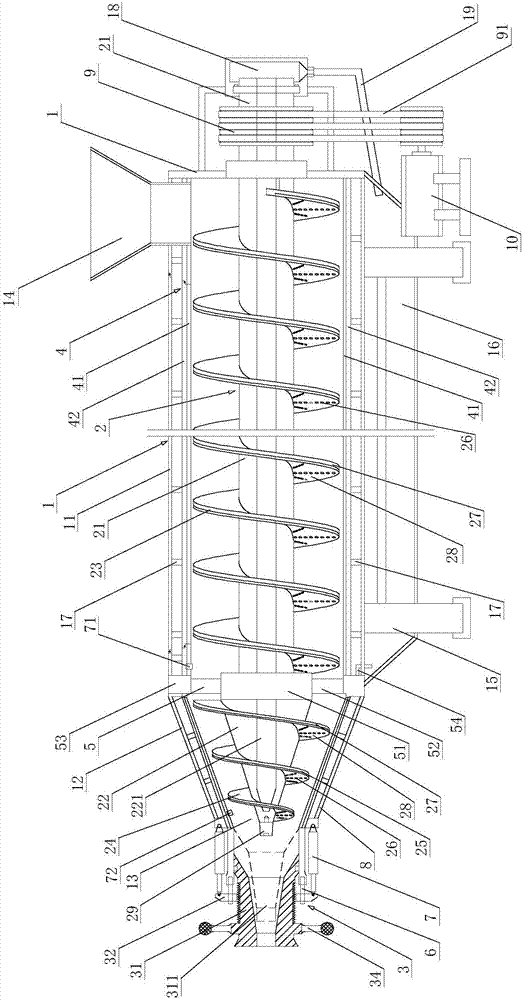

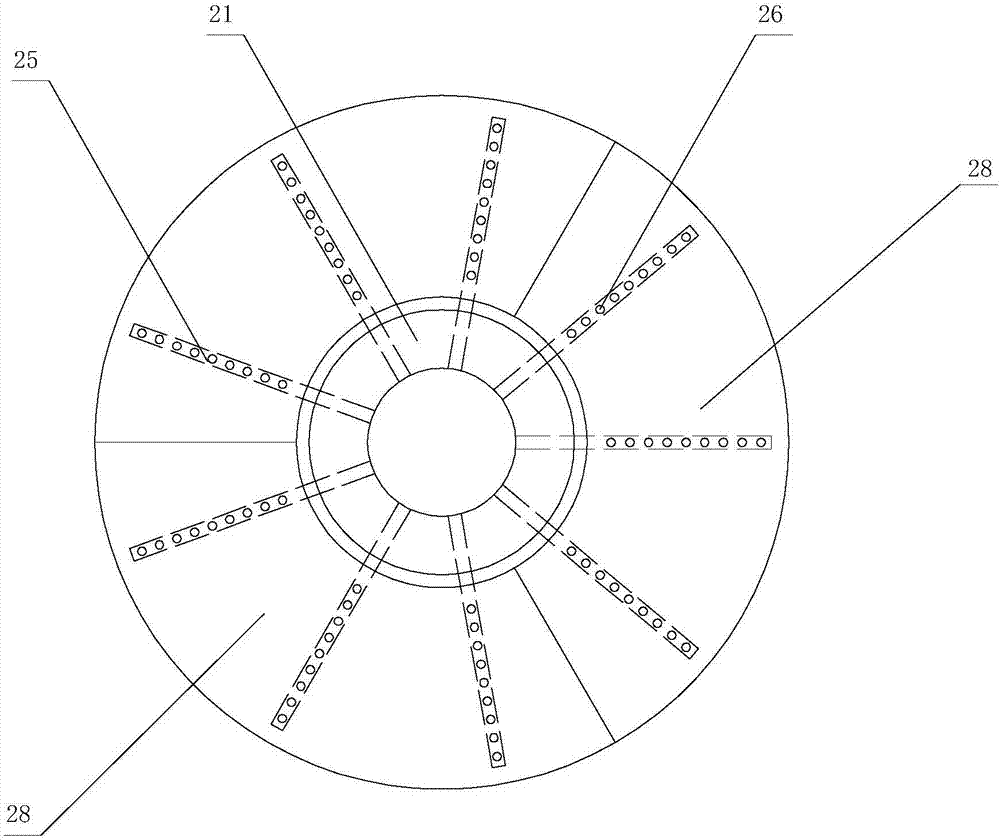

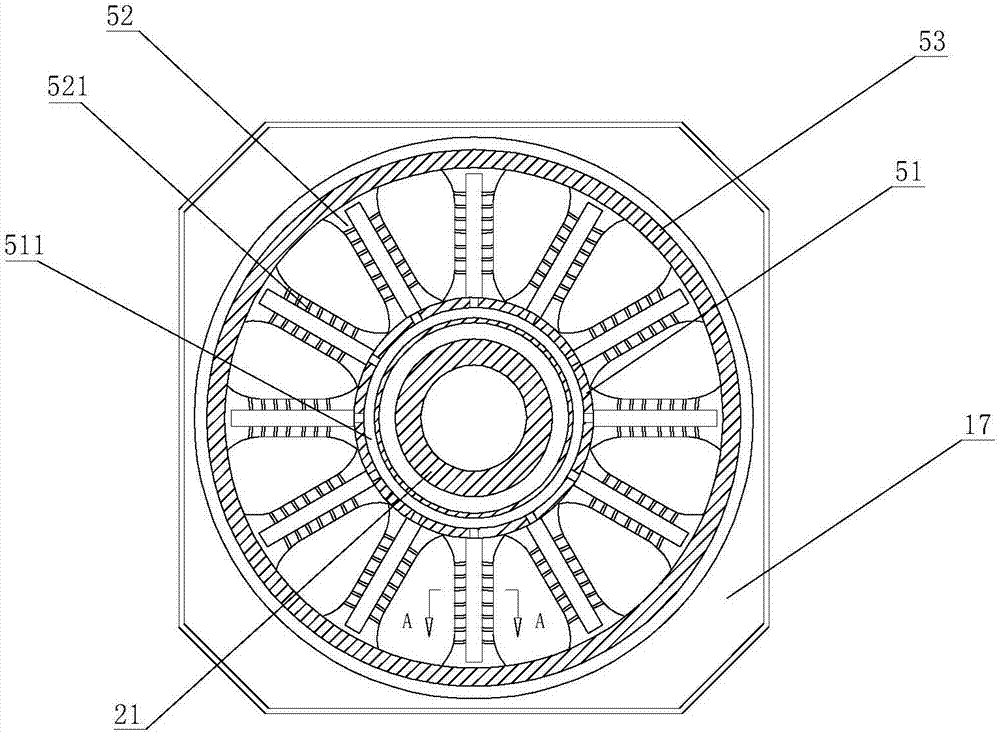

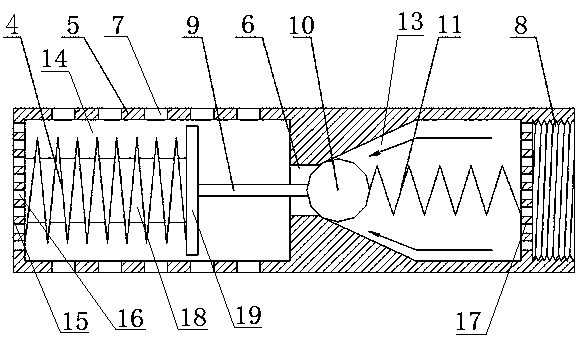

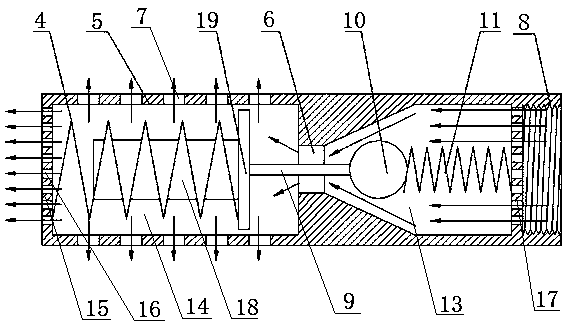

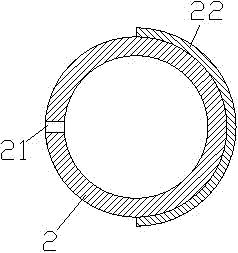

Novel horizontal screw-extrusion solid-liquid separation machine

The invention discloses a novel horizontal screw-extrusion solid-liquid separation machine. The novel horizontal screw-extrusion solid-liquid separation machine comprises a housing, a spoke support, a feeding dehydration mechanism and a pressure adjustment mechanism, wherein the housing comprises a main shell body and a conical shell body; the main shell body and the conical shell body are arranged at a front side and a rear side of the spoke support separately; a circular-barrel screen group is arranged in the main shell body; and a conical-barrel screen group matched with the conical shell body is arranged in the conical shell body. The feeding dehydration mechanism is arranged in the circular-barrel screen group, and comprises a hollow shaft and a front screw sheet; and the front screw sheet is arranged at an outer side of the hollow shaft. A conical press head is arranged at a rear end of the hollow shaft; and a rear screw sheet is arranged at an outer side of the conical press head. The pressure adjustment mechanism is arranged at a discharge port, and comprises a slide sleeve, a nut seat and a pressure adjustment cylinder group. According to the novel horizontal screw-extrusion solid-liquid separation machine disclosed by the invention, many dehydration structures are designed, classified dehydration is carried out on materials through the two screw sheets, and high dehydration capacity is achieved; a pressure on the materials can be adjusted in real time; and the novel horizontal screw-extrusion solid-liquid separation machine is small in size, high in efficiency, capable of avoiding material blockage, and high in automation degree.

Owner:苗增茂

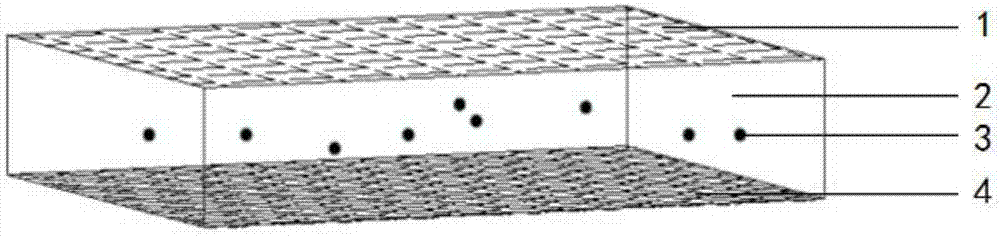

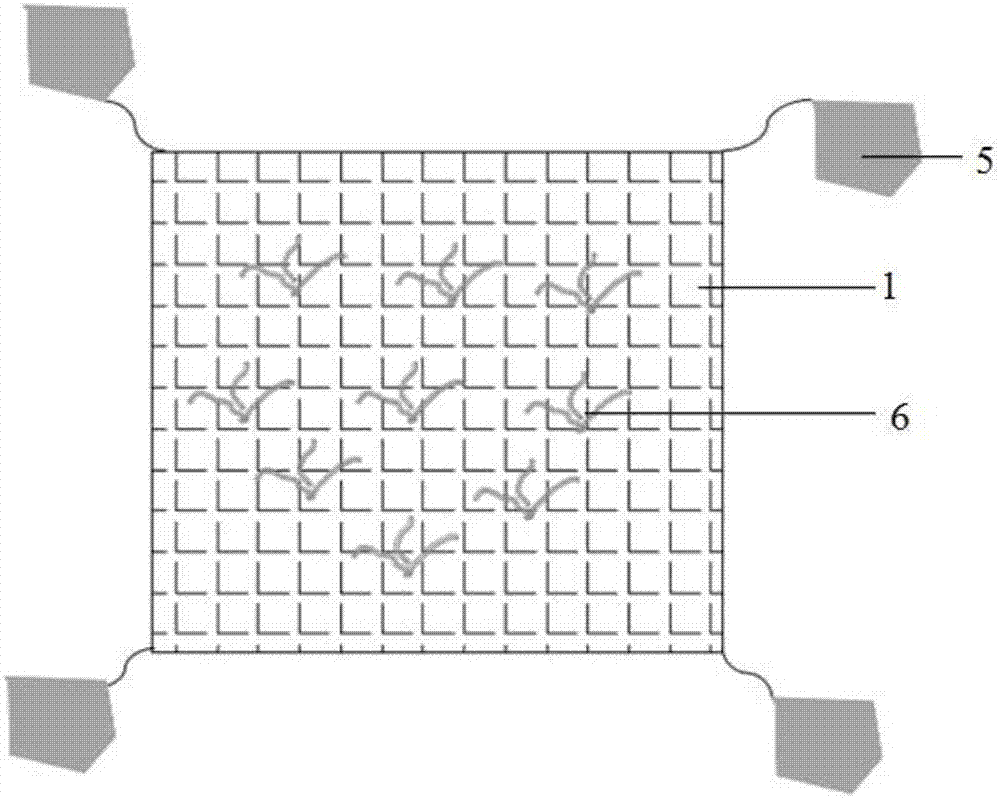

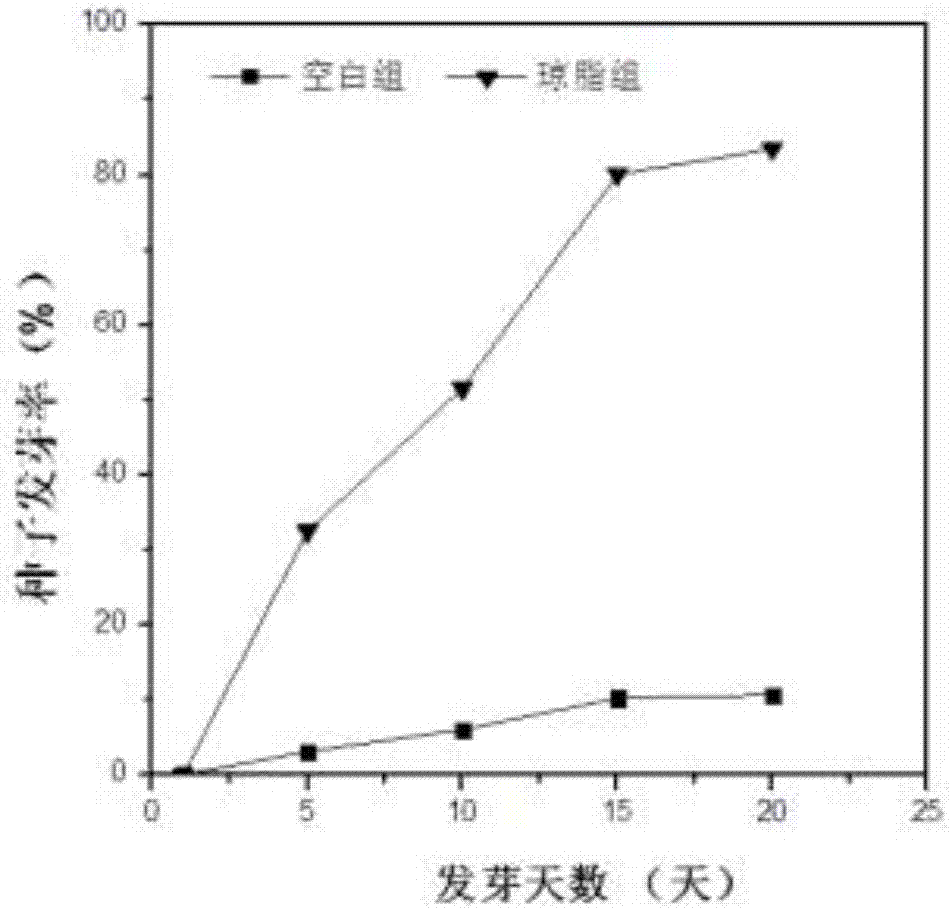

Method for quickly culturing and transplanting submerged plants

InactiveCN107396823APromote germinationPromote growthWater resource protectionCultivating equipmentsWater flowNonwoven fabric

The invention discloses a method for quickly culturing and transplanting submerged plants. According to the method, quick large-area transplanting of submerged plants at the bottom of a river can be realized; artificial seedling raising and quick transplanting and planting can be performed; and the method can not cause secondary nutritive salt input to the river, thereby causing no secondary harm to the environment. The method is characterized in that seeds of the submerged plants are fixed in agar, and the germination and the growth of the seeds are promoted through the nutrition effect and the fixing capability of the agar. A nonwoven fabric material used in the method is light and degradable, thereby causing no hidden secondary pollution to the environment. When transplanting is performed in a practical river channel, heavy stones are arranged around, so that seedlings can sink and be fixed to the bottom of the river, and can not float. Since the seedlings are fixed in the agar block, a phenomenon of seedling floating caused by matrix loosening due to water scouring can not exist. The method disclosed by the invention is simple in materials, simple to operate and low in production cost, can realize large-scale production, and is also applicable to a large-area river needing restoration.

Owner:SHANGHAI UNIV

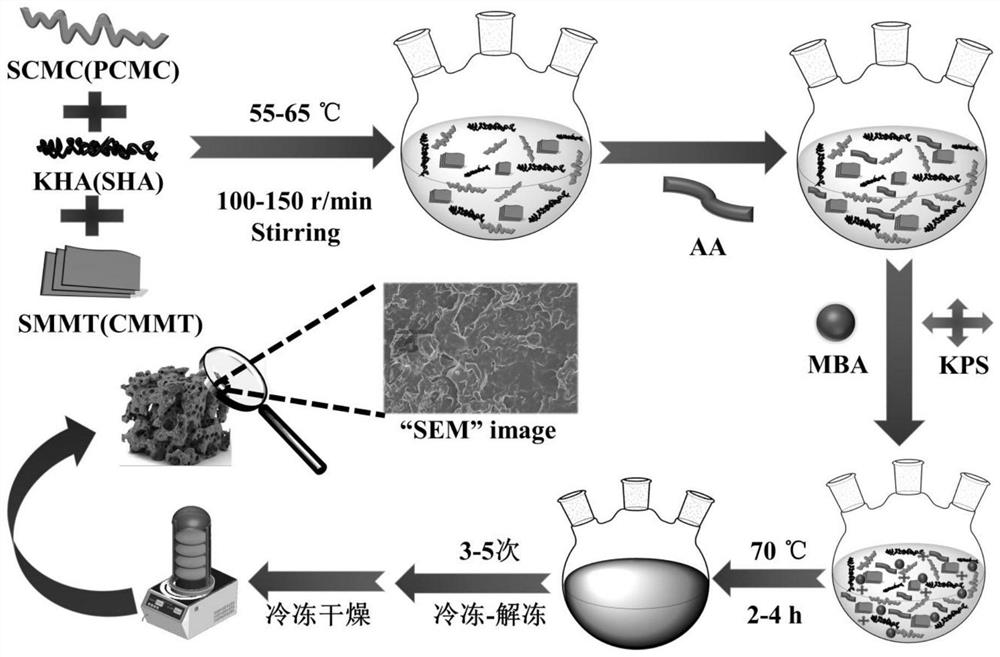

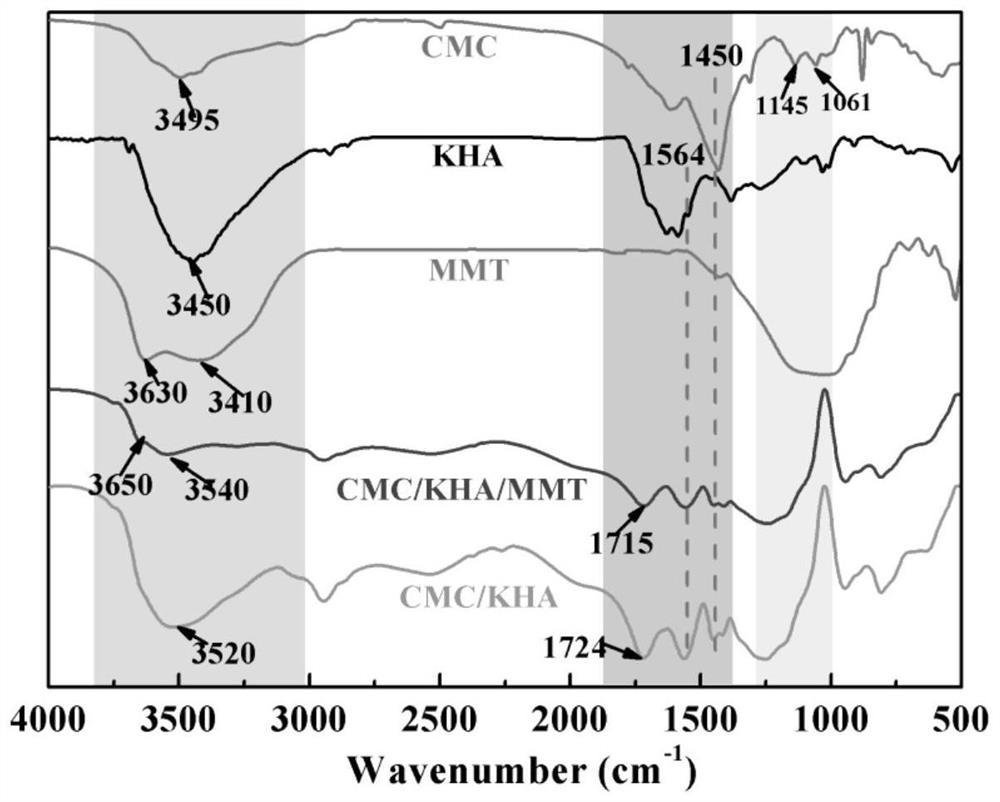

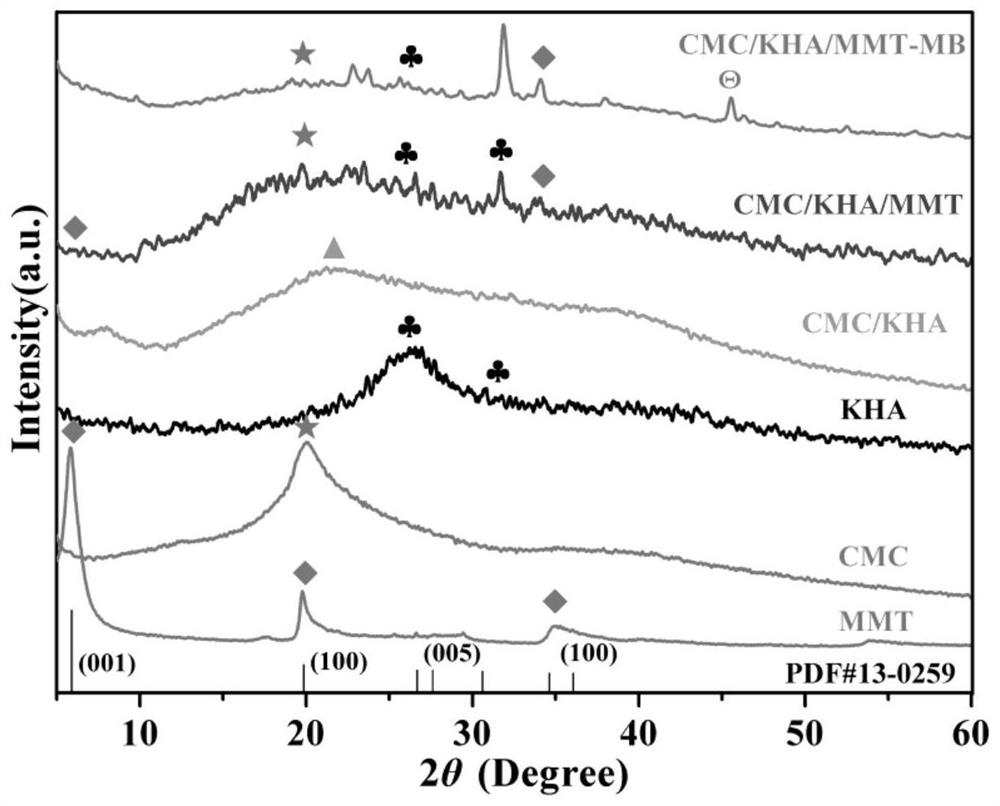

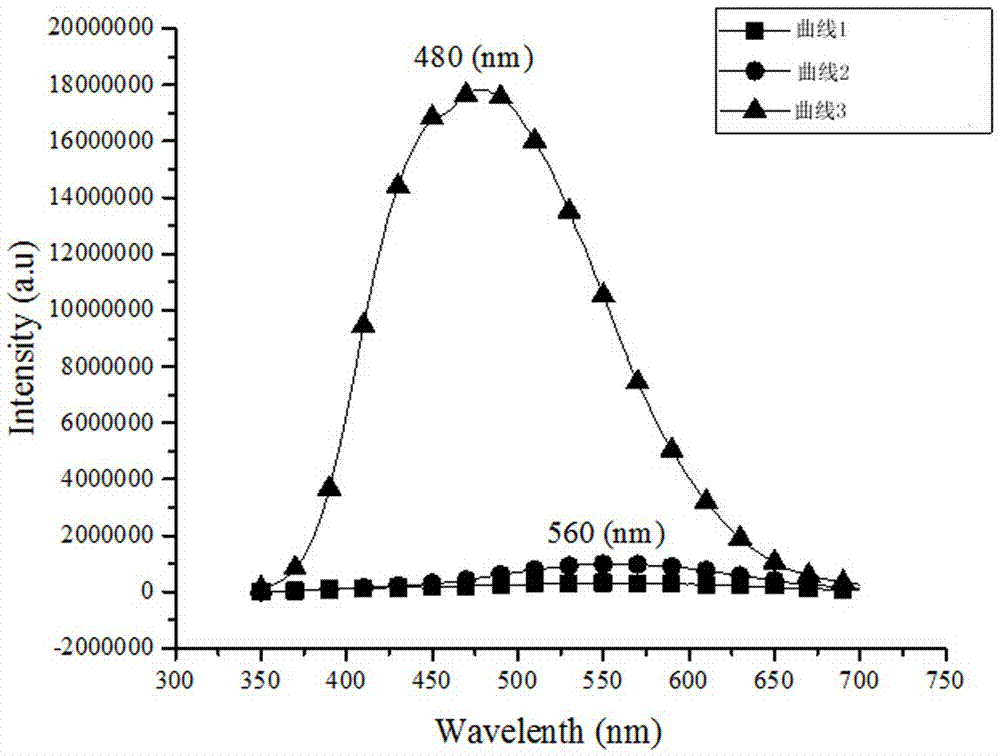

Humic acid type adsorbing material and preparation method and application thereof

PendingCN111849020ALarge specific surface areaMaintain specific surface areaOther chemical processesWater contaminantsCelluloseCarboxyl radical

Owner:SHAANXI UNIV OF SCI & TECH

Formula of tread rubber of low-rolling-resistance semi-steel radial tire

InactiveCN105801942AImprove environmental safetyLow heat generationRolling resistance optimizationEnvironmental resistancePolymer science

The invention relates to a formula of tread rubber of a low-rolling-resistance semi-steel radial tire. The formula is prepared from the following components: 20 to 30 parts of emulsion polymerized butadiene styrene rubber, 80 to 130 parts of solution polymerized butadiene styrene rubber, 5 to 20 parts of new-process carbon black, 50 to 125 parts of white carbon black, 2 to 15 parts of a super silane coupling agent Si747, 3 to 10 parts of environment-friendly oil, 2 to 6 parts of zinc oxide, 1.2 to 5.6 parts of stearic acid, 0.8 to 3.2 parts of sulfur and 1.2 to 4.2 parts of an accelerant NS. The tire produced by the formula provided by the invention has good environment-friendly property, low rolling resistance, high wear resistance and less generated heat, the oil consumption of vehicles can be reduced and the service life of the vehicle tire is prolonged.

Owner:JIANGSU HUAAN RUBBER TECH CO LTD

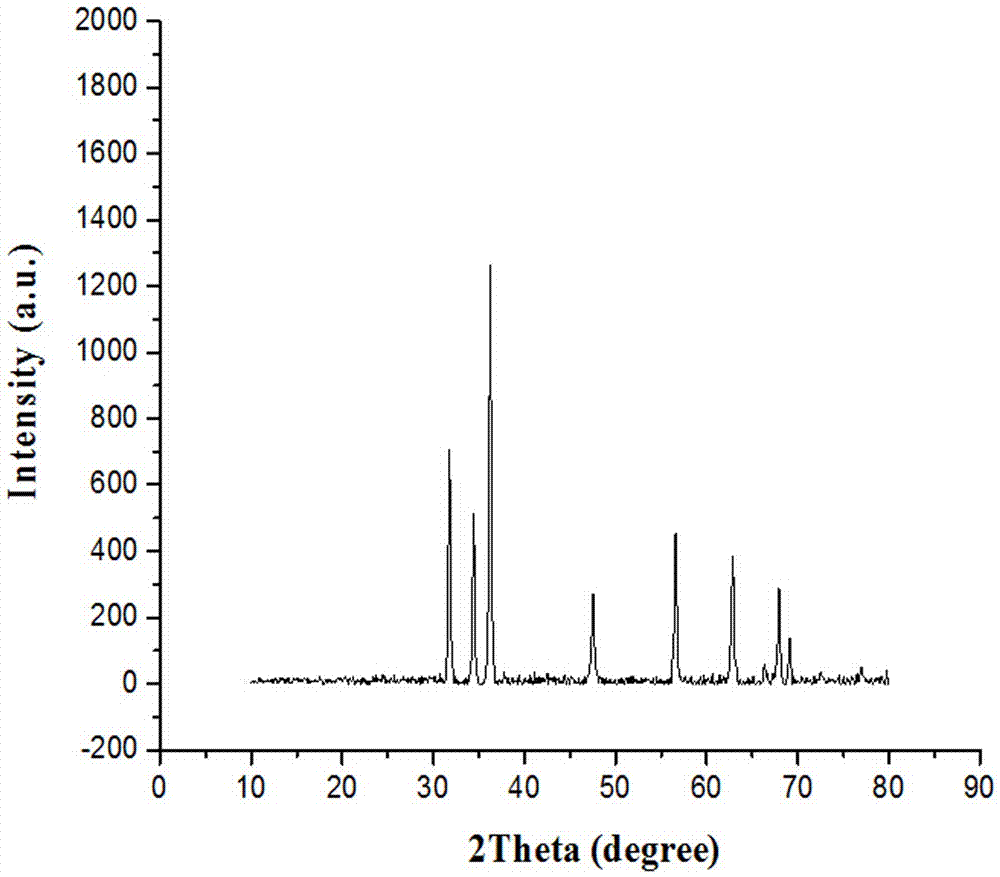

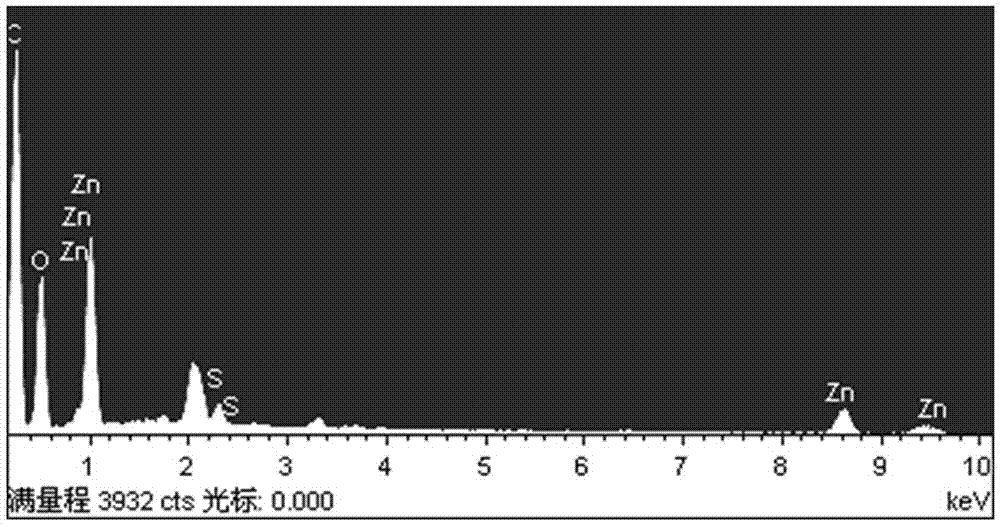

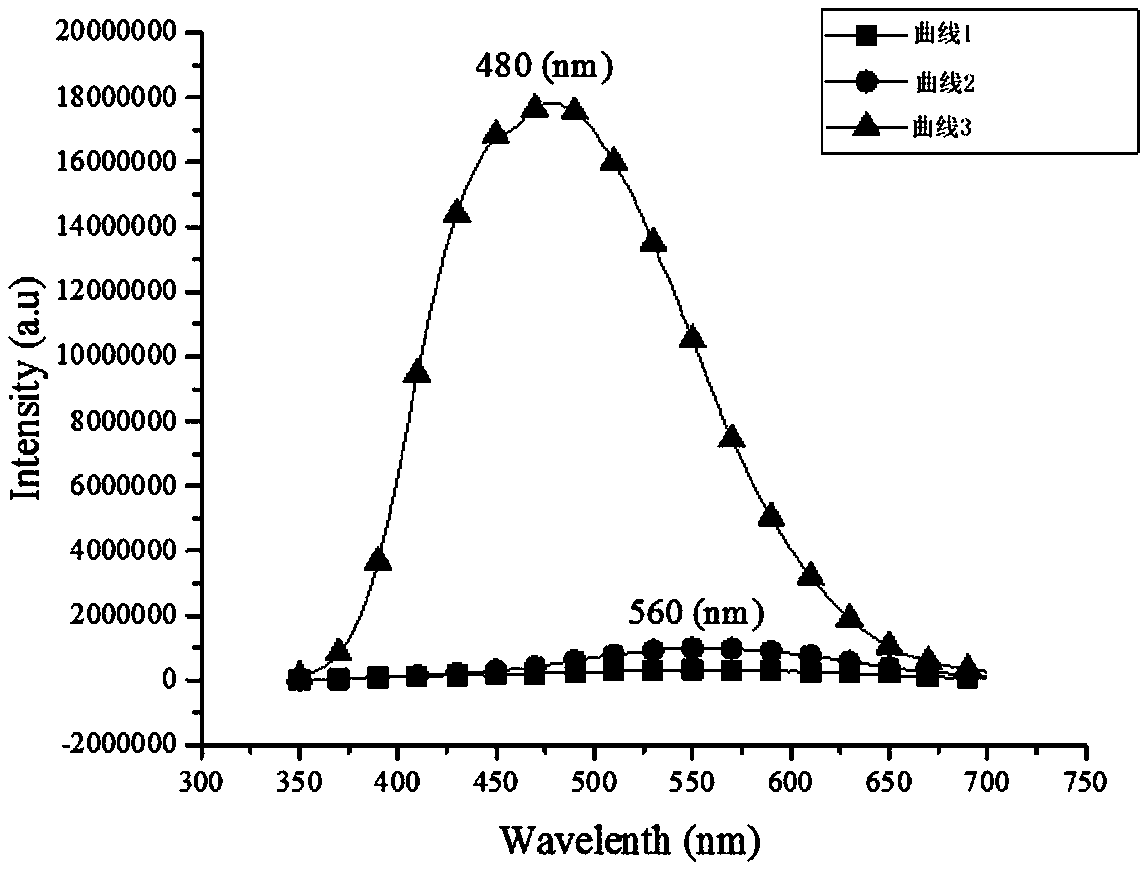

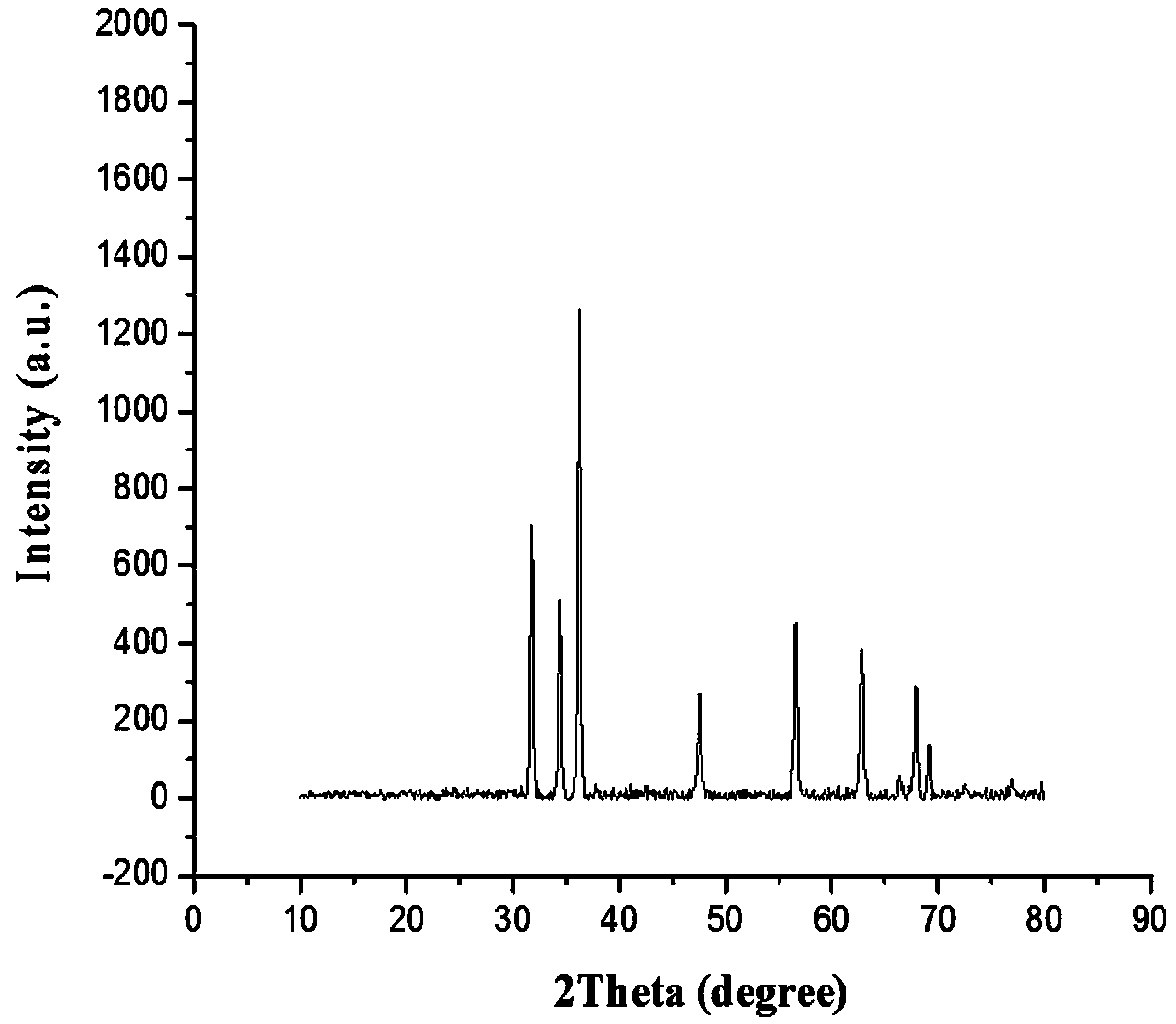

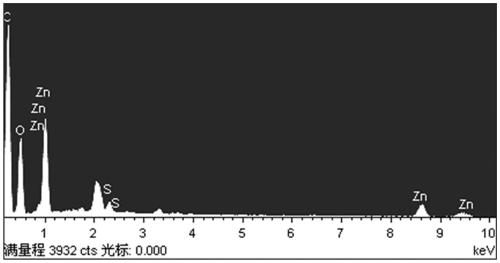

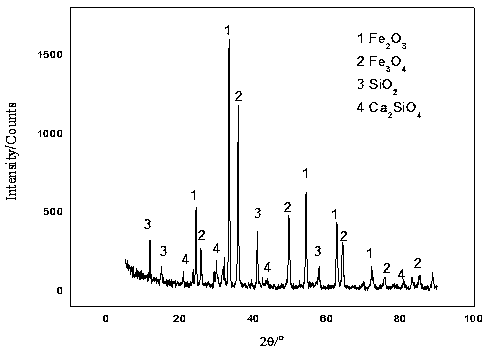

High-efficiency sulfur-doped zinc oxide nano material preparation method

ActiveCN107418560AImprove luminous performanceShape controllableLuminescent compositionsNano zinc oxideFluorescence

The invention provides a high-efficiency sulfur-doped zinc oxide nano material preparation method, which comprises the following steps: S1, utilizing a precipitation method to prepare a nano zinc oxide precursor solution; S2, sequentially adding thioacetamide and ethylene diamine tetraacetic acid into the nano zinc oxide precursor solution to react; S3, separating precipitate out after reaction is finished and cleaning and drying to obtain white solid particles; S4, thermally treating the white solid particles. According to the preparation method disclosed by the invention, the ethylene diamine tetraacetic acid is utilized to enable the thioacetamide to be a lot doped into the nano zinc oxide precursor solution; thus, high-concentrate sulfur doping in ZnO is achieved, and a defect structure and surface free energy of a ZnO nano material are changed; furthermore, fluorescent performance of the zinc oxide nano material is greatly enhanced.

Owner:JIANGXI SCI & TECH NORMAL UNIV

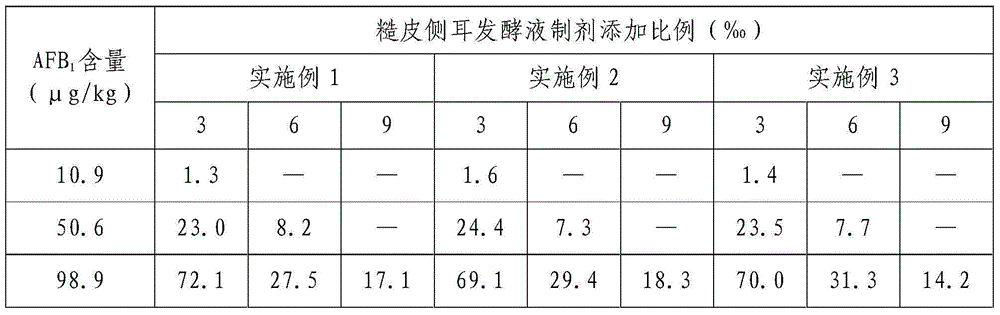

Preparation method of pleurotus ostreatus fermentation broth and application of fermentation broth in degradation of aflatoxin B1

InactiveCN104988183ASimple processMature technologyMicroorganism based processesFermentationPollutionVirulence

The invention relates to microbial fermentation, in particular to a preparation method of pleurotus ostreatus fermentation broth and application of the fermentation broth in degradation of aflatoxin B1. Pleurotus ostreatus CICC14012 is inoculated in an axenic culture medium containing carbon sources, nitrogen sources, inorganic salt and trace elements to conduct aerated fermentation cultivation to prepare the fermentation broth, and the fermentation broth can be used for degrading the virulence of the aflatoxin B1. By means of the method, the technical problems that an existing aflatoxin B1 removal method needs special conditions and special materials, is high in labor intensity and not complete in detoxification, has an effect on breaking nutritious components in processed fodder, and is severe in required condition, prone to producing chemical residuals and causing secondary pollution and the like are solved. The pleurotus ostreatus fermentation broth prepared through the method has the advantages of being easy and convenient in process, free of environment pollution and high in product safety, and has the advantages of being high in degradation speed, high in degradation rate, small in addition amount and the like when used for degrading the aflatoxin B1.

Owner:河北省微生物研究所有限公司

Automatic electric switch cabinet fire extinguishing system and fire recognition method

ActiveCN102743830BRealization of automatic fire extinguishingDoes not affect normal operationFire alarm radiation actuationAutomatic fire suppressionEngineering

The invention discloses an automatic electric switch cabinet fire extinguishing system and a fire recognition method, wherein the automatic electric switch cabinet fire extinguishing system comprises a fire extinguishing agent nozzle which is arranged in an electric switch cabinet; the fire extinguishing agent nozzle is connected with a storage device in which a non-conducting fire extinguishing agent is stored through a pipeline; an electromagnetic valve which is controlled by a central controller is arranged on a pipeline; a photoelectric sensor is also arranged in the electric switch cabinet; and the photoelectric sensor outputs a detection signal to the central controller and then the central controller judges whether to open the electromagnetic valve. The automatic electric switch cabinet fire extinguishing system is capable of responding sudden electric fire and reducing the loss caused thereby. Fire extinguishing agents such as heptafluoropropane and superfine dry powder are used and non-conducting, so that secondary danger caused by conduction of fire extinguishing agents does not occur; and the fire extinguishing agents are environmental-friendly, so that the damage to the environment caused by conduction of fire extinguishing agents also does not occur. The photoelectric sensor is used, so that the fire such as electric arc and the like in the switch cabinet can be rapidly and correctly detected.

Owner:XI AN JIAOTONG UNIV

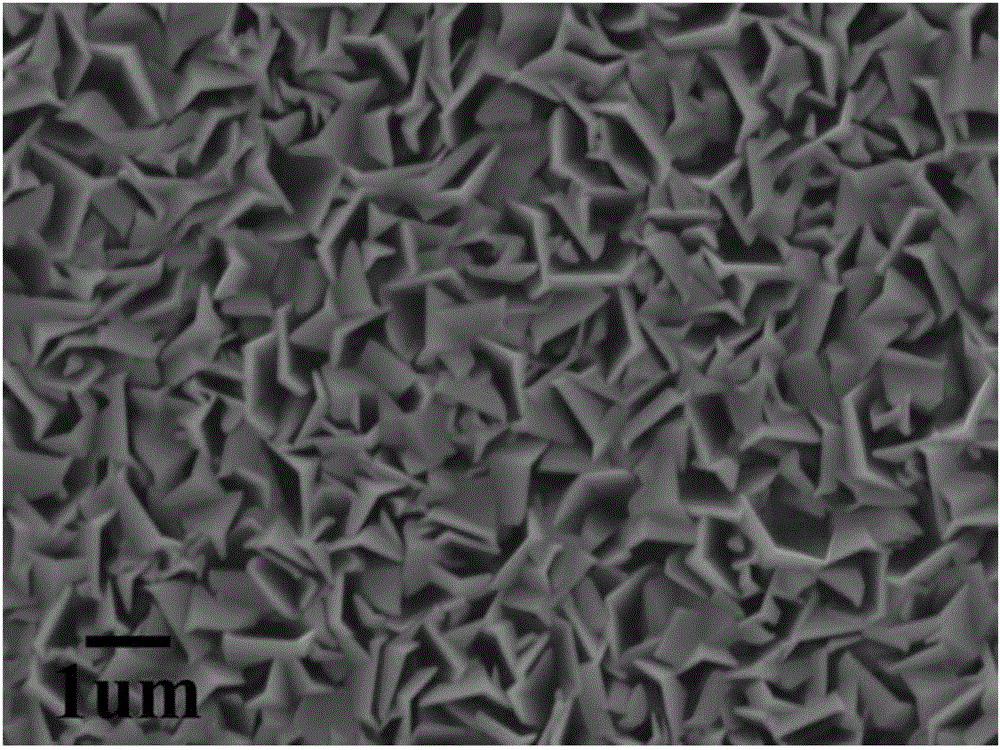

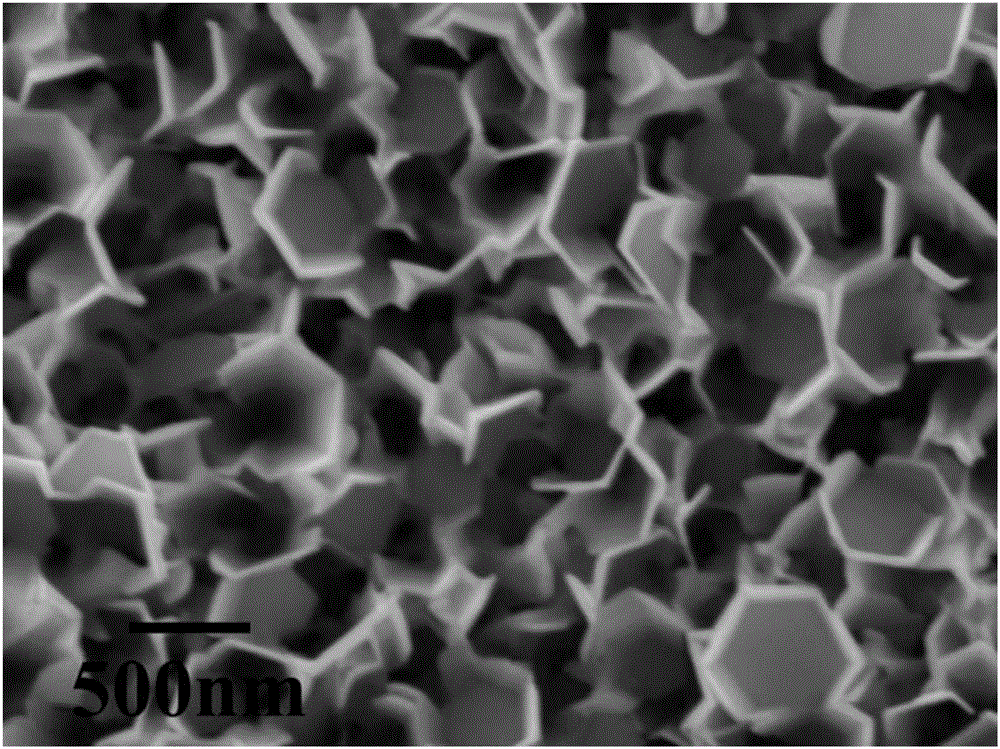

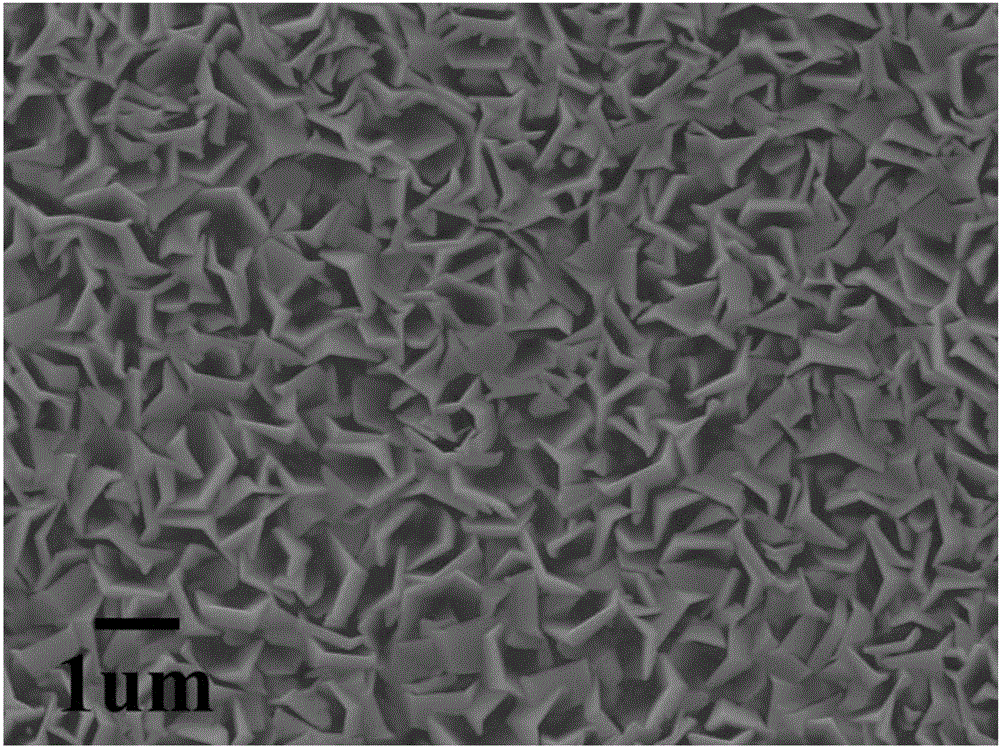

Preparation method of novel ZnO-nanosheet-structure coating

ActiveCN106746725AThe preparation method is non-toxicNo secondary hazardsCoatingsCorrosion reactionDip-coating

The invention discloses a preparation method of a novel ZnO-nanosheet-structure coating, belonging to the field of preparation of nano-structure coating materials. The method comprises the following steps: preparing a ZnO seed layer sol by a sol-gel process; preparing a ZnO seed layer film by a dip-coating process, and carrying out heat treatment in a muffle furnace; carrying out hydrothermal growth on the prepared ZnO seed layer film in the prepared ZnO growth solution; and finally, after the hydrothermal reaction finishes, continuing the corrosion reaction in the original growth solution for some time, and taking out the sample, thereby obtaining the novel ZnO-nanosheet-structure coating material. The observation and test by a scanning electronic microscope can be performed on the novel ZnO-nanosheet-structure coating to obtain the shape rules of the ZnO-nanosheet-structure coating. The method disclosed by the invention is a nontoxic green chemical technique, and does not generate secondary hazards; the method is low in cost and easy to implement; and the method has the characteristics of simple preparation technique and favorable feasibility.

Owner:TIANJIN CHENGJIAN UNIV

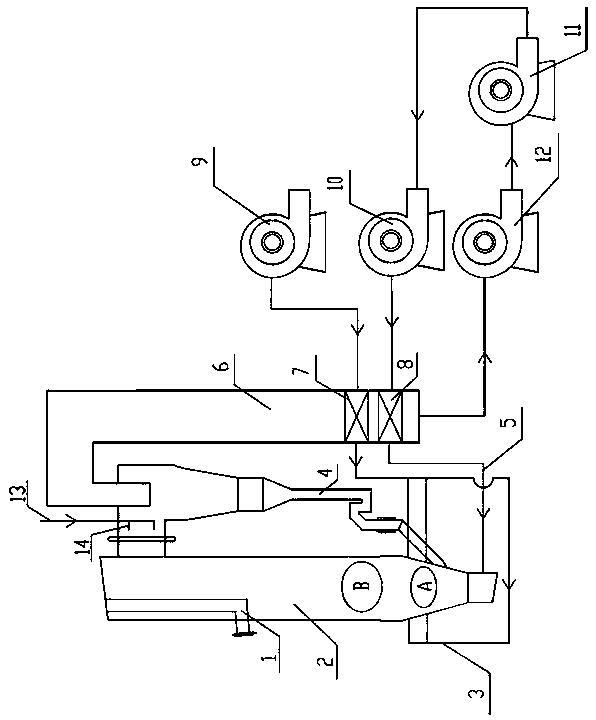

Denitrifying low-NOx circulating fluidized bed boiler and denitrifying low-NOx emission control process

InactiveCN108302521AImprove healthImprove denitrification efficiencyFluidized bed combustionApparatus for fluidised bed combustionAir volumeSlag

The invention relates to denitrifying low-NOx emission control process for a circulating fluidized bed boiler. The denitrifying low-NOx emission control process comprises the following steps that thearea of the evaporating heating surface in the boiler is increased, and the heat absorption capacity of the evaporating heating surface of a boiler furnace is changed; the size of hood small holes ofa wind-distribution plate is adjusted, and the size of slag discharging holes of the wind-distribution plate and the size of hood openings in the surrounding wall surfaces are increased; the inlet velocity and incident angle of an inlet flue of a cyclone separator are adjusted, the circulation area of a riser is adjusted according to the amount of fired coal of the boiler and the efficiency of thecyclone separator, the circulation area and the air volume of material-returning air of a material returning valve are adjusted, the flow rate of materials on the interface of a material returning system is controlled at 90-150kg / s through adjustment, the material circulation of the boiler is increased, and the burning temperature is reduced; and an appropriate amount of low-oxygen flue gas is extracted between a dust remover of the boiler and a draft fan and sent to a primary air inlet or a hot primary air outlet of an air pre-heater, the initial oxygen content of coal combustion is reduced,then the low-oxygen flue gas is fed into a primary air chamber at the bottom of the boiler, and the excess air coefficient of the primary air chamber at the bottom of the boiler is adjusted to be 0.4-0.8.

Owner:浙江百能科技有限公司 +2

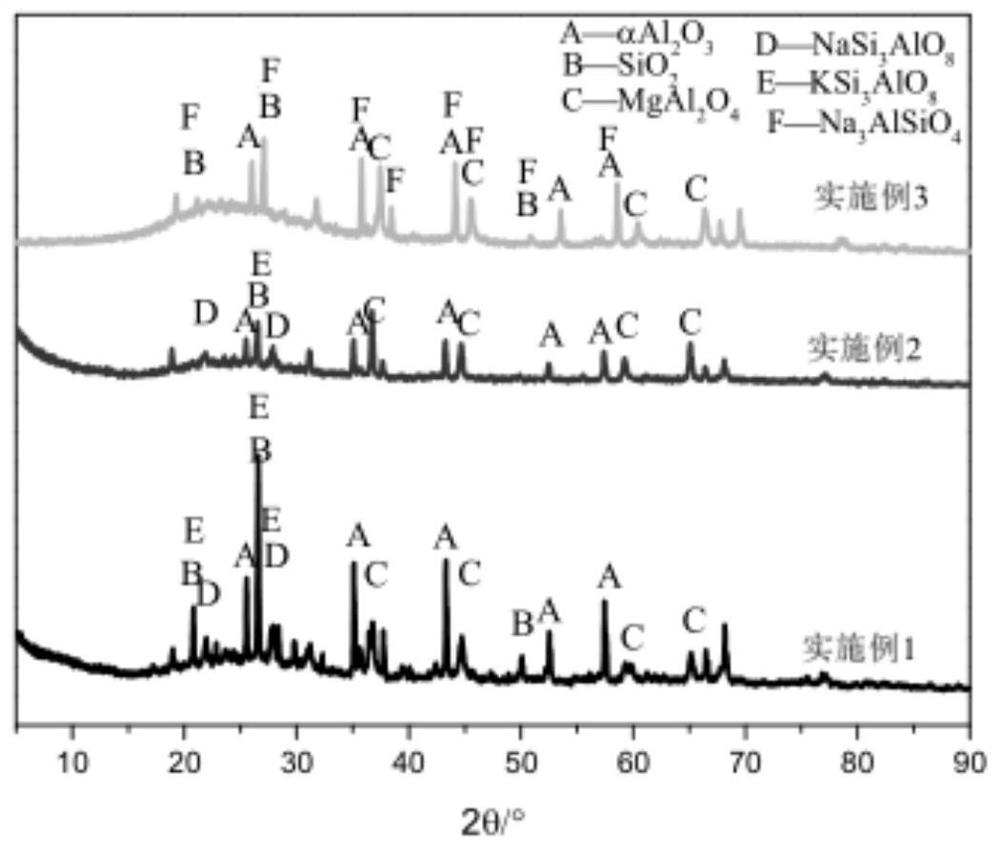

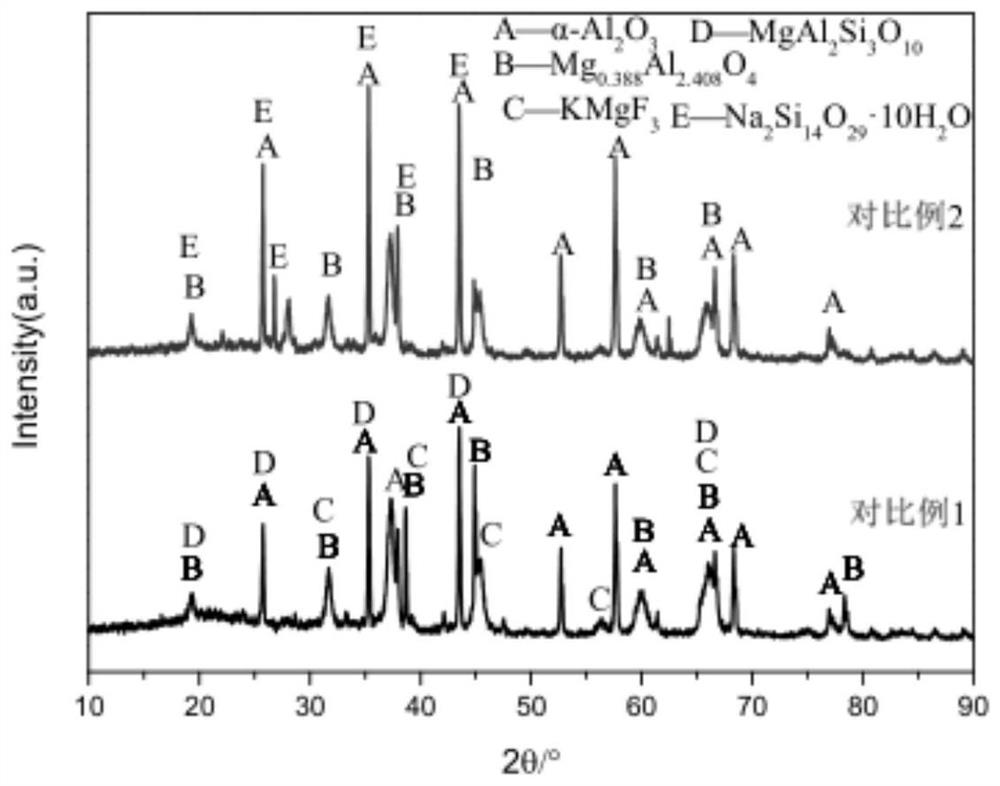

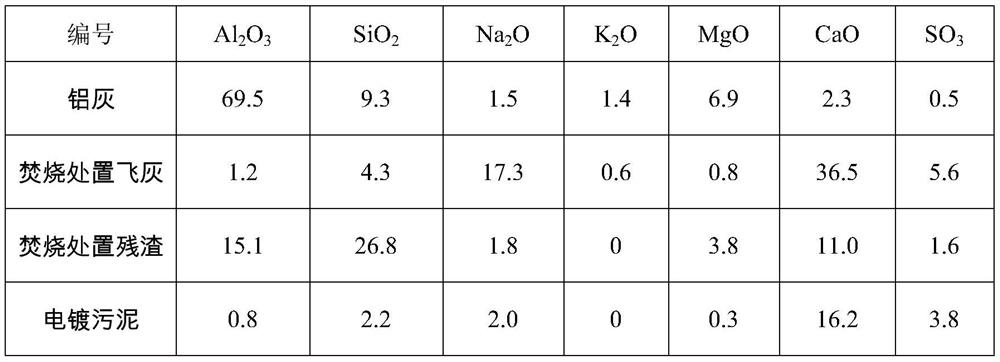

Aluminum ash-based porous ceramic material and preparation method thereof

The invention discloses an aluminum ash-based porous ceramic material and a preparation method thereof, raw materials including secondary aluminum ash, incineration treatment fly ash, incineration treatment slag, electroplating sludge and silicon-containing solid waste are sequentially subjected to mixing ball milling, high-pressure dry forming and firing, and the aluminum ash-based porous ceramic material is obtained. The method is simple to operate, no water participates in the preparation process, harmful gas released by reaction of aluminum ash with water is avoided, all the raw materials adopt solid waste, no additional commercial chemical reagent is needed, the cost is low, and the prepared porous ceramic material is small in volume weight, high in strength, good in heavy metal curing effect and free of secondary pollution.

Owner:武汉大学(肇庆)资源与环境技术研究院

Method for remediation of lead pollution on beach soil

ActiveCN102764756ANo secondary hazardsReduce consumptionContaminated soil reclamationSoil scienceEnvironmental engineering

The invention discloses a method for remediation of lead pollution on beach soil. The method disclosed by the invention comprises the following steps of: carrying out alternate drying and wetting treatment on the beach soil, regulating and controlling soil oxidation-reduction potential, thus oxidizable and reducible lead in the beach soil is released and is changed into soluble or exchangeable lead; and carrying out complexing, strengthening and analyzing on the released lead by utilizing chloride ion in sea water, soaking and washing the soil, and washing the lead away from soil body at a surface layer, thus the lead pollution on the soil at the surface layer is remediated. The method disclosed by the invention has the advantages that removal rate of pollutant is high, no chemical agent is required to be added and no secondary harm can be caused to the soil and also has the advantage that beach inning and pollution remediation can be carried out at the same time.

Owner:JINAN UNIVERSITY

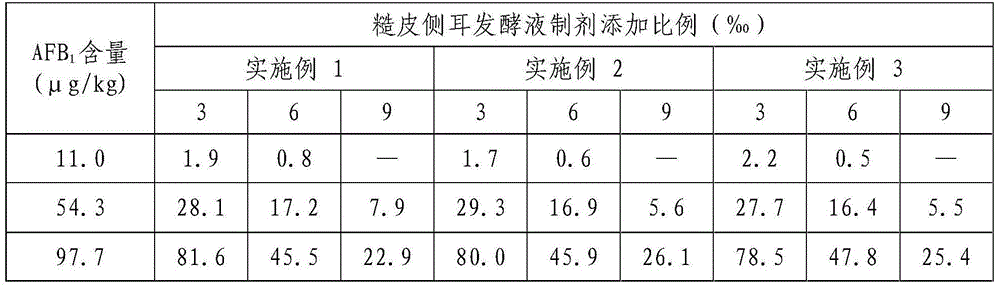

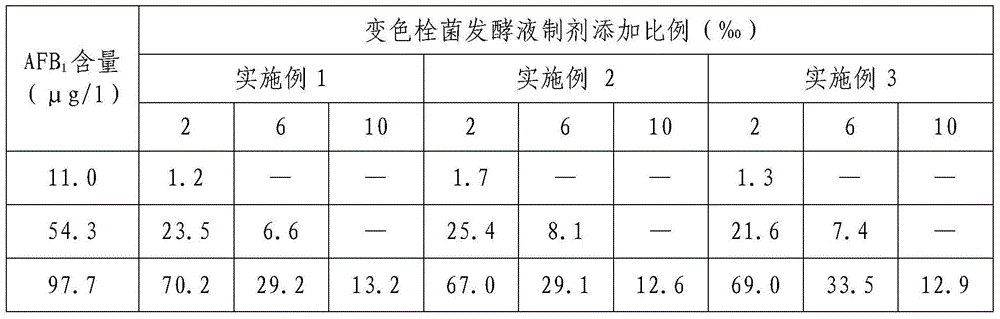

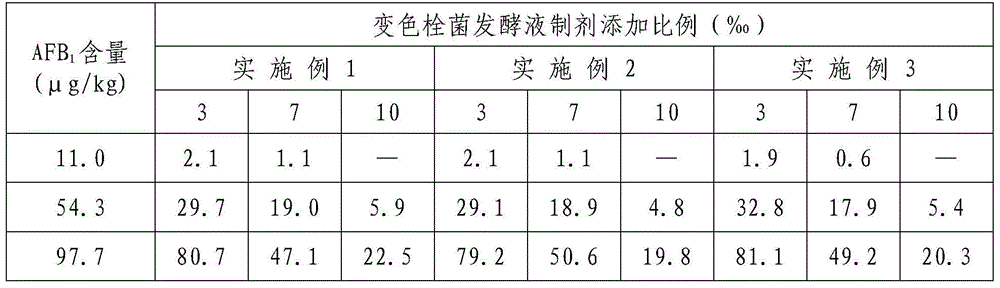

Preparation method of trametes versicolor fermentation liquor and application of trametes versicolor fermentation liquor in degrading aflatoxin B1

InactiveCN104830701ASignificant technological progressSimple processFungiMicroorganism based processesCulture mediumsPollution

The invention relates to microbial fermentation and in particular relates to a preparation method of trametes versicolor fermentation liquor and the application of the trametes versicolor fermentation liquor in degrading aflatoxin B1. The trametes versicolor PTrametes versicolor CICC 14001 is inoculated to a sterile culture medium containing a carbon source, a nitrogen source, inorganic salts and trace elements and fermented into the fermentation liquor under the condition of aeration; the trametes versicolor fermentation liquor prepared by use of the method can be applied to degrading the aflatoxin B1. The preparation method is used for solving the technical problems of the existing method, such as demand on specific conditions and materials, high labor intensity, incomplete detoxification, great damage to treated materials, demand on drastic conditions, secondary pollution always caused by generation of chemical residues, and has the advantages of simple and convenient process and high safety; besides, the trametes versicolor fermentation liquor is used for degrading the aflatoxin B1, and the degradation speed is high and the degradation rate is high.

Owner:河北省微生物研究所有限公司

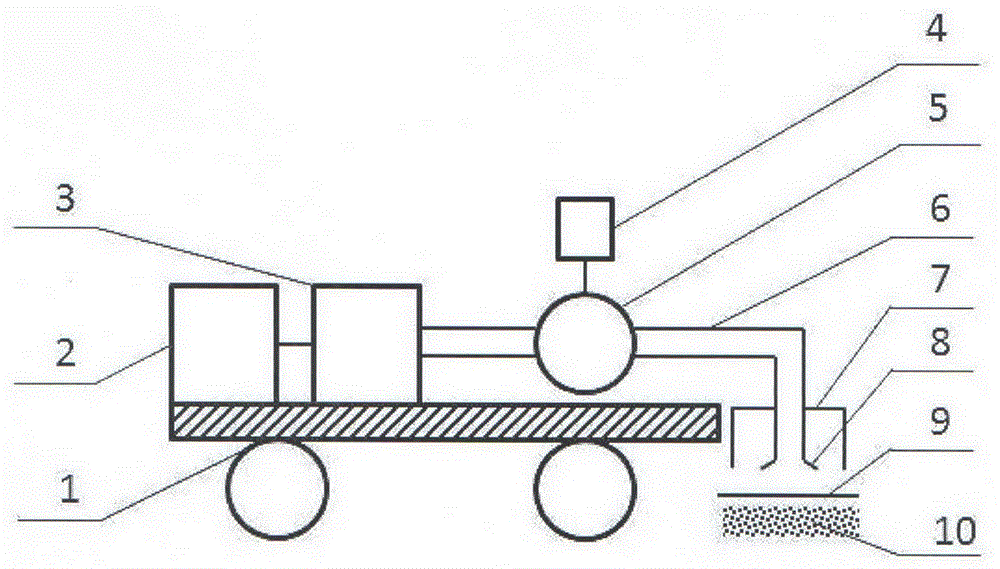

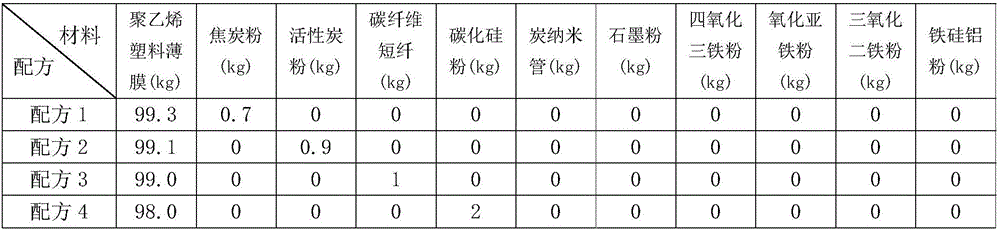

Method for quickly decomposing residual mulch

InactiveCN106180149AQuick breakdownNo secondary hazardsTransportation and packagingSolid waste disposalMicrowaveChemical effects

The invention relates to a method for quickly decomposing a residual mulch. A device related by the method consists of a vehicle-mounted platform, a controller, a microwave generator, a matching load, a circulator, a rectangular wave guide, a shielding device, a horn port surface wave guide and a mulch; when the residual mulch is decomposed, a microwave absorbing material is added; coke powder, silicon carbide powder and ferrite are firstly prepared as solution according to a conventional method for spraying on the residual mulch; or in the mulch production process, the microwave absorbing material is added, and the device is used for quickly decomposing. During operating, the controller in the device is firstly started; the microwave generator is started through the controller; meanwhile, the height from the horn port surface wave guide to the ground is adjusted; the mulch is radiated through microwaves generated by the microwave generator; the microwave absorbing material in the mulch quickly absorbs microwave energy; under heat effect and microwave chemical effect, the mulch remained on the ground is decomposed; and the advancing speed of the vehicle-mounted platform is adjusted according to the microwave radiation power, so that the safe, efficient, continuous and fast decomposition of the residual mulch is realized.

Owner:王钰淇

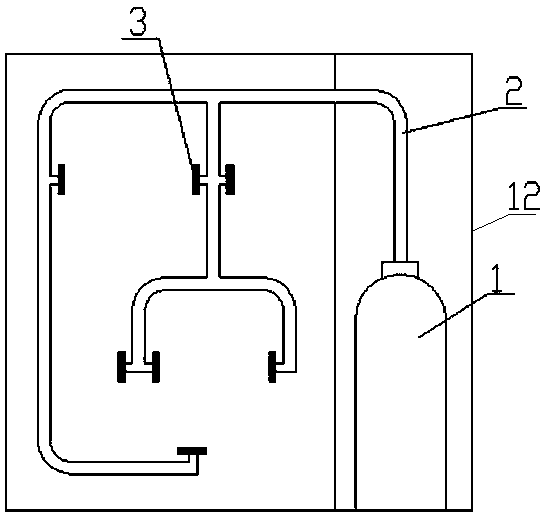

Electrical switch cabinet capable of automatically extinguishing fire

The invention discloses an electrical switch cabinet capable of automatically extinguishing fire. The electrical switch cabinet comprises a container bottle, a plurality of automatic nozzles and a fire extinguishing agent release tube, wherein the automatic nozzles comprise valve bodies, first cavities, second cavities, connecting channels, temperature sensing driving components, ejector pins, sealing balls and eccentric supporting springs; the temperature sensing driving components are capable of sensing the temperature of high-temperature gas in the electrical switch cabinet, taking action,driving the sealing balls to move, and opening the connecting channels, so that a non-conducting fire extinguishing agent in the container bottle can be sprayed out so as to extinguish fire; since thefire extinguishing agent is non-conducting, no secondary harm can be caused during the fire extinguishing process; through the arrangement of more than one automatic nozzle in the electrical switch cabinet, the automatic extinguishing of a fire disaster point can be accurately achieved and then the perfect conditions of the other components in the electrical switch cabinet can be guaranteed to the greatest extent; and furthermore, the temperature sensing driving component is sensitive to act, capable of controlling the opening and closing of the automatic nozzles, reliable in running, so thatthe running safety of the electrical switch cabinet can be effectively improved, no extra power source is needed during the use, and the reuse can be achieved.

Owner:LANZHOU SEEMINE SMA CO LTD

Environment-friendly recovery method for ethyl chloride production by-product sulfur

The invention relates to an environment-friendly recovery method for an ethyl chloride production by-product sulfur, comprising the following steps: step 1), placing small-particle sulfur of a by-product of ethyl chloride production in a high-shearing kettle, adding water, and conducting pulverizing to form a powder of 120 mesh or more; step 2), placing a pulverized sulfur suspension in a treatment kettle for water steam distillation; step 3), introducing a primary oxidant for primary oxidation reaction, wherein the primary oxidant is chlorine; step 4) after the primary oxidation reaction, introducing a secondary oxidant for a secondary oxidation reaction, and at the same time, adjusting the temperature in the treatment kettle to carry out a hydrolysis reaction, wherein the secondary oxidant is ozone; and step 5), after the secondary oxidation reaction and the hydrolysis reaction, cooling the temperature of the suspension, and conducting suction filtration, washing the obtained filtercake by clear water, conducting drying through baking or melting, and conducting slicing, so as to obtain a finished product sulfur. According to the present invention, the recovery method for the ethyl chloride production by-product sulfur is extremely friendly to environment.

Owner:扬州帮手科技有限公司

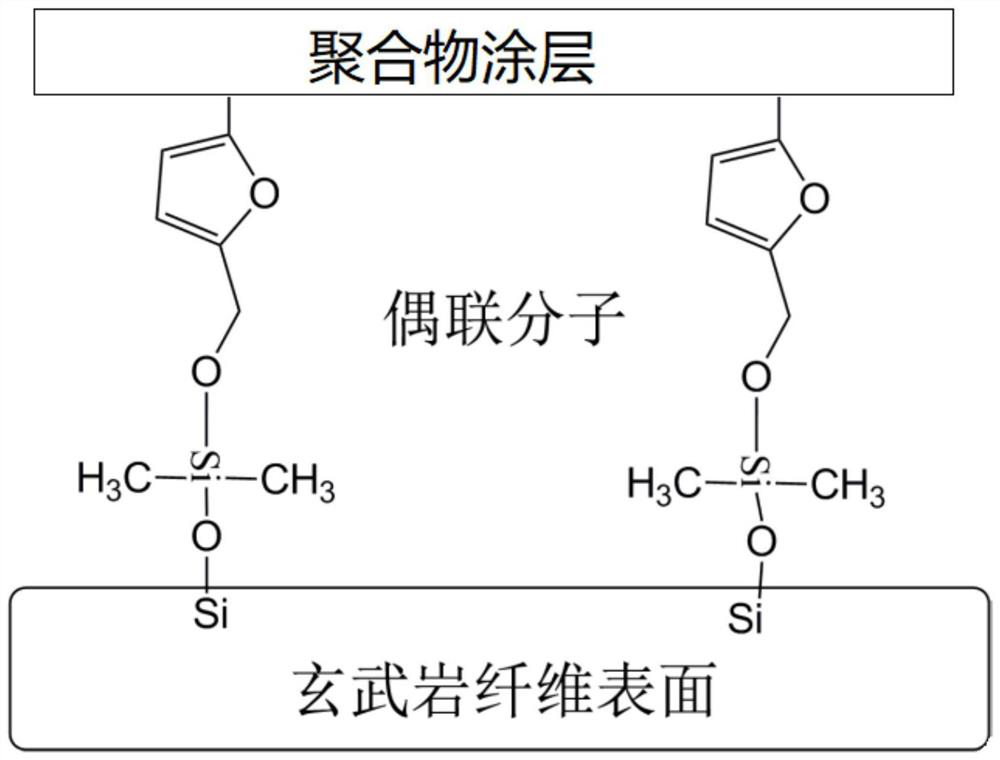

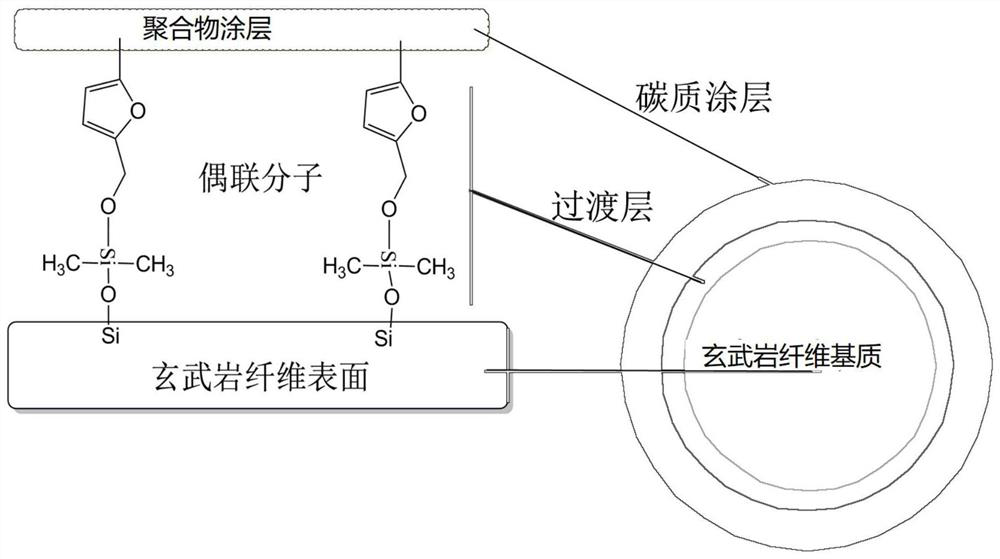

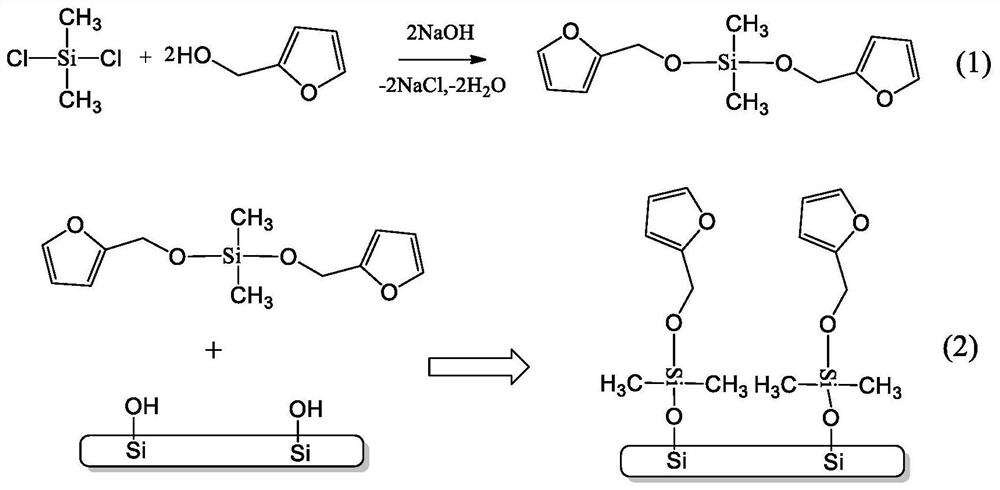

Coupling agent, porous carburizing coating fiber and preparation method

ActiveCN111607847AImprove mechanical propertiesPorosityFibre chemical featuresCarbon layerCarbon fibers

The invention relates to a coupling agent, a porous carburizing coating fiber and a preparation method thereof, and belongs to the technical field of carbon fiber material preparation. The inherent low-strength problem of an existing activated carbon fiber is solved. The preparation method of the porous carburizing coating fiber comprises the following steps that 1, a basalt fiber is subjected tosurface acid and alkali etching treatment; 2, the surface modified basalt fiber is coated with a tetrahydrofuran solution of bis(2-furylmethoxy)dimethylsilane and a tetrahydrofuran solution of furaldehyde and furan methanol condensation resin, and the coating layer is further polymerized and solidified; and 3, the basalt fiber after coating is carbonized and activated to obtain the basalt fiber with a porous carburizing coating. According to the preparation method, the basalt fiber is adopted as a matrix fiber, a porous carbon layer is formed by surface carburizing treatment, thus the porous carburizing coating fiber has the pore characteristics of the activated carbon fiber, and meanwhile has good mechanical strength of the basalt fiber.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Processing method for wastewater containing heavy metal chromium

InactiveCN105347486ANo secondary hazardsLow costWater contaminantsTreatment with aerobic and anaerobic processesSludgeChemical agent

The invention discloses a processing method for wastewater containing heavy metal chromium, and belongs to the technical field of wastewater processing. The processing method comprises getting river humus sludge, adding hydrochloric acid for acidifying processing, then performing sodium modification processing, spreading the humus mud powder subjected to sodium modification processing into wastewater, uniformly mixing and performing centrifugation separation, so as to obtain a precipitate; mixing the precipitate with sludge in a secondary sedimentation tank in chemical-engineering sewage pools, then culturing a water plant India canna in the sludge mixture, so as to adsorb heavy metal chromium in the sludge through India canna root, wherein the heavy metal chromium is enriched at leaves through stem transportation; culturing the capability of India canna adsorbing heavy metal chromium, then removing the leaves and stems and keeping the roots, planting India canna into to-be-processed chromium-containing wastewater, and leaving India canna to natural grow and propagate and adsorb the heavy metal in wastewater. The embodiment proves that the method is unique, relatively low in cost, free of any chemical agents and free of harm to environment, and finally enables the removal rate of the heavy metal chromium in wastewater to be up to 95% or more.

Owner:仇颖超

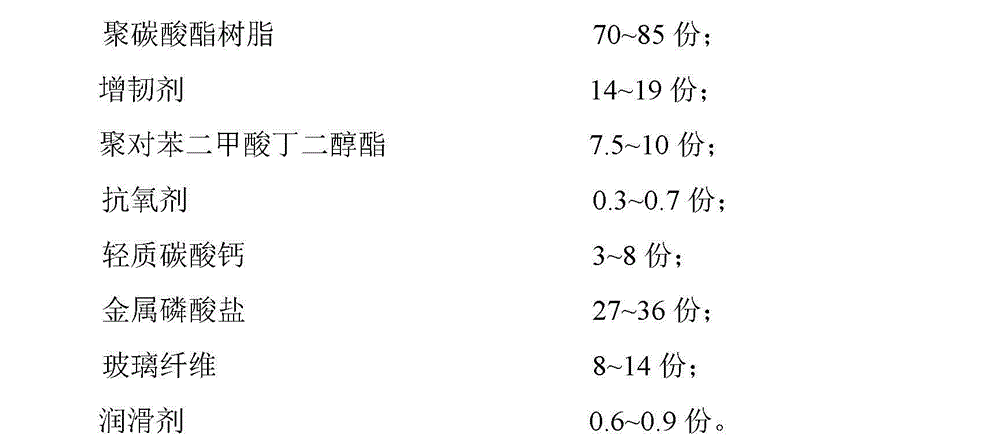

Halogen-free flame-retardant glass fiber-reinforced polycarbonate alloy material

The invention provides a halogen-free flame-retardant glass fiber-reinforced polycarbonate alloy material, which belongs to the technical field of high polymer materials. The polycarbonate alloy material comprises the following raw materials by weight: 70 to 85 parts of a polycarbonate resin, 14 to 19 parts of a toughening agent, 7.5 to 10 parts of polyethylene terephthalate, 0.3 to 0.7 part of an antioxidant, 3 to 8 parts of light calcium carbonate, 27 to 36 parts of metal phosphate, 8 to 14 parts of glass fibers and 0.6 to 0.9 part of a lubricant. The provided halogen-free flame-retardant glass fiber-reinforced polycarbonate alloy material has high-modulus resistance and high rigidity, is applicable to production of automobile parts with high requirements on precision and has bending strength of 105 to 130 MPa, flexural modulus of 3400 to 4100 MPa, elongation at break of 15 to 20%, notched impact strength of 10 to 15 KJ / m2 (under the condition of -40 DEG C), heat distortion temperature of 110 to 130 DEG C and flame resistance of V-0 (UL-94-1.6 mm). Poisonous and harmful halogen is not released during combustion of the alloy material, thereby causing no secondary harm.

Owner:苏州宇度医疗器械有限责任公司

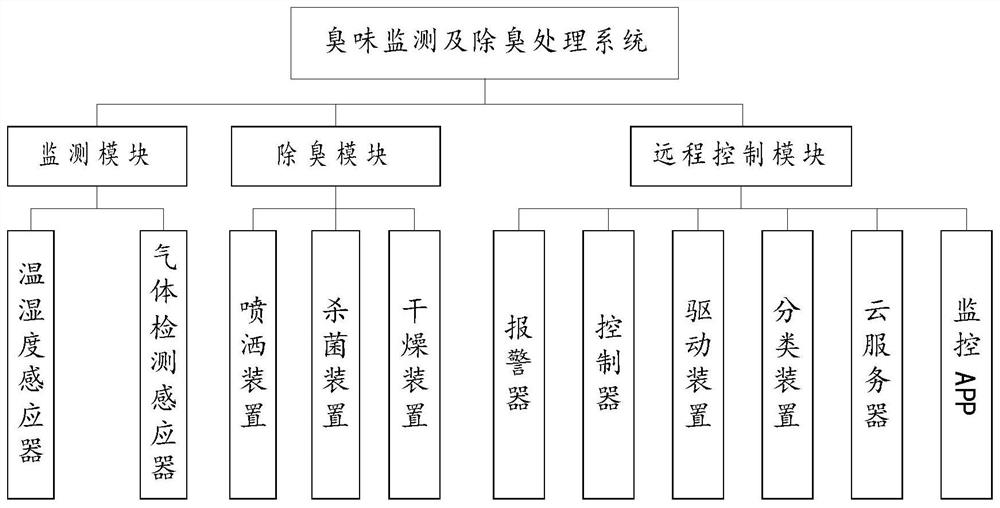

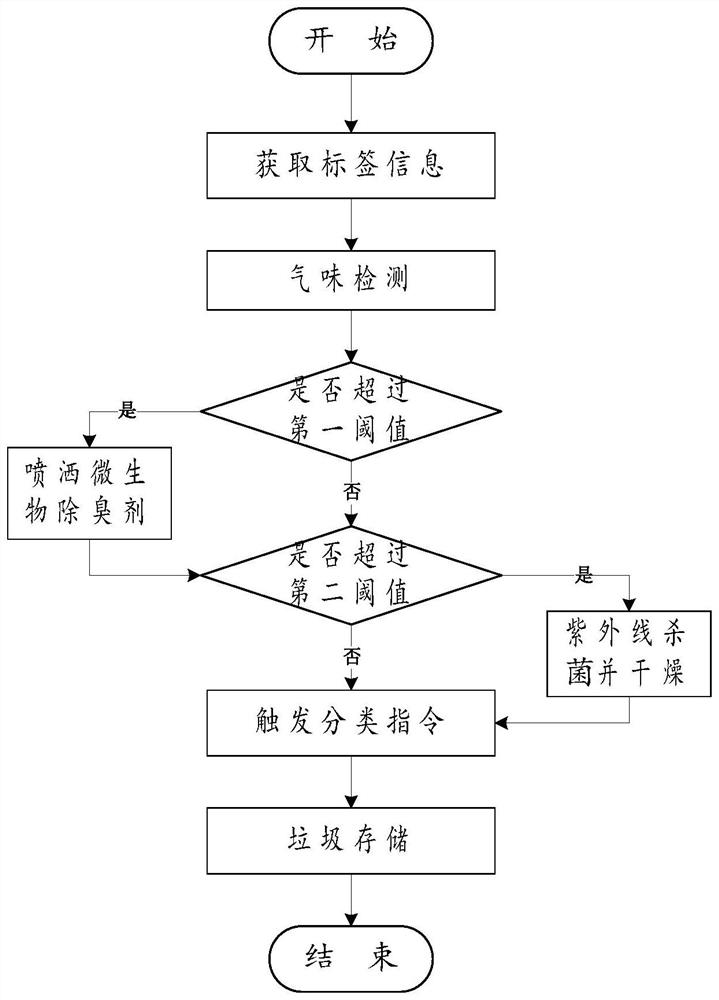

Odor monitoring and deodorizing treatment system for dustbin

PendingCN114229268AAutomated operabilityEasy to handleRefuse receptaclesRefuse cleaningProcess engineeringRefuse Disposals

The invention discloses an odor monitoring and deodorization treatment system for garbage cans, which comprises a monitoring module, a deodorization module and a remote control module, the monitoring module is used for generating temperature and humidity information and odor information of garbage, the deodorization module is used for completing deodorization operation according to the monitoring information, and the remote control module is used for realizing automatic garbage classification. By the adoption of the odor monitoring and deodorization treatment system, deodorization operation and classification operation of garbage can be automatically achieved, and the garbage treatment effect is better.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

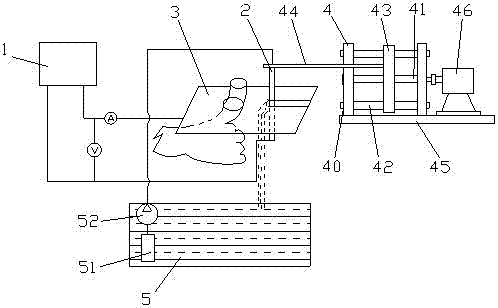

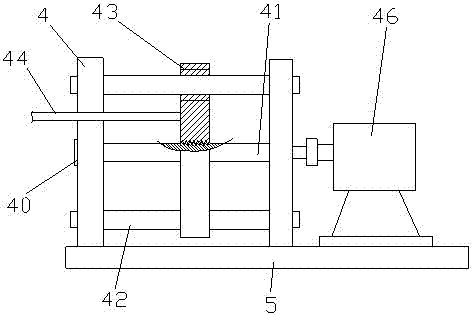

Metal sheet electrochemical inner spray cutting forcible entry device and method

InactiveCN107262850AReduce volumeReduce feverMachining working media supply/regenerationElectricityElectrolysis

The invention relates to a metal sheet electrochemical inner spray cutting forcible entry device and method. The device comprises an electrolysis device and an electrolyte supplying device, wherein the electrolysis device comprises an output power source and an electrode tube; two electrodes of the output power source are electrically connected with a metal sheet and the electrode tube correspondingly; the electrode tube is of a hollow structure; at least one spray hole is formed in the side portion of the electrode tube; and the electrolyte supplying device communicates with the electrode tube. The metal sheet electrochemical inner spray cutting forcible entry device and method are safe in use and do not bring secondary hazards.

Owner:朱明方东

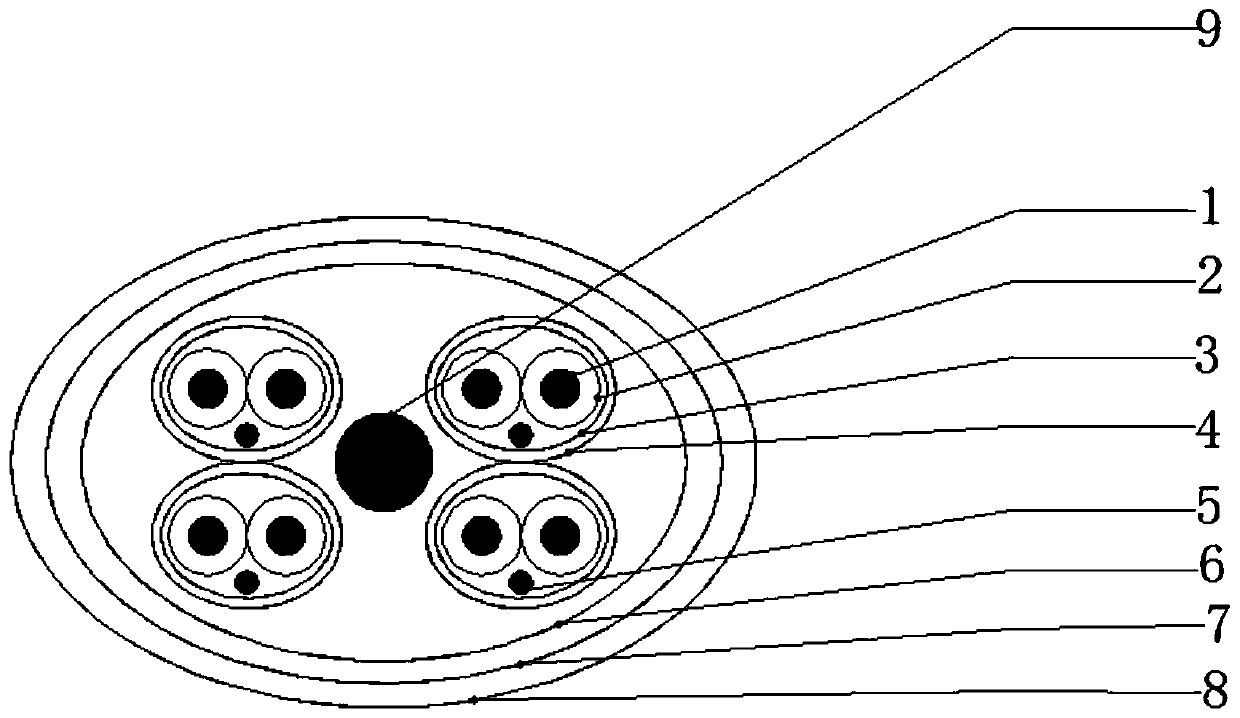

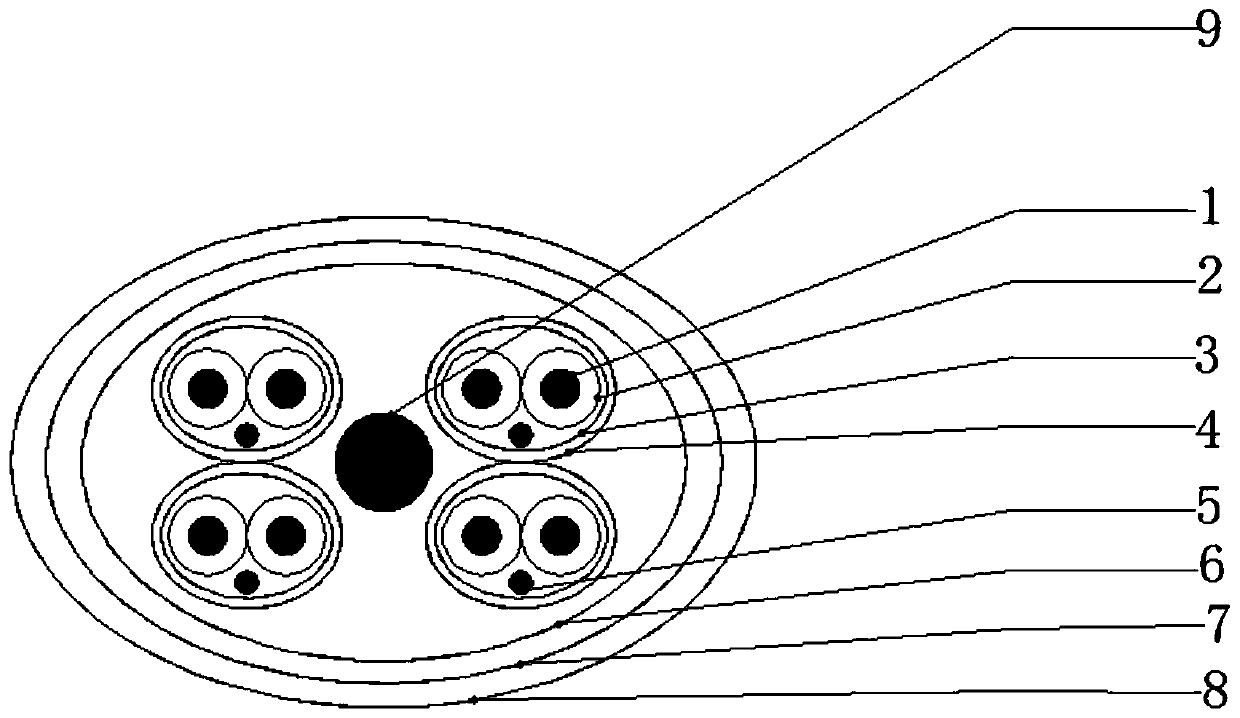

Fireproof railway digital signal cable and manufacturing method thereof

PendingCN110033882ALower average dielectric constantIncrease transfer ratePlastic/resin/waxes insulatorsInsulated cablesElectrical conductorReliable transmission

The invention relates to the technical field of cables, in particular to a fireproof railway digital signal cable and a manufacturing method thereof. The fireproof railway digital signal cable comprises a twisted body and a pair of signal lines, wherein the twisted body comprises an insulation line core and a diversion line, the diversion line is twisted on the insulation line core, the insulationline core comprises an inner conductor and an inner insulation layer, the inner insulation layer wraps an outer side of the inner conductor, a shielding layer wraps a surface of the twisted body, anouter insulation layer wraps an outer side of the shielding layer, the pair of signal lines are two outer insulation layers pasted together, a tensile layer is inserted between the pair of signal lines in a penetrating way, an internal fireproof layer wraps outer sides of the pair of signal lines, an oxygen isolation layer is pressed at an outer side of the internal fireproof layer, and an external fireproof layer is pressed on a surface of the oxygen isolation layer. The fireproof railway digital signal cable has the characteristics of small transmission attenuation value in a high- and low-temperature environment, high transmission rate, stable and reliable transmission performance and the like, and the cost is reduced.

Owner:湖北宇洪光电实业有限公司

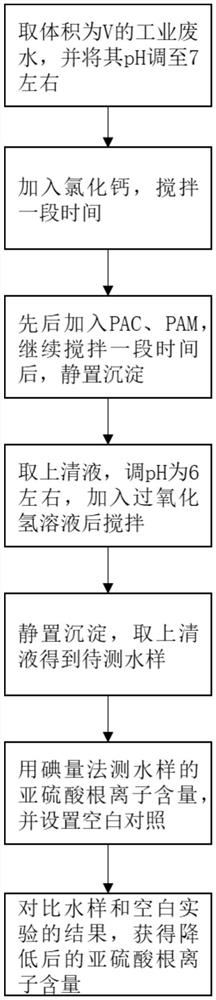

Method for reducing content of sulfite ions in printing and dyeing decoloration wastewater

PendingCN113045038AReduce contentReduce use costWater contaminantsMultistage water/sewage treatmentIndustrial waste waterSulfate radicals

The invention discloses a method for reducing the content of sulfite ions in printing and dyeing decoloration wastewater, belonging to the field of industrial wastewater treatment. The method comprises the following specific steps: adjusting the pH value of a water sample to be about 7, sequentially adding calcium chloride, a PAC solution and a PAM solution, conducting stirring for a period of time, carrying out standing for precipitation, and taking a supernatant; and adjusting the pH value of the supernatant to about 6, adding an H2O2 solution, carrying out stirring and standing, and taking a supernatant water sample. According to the results of testing, the content of sulfite ions in the treated wastewater sample is obviously reduced, and the method has the advantages of low comprehensive cost, simplicity and convenience in operation and the like. The method provided by the invention is suitable for treating printing and dyeing decoloration wastewater with a very high sulfite ion content.

Owner:CHINA JILIANG UNIV

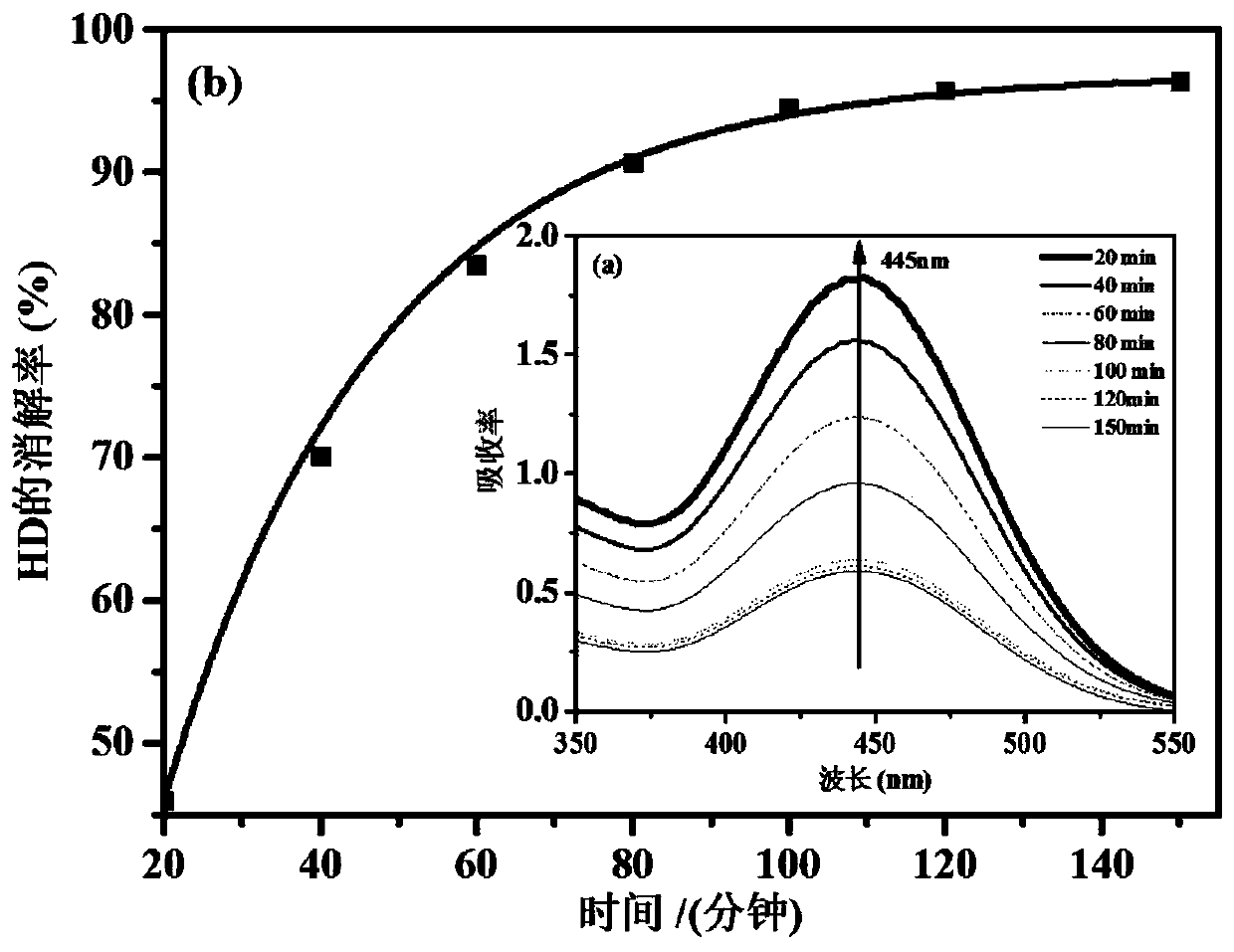

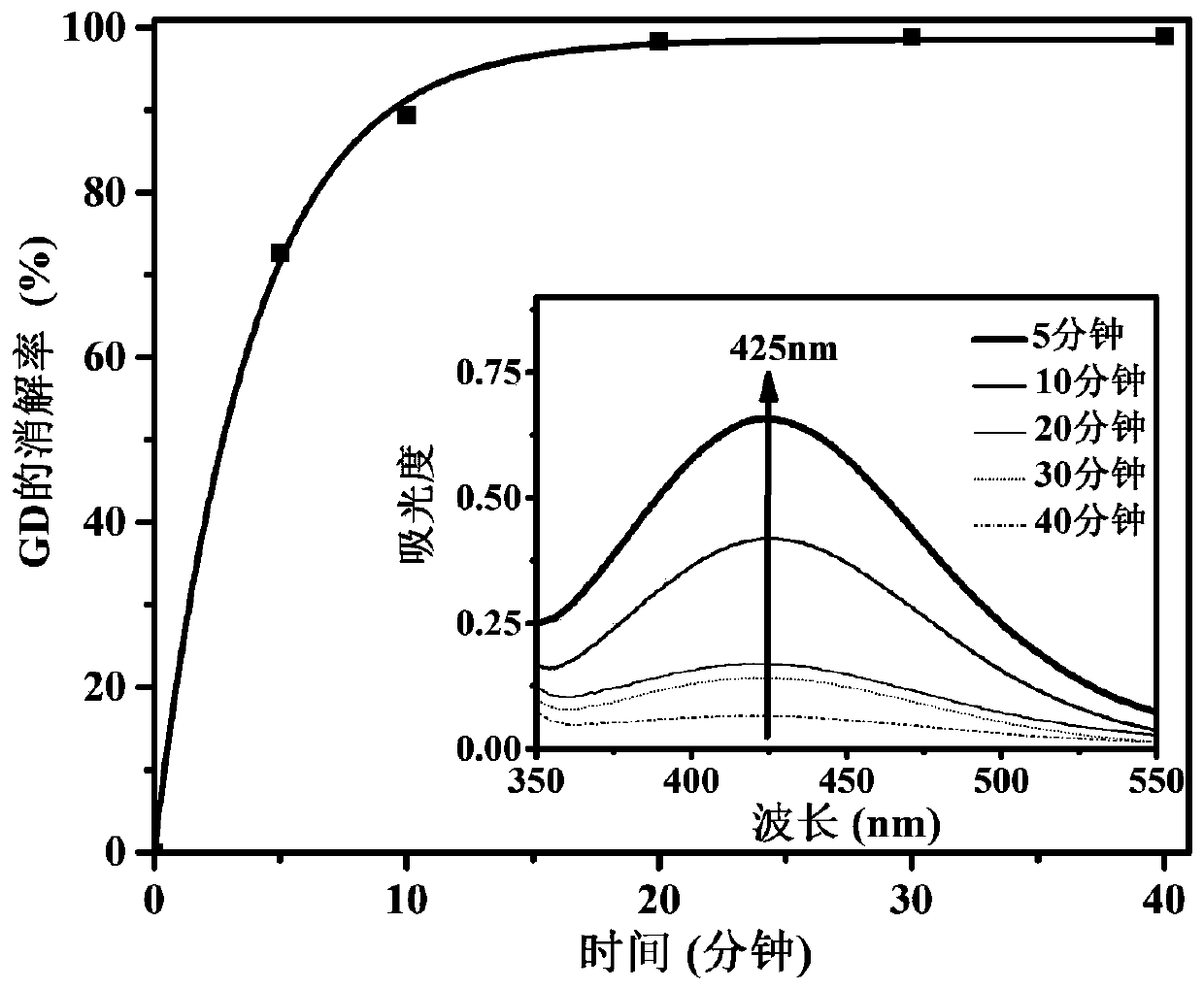

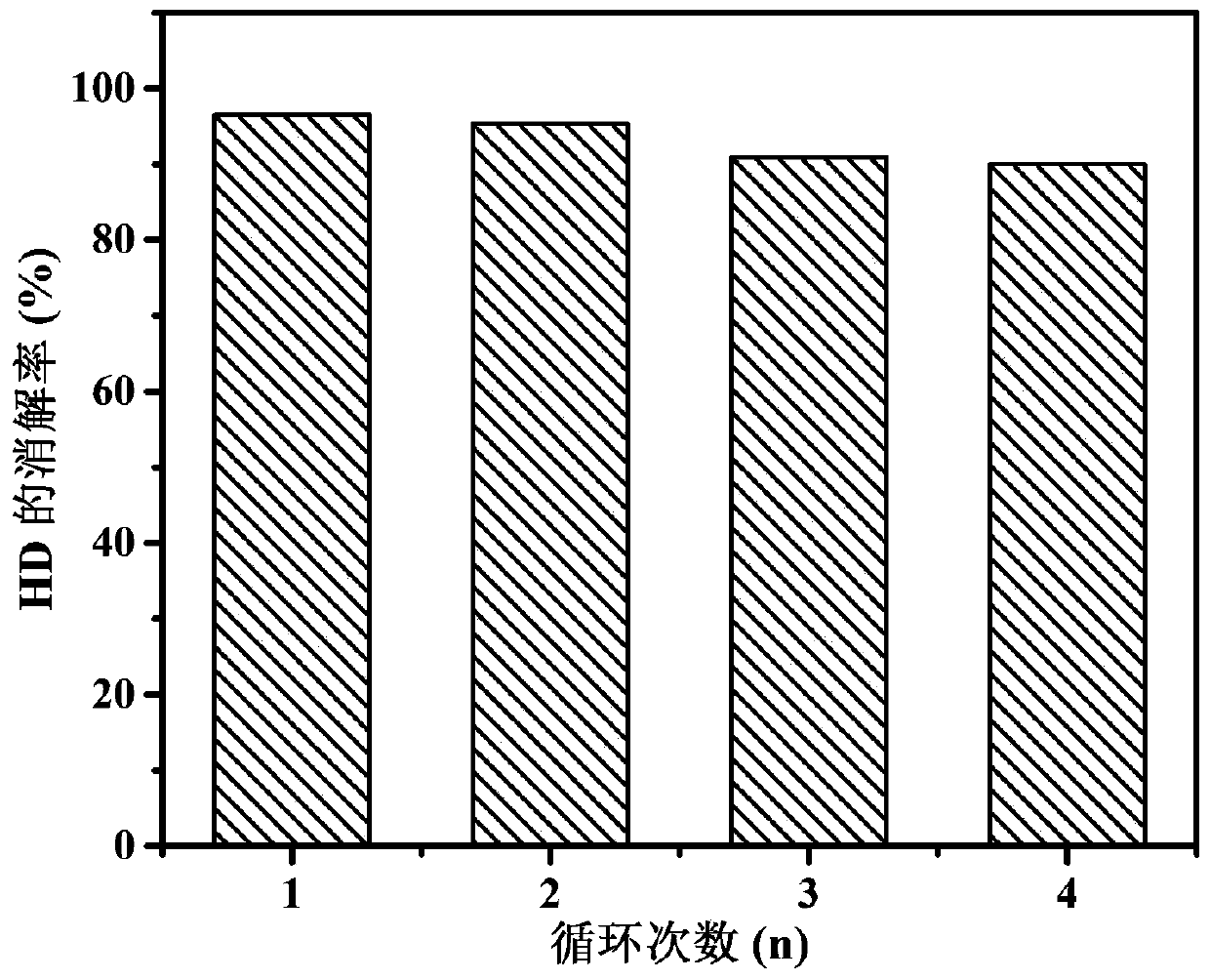

Difunctional chemical warfare agent degradation material and preparation method thereof

InactiveCN110960825AMultifacetedEasy to adjustChemical protectionEnzyme structureCombinatorial chemistry

The invention discloses a bifunctional chemical warfare agent degradation material with a bionic enzyme structure and a preparation method of the bifunctional chemical warfare agent degradation material. The bifunctional chemical warfare agent degradation material disclosed by the invention is obtained by reacting polyaluminate cation clusters with a phosphotriesterase-imitating structure with polyacid anions with chemical warfare agent degradation function. The preparation method comprises the following steps: mixing an polyaluminate cation cluster solution with a polyoxometallate solution ofthe same concentrations at the volume ratio of 1:1, standing an obtained mixed solution for three days, and filtering and drying the product to obtain the bifunctional chemical warfare agent degradation material. The bifunctional chemical warfare agent degradation material disclosed by the invention can synergistically exert the effects of polyaluminate cation clusters and polyacids, realize degradation on mustard gas and soman through two mechanisms of hydrolysis and oxidation, and can degrade mustard gas and soman to generate non-toxic products without causing secondary harm; after the bifunctional chemical warfare agent degradation material is recycled for four times, good degradation performance of the bifunctional chemical warfare agent degradation material can still be maintained.

Owner:BEIJING UNIV OF CHEM TECH +1

Lanthanum-silicon composite oxide catalyst and method for treating high-concentration formaldehyde wastewater by using lanthanum-silicon composite oxide catalyst

PendingCN114082414AEasy to prepareImprove stabilityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicic acid

The invention relates to a lanthanum-silicon composite oxide catalyst and a method for treating high-concentration formaldehyde wastewater by using the lanthanum-silicon composite oxide catalyst, and belongs to the technical field of wastewater treatment. The lanthanum-silicon composite oxide catalyst is prepared by dropwise adding a lanthanum nitrate solution into an ethyl orthosilicate ethanol solution, reacting, drying and roasting. According to the prepared lanthanum-silicon composite oxide catalyst, the catalytic activity of the active component lanthanum oxide in the lanthanum-silicon composite oxide is improved, the activation energy of formaldehyde oxidation reaction is reduced, and the formaldehyde oxidation capability of potassium hydrogen persulfate is enhanced. The method comprises the following steps of: by taking the lanthanum-silicon composite oxide as a catalyst and potassium hydrogen persulfate as an oxidizing reagent, stirring and reacting at 25-45 DEG C for 5-60 minutes, and catalytically oxidizing formaldehyde into carbon dioxide and water. According to the method, high-concentration formaldehyde wastewater can be effectively treated, and the catalyst is easy to recover, reusable, environment-friendly, safe and non-toxic.

Owner:TAIYUAN INST OF TECH

Filling slurry for filling mining method and preparation method for filling slurry

ActiveCN102531482BMeet environmental protection requirementsNo secondary hazardsSolid waste managementHigh concentrationSocial benefits

The invention discloses filling slurry for a filling mining method and a preparation method for the filling slurry. The filling slurry is prepared from the following materials: tailings, ultrafine powder, cement and debris, wherein the tailings are mill tailings at the concentration of about 20 percent, and are thickened into high-concentration tailings at the concentration of over 65 percent; the ultrafine powder is obtained by finely grinding phosphorous slag which is discharged as waste residue after yellow phosphorus is prepared by a hot method or phosphate ores are calcined by other methods until the fineness is equivalent to that of the cement, and the cement and the ultrafine powder are jointly taken as a cementitous material; and the debris is crushed into particles with the particle size of less than 2cm, and the tailings at the concentration of over 65 percent are conveyed to a filling slurry preparation station through a pipeline and are prepared into filling slurry at the concentration of equal to or more than 70 percent by using stirring equipment. The invention is characterized in that: the filling slurry has a remarkable social benefit; a series of problems about mining filling are solved; and more importantly, the national environmental protection requirements are met, and the secondary harm is avoided. The filling slurry is applicable to the filling mining method and is particularly applicable to middle and low grade phosphorus mines.

Owner:WENGFU (GRP) CO LTD

Mine subsequent cemented and non-cemented filling mining method

ActiveCN102562068BImprove mining recoveryRealize waste-free miningUnderground miningSurface miningHigh concentrationSocial benefits

The invention discloses a mine subsequent cemented and non-cemented filling mining method, comprising the following steps: (1) preparing chambers; (2) preparing for chamber filling; (3) preparing for filling: making tailing, cement, super-micro powder and aggregate made from mining waste rock into a filling slurry with the concentration of larger than 70 %, carrying out cemented filling by applying pressure or flowing automatically to the prepared mining chambers, and carrying out non-cemented filling only by directly filling the mining chambers with high-concentration tailing having the concentration of larger than 65 % and mining waste rock having the particle size of less than 2 cm; (4) stoping and filling the chambers: stoping and filling the next adjacent chamber in every four chambers, wherein the cemented and non-cemented filling modes are carried out alternately between the adjacent chambers; and (5) managing after filling. The invention has significant economic social benefits, and is suitable for mining with the filling mining method, especially for the mid-low grade phosphate rock.

Owner:WENGFU (GRP) CO LTD

A kind of preparation method of highly efficient sulfur-doped zinc oxide nanomaterial

ActiveCN107418560BEnabling Broadband Spectral ConversionEfficient photoluminescent effectLuminescent compositionsEthylene diamine tetra aceticEthylene diamine

The invention provides a high-efficiency sulfur-doped zinc oxide nano material preparation method, which comprises the following steps: S1, utilizing a precipitation method to prepare a nano zinc oxide precursor solution; S2, sequentially adding thioacetamide and ethylene diamine tetraacetic acid into the nano zinc oxide precursor solution to react; S3, separating precipitate out after reaction is finished and cleaning and drying to obtain white solid particles; S4, thermally treating the white solid particles. According to the preparation method disclosed by the invention, the ethylene diamine tetraacetic acid is utilized to enable the thioacetamide to be a lot doped into the nano zinc oxide precursor solution; thus, high-concentrate sulfur doping in ZnO is achieved, and a defect structure and surface free energy of a ZnO nano material are changed; furthermore, fluorescent performance of the zinc oxide nano material is greatly enhanced.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Method for recovering vanadium ferrochrome from vanadium-chromium tailings

The invention discloses a method for recovering vanadium ferrochrome from vanadium-chromium tailings. The method comprises the following steps of grinding vanadium-chromium tailings, adding lime and water, uniformly mixing, and uniformly mixing at 80-100 DEG C for 5-15 min to obtain a digestive material; adding the digesting material into a puffing machine to be sealed, keeping the temperature for10-30 min at the temperature 150-230 DEG C and the pressure 0.5-3.0MPa, opening a discharging port of the puffing machine, and obtaining the puffing material at the discharging port; the puffing material shaking table is subjected to one-time reselection to separate the light phase and the heavy phase, the vanadium ferrochrome is rich in heavy phase, sodium is removed by about 60% and sulfur is removed by about 90%, the vanadium chromium above 80% in the vanadium-chromium tailings can be recovered, and the sulfur is removed by about 90%; the light phase is discarded slag, and the soluble chromium (1.5mg / L, consistent with HJ / T 301-2007 chromium slag pollution treatment environmental protection technical specification) is contained. The method is simple in process and low in cost.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com