Novel horizontal screw-extrusion solid-liquid separation machine

A solid-liquid separator and horizontal screw technology, applied in the field of machinery, can solve problems such as easy blockage of materials and poor dehydration effect, and achieve the effects of improving efficiency, saving storage space, and reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

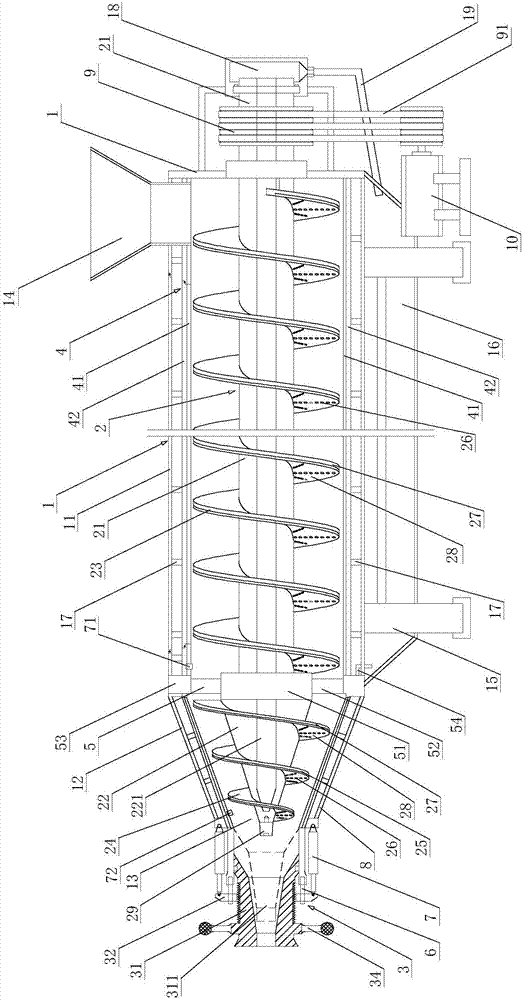

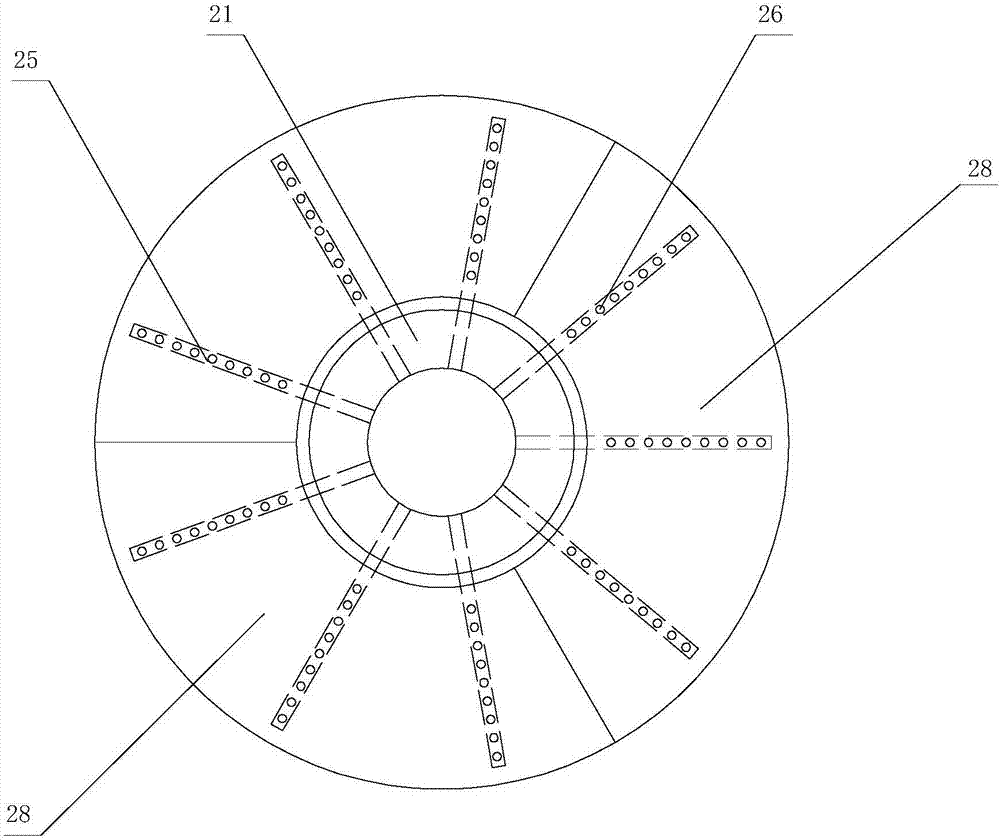

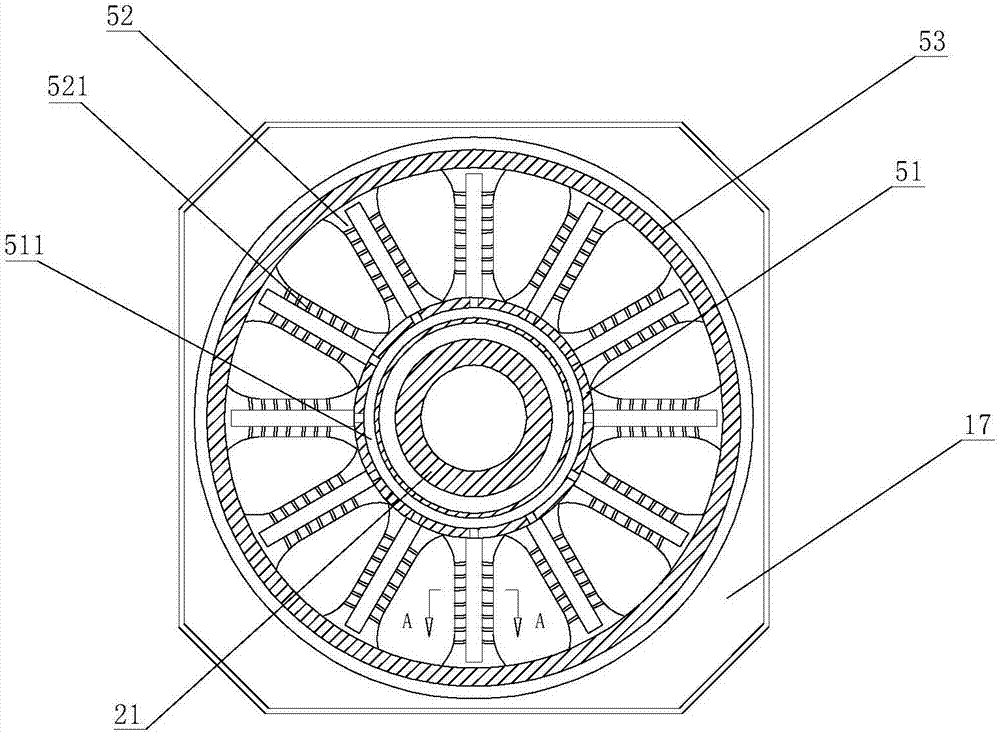

[0022] combine Figure 1 to Figure 4 , a new horizontal screw extrusion solid-liquid separator, including a shell 1, a spoke bracket 5, a feeding dehydration mechanism 2 and a pressure adjustment mechanism 3, and the spoke bracket 5 includes a bearing seat 51, an outer fixing ring 53 and a plurality of supporting parts 52 The bearing seat 51 is integrally connected with the inner side wall of the outer fixing ring 53 through a plurality of support portions 52 uniformly arranged in a ring. The housing 1 includes a main housing 11 and a conical housing 12, the conical housing 12 is located behind the main housing 11, and the main housing 11 and the conical housing 12 are respectively fixedly mounted on the front and rear sides of the spoke bracket 5 . The large-diameter end of the front end of the conical housing 12 is fixedly connected with the outer fixing ring 53 of the spo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com