Isolation capacitor and preparation method thereof

A technology of isolation capacitors and isolation holes, which is applied in the field of data isolation, can solve the problems of increasing process costs and achieve the effects of increasing additional costs, reducing design difficulty, and reducing capacitance values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention also discloses a method for preparing an isolation capacitor, comprising:

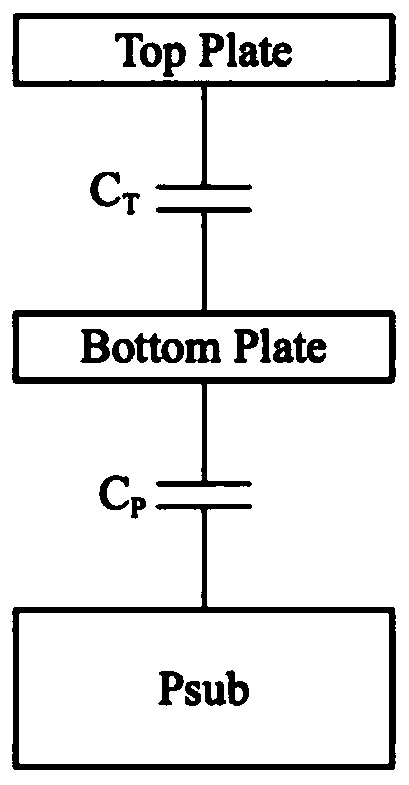

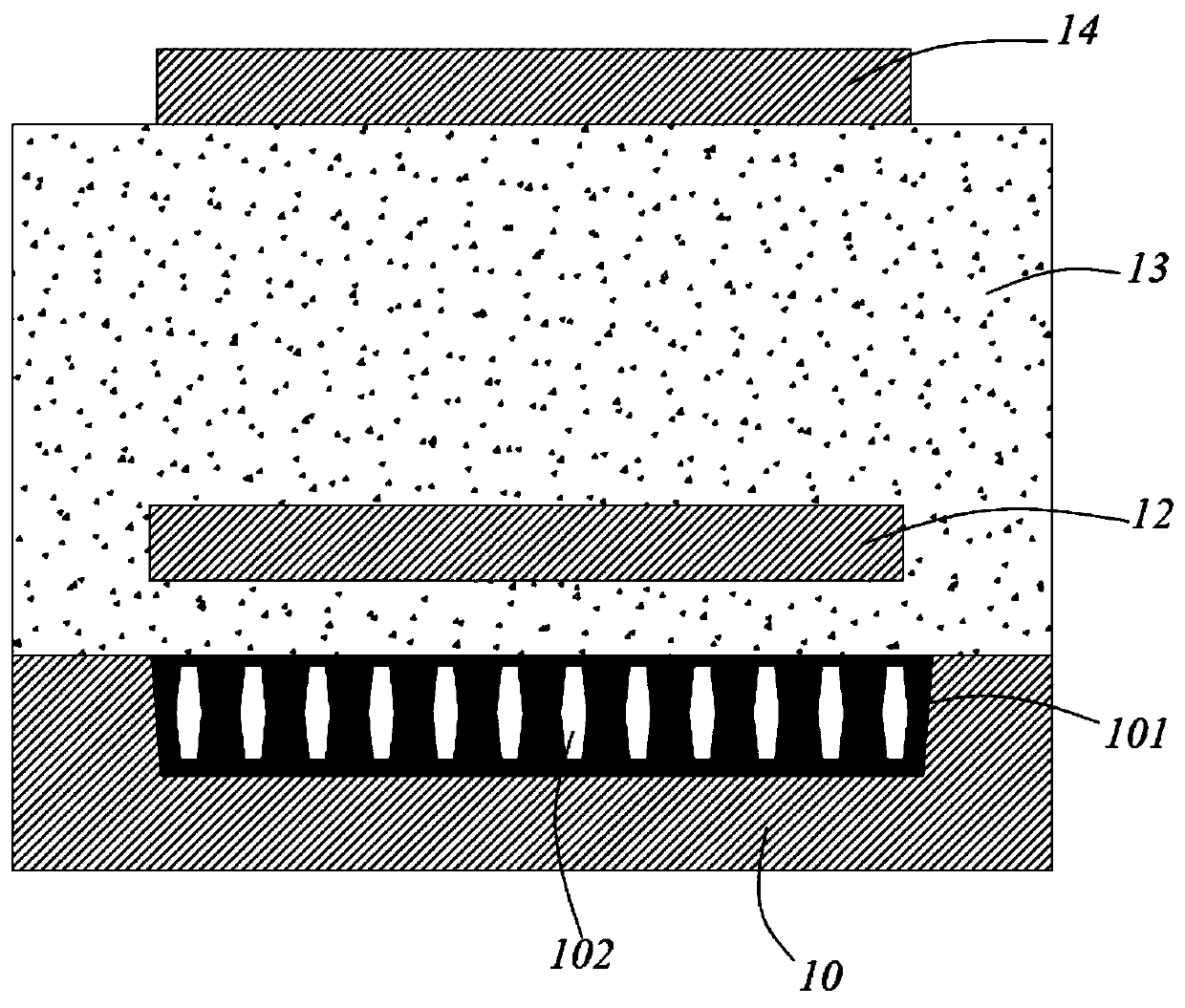

[0040] S1. A substrate is provided, and a shallow trench isolation region is formed on the substrate through a shallow trench isolation process, and the shallow trench isolation region includes a plurality of isolation holes distributed at intervals;

[0041] S2, oxidizing the shallow trench isolation region through an oxidation process;

[0042] S3, depositing an oxide layer in the isolation hole of the shallow trench isolation area, and forming a number of pores in the shallow trench isolation area due to insufficient filling;

[0043] S4, sequentially forming a first electrode plate, a dielectric layer, and a second electrode plate on the substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com