Fireproof railway digital signal cable and manufacturing method thereof

A technology for digital signal cables and manufacturing methods, applied in the direction of insulated cables, twisted/quadruple twisted cables, cables, etc., which can solve the problems of high production cost, large transmission loss of digital signal cables, and poor fireproof performance and other problems, to achieve the effect of saving insulating materials, reducing the average dielectric constant, and stabilizing the structure of the wire pair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

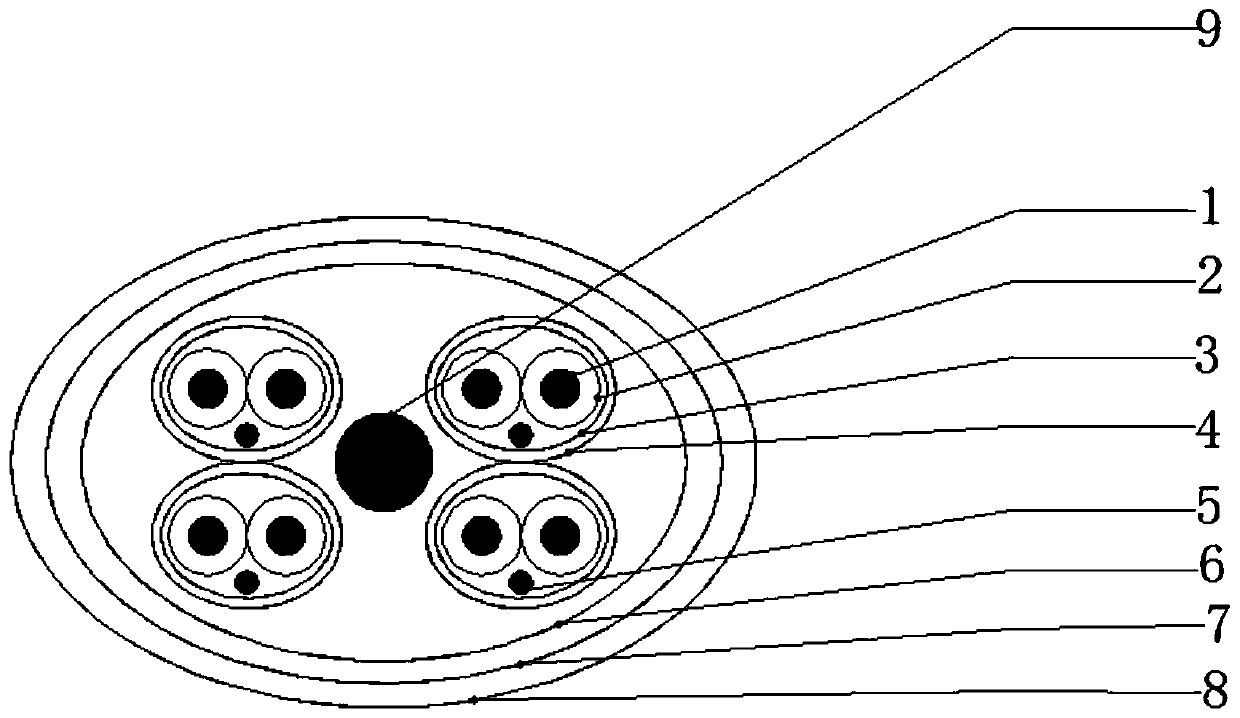

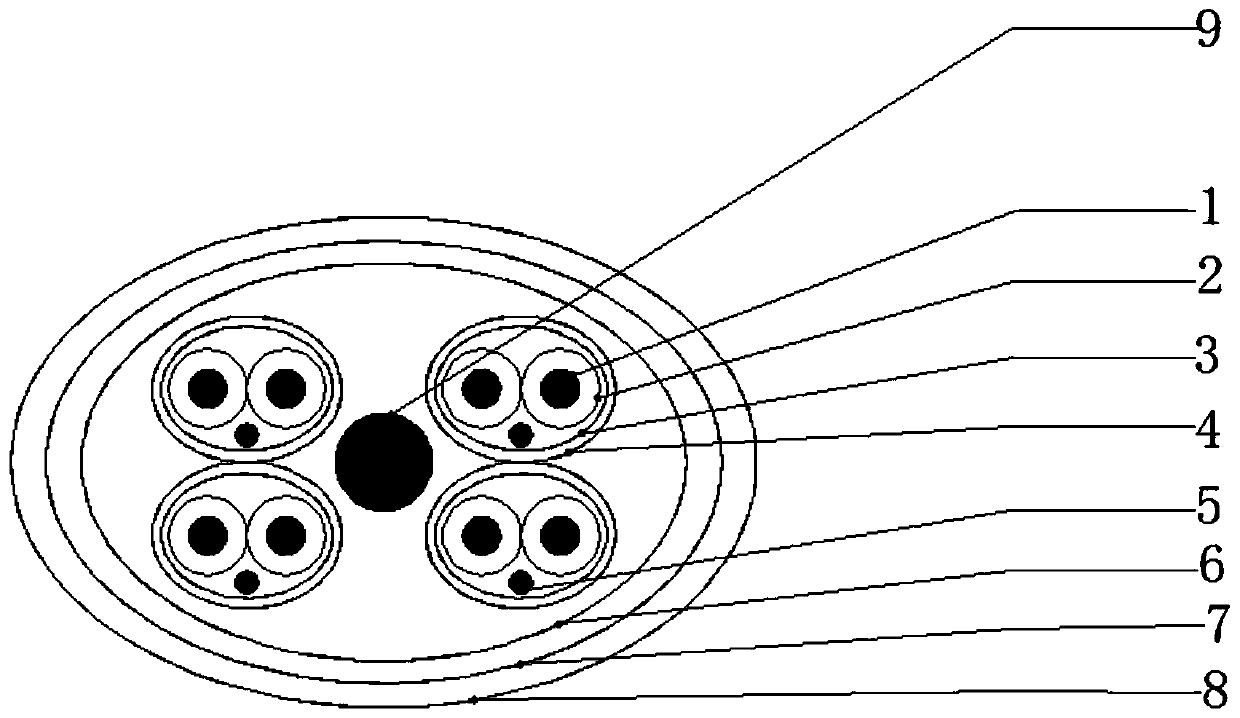

[0019] refer to figure 1 A fire-resistant railway digital signal cable and a manufacturing method thereof, comprising a twisted body and a signal wire pair, the twisted body includes an insulated wire core and a current guide wire 5, the current guide wire 5 is twisted on the insulated wire core, and the insulated wire core includes The inner conductor 1 and the inner insulating layer 2, the inner insulating layer 2 is wrapped on the outside of the inner conductor 1, the shielding layer 3 is wrapped on the surface of the stranded body, the outer side of the shielding layer 3 is wrapped with an outer insulating layer 4, and the signal line pair is specifically two oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com