Metal sheet electrochemical inner spray cutting forcible entry device and method

A metal sheet and electrochemical technology, which is applied in the field of electrochemical internal spray cutting and demolition devices for sheet metal, can solve the problems of high tool cost, lack of success, inability to demolition, etc., and achieves low cost, simple operation and easy control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

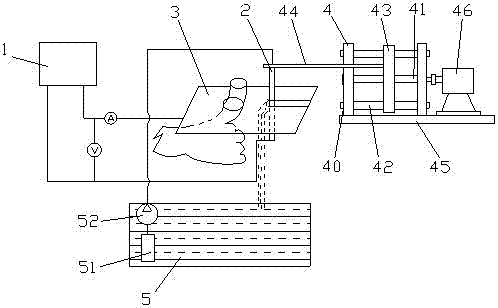

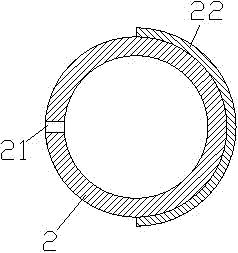

[0030] Such as figure 1 , 2 1. A kind of sheet metal electrochemical internal jet cutting and breaking device shown in 3 includes an electrolysis device and an electrolyte supply device. The electrolysis device includes an output power supply 1 and an electrode tube 2. 3 and the electrode tube 2 are electrically connected; the electrode tube 2 is a hollow structure, and a plurality of spray holes 21 are arranged on the side of the electrode tube 2; the electrolyte supply device is communicated with the electrode tube 2. Wherein, a ceramic insulating layer 22 is attached to one side of the electrode tube 2 , and the ceramic insulating layer 22 is attached to a half circle of the electrode tube 2 .

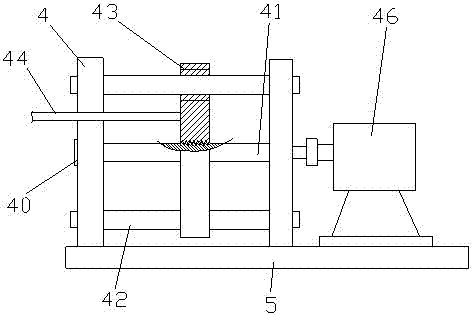

[0031] It also includes a feeding device for pushing the electrode tube 2; the feeding device includes a fixed bracket 4, a screw rod 41 rotated in the fixed bracket 4, two upper and lower guide rods 42 fixedly arranged in the fixed bracket 4 , a mobile slide 43 threaded with the ...

Embodiment 2

[0038] Such as figure 1 , 2 . A metal thin plate electrochemical internal jet cutting and breaking method shown in 3 includes the following steps, step 1: connect the anode of the output power supply 1 to the metal thin plate 3 to be cut, and connect the cathode of the output power supply 1 to the electrode tube 2; wherein A ceramic insulating layer 22 is attached to one side of the electrode tube 2 , and the ceramic insulating layer 22 is attached to a half circle of the electrode tube 2 .

[0039] Step 2: Connect the electrolyte supply device to the electrode tube 2;

[0040] Step 3: Turn on the output power, push the electrode tube 2 to cut the metal sheet 3 .

[0041] Wherein, a plurality of injection holes 21 are provided on the side of the electrode tube 2 . The interval between adjacent injection holes 21 is 1 mm, and the inner diameter of the injection holes 21 is 1 mm.

[0042] Using the metal sheet electrochemical internal jet cutting and demolition method descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com