Method for quickly decomposing residual mulch

A mulching film and ground technology, which is used in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of time-consuming and laborious recycling, low price, and difficult to decompose, and achieves great promotion and application potential and adaptability. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

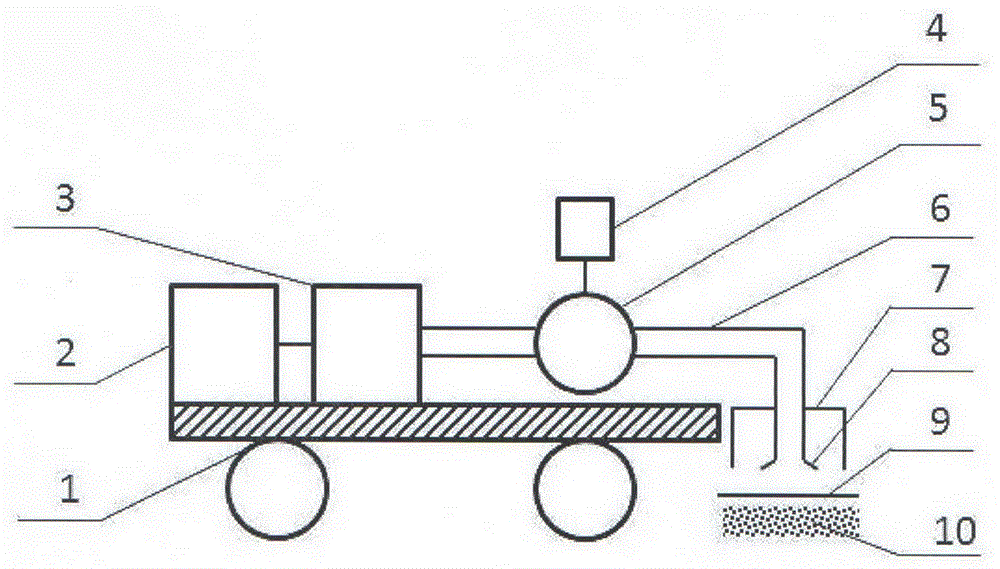

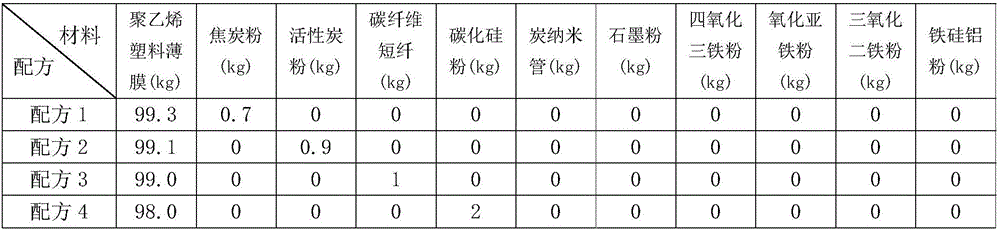

[0020] The present invention is a method for quickly decomposing residual mulch. The device involved in the method is composed of a vehicle-mounted platform, a controller, a microwave generator, a matching load, a circulator, a rectangular waveguide, a shielding device, a bell mouth surface waveguide and a mulch. On one side of the vehicle-mounted platform 1, a controller 2 and a microwave generator 3 are respectively fixed, one end of the microwave generator 3 is connected to the controller 2, and the other end of the microwave generator 3 is connected to a rectangular waveguide 6, and the middle part of the rectangular waveguide 6 is fixed with The circulator 5 and the other end of the rectangular waveguide 6 respectively fix the shielding device 7 and the bell mouth surface waveguide 8, the matching load 4 is connected to the circulator 5, and the magnetron in the microwave generator 3 is a single 915MHz, 2450MHz frequency magnetron Tube or 5.8GHz frequency magnetron, or a c...

Embodiment 2

[0031] The device in the described method is carried out according to embodiment 1, and concrete operation is carried out according to the following steps:

[0032] Raw material mixing method: (polypropylene plastic film)

[0033] a. Taking the 100kg plastic film as the base, the plastic film is made of polypropylene plastic film, and the microwave absorbing material with a particle size of 4 microns is coke powder, activated carbon powder, carbon fiber short fiber, silicon carbide powder, carbon nanotube, graphite powder, tetraoxide Iron powder, ferrous oxide powder, ferric oxide powder or sendust powder, mixed evenly, and then made by conventional film forming process, wherein the microwave absorbing material accounts for 0.7%-7% of the total weight of the film; See Table 2.

[0034] Table 2: The formula of raw material ingredients contained in every 100kg film

[0035]

[0036] b. Transport the vehicle-mounted platform 1 to the field, and set the power of the microwave...

Embodiment 3

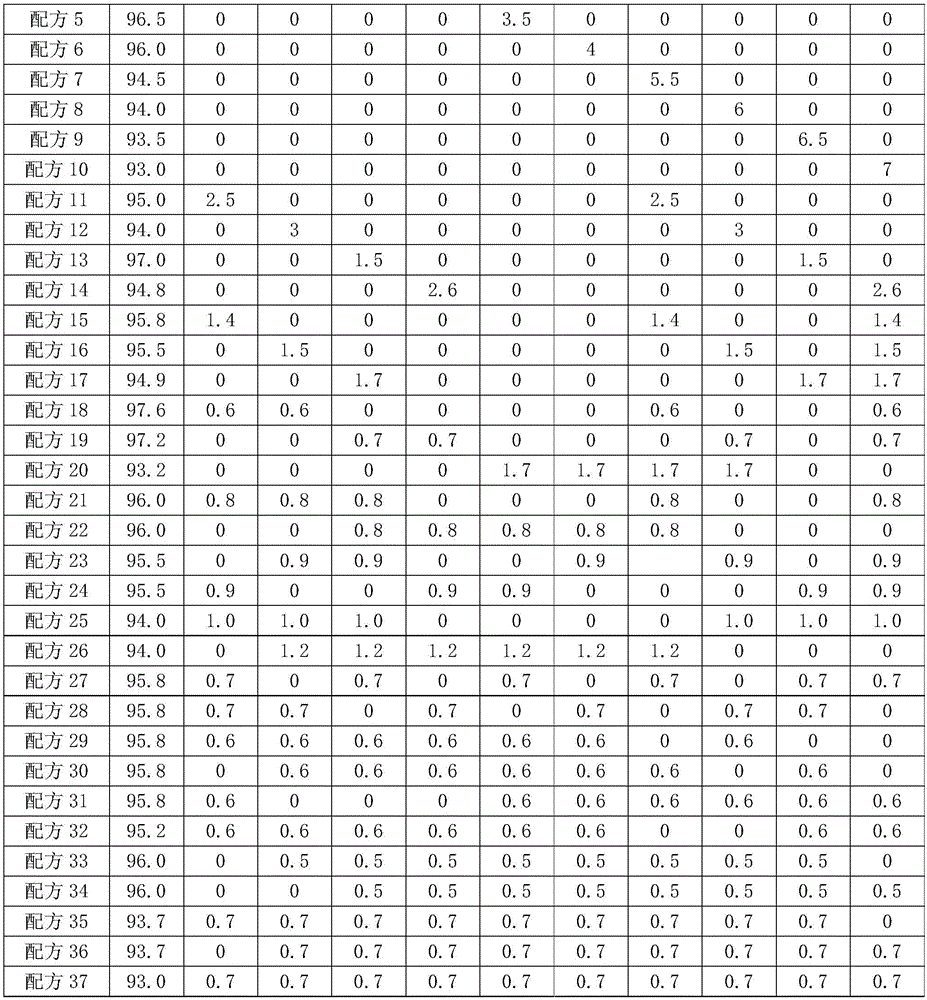

[0040] The device in the described method is carried out according to embodiment 1, and concrete operation is carried out according to the following steps:

[0041] Raw material mixing method (biodegradable film)

[0042] a. Taking the 100kg plastic film as the base, the plastic film is a biodegradable film, and the microwave absorbing material with a particle size of 5 microns is added as coke powder, activated carbon powder, carbon fiber short fiber, silicon carbide powder, carbon nanotube, graphite powder, tetraoxide Iron powder, ferrous oxide powder, ferric oxide powder or sendust powder, mixed evenly, and then made by conventional film forming process, wherein the microwave absorbing material accounts for 0.7%-7% of the total weight of the film; See Table 3.

[0043] Table 3: The formula of raw material ingredients contained in every 100kg film

[0044]

[0045]

[0046] b. Transport the vehicle-mounted platform 1 to the field, and set the power of the microwave g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com